Phosphor powder with adjustable near-ultraviolet excitation light color by single matrix and preparation method thereof

A near-ultraviolet and excitation light technology, used in luminescent materials, chemical instruments and methods, sustainable architecture, etc., can solve the problems of insufficient mixing uniformity and light color stability, poor color rendering of light sources, complex design, etc., and achieve the preparation method. Simple and feasible, high luminous intensity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) According to the molar ratio of Ba : Mg : Si : Eu : Ga = 0.99 : 1.99 : 2 : 0.01 : 0.01, weigh BaO and 4MgCO 3 •Mg(OH) 2 • 5H 2 O, SiO 2 、Eu 2 o 3 , Ga 2 o 3 , and then mix well;

[0020] (2) Put the mixed material obtained in step (1) into a crucible and pre-fire it at 850°C, keep it warm for 6 hours, and cool it naturally with the furnace temperature;

[0021] (3) Grind the mixed material after pre-burning in step (2) again and place it in reducing gas H 2 + N 2 After holding at 1230℃ for 10 hours, cool naturally with the furnace temperature, and after grinding, the silicate white phosphor Ba which is co-doped with europium ions and gallium ions 0.99 Eu 0.01 Mg 1.99 Ga 0.01 Si 2 o 7 .

Embodiment 2

[0023] (1) According to the molar ratio of Ba : Mg : Si : Eu : Ga = 0.98 : 1.98 : 2 : 0.02 : 0.02, weigh BaO and 4MgCO 3 •Mg(OH) 2 • 5H 2 O, SiO 2 、Eu 2 o 3 , Ga 2 o 3 , and then mix well;

[0024] (2) Put the mixed material obtained in step (1) into a crucible and pre-fire it at 600°C, keep it warm for 10 hours, and cool it naturally with the furnace temperature;

[0025] (3) Grind the pre-calcined mixed material in step (2) again and put it under reducing gas CO, keep it at 1230°C for 10 hours, then cool it naturally with the furnace temperature, and get co-doped with europium ions and gallium ions after grinding Silicate white phosphor Ba 0.98 Eu 0.02 Mg 1.98 Ga 0.02 Si 2 o 7 .

Embodiment 3

[0027] (1) According to the molar ratio of Ba : Mg : Si : Eu : Ga = 0.96 : 1.96 : 2 : 0.04 : 0.04, weigh BaCO 3 , MgO, SiO 2 、Eu 2 o 3 , Ga 2 o 3 , and then mix well;

[0028] (2) Put the mixed material obtained in step (1) into a crucible and pre-fire it at 850°C, keep it warm for 6 hours, and cool it naturally with the furnace temperature;

[0029] (3) Grind the mixed material after pre-burning in step (2) again and place it in reducing gas H 2 + N 2 After holding at 1230℃ for 10 hours, cool naturally with the furnace temperature, and after grinding, the silicate white phosphor Ba which is co-doped with europium ions and gallium ions 0.96 Eu 0.04 Mg 1.96 Ga 0.04 Si 2 o 7 .

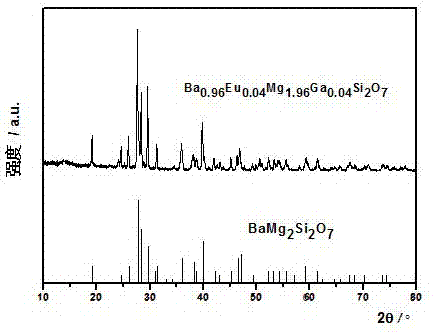

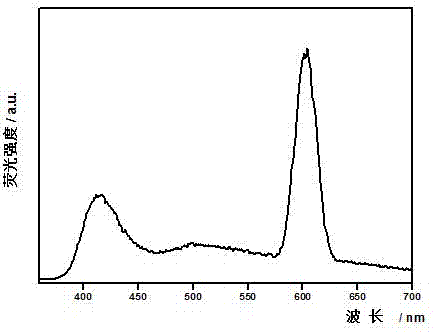

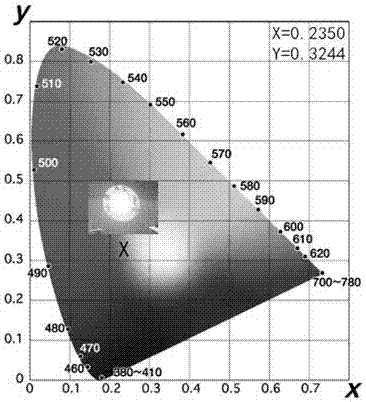

[0030] attached figure 1 is in reducing gas H 2 + N 2 The silicate white phosphor Ba 0.96 Eu 0.04 Mg 1.96 Ga 0.04 Si 2 o 7 X-ray powder diffraction pattern. The phase search found that the diffraction peaks of the obtained products all corresponded to the standard card JCPDS10-00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com