Method for preparing silicon dioxide (SiO2) aerogel with continuous density gradient

A density gradient and aerogel technology, applied in the direction of silica, silicon oxide, etc., can solve problems such as difficulty in application, and achieve the effect of complete molding structure, density distribution, and large density difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) A one-step catalytic sol-gel method is adopted, with tetraethyl orthosilicate, absolute ethanol, deionized water, and hydrofluoric acid as raw materials, with volume ratios of 1:1:0.25:0.04 and 1:4:0.25, respectively : 0.07 Configure two sols with different target densities, high and low;

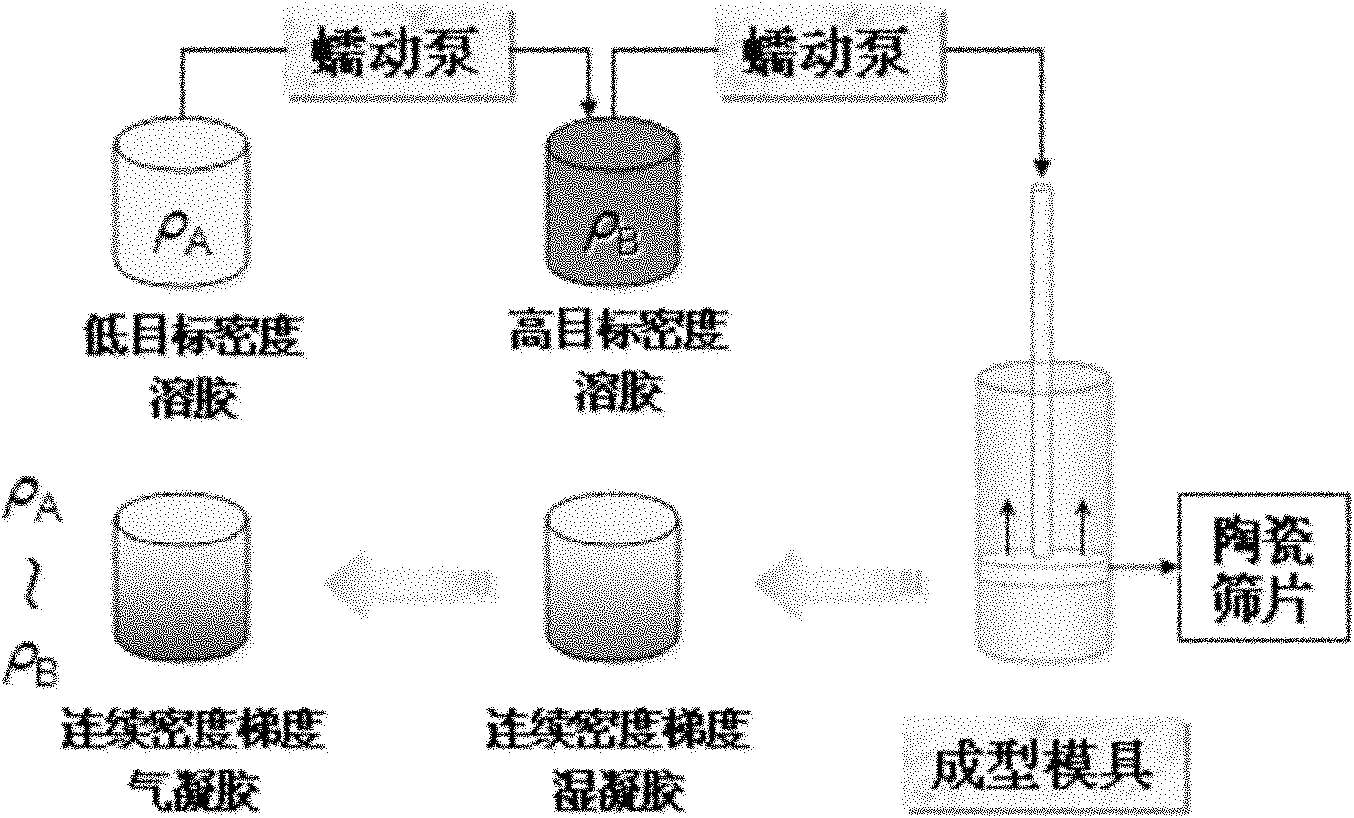

[0035] (2) Self-designed and built density gradient hybrid molding device;

[0036] (3) Slowly add the low target density sol to the high target density sol at a speed of 15rad / min through a peristaltic pump, and keep stirring, and at the same time, slowly add the mixed sol to the molding mold at a speed of 15rad / min with a peristaltic pump, Preparation of continuous density gradient SiO 2 Sol;

[0037] (4) The continuous density gradient SiO 2 The sol was left at 40°C for 1 hour to prepare a continuous density gradient SiO 2 wet gel;

