SCR denitration system ammonia spraying optimization method based on weight valve regulation and control

An optimization method and weight valve technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of poor mixing uniformity of ammonia nitrogen equivalent, excessive ammonia escape, and low denitration efficiency, and reduce ammonia escape and ammonia. dosage, improve denitrification efficiency, and ensure the effect of ammonia-nitrogen mixing equivalent ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of this technical solution. It should be understood that the embodiment is to illustrate the present invention, but the protection scope of the present invention is not limited to the embodiment.

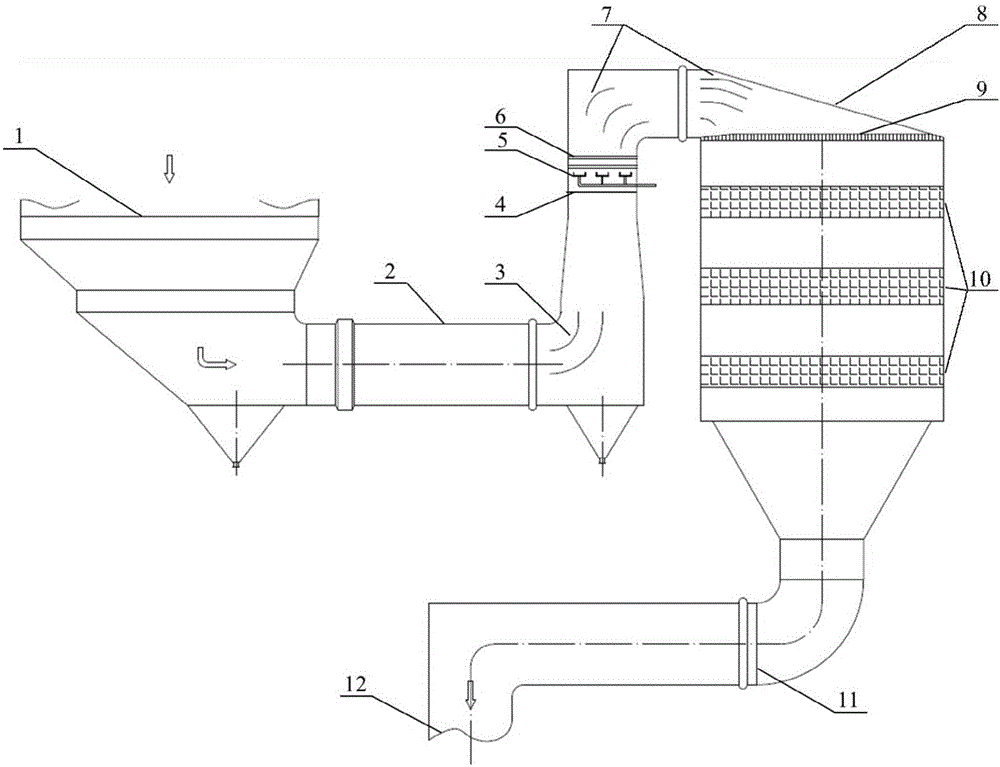

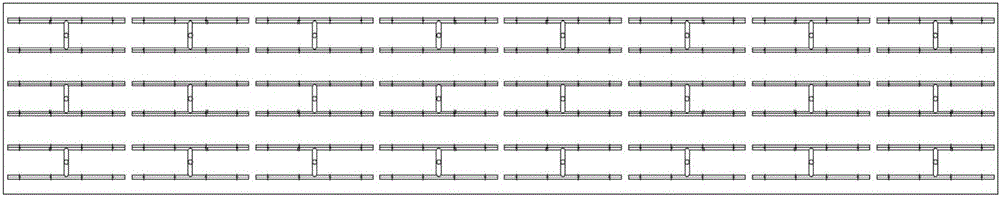

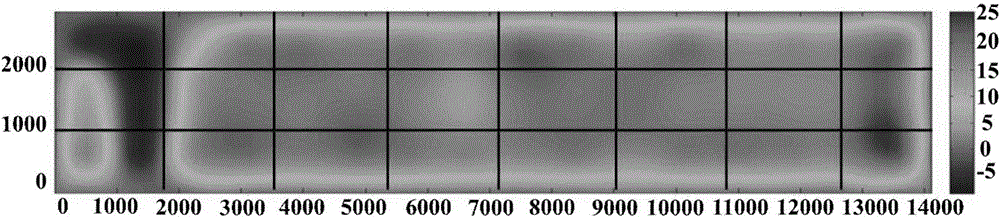

[0031]This implementation case is aimed at optimizing the ammonia injection control of the SCR denitrification system for a 660MW ultra-supercritical coal-fired generating set in a power plant. The overall structure diagram is attached figure 1 shown. The ammonia injection system is composed of 1 master valve, 2 automatic regulating valves (controlling the amount of ammonia injection on A and B sides respectively), 48 manual butterfly valves (24 on each side) and other components to jointly control the amount of ammonia injection. The following describes the optimization control of ammonia injection on the B side of the SCR denit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com