High precision vibration sensor

A vibration sensor and vibration sensing technology, applied in the field of sensors, can solve the problems of noise reduction measures discount, vibration noise frequency point drift, cost increase, etc., to achieve the effect of extended reliability and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

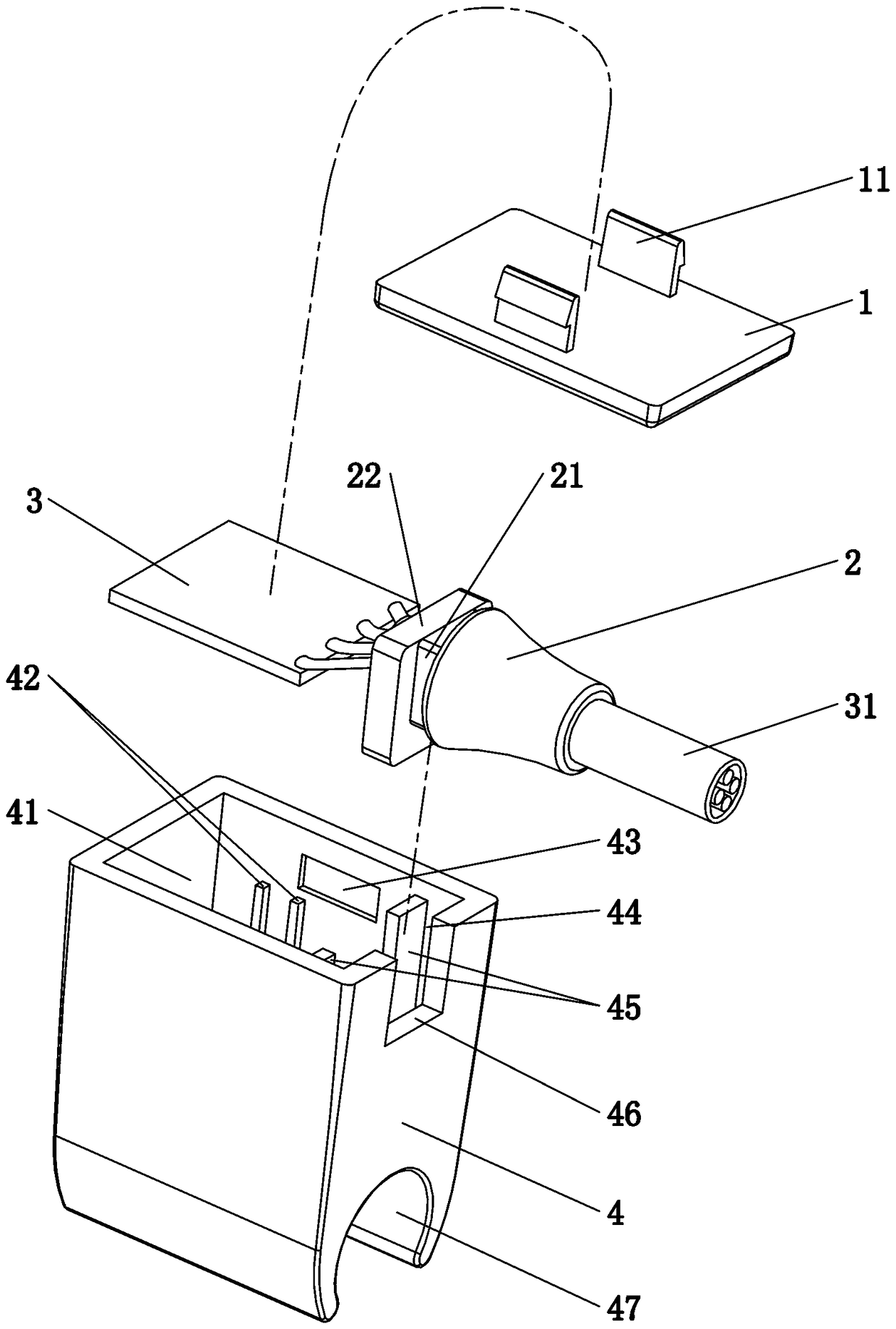

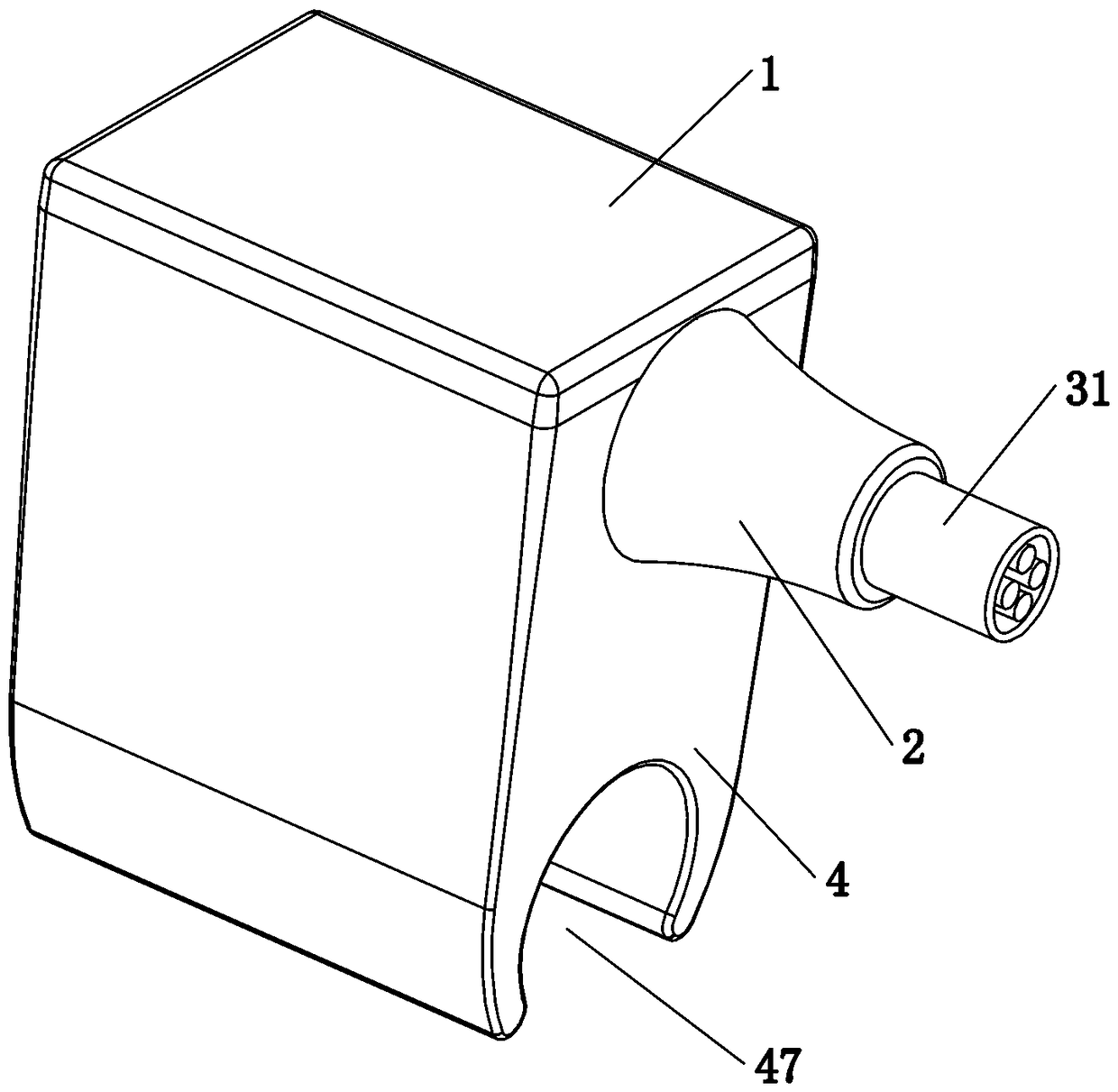

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

