Preparation method of SiC fiber enhanced ceramic-based composite material

A composite material and fiber-reinforced technology, which is applied in the field of composite materials, can solve the problems of high temperature resistance, poor mechanical properties, and long preparation cycle, and achieve excellent high temperature stability, low porosity, and excellent wave-absorbing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

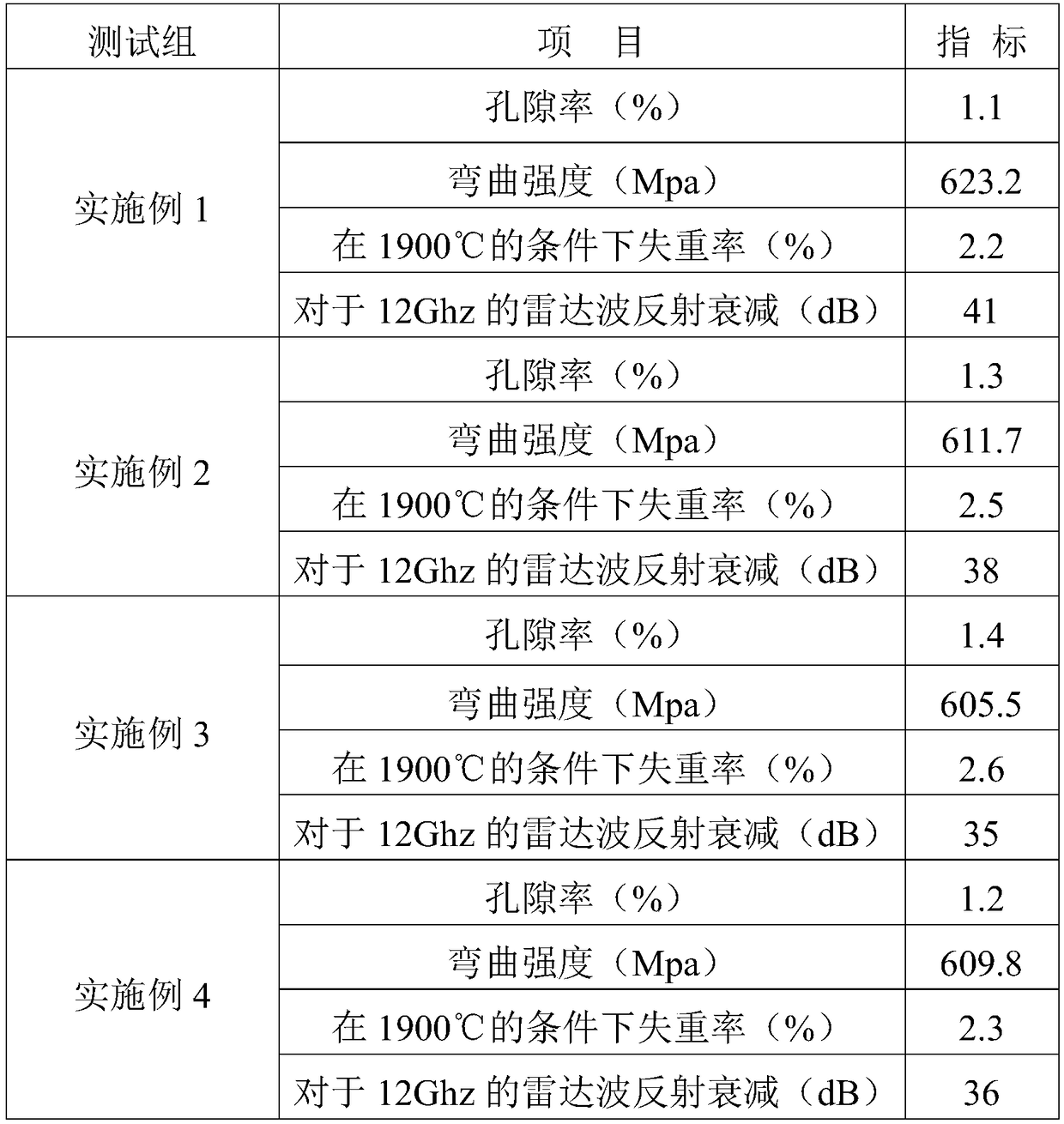

Examples

Embodiment 1

[0026] A preparation method of a SiC fiber reinforced ceramic matrix composite material in this embodiment, the specific steps are as follows:

[0027] 1. Contains ZrB 2 Preparation of the SiBCN-Ti precursor powder: Synthesize the titanium-containing polysilaborazane PBSZ precursor with hexamethyldisilazane, boron trichloride, trichlorosilane, and dichlorotitanium dichloride as raw materials, wherein The molar ratio of hexamethyldisilazane, boron trichloride, trichlorosilane and titanocene dichloride is 20:15:4:2; the synthesized titanium-containing PBSZ precursor is dissolved in toluene to obtain titanium-containing PBSZ precursor solution, and ZrB with a particle size of 400nm 2 The ceramic powder is added to the prepared titanium-containing PBSZ precursor solution to obtain a mixed slurry, and the added ZrB 2 The mass ratio of the ceramic powder to the titanium-containing PBSZ precursor solution in the titanium-containing PBSZ precursor solution is 1:4; the prepared mixed...

Embodiment 2

[0031] A preparation method of a SiC fiber reinforced ceramic matrix composite material in this embodiment, the specific steps are as follows:

[0032] 1. Contains ZrB 2 Preparation of the SiBCN-Ti precursor powder: Synthesize the titanium-containing polysilaborazane PBSZ precursor with hexamethyldisilazane, boron trichloride, trichlorosilane, and dichlorotitanium dichloride as raw materials, wherein The molar ratio of hexamethyldisilazane, boron trichloride, trichlorosilane and titanocene dichloride was 15:20:5:1; the synthesized titanium-containing PBSZ precursor was dissolved in xylene to obtain PBSZ precursor solution of titanium, and ZrB with a particle size of 300nm 2 The ceramic powder is added to the prepared titanium-containing PBSZ precursor solution, and the added ZrB 2 The mass ratio of the ceramic powder to the titanium-containing PBSZ precursor solution in the titanium-containing PBSZ precursor solution was 1:3, and then cross-linked at 200°C for 6h to obtain t...

Embodiment 3

[0036] A preparation method of a SiC fiber reinforced ceramic matrix composite material in this embodiment, the specific steps are as follows:

[0037] 1. Contains ZrB 2 Preparation of the SiBCN-Ti precursor powder: Synthesize the titanium-containing polysilaborazane PBSZ precursor with hexamethyldisilazane, boron trichloride, trichlorosilane, and dichlorotitanium dichloride as raw materials, wherein The molar ratio of hexamethyldisilazane, boron trichloride, trichlorosilane and titanocene dichloride was 15:15:5:2; the synthesized titanium-containing PBSZ precursor was dissolved in xylene to obtain PBSZ precursor solution of titanium, and ZrB with a particle size of 500nm 2 The ceramic powder is added to the prepared titanium-containing PBSZ precursor solution, and the added ZrB 2 The mass ratio of the ceramic powder to the titanium-containing PBSZ precursor solution in the titanium-containing PBSZ precursor solution was 1:2, and then cross-linked at 200 ° C for 4 h to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com