Automatic optical detection device of online PCB board

An automatic optical detection, PCB board technology, applied in the direction of measuring devices, material analysis through optical means, scientific instruments, etc., can solve the problem of inability to fully and effectively control product quality, inability to effectively achieve full-process detection, full automation and efficiency Discounts and other issues to achieve the effect of improving efficiency, ensuring quality, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

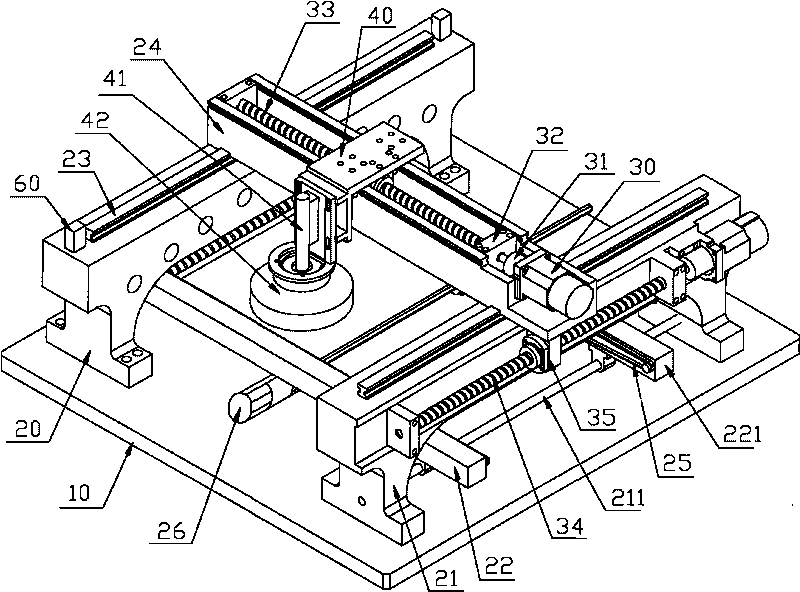

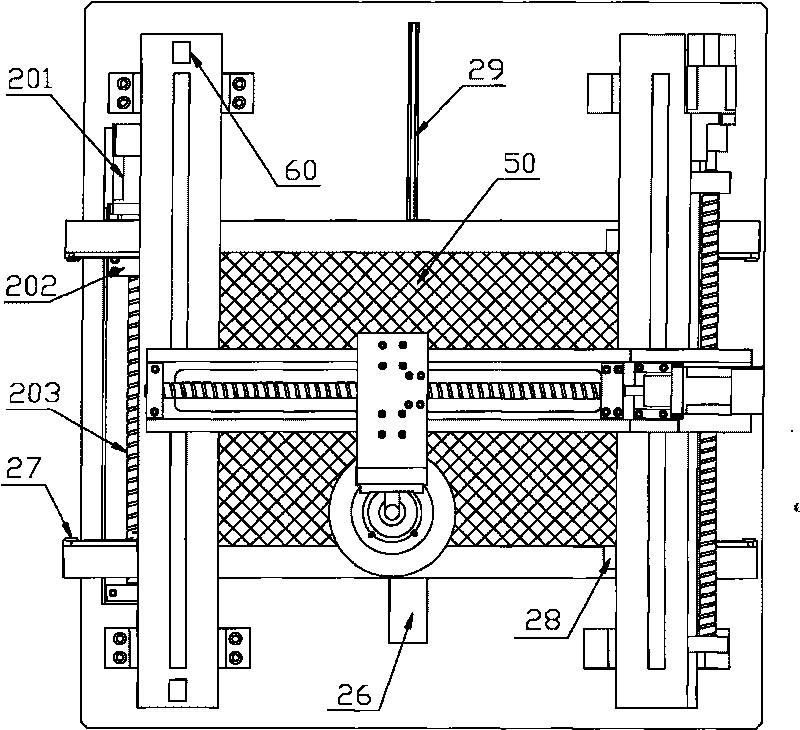

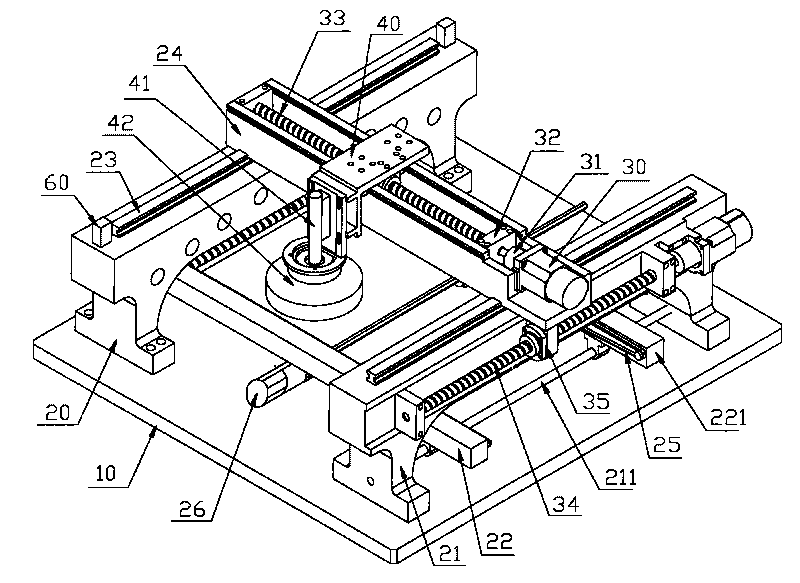

[0012] Such as figure 1 , figure 2 An on-line automatic optical inspection device for PCB boards shown has a base 10, and an entrance arch bridge seat 20 and an exit arch bridge seat 21 are arranged in parallel on both sides of the base 10, and the entrance arch bridge seat 20 and the exit arch bridge seat 21 A guide rail 23 is arranged on the top of the guide rail 23, and the upper cross frame of the guide rail 23 is provided with a sliding connection between the beam seat 24 and the guide rail 23. The transmission device is installed inside the beam seat 24, and the transmission device is composed of a stepping motor 30, a coupling 31, a nut seat 32 and a screw 33. The transmission device is connected to the follower 40 equipped with a detection camera 41 and a light source lampshade 42. The outlet arch bridge seat 21 is provided with a support for connecting a fixed loading platform 22 and adjusting The support bar 211 at one end of the loading platform 221, the fixed loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com