Static electricity and inorganic porous ceramics combined dusty gas purification device

An inorganic porous, ceramic tube technology, which is used in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of inability to clean dust, small air resistance of powder cakes, and oxidative damage of cloth bags, and achieve easy charging and air resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

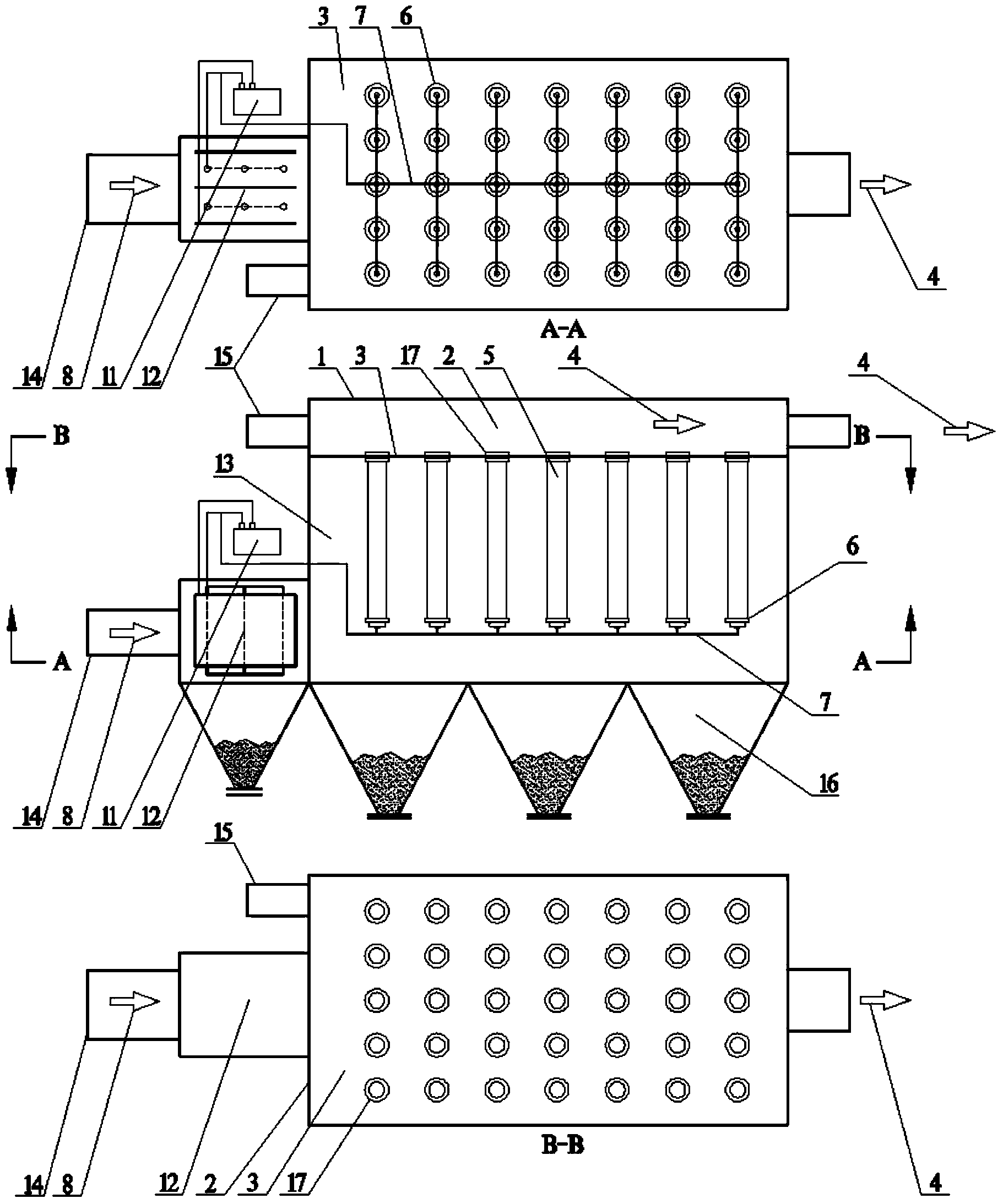

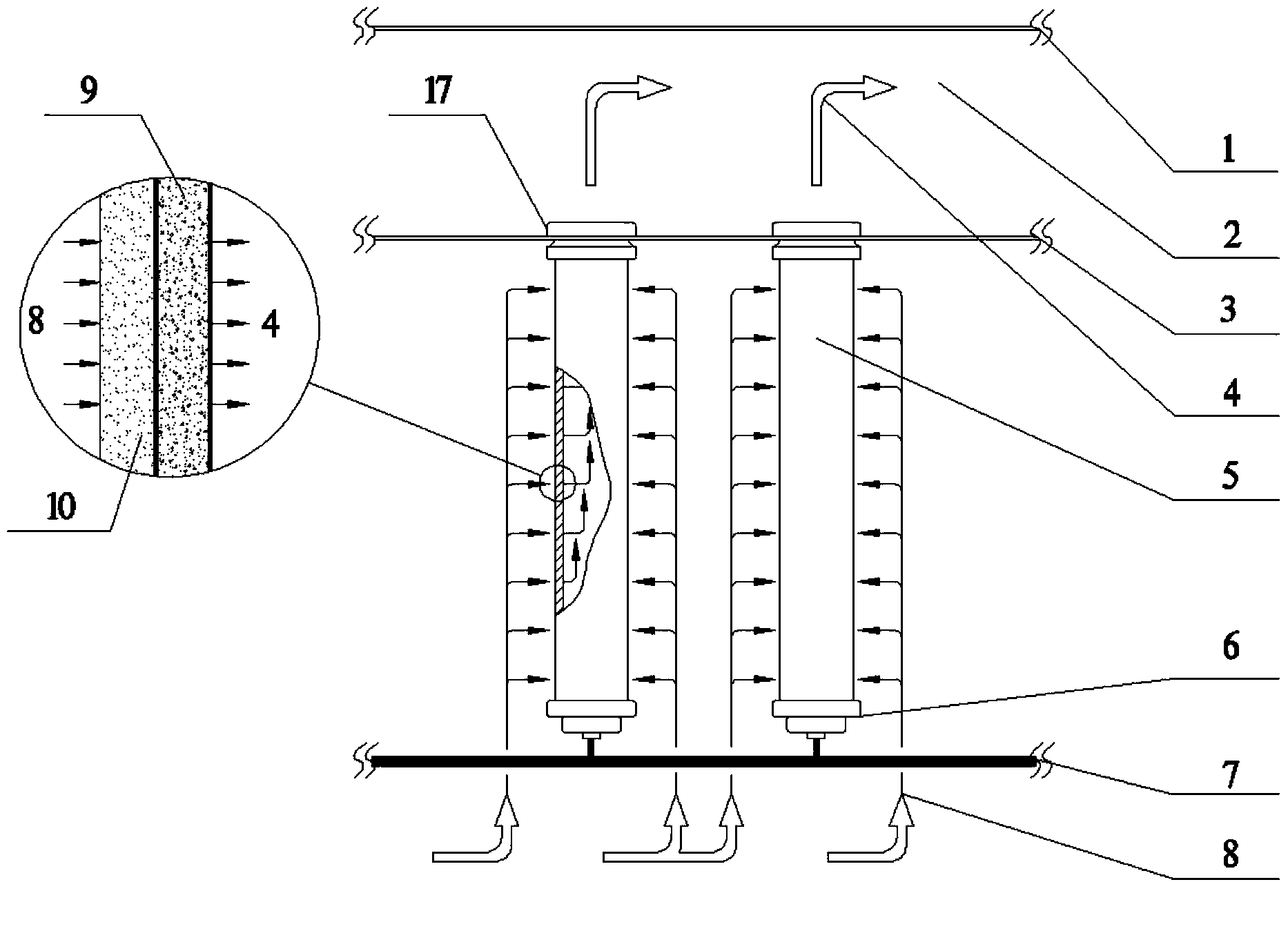

[0022] Take 9 SiC porous ceramic tubes with a length of 0.2m, a diameter of 50mm, a wall thickness of 5mm, and a porosity of 15%. The corona pole of the electrostatic charging module is a wire with a length of 0.3m and a cross-sectional diameter of 2mm, a voltage of 40kV, a flat plate with a cross-section of the dust collection pole of 30cmX40cm, and a distance of 10cm between the dust collection poles to obtain the high-efficiency dust binding device.

Embodiment 2

[0024] Take 17 SiC porous ceramic tubes with a length of 1m, a diameter of 100mm, a wall thickness of 5mm, and a porosity of 50%. The tube bundles are arranged according to the principle that three adjacent tube bundles form an equilateral triangle. The corona electrode of the charging module is a wire with a length of 0.6m and a cross-sectional diameter of 3mm, the voltage is 80kV, the cross-section of the dust collection electrode is a flat plate of 30cmX50cm, and the distance between the plates is 20cm, and the high-efficiency dust-binding device is obtained.

Embodiment 3

[0026] Take 20 SiC porous ceramic tubes with a length of 2m, a diameter of 200mm, a wall thickness of 10mm, and a porosity of 80%, and arrange the tube bundles according to the principle that three adjacent tube bundles form an equilateral triangle. A star-shaped wire with a length of 0.5m and a nominal diameter of 4mm, a voltage of 40kV, a flat plate with a cross-section of the dust collector of 50cmX50cm, and a distance between the plates of 20cm can obtain the high-efficiency dust-trap device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com