Porous SiC prefabricated product, its preparation method and ceramic-metal composite material

A technology of porous ceramics and preforms, which is applied in the field of porous ceramics, and can solve the problems of damage to porous ceramic preforms, poor bending strength, and reduced pass rate of ceramic-metal composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The aforementioned porous SiC preform provided by the present invention can be prepared by referring to conventional methods in the prior art. In a preferred embodiment of the present invention, a method for preparing a porous SiC preform comprises the following steps: mixing 100 parts by weight of SiC particle mixture, 0.1-5 parts by weight of Na 2 SiO 3 , 0.1-5 parts by weight of Al 2 o 3The particles are mixed with a binder, an optional curing agent, an optional auxiliary agent, and an optional solvent to obtain a raw material mixture; the raw material mixture is dry-pressed to obtain a green preform; the green preform is heated to the first temperature, keep warm for degumming treatment, and then heat to the second temperature to obtain a porous SiC preform, wherein the SiC particle mixture contains three groups of SiC particles with different particle sizes in the range of D50, and the particle size D50 of the second group of SiC particles is the same as that of ...

Embodiment 1 to 5

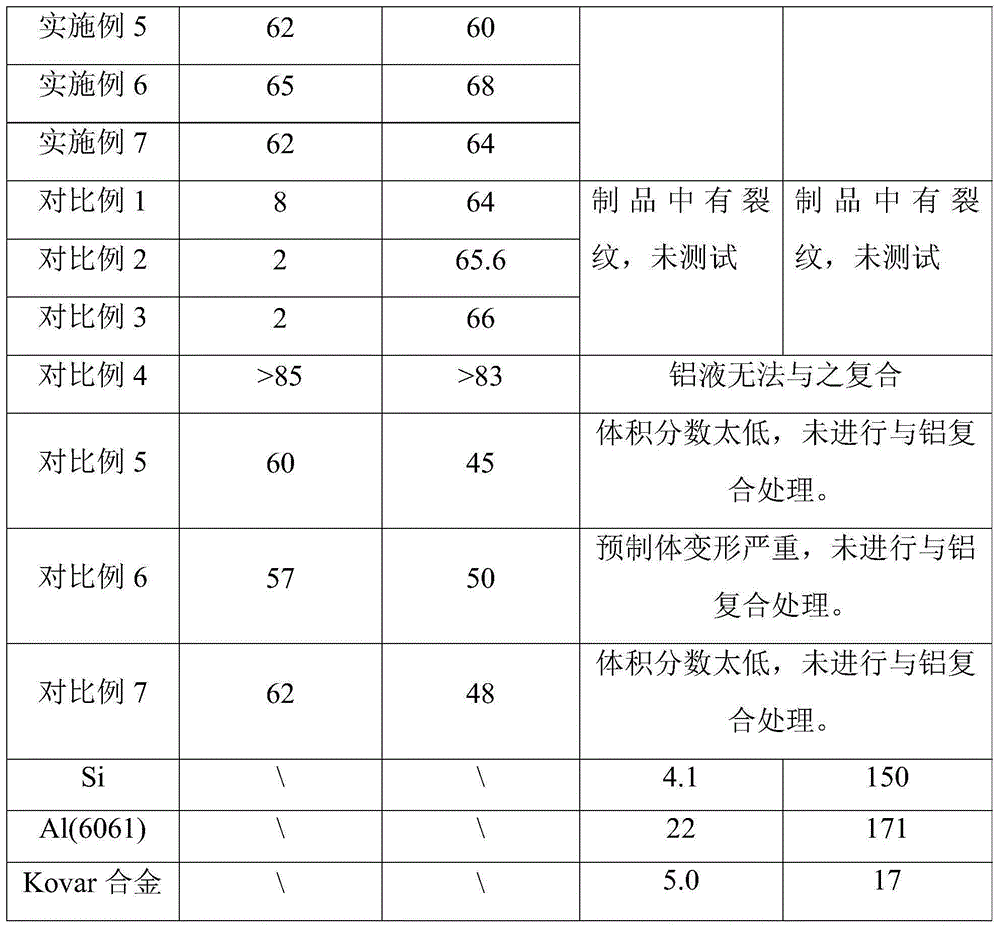

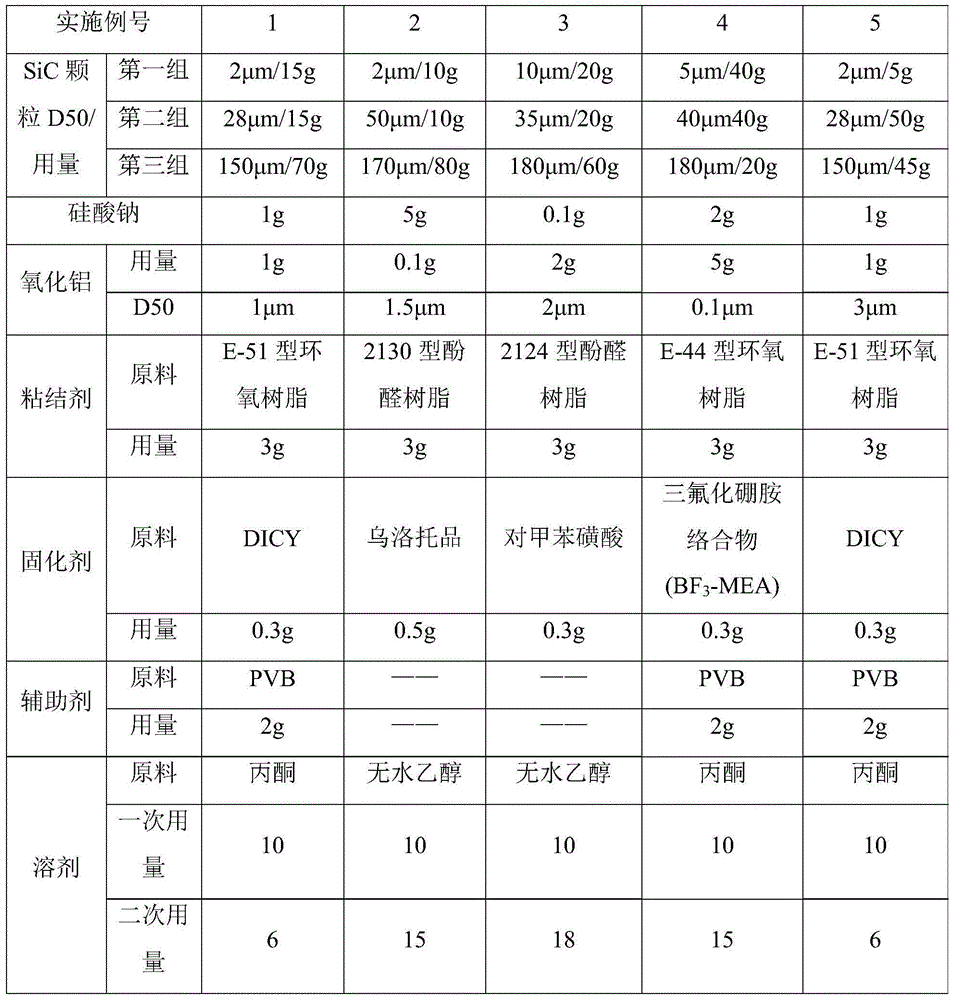

[0042] (1) Raw material ratio: as shown in Table 1:

[0043] Table 1

[0044]

[0045] (2) Preparation method of porous SiC preform:

[0046] The first group of SiC particles, the second group of SiC particles, the third group of SiC particles, Na 2 SiO 3 、Al 2 o 3 The particles were dry mixed for 2 hours to obtain mixture A;

[0047] Mix the binder, curing agent, auxiliary agent and solvent (one-time usage) for 1 hour to obtain mixture B;

[0048] The mixture B was added to the mixture A, and the solvent (secondary amount) was added for wet mixing for 5 hours to obtain the raw material mixture.

[0049] Dry the raw material mixture in an oven (40° C.) for 30 minutes, mold the dried raw material mixture in a dry press mold with a pressure of 100 MPa, and a molding holding time of 120 seconds to obtain a green preform;

[0050] Raise the temperature of the green preform to 600°C (first temperature) at a primary heating rate of 1°C / min and keep it warm for 1 hour; then...

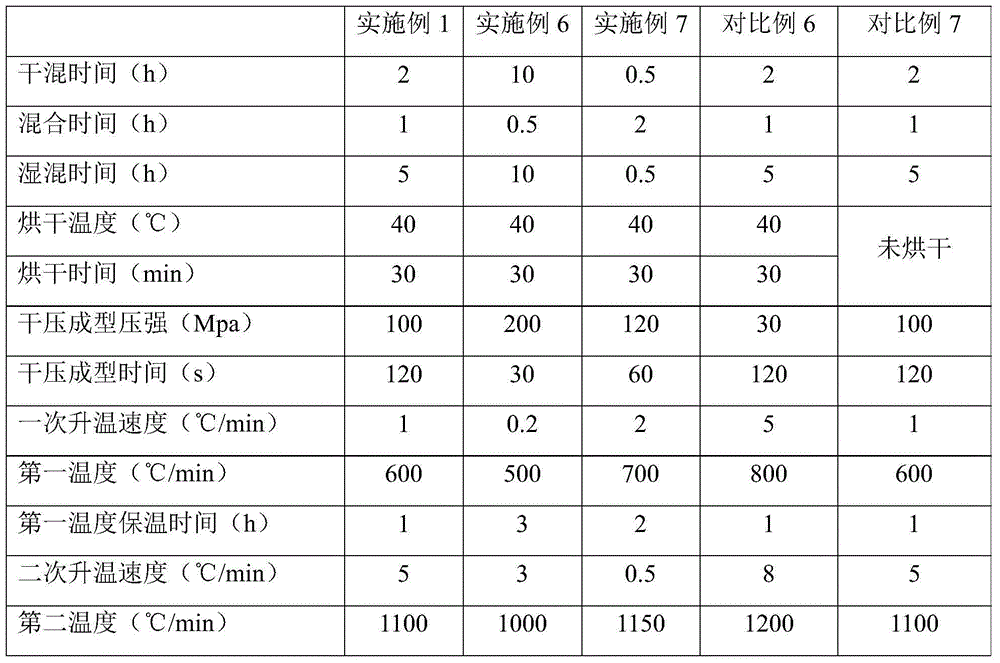

Embodiment 6-7

[0056] (1) raw material proportioning: with embodiment 1.

[0057] (2) Preparation method of porous SiC preform: refer to Example 1, wherein the parameters of each step are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com