Method for preparing SiC3D/Al composite material through squeezing impregnation method

A technology of composite material and impregnation method, which is applied in the field of composite material preparation, can solve the problems of low-carbon steel auxiliary mold demoulding difficulties, large machining volume, etc., and achieve low price, improved demoulding efficiency, and mature and stable preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of SiC 3D / Al composite material (in this embodiment, Al is ZL102, i.e. SiC 3D / Al composite material is SiC 3D / ZL102).

[0042] SiC 3D / Al composites were prepared according to the following steps:

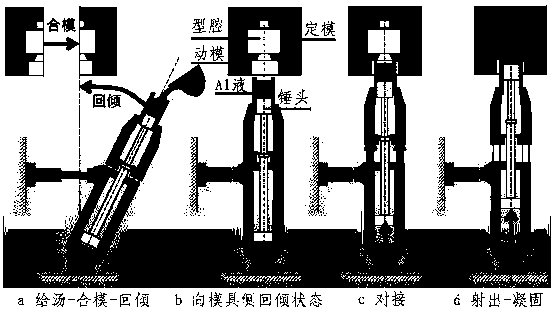

[0043] S1. According to the required SiC 3D / Al composite workpiece structure and dimensions, respectively design the structure and size of soluble ceramic auxiliary mold and steel mold, process and prepare soluble ceramic auxiliary mold and steel mold.

[0044] In order to ensure that the porous SiC preform can be placed smoothly, a gap of 0.5-1.0mm is left between the inner wall of the soluble ceramic auxiliary mold and the porous SiC preform; Drainage holes are designed in the seepage direction, and the drainage holes occupy 20% to 30% of the area of the panel. A gap of 0.5-1.0 mm is reserved between the cavity of the steel mold and the auxiliary mold.

[0045] S2. After the porous SiC prefabricated body is placed in the soluble ceramic auxiliary m...

Embodiment 2

[0057] Preparation of SiC 3D / Al composite material (in this embodiment, Al is ZL201, i.e. SiC 3D / Al composite material is SiC 3D / ZL201).

[0058] SiC 3D / Al composites were prepared according to the following steps:

[0059] S1. According to the required SiC 3D / Al composite workpiece structure and dimensions, respectively design the structure and size of soluble ceramic auxiliary mold and steel mold, process and prepare soluble ceramic auxiliary mold and steel mold.

[0060] In order to ensure that the porous SiC preform can be placed smoothly, a gap of 0.5-1.0mm is left between the inner wall of the soluble ceramic auxiliary mold and the porous SiC preform; Drainage holes are designed in the seepage direction, and the drainage holes occupy 20% to 30% of the area of the panel. A gap of 0.5-1.0 mm is reserved between the cavity of the steel mold and the auxiliary mold.

[0061] S2. After the porous SiC prefabricated body is placed in the soluble ceramic auxiliary m...

Embodiment 3

[0073] Preparation of SiC 3D / Al composite material (in this embodiment, Al is ZL101, that is, SiC 3D / Al composite material is SiC 3D / ZL101).

[0074] SiC 3D / Al composites were prepared according to the following steps:

[0075] S1. According to the required SiC 3D / Al composite workpiece structure and dimensions, respectively design the structure and size of soluble ceramic auxiliary mold and steel mold, process and prepare soluble ceramic auxiliary mold and steel mold.

[0076] In order to ensure that the porous SiC preform can be placed smoothly, a gap of 0.5-1.0mm is left between the inner wall of the soluble ceramic auxiliary mold and the porous SiC preform; Drainage holes are designed in the seepage direction, and the drainage holes occupy 20% to 30% of the area of the panel. A gap of 0.5-1.0 mm is reserved between the cavity of the steel mold and the auxiliary mold.

[0077] S2. After the porous SiC prefabricated body is placed in the soluble ceramic auxilia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com