Method for preparing polyvinylidene fluoride micro-porous film with thermal induced phase separation method

A technology of thermally induced phase separation and polyvinylidene fluoride, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of environmental pollution and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 40g of polyvinylidene fluoride resin with a weight average molecular weight of 350,000 and a mixture of 160g of co-solvent into a stirred tank. The co-solvent is made by mixing benzyl benzoate and dimethyl phthalate, of which 80g benzyl benzoate . Heat to 200 in a stirred tank 。 C, stirring speed is 30r / min, nitrogen protection, heating for 7 hours, degassing becomes a homogeneous solution; 。 Scrape it into a flat film in a high temperature environment of C, cool it naturally, take out the flat film, immerse it in absolute ethanol for 24 hours, then replace it with absolute ethanol, immerse it for another 24 hours, then remove it from absolute ethanol, and dry at room temperature .

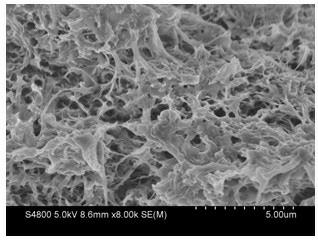

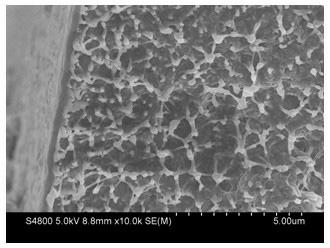

[0017] The obtained flat film is observed by electron microscope (liquid nitrogen freezing and quenching) structure, see the electron microscope picture figure 1 , The section is a bi-continuous structure, and the average pore diameter of the membrane pores is about 0.5μm.

Embodiment 2

[0019] Add 100g of polyvinylidene fluoride resin with a weight average molecular weight of 350,000, and a mixture of 100g of co-solvent into the stirred tank. The co-solvent is made by mixing dibutyl sebacate and glyceryl triacetate, among which dibutyl sebacate For 70g. Heat to 180 in a stirred tank 。 C, the stirring speed is 50r / min, nitrogen protection, heating for 7 hours, it is a homogeneous solution; vacuum degassing; the polymer solution is extruded from the annular gap of the spinneret under the action of the gear pump; the extrusion rate is 1ml / s, spraying Wire head temperature is 175 。 C; Injecting cavity gas into the inner hole of the spinneret N 2 Make the extrudate have a hollow structure; N 2 The flow rate of the film-forming fluid is 0.5ml / s; the film-forming fluid and the cavity-forming gas move along the axial direction and gradually become thinner under the action of traction; the film-forming fluid gradually cools in the air environment, and the L-L phase sepa...

Embodiment 3

[0022] Add 60 g of polyvinylidene fluoride resin with a weight average molecular weight of 500 000 and a mixture of 140 g of co-solvent into a stirred tank. The co-solvent is made by mixing benzyl benzoate and dimethyl phthalate. The mass score is 98g. Heat to 200 in a stirred tank 。 C, nitrogen protection, heating for 7 hours, a homogeneous solution; vacuum degassing; the polymer solution is extruded from the annular gap of the spinneret under the action of a gear pump; the extrusion rate is 1ml / s, and the spinneret temperature is 190 。 C; Injecting cavity gas into the inner hole of the spinneret N 2 Make the extrudate have a hollow structure; N 2 The flow rate of the film-forming fluid is 0.5ml / s; the film-forming fluid and the cavity-forming gas move along the axial direction under the action of traction and gradually refine; then the water bath (15 。 C) Curing, this process is accompanied by the volatilization of the diluent to the environment; after curing, the hollow fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com