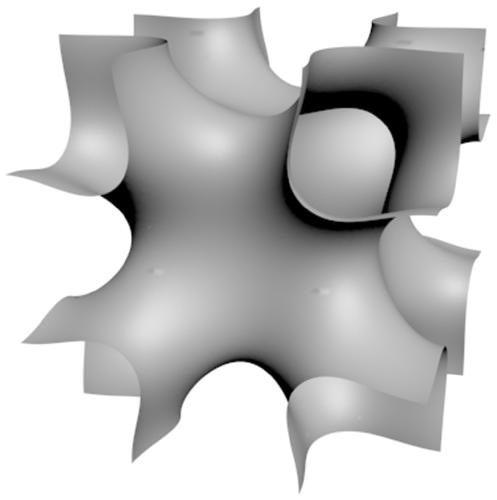

Preparation method of copper/silicon carbide composite material based on I-WP curved surface

A technology of I-WP and composite materials, applied in ceramic products, applications, household appliances, etc., can solve the problems of reduced strength and wear resistance, easy cracks, collapse, etc., and achieve performance optimization, high specific strength, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

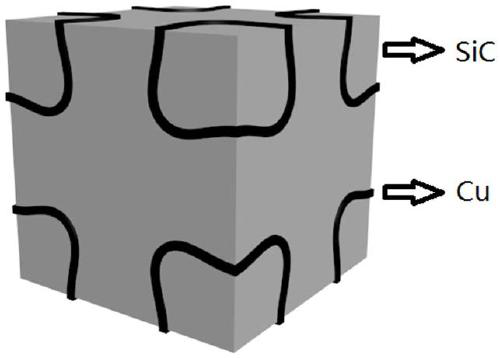

[0019] (1) Preparation of the PLA skeleton: use the fused deposition 3D printer to directly print the I-WP surface structure of the designed PLA material, with a layer thickness of 0.1mm, a cube with a side length of 4×4×4cm, a period parameter of 2, and a curved surface Thickness 1mm;

[0020] (2) Preparation of ceramic powder: SiC powder, talcum powder, Al 2 o 3 Powder and Y 2 o 3 The powder and cellulose are weighed and mixed according to the ratio of 90.5:4.0:1.5:1.0:3.0. After ball milling for 4 hours, sieve to obtain ceramic powder with a particle size of ≤1 μm;

[0021] (3) Preparation of ceramic slurry: Pour the ceramic powder described in step (2) into absolute ethanol, the mass ratio of powder to absolute ethanol is 2:1, and adjust the pH to 10 with ammonia water. Put it in a drum-type ball mill for mixing for 3 hours, and the rotation speed is 250r / min, so that all kinds of materials are mixed evenly to form a slurry, and then aged for 1 day to obtain a silicon ...

Embodiment 2

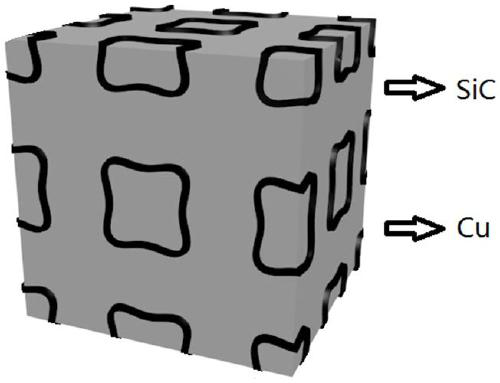

[0026] (1) Preparation of PLA skeleton: use the fused deposition 3D printer to directly print the I-WP surface structure of the designed PLA material, with a layer thickness of 0.1mm, a cube with a side length of 4×4×4cm, a period parameter of 3, and a curved surface Thickness 1mm;

[0027] (2) Preparation of ceramic powder: SiC powder, talcum powder, Al 2 o 3 Powder and Y 2 o 3 The powder and cellulose are weighed and mixed according to the ratio of 90.5:4.0:1.5:1.0:3.0. After ball milling for 4 hours, sieve to obtain ceramic powder with a particle size of ≤1 μm;

[0028] (3) Preparation of ceramic slurry: Pour the ceramic powder described in step (2) into absolute ethanol, the mass ratio of powder to absolute ethanol is 2:1, and adjust the pH to 10 with ammonia water. Put it in a drum-type ball mill for mixing for 3 hours, and the rotation speed is 250r / min, so that all kinds of materials are mixed evenly to form a slurry, and then aged for 1 day to obtain a silicon carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com