Supporting structure of curved glass and mounting method of supporting structure

A curved glass and support structure technology, applied in chemical instruments and methods, glass/slag layered products, building components, etc., can solve problems such as curved glass deformation, optical deformation, glass cracking or breaking, and achieve safe and fast support, Not easy to be damaged, the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

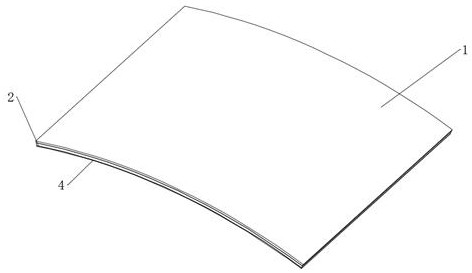

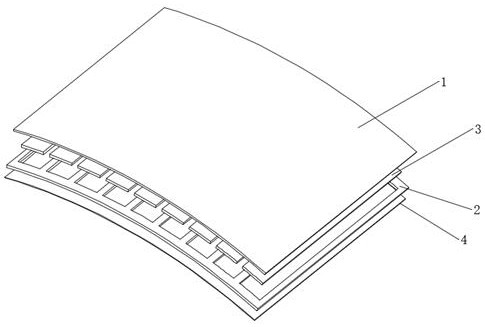

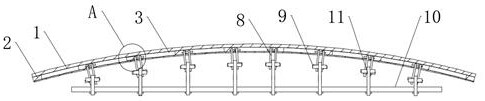

[0044] see Figure 1-3, A support structure for curved glass and an installation method thereof, comprising a curved glass main body 1, a metal frame 2 is laid on the lower surface of the curved glass main body 1, a plurality of evenly distributed through holes are opened on the metal frame 2, and the through holes are fixed inside A transparent resin plate 3 is connected. The transparent resin plate 3 is made of transparent thermosetting resin. A metal frame 2 and the curved glass body 1 are bonded by transparent resin glue. The light transmittance of the transparent resin glue after molding is the same as that of the transparent resin plate 3. A plurality of evenly distributed fixing plates 5 are connected between the metal frame 2 and the transparent resin plate 3 , the end of the metal frame 2 away from the curved glass body 1 is covered with a protective film 4 , and the transparent resin plate 3 and the protective film 4 are threadedly connected with a protective film 4 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com