Method for distribution control of drum type washing machine before drying clothes

A drum washing machine, distributed control technology, applied to the control device of the washing machine, washing device, textile and paper making, etc., can solve the problem of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The unbalance amount mentioned in the present invention corresponds to the unbalanced weight generated when the load distribution in the bucket is not completely uniform.

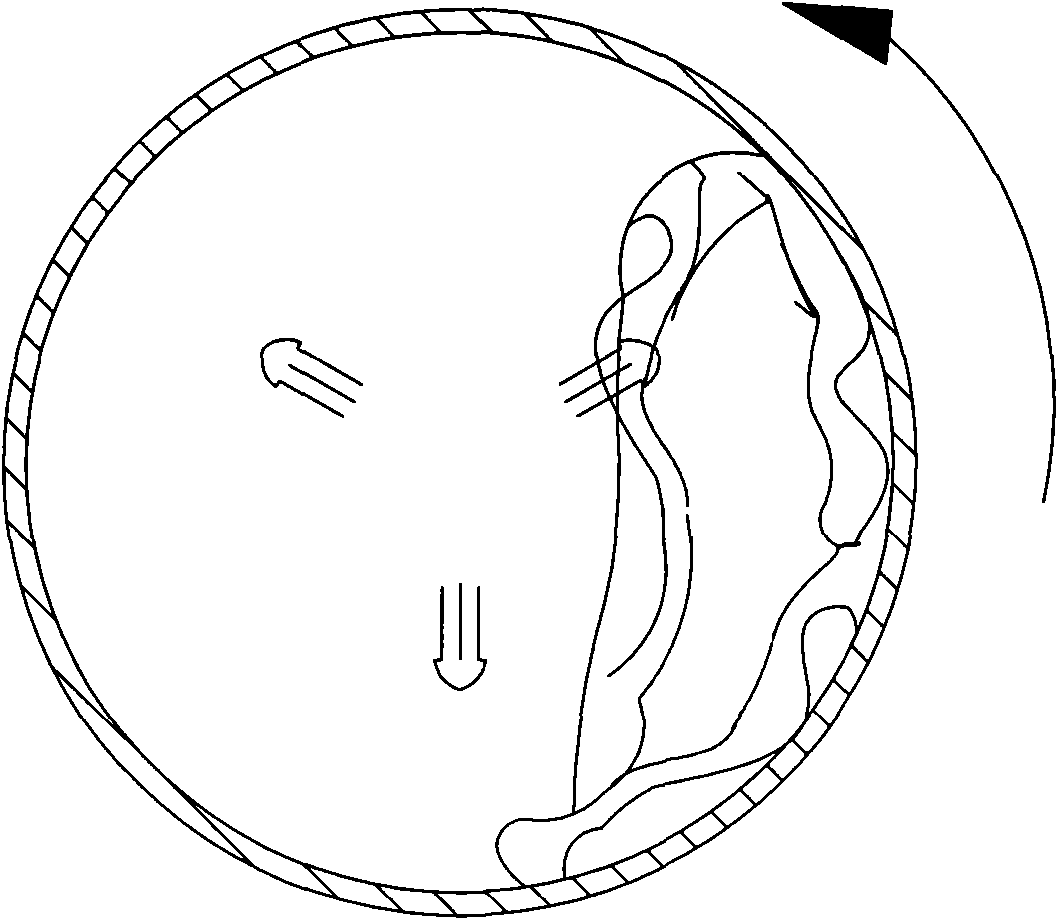

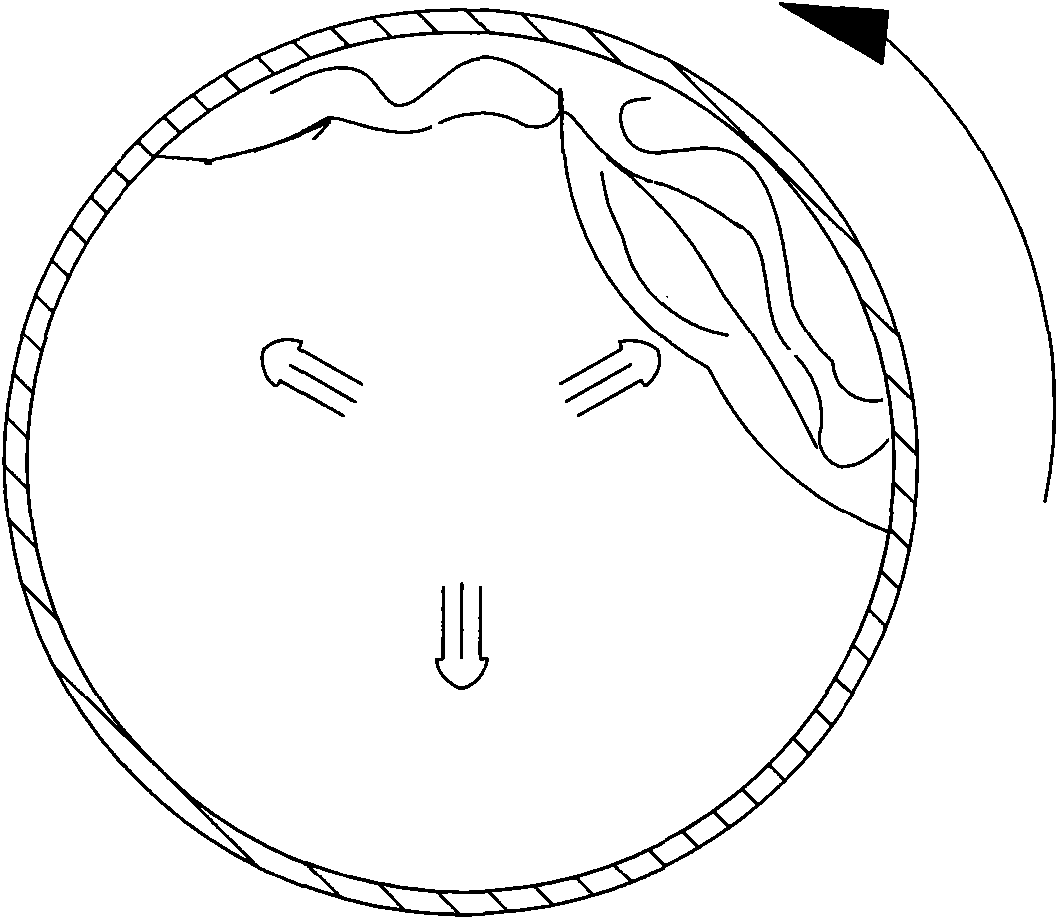

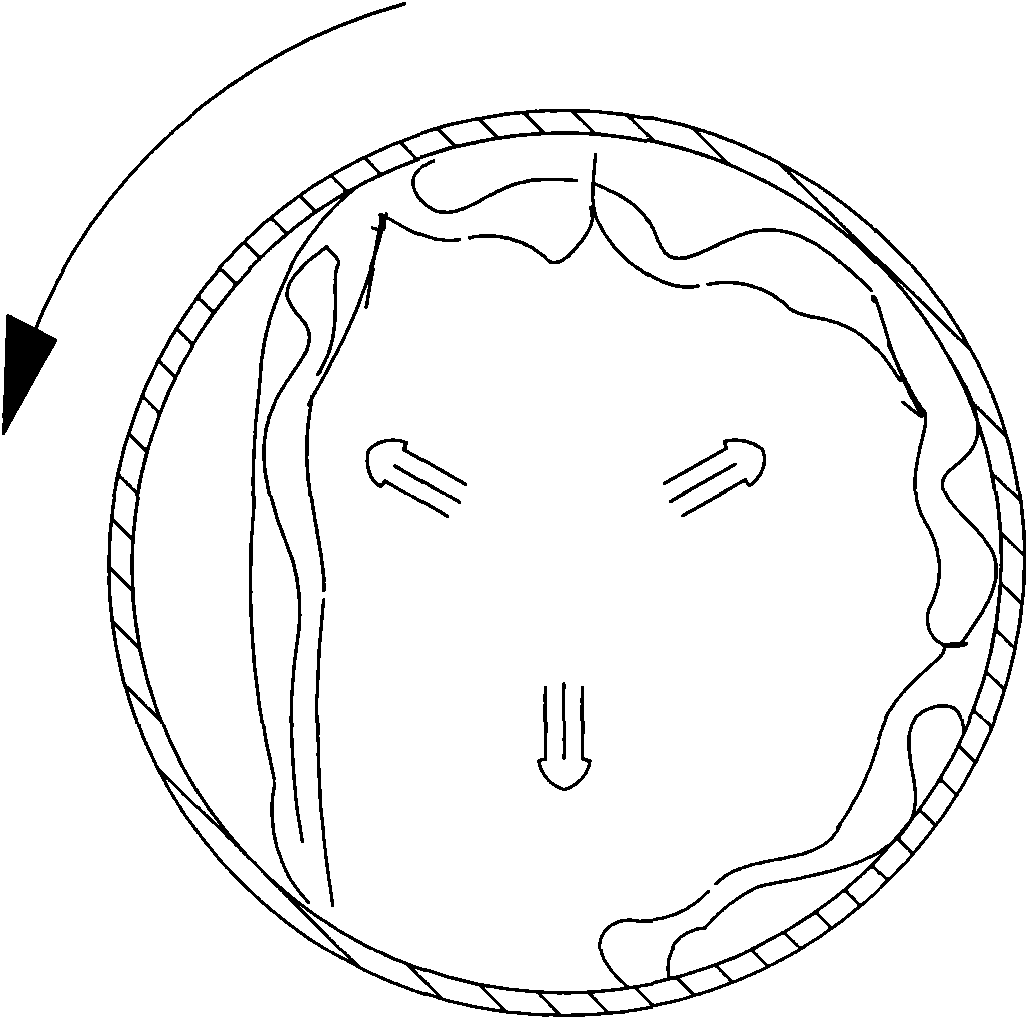

[0037] like Figure 5 As shown, it is a schematic diagram of the drum speed control curve. Its purpose is to make the clothes evenly distributed before drying. The drum speed control is implemented in the following four stages:

[0038] The first stage is the drainage stage S1. During the drainage process, the drum of the washing machine rotates clockwise and counterclockwise at a speed between 40 and 60 revolutions per minute. During this process, any rotation-to-stop ratio is used. The rotation speed needs to be determined according to the model. An optimal value (corresponding to Figure 5 in a speed);

[0039] The second stage, the counterclockwise rapid rise stage S2, the speed increases from the low speed drainage speed to 73 revolutions per minute. The speed increase at this stage must be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com