Directional porous SiC and diamond reinforced Al base composite material and preparation method thereof

A diamond-reinforced, composite material technology, applied in the field of high thermal conductivity metal matrix composite materials and preparation for electronic packaging, to achieve the effects of easy realization, simple preparation process, and reduced thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

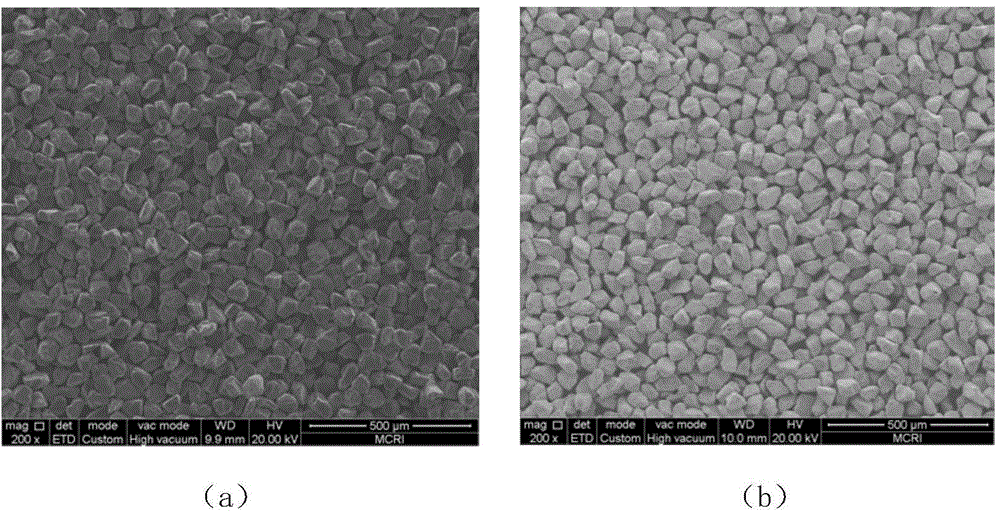

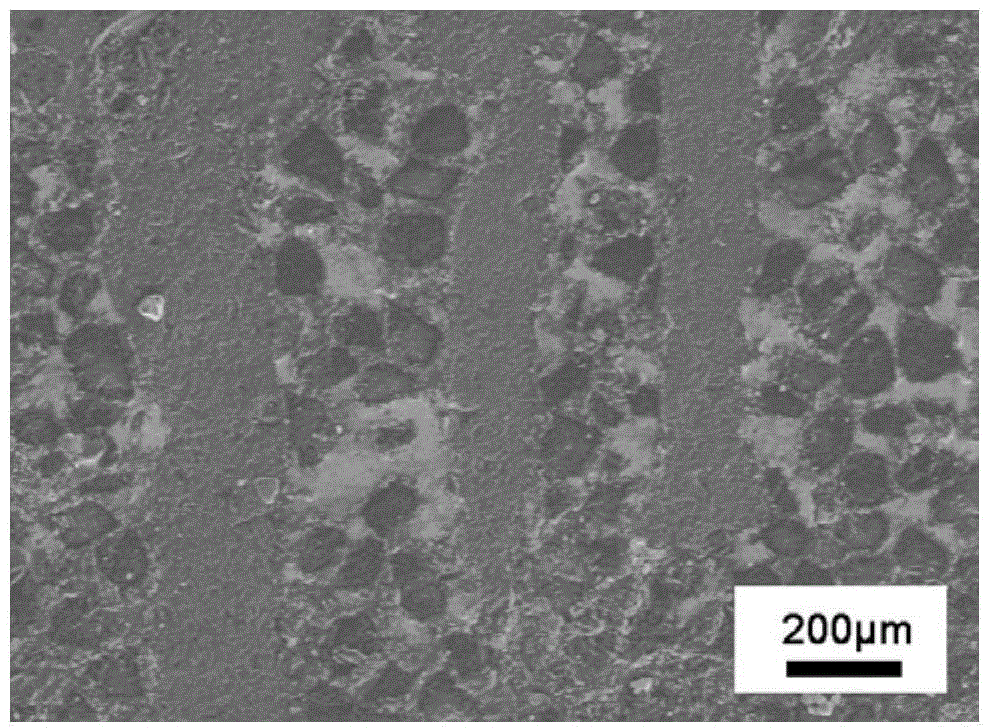

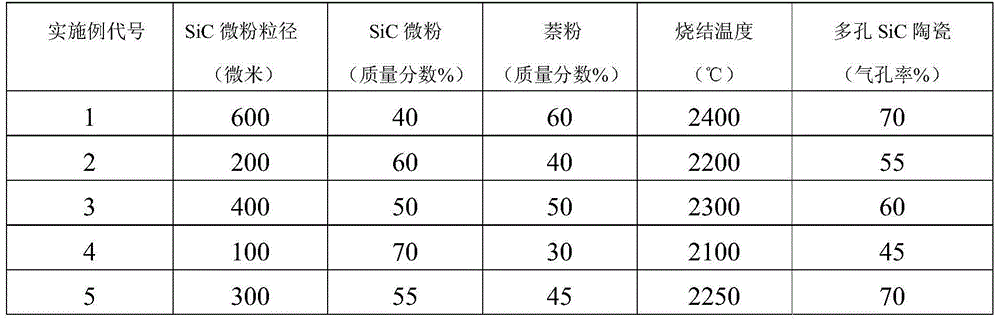

[0031] A hybrid reinforced Al-based composite material of oriented porous SiC ceramics and diamond particles, in terms of volume fraction, composed of a SiC ceramic phase, a diamond particle phase and an Al metal phase composed of Table 1, wherein the SiC ceramic phase is a three-dimensional network porous Skeleton structure, these pores are roughly arranged in one direction and communicate with each other to form directional pores, which are loosely filled by diamond particles, and the Al metal phase melts into the directional pores of porous SiC ceramics filled with diamond particles, and is completely densely filled . (see figure 2 ).

[0032] The preparation process of the above-mentioned oriented porous SiC ceramics and diamond particle hybrid reinforced Al-based composite material includes the following steps:

[0033] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com