First-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete

A technology of concrete filled steel tube and tied arch bridge, which is applied in the direction of bridges, arch bridges, bridge construction, etc., can solve the problems of large influence on river navigation, long construction period and cost of engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The under-supported concrete-filled steel tube tied arch bridge adopts the stiff skeleton construction method of arch first and then girder, first longitudinal girder and then cross girder. The specific construction process is as follows:

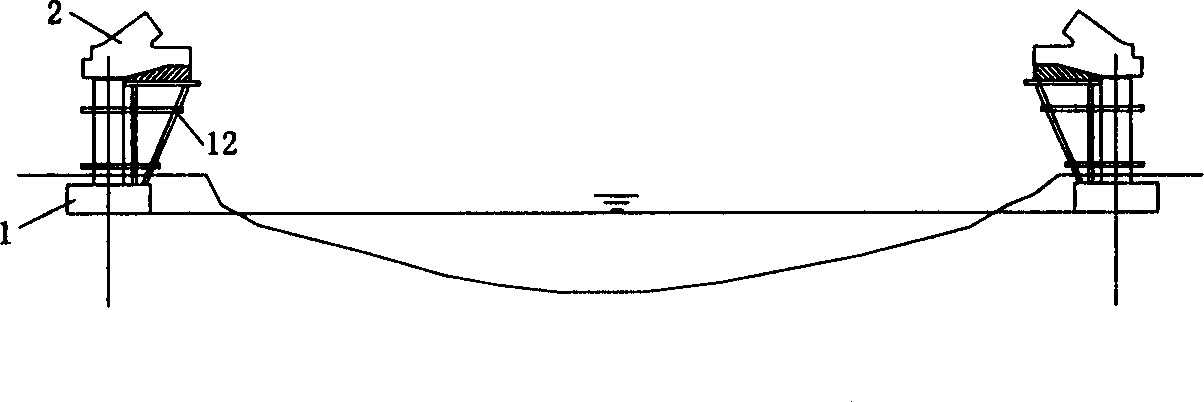

[0021] Step 1: (see figure 1 , figure 2 )

[0022] 1. Construction of the main bridge pier 1 bored piles, caps and columns;

[0023] 2. Set up support 12 at arch foot 2 and end beam 3 of the pier of the main bridge, and construct the concrete structure of arch foot and end beam;

[0024] 3. After the concrete of the arch foot and the end beam reaches the design strength, tension the horizontal prestressed steel cable 4 of the end beam.

