A kind of preparation method of porous silicon carbide ceramic material

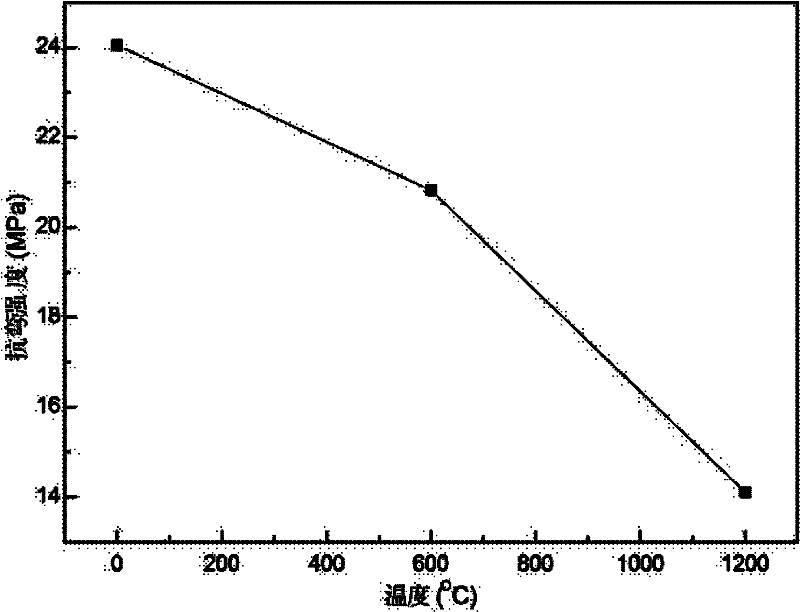

A technology of porous silicon carbide and ceramic materials, applied in the field of ceramic materials, can solve problems such as poor mechanical properties at high temperature, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 15g of SiC (the average particle size of SiC powder is 0.5μm), 0.09g of B, 0.47g of C, 0.3g of polyethyleneimine and 11.42g of deionized water, add them to a 250mL polyethylene grinding bottle, and add 15 g of SiC balls were milled for 24 hours to obtain a uniformly dispersed ceramic water-based slurry with a solid content of 55 wt% (solid content%=SiC / (SiC+sintering aid+dispersant+water)). Add 7.5 g of 12 wt % polyvinyl alcohol (PVA) aqueous solution to the ceramic water-based slurry, and continue ball milling for 24 hours to obtain a uniformly dispersed slurry. Pour the dispersed slurry into the prepared mold, put it into the freezer of the refrigerator and freeze it at -18°C to -20°C for about 12 hours to obtain a frozen green body. Take the frozen green body out of the mold, put it into the drying box of the freeze dryer immediately, first keep it at 10°C and a vacuum of 9Pa for 4 hours, then raise the temperature to 60°C, and keep it warm for about 5 hours to...

Embodiment 2

[0037]The only difference between this embodiment and Example 1 is that 0g, 2.5g, and 12.5g of polyvinyl alcohol (PVA) aqueous solution with a concentration of 12wt% are added to the ceramic water-based slurry, and the remaining contents are the same as in Example 1. described in .

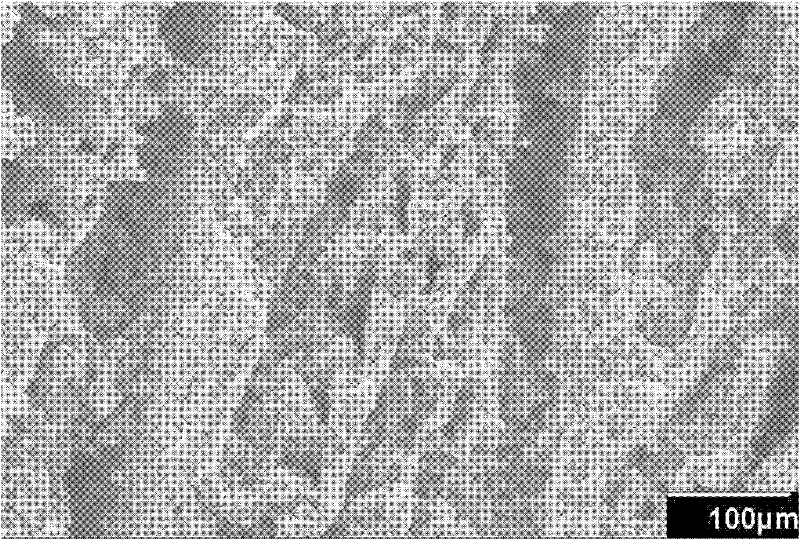

[0038] Figure 4 It is the scanning electron microscope image of the silicon carbide ceramic material prepared under the addition amount of different organic polymers, in the figure: a is the silicon carbide ceramic material prepared without adding polyvinyl alcohol, and b is the addition of 2.5g of polyvinyl alcohol with a concentration of 12wt%. The silicon carbide ceramic material prepared by polyvinyl alcohol (PVA) aqueous solution, c is the silicon carbide ceramic material prepared by adding 7.5g concentration of polyvinyl alcohol (PVA) aqueous solution; d is the addition of 12.5g concentration is 12wt% % of polyvinyl alcohol (PVA) aqueous solution made of silicon carbide ceramic material; b...

Embodiment 3

[0042] The only difference between this example and Example 1 is that 14.44g of SiC (average particle size of SiC powder is 0.5μm), 0.09g of B, 0.47g of C, and 0.3g of polyethyleneimine are added successively to 15g of SiC. Ionized water was used to prepare a ceramic water-based slurry with a solid content of 50 wt%, and all the other contents were the same as those described in Example 1.

[0043] Figure 7 It is the relationship diagram of different slurry solid content and the porosity of the prepared silicon carbide ceramic material, by Figure 7 It can be seen that the porosity gradually decreases with the increase of solid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Room temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com