Silica gel lens, fabrication method of silica gel lens and LED light emitting device comprising silica gel lens

A technology of silica gel lens and light-emitting devices, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low light efficiency of LED light-emitting devices, achieve the effects of improving light efficiency, facilitating processing, improving luminous efficiency and luminous quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

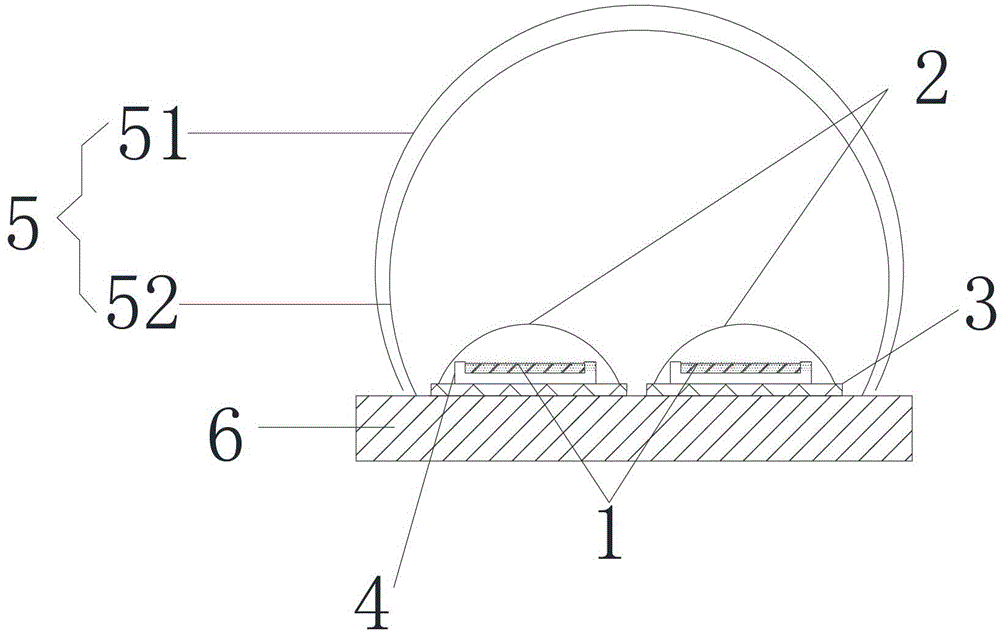

[0037] In yet another typical embodiment of the present invention, a method for preparing a silica gel lens is also provided, including: step A, mixing quantum dot polymer dispersion with a mass ratio of 1:3~7:40~50, fluorescent Mix the powder and silica gel to form a rubber mixture; step B, put the rubber mixture into the molding mold of the silicone lens, and evacuate until there are no visible air bubbles; and step C, inject the rubber mixture treated in step B to obtain a silicone lens .

[0038] The process of mixing the quantum dot polymer dispersion, fluorescent powder and silica gel to form the mixed glue can be done by magnetic stirring or mechanical stirring. It is preferable to use a special glue mixing machine to speed up the formation of the mixed glue; after injecting the mixed glue into the mold Vacuumize the bubbles to avoid affecting the light effect of the silicone lens due to the existence of bubbles in the silicone lens; due to the high production efficienc...

