Structure and construction method of small-space floor support plate under roof reverse process construction

A kind of floor slab, small space technology, applied in the direction of floor slab, building components, building structure, etc., to overcome the difficulty of supporting formwork installation, reduce the difficulty of construction, and be easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

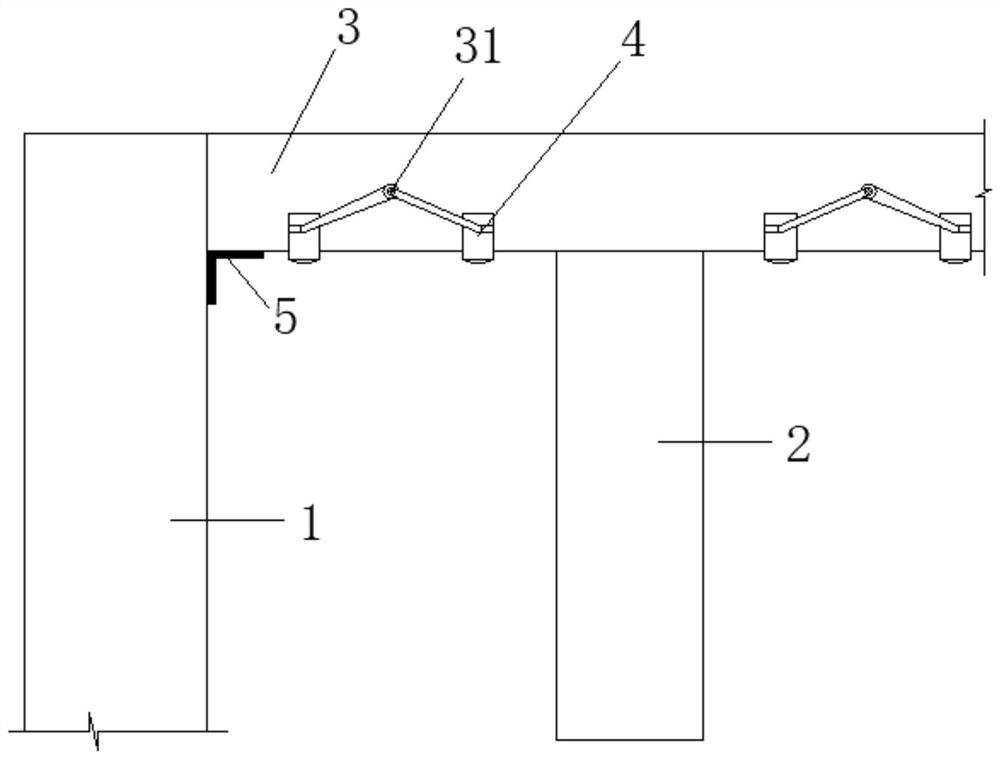

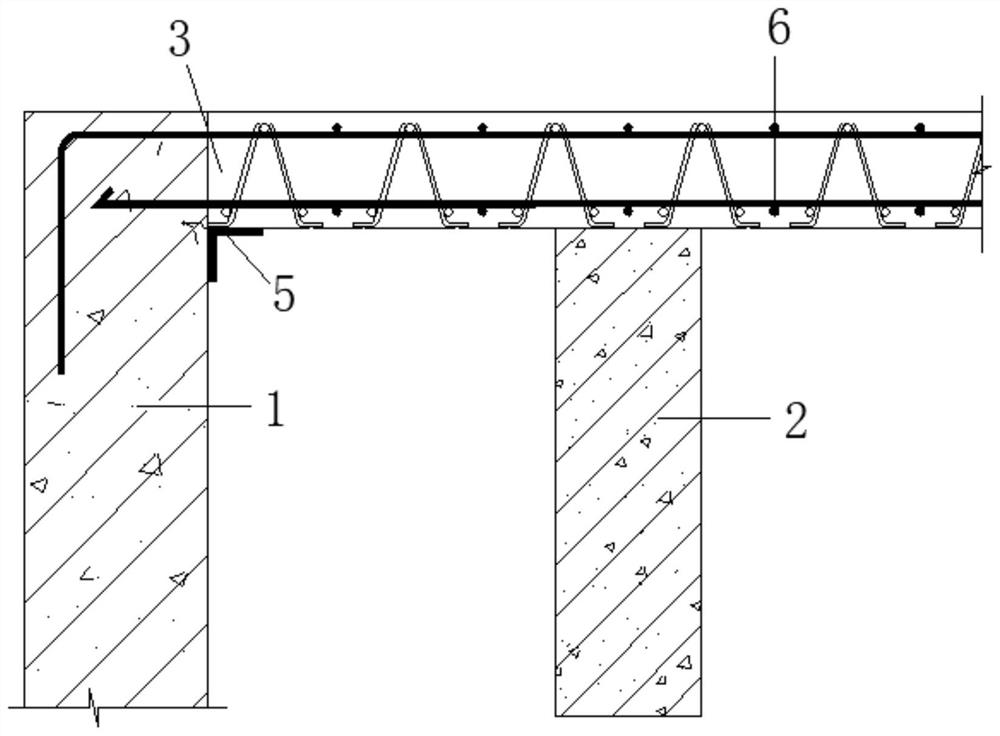

[0026] as attached Figure 1-3 Shown:

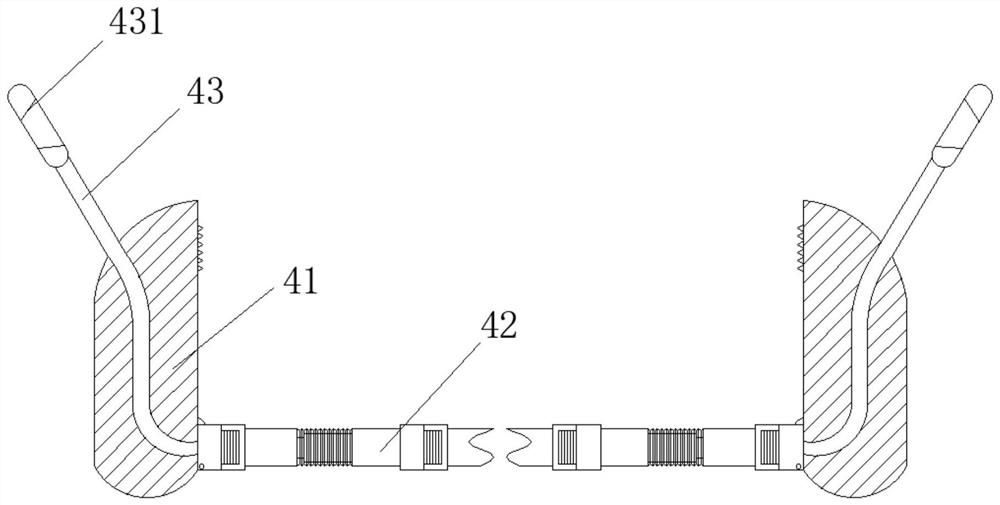

[0027] The present invention provides a structure of a floor deck in a small space under roof reverse process construction, including: a shear wall 1, a support wall 2, and a steel bar truss floor deck 6, and is characterized in that the side of the steel bar truss floor deck 6 is provided with There are floor deck side seals 3, and several locking rods 31 are arranged on the side of the floor deck side seals 3, and the outer sides of the two oppositely arranged floor deck side seals 3 are provided with floor deck seals. Mechanism 4, the locking rod 31 is used to fix the floor deck sealing mechanism 4; the floor deck sealing mechanism 4 includes: a sticking sheet 41 attached to the outside of the floor deck side sealing sheet 3, The bottom stay 42 that is rotated on the side of the sticking sheet 41, the traction belt 43 provided inside the bottom stay 42, the tail ends of the two traction belts 43 can be nested and connected together, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com