Method for preparing anti-oxidation multiple phase coating of carbon/carbon composite material surface

A technology of carbon composite materials and composite materials, which is applied in the field of preparation of multi-phase anti-oxidation coatings on the surface of carbon/carbon composite materials. and other problems, to achieve the effect of improving thermal shock resistance and solving the mismatch of thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

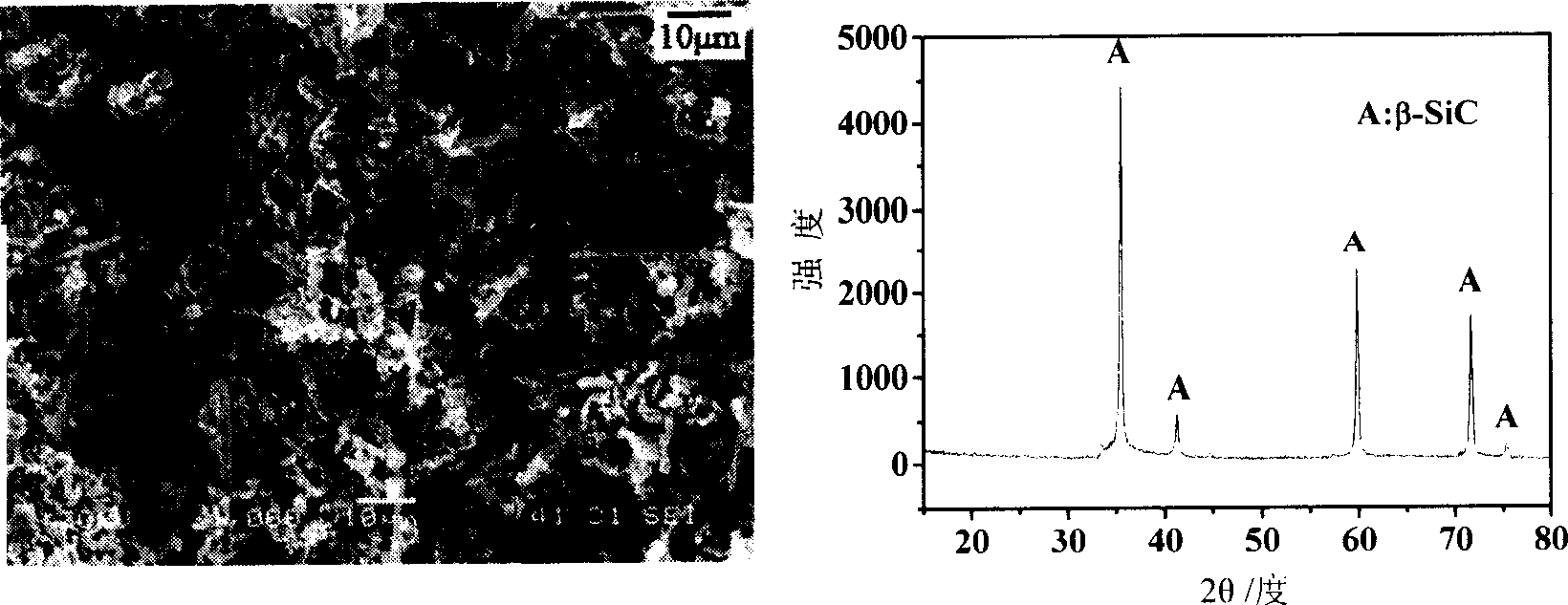

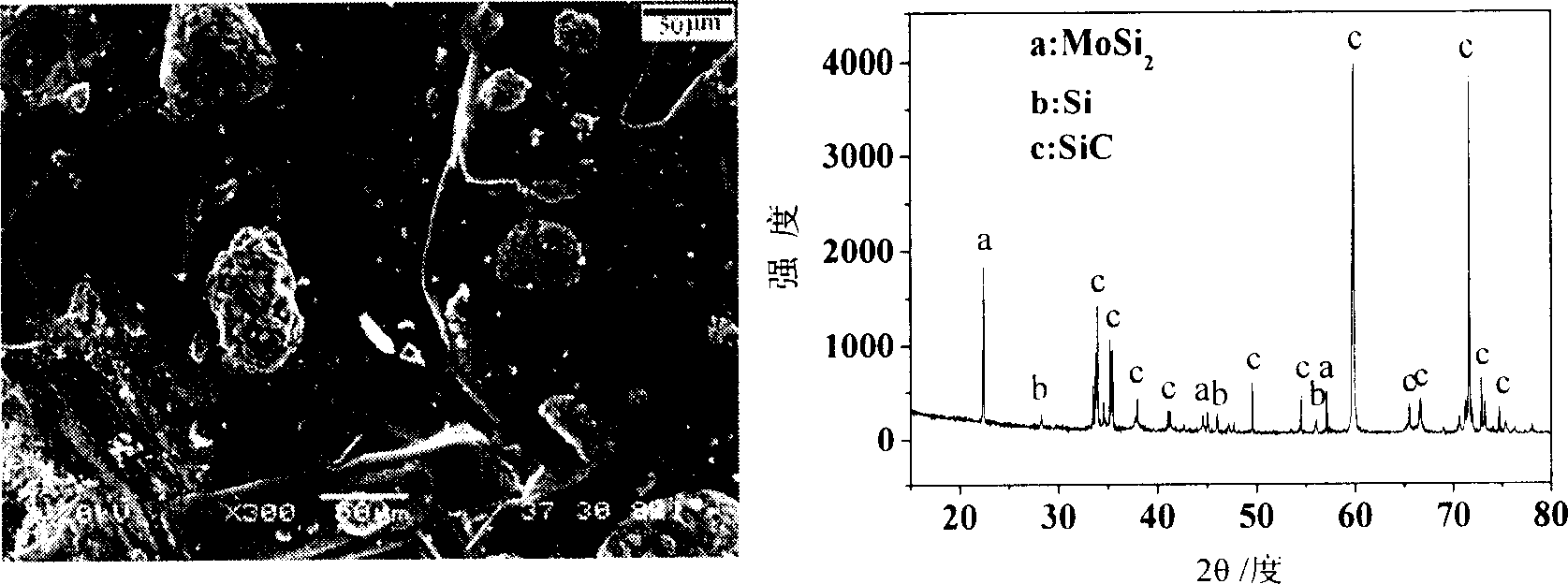

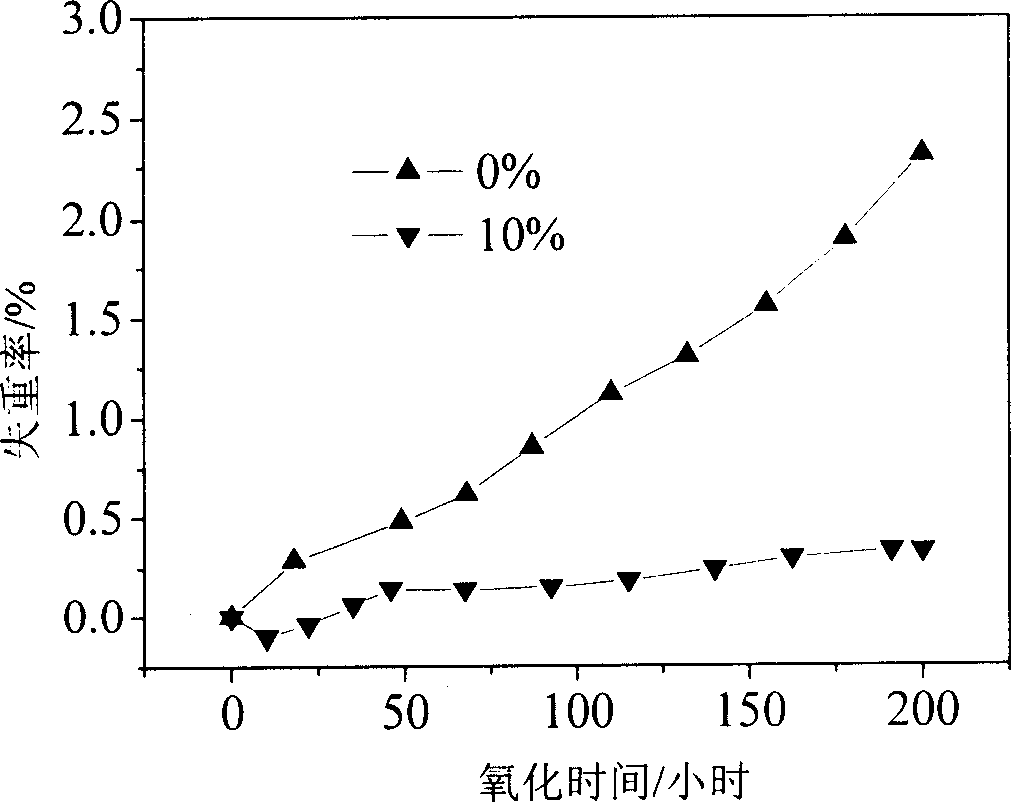

Embodiment 1

[0020] Embodiment 1: take by weight respectively the Si powder of 65%, the C powder of 13%, the Al of 10% 2 o 3 Powder, 12% β-SiC whiskers. Put the β-type SiC whiskers into a container filled with ethanol solution for ultrasonic dispersion treatment, and the dispersion time is 10 minutes. The weighed Si powder, C powder and Al 2 o 3 Pour the powder into the above container, and use a magnetic stirrer to stir and mix to prepare a slurry. The stirrer speed is 2.5 rpm, and the stirring time is 35 minutes. At the same time, the C / C composites were polished and polished with No. 400, No. 800 and No. 