cBN/tin composite powder and preparation method thereof

A composite powder and composite particle technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of difficulty in obtaining polycrystalline cubic boron nitride, hindering the bonding of cBN particles, and high cost, achieving good Affinity and wettability, expanding product range, reducing effects of temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

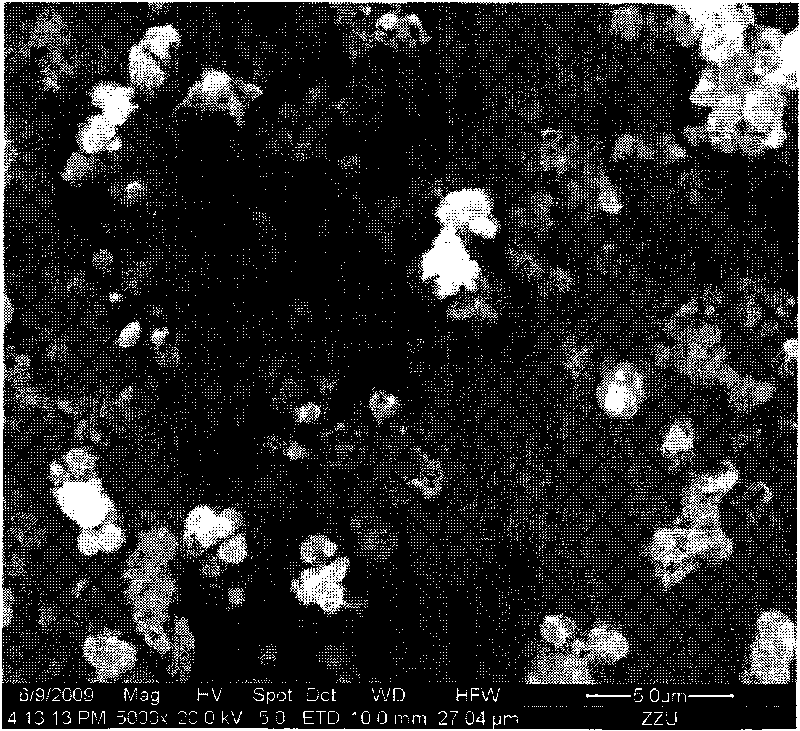

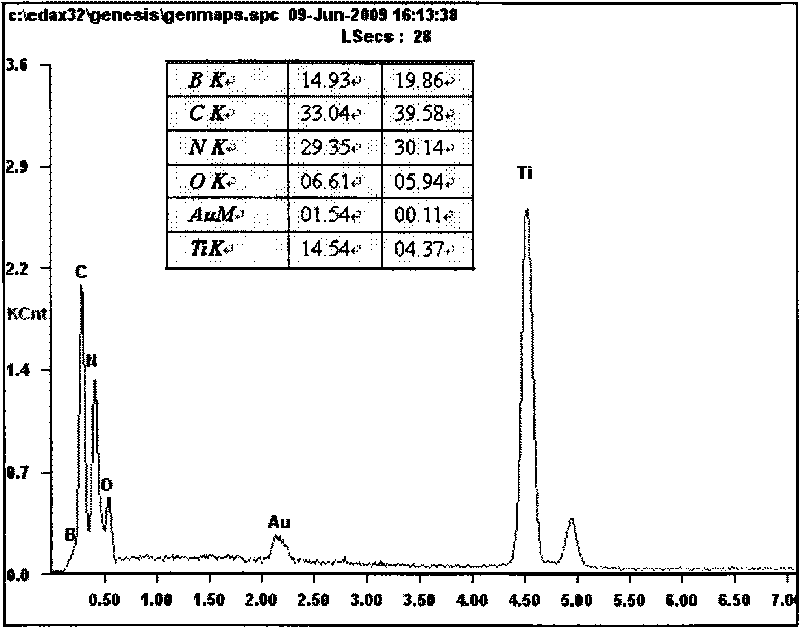

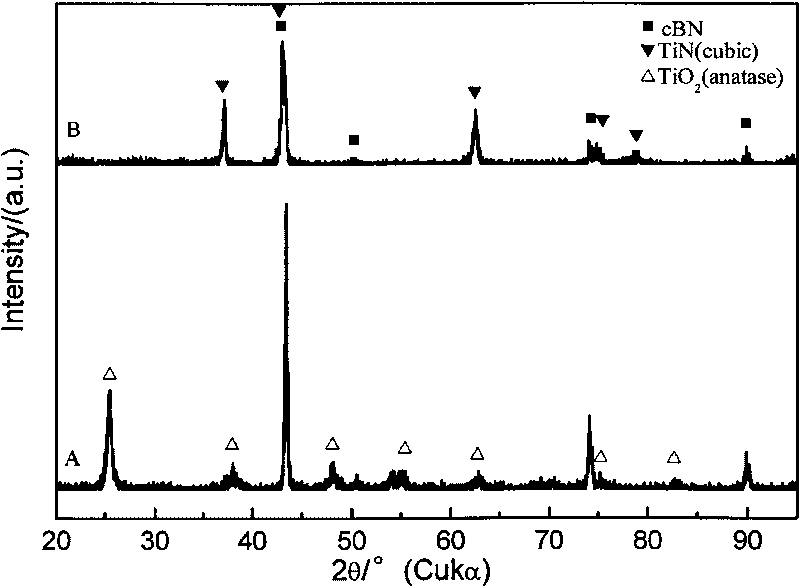

[0031] Weigh 2.52g of acid-treated cBN powder (particle size: 0.01-0.5μm), put it into a 500ml ball mill jar, add 3.47g of butyl titanate, 20ml of absolute ethanol and 200g of balls (Φ5) at the same time, mill and stir 5 hours, rotating speed 150r / min, then add 200ml of distilled water, continue ball milling and stirring for 12 hours, control the pH value to 7-12 during the reaction, then let it stand for 10 hours, centrifuge, and wash the solid particles twice with water, ethanol Wash once, dry in vacuum at 150°C for 0.5 hour, put it in an alumina crucible, put it in a resistance furnace and calcinate in air at 450°C for 1 hour to obtain cBN / TiO 2 Composite powder, the cBN / TiO 2 The composite powder is placed in a tubular (quartz tube) resistance furnace with programmable temperature rise, the two ends of the quartz tube are sealed, and the flow rate of 100ml / min is first passed through N 2 For 1 hour, remove the air in the tube, heat while ventilating the gas, the heating r...

Embodiment 2

