Method for preparing anti-oxidation multiple phase coating of carbon/carbon composite material surface

A technology of carbon composite materials and composite materials, which is applied in the field of preparation of multi-phase anti-oxidation coatings on the surface of carbon/carbon composite materials, which can solve the problems of high-temperature anti-oxidation temperature, poor thermal shock resistance and erosion resistance, and easy cracking of coatings and other problems, to achieve the effect of improving thermal shock resistance and solving the mismatch of thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

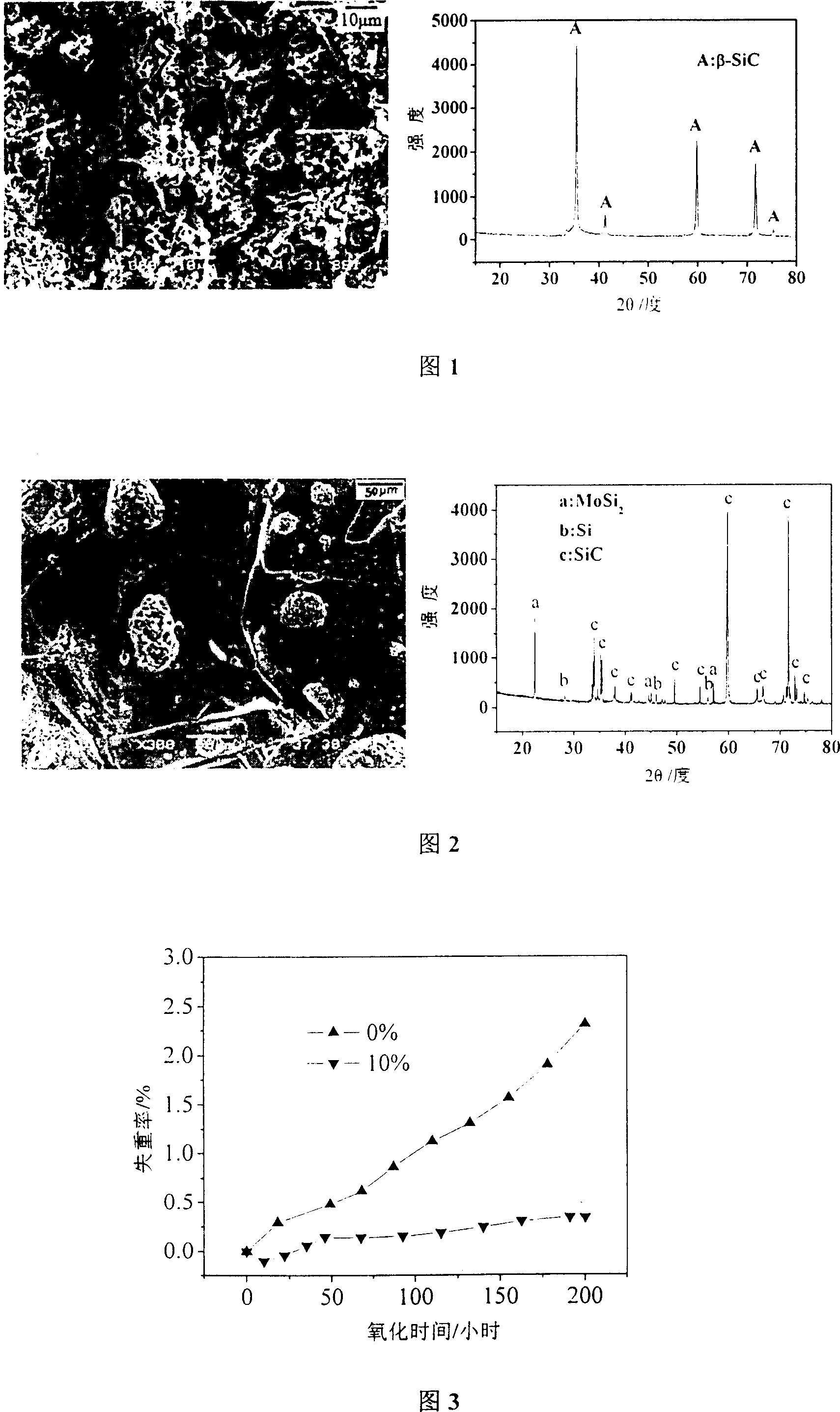

Embodiment 1

[0020] Embodiment 1: take by weight respectively the Si powder of 65%, the C powder of 13%, the Al of 10% 2 o 3 Powder, 12% β-SiC whiskers. Put the β-type SiC whiskers into a container filled with ethanol solution for ultrasonic dispersion treatment, and the dispersion time is 10 minutes. The weighed Si powder, C powder and Al 2 o 3 Pour the powder into the above container, and use a magnetic stirrer to stir and mix to prepare a slurry. The stirrer speed is 2.5 rpm, and the stirring time is 35 minutes. At the same time, the C / C composites were polished and polished with No. 400, No. 800 and No. 1000 sandpapers respectively, washed with absolute ethanol, and dried in an oven at 100°C for later use. The purity of Si powder is 99.5%, the particle size is 300 mesh, the purity of C powder is 99%, the particle size is 320 mesh, Al 2 o 3 The purity of the powder is 99.9%, the particle size is 320 mesh, MoSi 2 The purity of the powder is 99%, the particle size is 300 mesh, the ...

Embodiment 2

[0027]Embodiment 2: take by weight respectively the Si powder of 70%, the C powder of 10%, the Al of 5% 2 o 3 Powder, 15% β-SiC whiskers. Put the β-type SiC whiskers into a container filled with ethanol solution for ultrasonic dispersion treatment, and the dispersion time is 11 minutes. The weighed Si powder, C powder and Al 2 o 3 The powder was poured into the above-mentioned container, and a magnetic stirrer was used to stir and mix to prepare a slurry. The speed of the stirrer was 3 revolutions per second, and the stirring time was 33 minutes. At the same time, the C / C composites were polished and polished with No. 400, No. 800 and No. 1000 sandpapers respectively, washed with absolute ethanol, and dried in an oven at 100°C for later use. The purity of Si powder is 99.5%, the particle size is 300 mesh, the purity of C powder is 99%, the particle size is 320 mesh, Al 2 o 3 The purity of the powder is 99.9%, the particle size is 320 mesh, MoSi 2 The purity of the powde...

Embodiment 3

[0032] Embodiment 3: take by weight respectively the Si powder of 75%, the C powder of 15%, the Al of 5% 2 o 3 Powder, 5% β-SiC whiskers. Put the β-type SiC whiskers into a container filled with ethanol solution for ultrasonic dispersion treatment, and the dispersion time is 13 minutes. The weighed Si powder, C powder and Al 2 o 3 Pour the powder into the above container, and use a magnetic stirrer to stir and mix to prepare a slurry. The stirrer speed is 3.5 rpm, and the stirring time is 35 minutes. At the same time, the C / C composites were polished and polished with No. 400, No. 800 and No. 1000 sandpapers respectively, washed with absolute ethanol, and dried in an oven at 100°C for later use. The purity of Si powder is 99.5%, the particle size is 300 mesh, the purity of C powder is 99%, the particle size is 320 mesh, Al 2 o 3 The purity of the powder is 99.9%, the particle size is 320 mesh, MoSi 2 The purity of the powder is 99%, the particle size is 300 mesh, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com