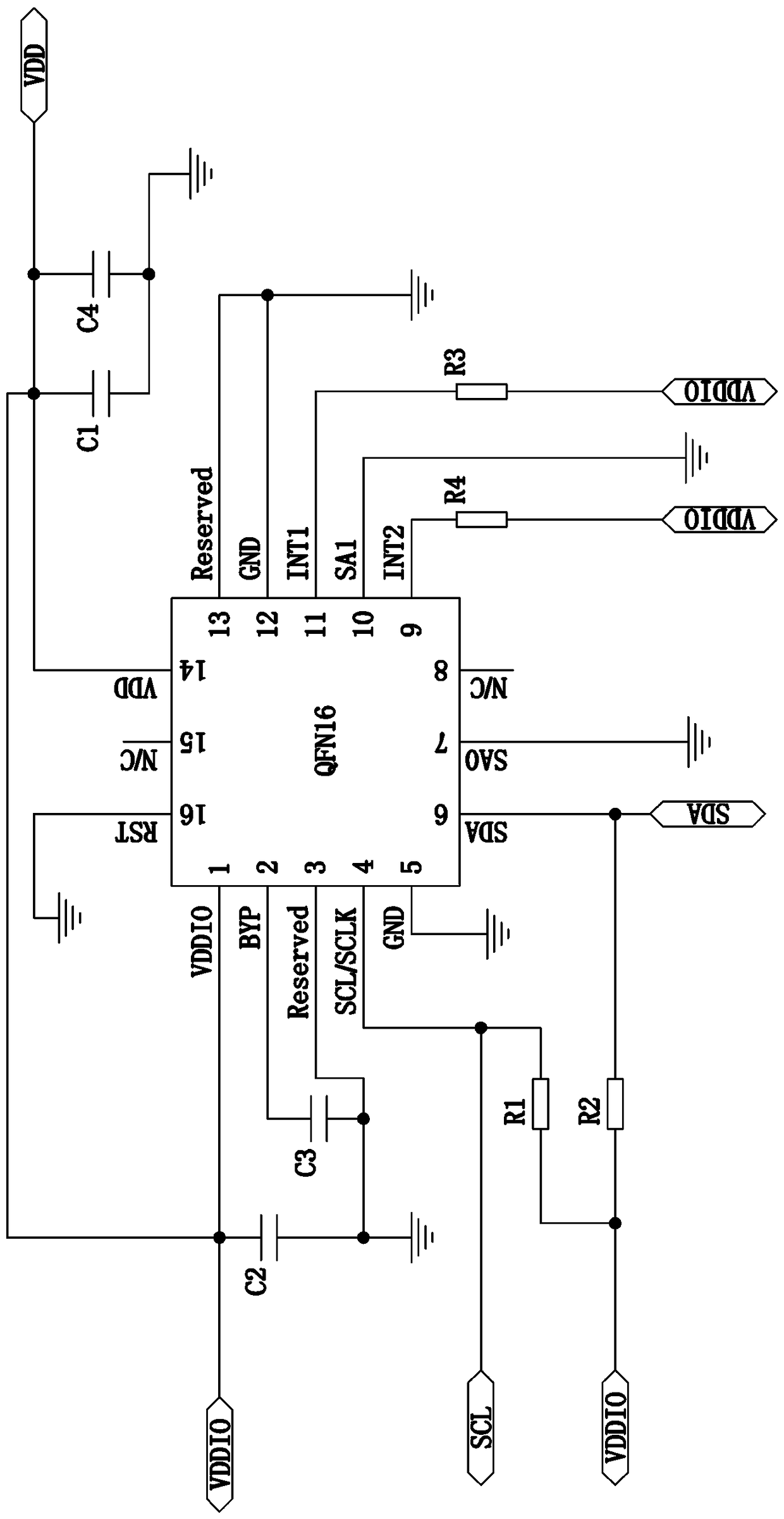

[0029] see Figure 1 to Figure 7 Shown, a kind of high-precision vibration sensor comprises vibration sensing circuit board 3, and described vibration sensing circuit board 3 is provided with the vibration sensing circuit that is made of 16 single-chip microcomputer memory chips and a plurality of capacitors, resistance, and a plurality of capacitors The resistor and the resistor are respectively electrically connected to the 16-bit single-chip memory chip, and the 16-bit single-chip memory chip is provided with a power line and a serial bus.

[0030] The 16-bit single-chip microcomputer memory chip is a QFN16 single-chip microcomputer. The single-chip microcomputer of the described QFN16 model is provided with VDDIO pin, BYP pin, the first Reserved pin, SCL / SCLK pin, the first GND pin, SDA pin, SA0 pin, the first N / C pin, INT2 pin, SA1 pin, INT1 pin, secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com