1000 sandpapers respectively, washed with absolute ethanol, and dried in an oven at 100°C for later use. The purity of Si powder is 99.5%, the particle size is 300 mesh, the purity of C powder is 99%, the particle size is 320 mesh, Al 2 o 3 The purity of the powder is 99.9%, the particle size is 320 mesh, MoSi 2 The purity of the powder is 99%, the particle size is 300 mesh, the ...

Embodiment 2

[0026] Embodiment 2: take by weight respectively the Si powder of 70%, the C powder of 10%, the Al of 5%2 o 3 Powder, 15% β-SiC whiskers. Put the β-type SiC whiskers into a container filled with ethanol solution for ultrasonic dispersion treatment, and the dispersion time is 11 minutes. The weighed Si powder, C powder and Al 2 o 3 The powder was poured into the above-mentioned container, and a magnetic stirrer was used to stir and mix to prepare a slurry. The speed of the stirrer was 3 revolutions per second, and the stirring time was 33 minutes. At the same time, the C / C composites were polished and polished with No. 400, No. 800 and No. 1000 sandpapers respectively, washed with absolute ethanol, and dried in an oven at 100°C for later use. The purity of Si powder is 99.5%, the particle size is 300 mesh, the purity of C powder is 99%, the particle size is 320 mesh, Al 2 o 3 The purity of the powder is 99.9%, the particle size is 320 mesh, MoSi 2 The purity of the powder...

Embodiment 3

[0031] Embodiment 3: take by weight respectively the Si powder of 75%, the C powder of 15%, the Al of 5% 2 o 3 Powder, 5% β-SiC whiskers. Put the β-type SiC whiskers into a container filled with ethanol solution for ultrasonic dispersion treatment, and the dispersion time is 13 minutes. The weighed Si powder, C powder and Al 2 o 3 Pour the powder into the above container, and use a magnetic stirrer to stir and mix to prepare a slurry. The stirrer speed is 3.5 rpm, and the stirring time is 35 minutes. At the same time, the C / C composites were polished and polished with No. 400, No. 800 and No. 1000 sandpapers respectively, washed with absolute ethanol, and dried in an oven at 100°C for later use. The purity of Si powder is 99.5%, the particle size is 300 mesh, the purity of C powder is 99%, the particle size is 320 mesh, Al 2 o 3 The purity of the powder is 99.9%, the particle size is 320 mesh, MoSi 2 The purity of the powder is 99%, the particle size is 300 mesh, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com