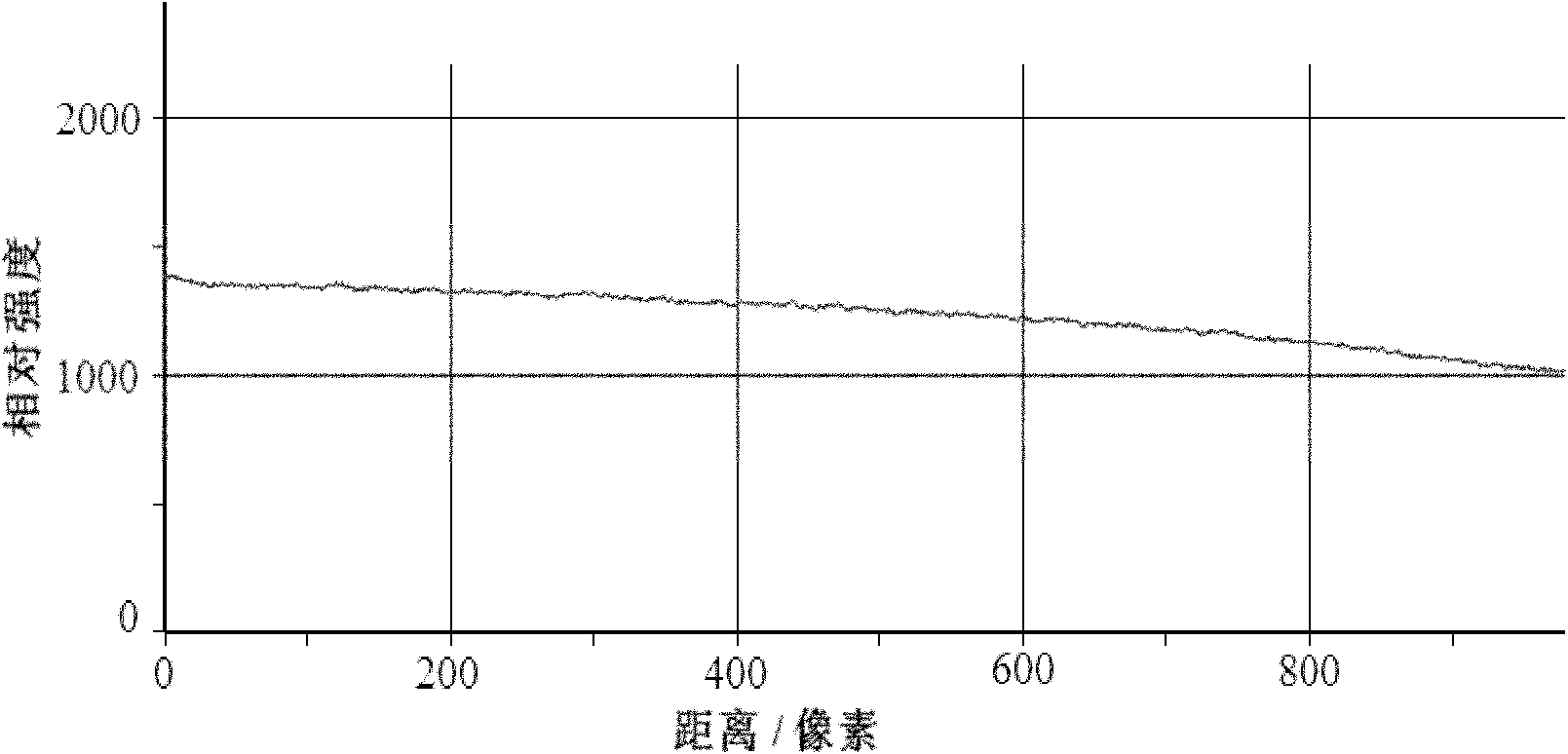

[0038] (5) Soak the above wet gel in ethanol for aging for 72 hours, during which the ethanol was replaced twice, and then put into an autoc...

Embodiment 2

[0040] (1) A one-step catalytic sol-gel method is adopted, with ethyl orthosilicate, absolute ethanol, deionized water, and hydrofluoric acid as raw materials, with a volume ratio of 1:3:0.25:0.06 and 1:6:0.25, respectively : 0.1 Configure two sols with different target densities, high and low;

[0041] (2) Self-built density gradient hybrid molding device;

[0042] (3) Slowly add the low target density sol to the high target density sol through a peristaltic pump at a speed of 5 rad / min, and keep stirring, and at the same time, use a peristaltic pump to slowly add the mixed sol to the forming mold at a speed of 5 rad / min, Preparation of continuous density gradient SiO 2 Sol;

[0043] (4) The continuous density gradient SiO 2 The sol was left to stand at 10°C for 3 hours to prepare a continuous density gradient SiO 2 wet gel;

[0044] (5) Soak the above wet gel in ethanol for aging for 72 hours, during which the ethanol was replaced twice, and then placed in an autoclave ...

Embodiment 3

[0046] (1) A one-step catalytic sol-gel method is adopted, with ethyl orthosilicate, absolute ethanol, deionized water, and hydrofluoric acid as raw materials, with a volume ratio of 1:1:0.25:0.04 and 1:6:0.25, respectively : 0.1 Configure two sols with different target densities, high and low;

[0047] (2) Self-built density gradient hybrid molding device;

[0048] (3) Slowly add the low target density sol to the high target density sol through a peristaltic pump at a speed of 10rad / min, and keep stirring, and at the same time, use a peristaltic pump to slowly add the mixed sol to the forming mold at a speed of 10rad / min, Preparation of continuous density gradient SiO 2 Sol;

[0049] (4) The continuous density gradient SiO 2 The sol was left at 20°C for 3 hours to prepare a continuous density gradient SiO 2 wet gel;

[0050] (5) The wet gel was soaked in ethanol for 120 hours and aged for 120 hours, during which the ethanol was replaced twice, and then put into an autocl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com