Bridge intelligent cable system with built-in fiber grating sensor

A grating sensor, fiber grating technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of easy damage, fiber grating fragility, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

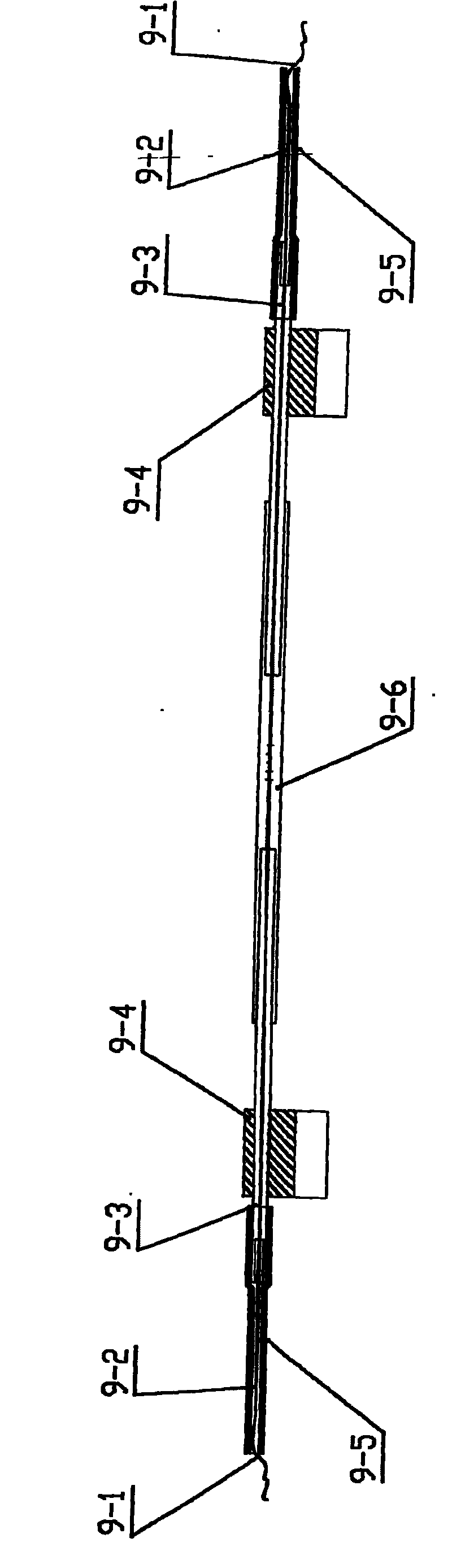

[0026] It has always been a difficult research point to measure the stress state of the cable with the built-in sensor. The packaging structure of the cable built-in fiber grating strain sensor 9 is as follows:

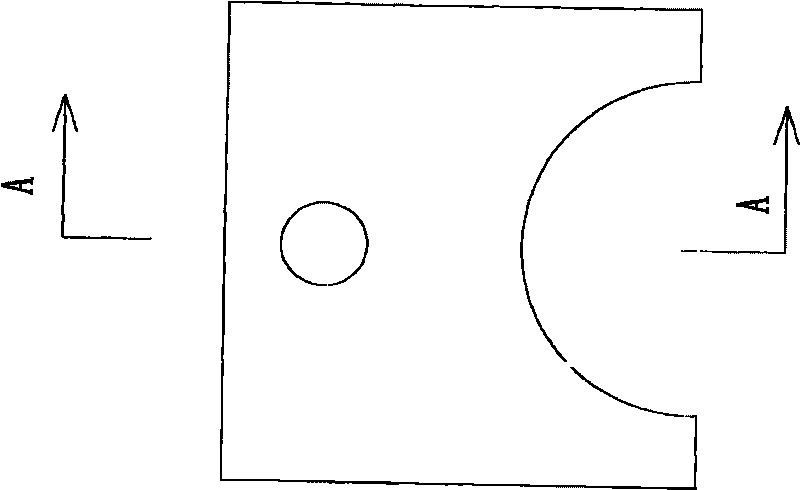

[0027] see figure 1 , figure 1 It is a structural schematic diagram of the fiber grating strain sensor involved in the present invention. Depend on figure 1 It can be seen that the fiber grating strain sensor 9 involved in the present invention includes a first fiber grating 9-1, a second steel pipe 9-2, a first steel pipe 9-3, a slightly thicker first protective steel pipe 9-6 and a The support 9-4 connected with the cable wire, the first protection steel pipe 9-6 has one piece, the first steel pipe 9-3, the support 9-4 and the second steel pipe 9-2 all have two pieces, two pieces The first steel pipe 9-3, the two supports 9-4 and the two second steel pipes 9-2 are symmetrically arranged on the left and right sides of the first protection steel pipe 9-6, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com