Preparation method for dispersively distributed self-healing phase B12(C,Si,B)3 modified SiC/SiC compound material

A composite material and dispersion distribution technology, which is applied in the field of preparation of dispersion distribution self-healing phase B123 modified SiC/SiC composite materials, can solve problems such as fracture toughness, and achieve the advantages of promoting crack deflection, reducing damage and short holding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

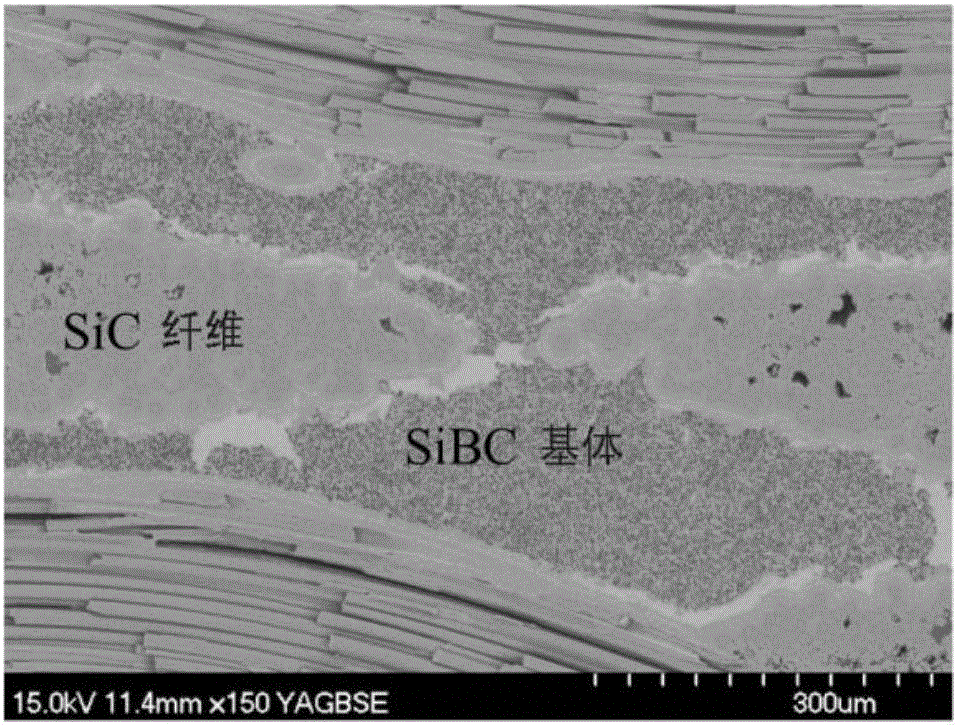

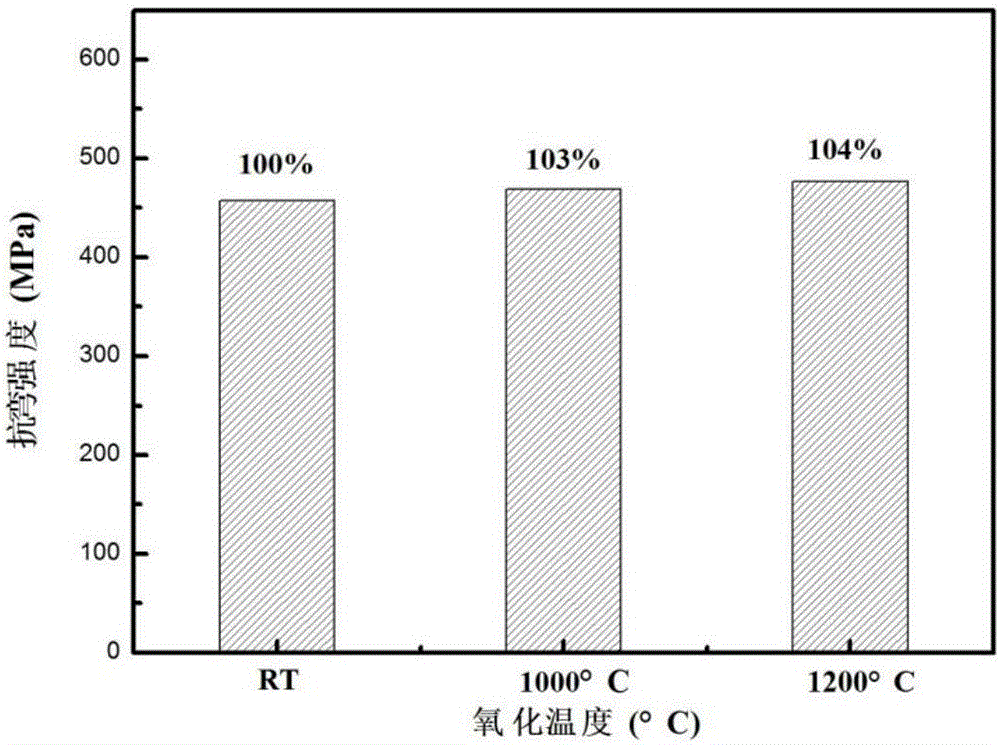

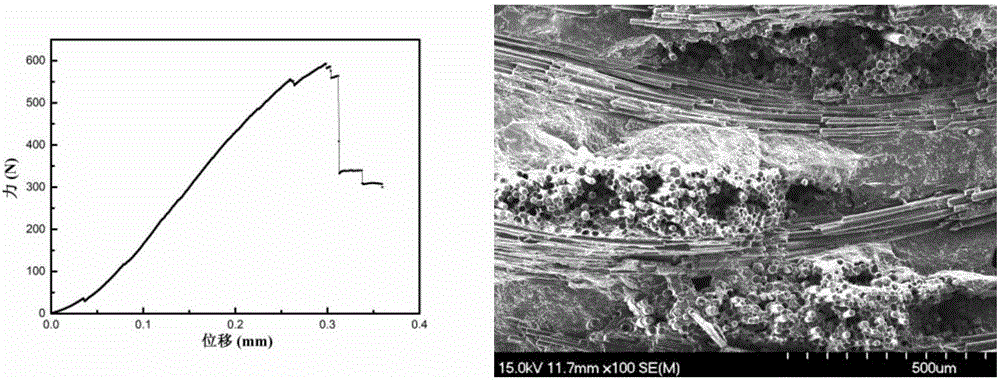

[0027] Example 1: The selected 2D porous Tyranno ZMI SiC fiber preform was ultrasonically cleaned and dried; then the BN interface and SiC matrix were sequentially deposited in the fiber preform by the CVI method to make a 2D porous Tyranno ZMI SiC / SiC composite material prefabrication body. Among them, BN deposition temperature: 600°C, holding time: 32h, SiC deposition temperature: 950°C, holding time: 240h; the density of the obtained porous SiC / SiC composite preform is 1.8g / cm 3 , The open porosity is 19vol.%. Add 1.5g of polyethyleneimine dispersant to 300g of absolute ethanol, stir magnetically until the dispersant dissolves, then add 75g of phenolic resin, 7.5g of hexamethylenetetramine, and 135g of B with a particle size of 1.5μm 4 C powder; stir evenly with a magnetic force and pour into an agate ball mill jar, add agate balls, and wet ball mill on a planetary ball mill for 10 hours to make a precursor slurry impregnation solution. Pour the prepared precursor slurry ...

Embodiment 2