[0033] Weigh 2.50g of acid-treated cBN powder (with a particle size of 1-2μm), put it into a 500ml ball mill jar, add 4.11g of butyl titanate, 37ml of absolute ethanol and 200g of balls (Φ5), and mill for 5 hour, rotating speed 150r / min, then add 200ml of distilled water, continue ball milling and stirring for 18 hours, control the pH value to 7-12 during the reaction process, then let it stand for 10 hours, centrifuge, and wash the obtained solid particles twice with water and ethanol 1 time, vacuum dry at 150°C for 1 hour, then place it in an alumina crucible, put it in a resistance furnace and calcinate in air at 450°C for 1 hour to obtain cBN / TiO 2 Composite powder, the cBN / TiO 2 The composite powder is placed in a tubular (quartz tube) resistance furnace with programmable temperature rise, the two ends of the quartz tube are sealed, and the flow rate of 100ml / min is first passed through N 2 For 1 hour, remove the air in the tube, heat while ventilating the gas, the heati...

Embodiment 3

[0035] Weigh 2.50g of acid-treated cBN powder (particle size: 2-4μm), put it into a 500ml ball mill jar, add 6.85g of butyl titanate, 34ml of absolute ethanol and 200g of balls (Φ5), and mill for 12 hour, rotating speed 150r / min, then add 250ml of distilled water, continue ball milling and stirring for 24 hours, control the pH value to 7-12 during the reaction, then let it stand for 10 hours, centrifuge, and wash the obtained solid particles twice with water and ethanol 1 time, vacuum dry at 150°C for 1 hour, then place it in an alumina crucible, put it in a resistance furnace and calcinate in air at 500°C for 1 hour to obtain cBN / TiO 2 Composite powder, the cBN / TiO 2 The composite powder is placed in a tubular (quartz tube) resistance furnace with programmable temperature rise, the two ends of the quartz tube are sealed, and the flow rate of 100ml / min is first passed through N 2 For 1 hour, remove the air in the tube, heat while ventilating the gas, the heating rate is 5°C / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com