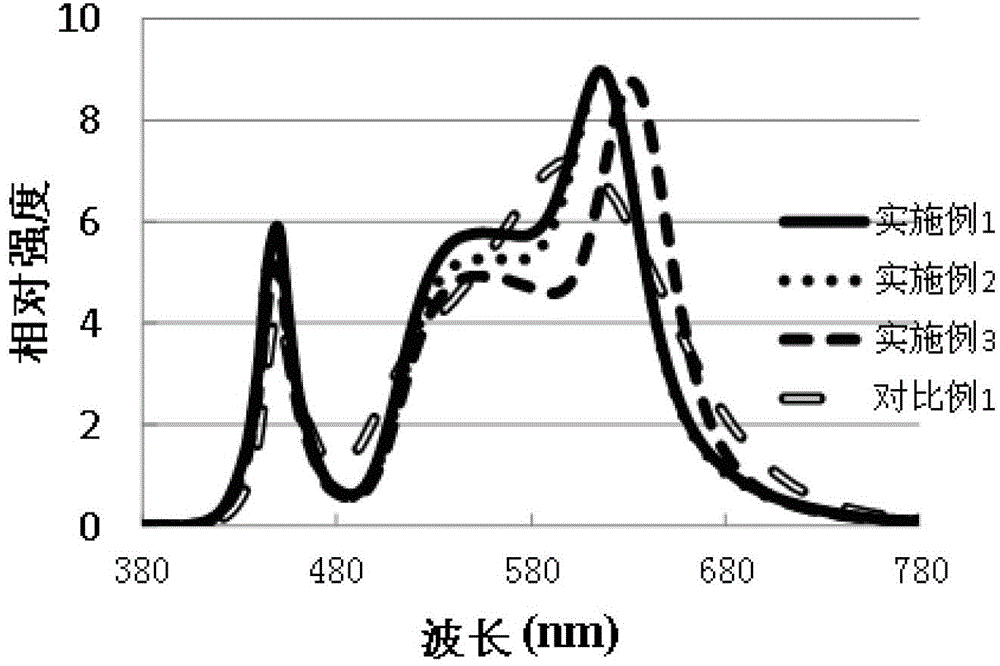

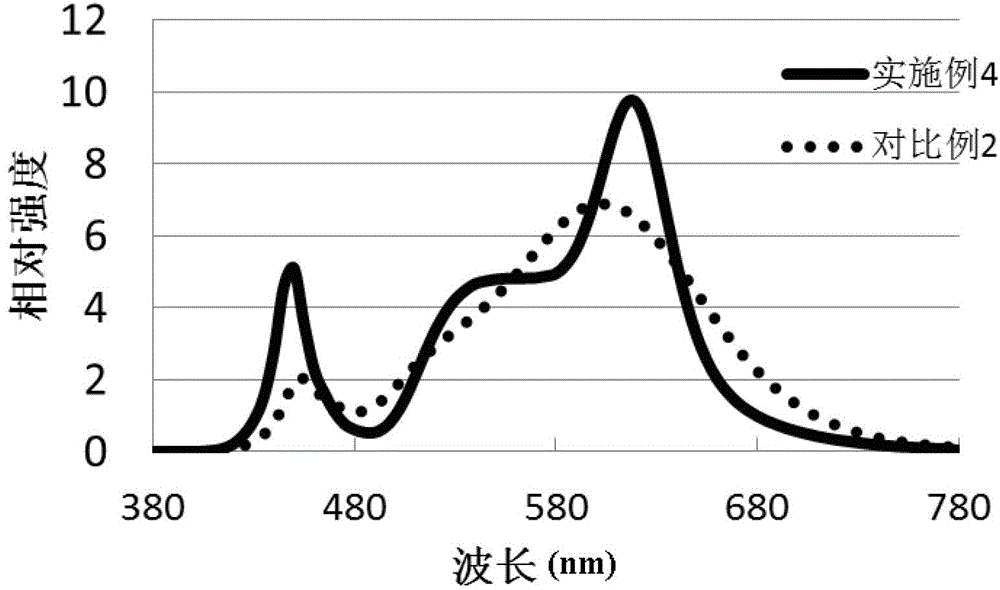

Embodiment 1

[0057] Mix 0.135g of YAG phosphor powder of model Y6BH-015 into 1.5g of Dow Corning optical base silica gel 6003, and use a mixer of model DAC150.1FVZX to stir 5 times at a speed of 3000r / min for 40 seconds each time to make the phosphor uniform Disperse in silica gel to form a mixed rubber. After each stirring, cool down for 30 seconds before the next stirring to keep the temperature below 40°C to prevent overheated silica gel from solidifying. Inject the above mixed rubber into the mold, vacuumize until there are no obvious bubbles; then place the mold filled with the mixed rubber in an oven at 150°C for 30 minutes and take it out. After the mold drops to room temperature, remove the mold and take out the phosphor silicone lens. . After completion, 0.2g of acrylate-modified silicone resin {CH 2 =CHCOO[(CH 3 ) 2 SiO] 60 OCCH=CH 2 ]} coated on the inner surface of the phosphor silicone lens, where the CdSe / ZnS quantum dot material is in the acrylate modified silicone resi...

Embodiment 2

[0059] Mix 0.135g of YAG phosphor powder of model Y6BH-015 into 1.5g of Dow Corning Optical Polar Silica Gel 6003, and stir 5 times with a mixer of model DAC150.1FVZX at a speed of 3000r / min for 40 seconds each time to make the phosphor even Disperse in silica gel to form a mixed rubber. After each stirring, cool down for 30 seconds before the next stirring to keep the temperature below 40°C to prevent overheated silica gel from solidifying. Inject the above mixed rubber into the mold, and vacuum until there are no obvious air bubbles; then place the mold filled with the mixed rubber in an oven at 200°C for 1 minute and take it out. After the mold drops to room temperature, remove the phosphor silica gel. lens. After completion, 0.3g of organosiloxane resin {CH 2 =CH(CH 3 ) 2 SiO[(CH 2 =CH)(CH 3 )SiO] 5 [(CH 3 )SiO] 60 (CH 3 ) 2 SiCH=CH 2 ]} coated on the outer surface of phosphor silicone lens, where CdSe / ZnS quantum dot material is in organosiloxane resin {CH 2 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com