Construction method for bridge steel box basket arch

A construction method and bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of structural alignment, difficult to control welding seam quality, difficult to ensure construction safety, etc., to improve the quality control ability, significantly Economic benefits and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with embodiment.

[0021] A construction method for a new type of bridge steel box lifting blue arch is as follows:

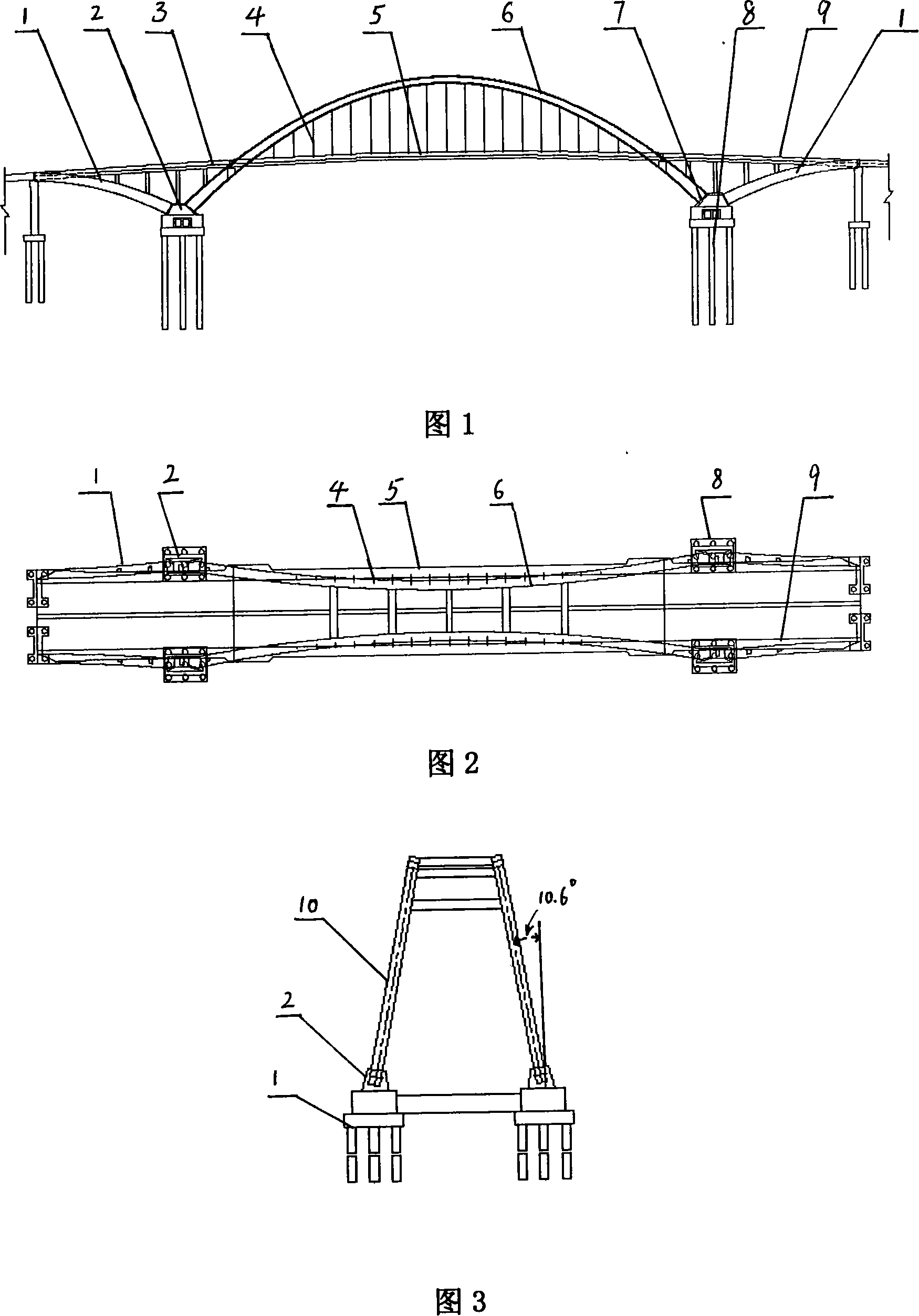

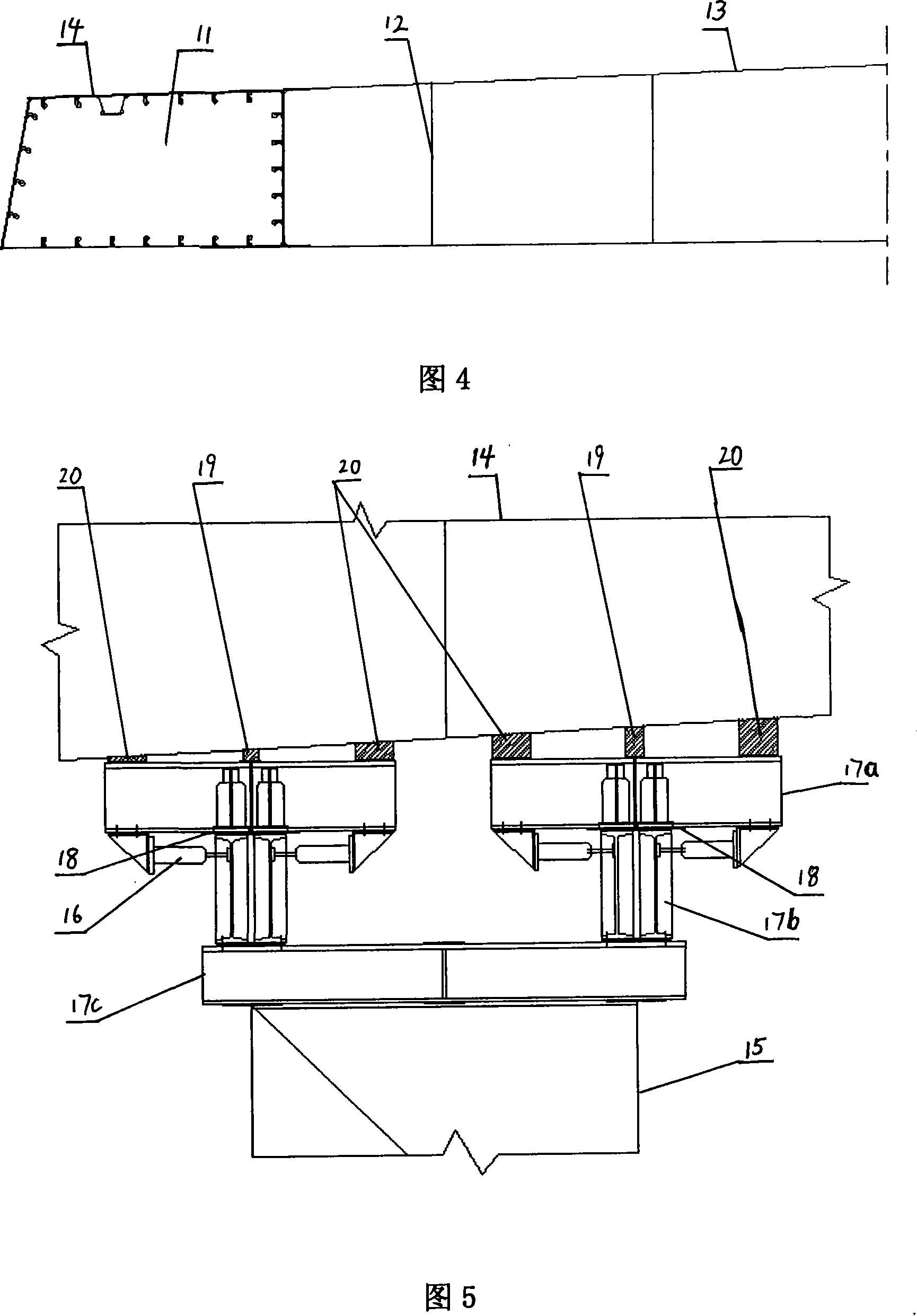

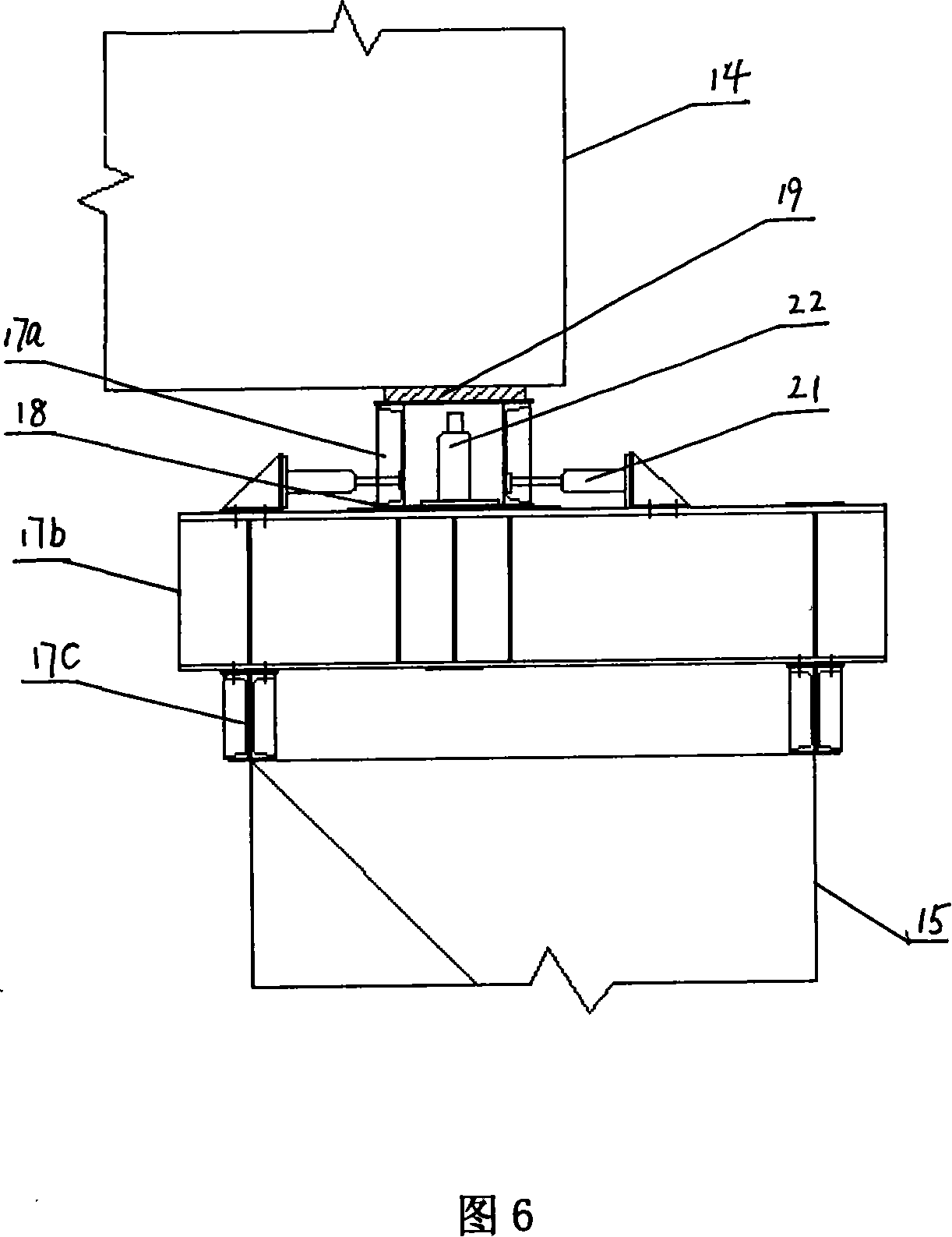

[0022] A. First determine the structural type of the bridge, the rise-span ratio, the inclination angle of the arch rib, the arch axis type, and the section form of the arch rib. The structural type of the bridge is side arch 1 + main arch 6 + side arch 1, main arch 6, The rise-span ratio of arch 1 is 1 / 4, the main arch 6 and side arch 1 are inwardly inclined with an angle of 10.6°, the arch axis type is a quadratic parabola, the arch rib 10 adopts a rectangular steel box stiffened beam section, side arch 1, main arch 1 The arch 6 is connected at the arch foot 7 through the abutment 2, and is consolidated with the main pier 8. The steel box girder 14 is composed of a mid-span steel box girder 5 and a side-span steel box girder 9. The standard section of each steel box girder 14 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com