Method for preparing porous SiC ceramic based on 3D (three dimensional) molding technology

A ceramic and technical technology, which is applied in the field of preparing porous SiC ceramics based on 3D molding technology, can solve the problems of low porosity of molded parts, and achieve the effects of fast molding speed, high raw material utilization, high porosity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

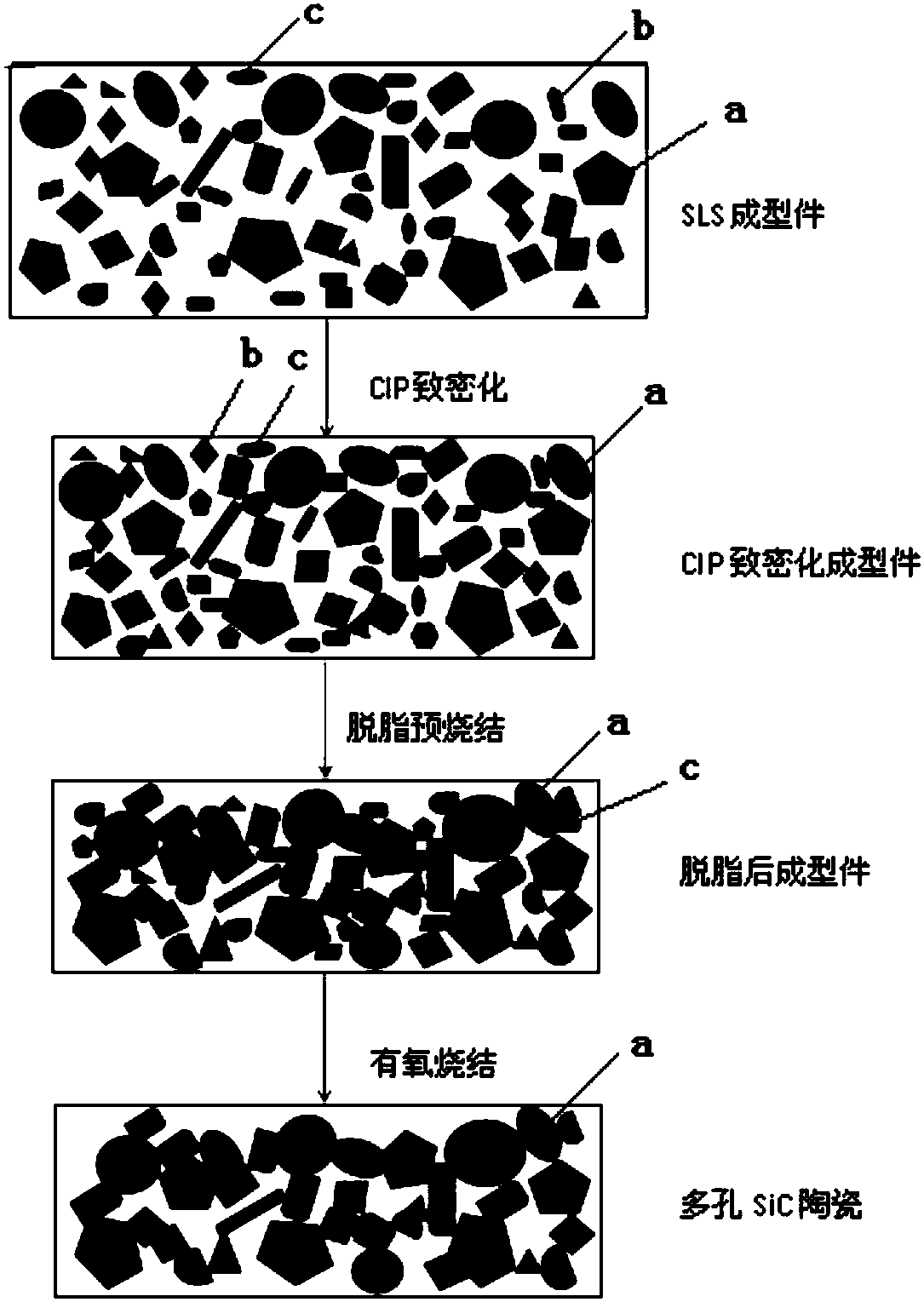

[0020] Specific Embodiment 1: The method for preparing porous SiC ceramics based on 3D forming technology in this embodiment is carried out according to the following steps:

[0021] 1. Draw the 3D model of porous SiC ceramics, and then convert it into an STL format file;

[0022] 2. Import the STL format file into the SLS molding machine, set the scanning speed to 1000mm / s~2000mm / s, the thickness of each layer to 0.05mm~0.2mm, and the preheating temperature to 40~70℃, and then use the computer layered slicing software Process the model into thin slices with a set thickness;

[0023] 3. Pour SiC powder, binder powder and pore-forming agent into the mixer to mix the powder to obtain a uniformly mixed composite powder;

[0024] 4. Add the composite powder into the working cylinder of the SLS molding machine, use the roller to spread the powder, let it stand for 30 minutes, then heat the working cylinder to the preheating temperature set in step 2, start processing, laser sinter...

specific Embodiment approach 2

[0031] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 2, the scanning speed is set to 1000 mm / s, the thickness of each layer is 0.1 mm, and the preheating temperature is 45 ° C. Others are the same as specific embodiment 1. .

specific Embodiment approach 3

[0032] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: in step three, the speed of the mixer is 50r / min, and the powder mixing time is 8h, and the others are the same as specific embodiment one or two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com