[0030] Example 2: The selected 2D porous Amosic SiC fiber preform is ultrasonically cleaned and dried; then the BN interface and SiC matrix are sequentially deposited in the fiber preform by the CVI method to make a 2D porous Tyranno ZMI SiC / SiC composite material preform . Among them, BN deposition temperature: 650°C, holding time: 20h, SiC deposition temperature: 1050°C, holding time: 160h; the density of the obtained porous SiC / SiC composite preform is 2.0g / cm 3 , The open porosity is 20vol.%. Add 2g of polyethyleneimine dispersant to 300g of absolute ethanol, stir magnetically until the dispersant dissolves, then add 90g of phenolic resin, 9g of hexamethylenetetramine, and 150g of B with a particle size of 1.5μm 4 C powder; stir evenly with a magnetic force and pour into an agate ball mill tank, add agate balls, and wet ball mill on a planetary ball mill for 11 hours to prepare a precursor slurry impregnation solution. Pour the prepared precursor slurry impregnation solu...

Embodiment 3

[0032] Example 3: The selected 2.5D porous Tyranno ZMI SiC fiber preform was ultrasonically cleaned and dried; then the BN interface and SiC matrix were sequentially deposited in the fiber preform by chemical vapor deposition to make 2D porous Tyranno ZMI SiC / SiC composite material preform. Among them, BN deposition temperature: 630°C, holding time: 25h, SiC deposition temperature: 1000°C, holding time: 200h; the density of the obtained porous SiC / SiC composite preform is 1.7g / cm 3 , The open porosity is 30vol.%. Add 4g of polyethyleneimine dispersant to 400g of absolute ethanol, stir magnetically until the dispersant is dissolved, then add 140g of phenolic resin, 14g of hexamethylenetetramine, and 200g of B with a particle size of 2μm. 4 C powder; stir evenly with a magnetic force and pour into an agate ball mill tank, add agate balls, and wet ball mill on a planetary ball mill for 12 hours to make a precursor slurry impregnation solution. Pour the prepared precursor slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com