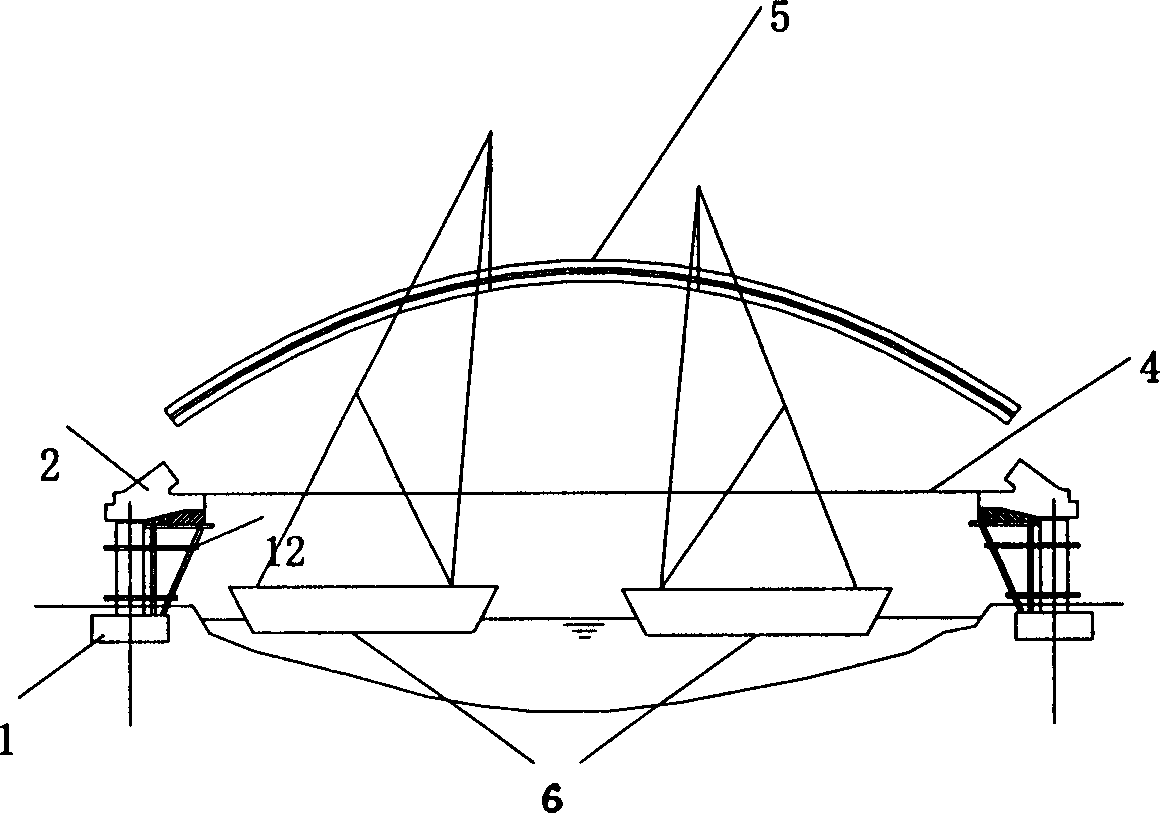

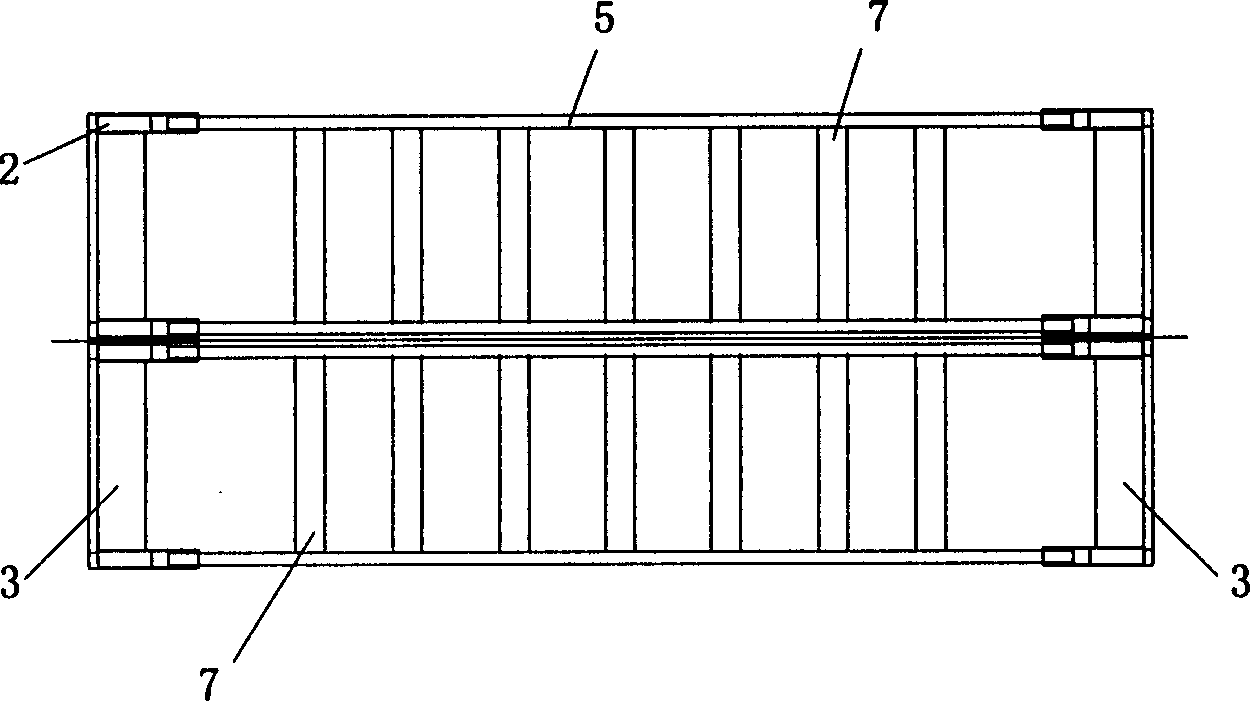

[0025] Step two: (see figure 2 , image 3 )

[0026] 1. The prefabricated steel pipe arch rib 5 is inspected and shipped, and transported to the construction site in sections;

[0027] 2. The steel pipe arch ribs are assembled and formed on the construction site, and are hoisted into place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com