Reinforced concrete arch bridge construction method

A technology of reinforced concrete and construction method, applied in arch bridges, bridges, bridge forms, etc., can solve the problems of soft soil and weak support structure, and achieve the effects of saving materials, convenient disassembly, and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

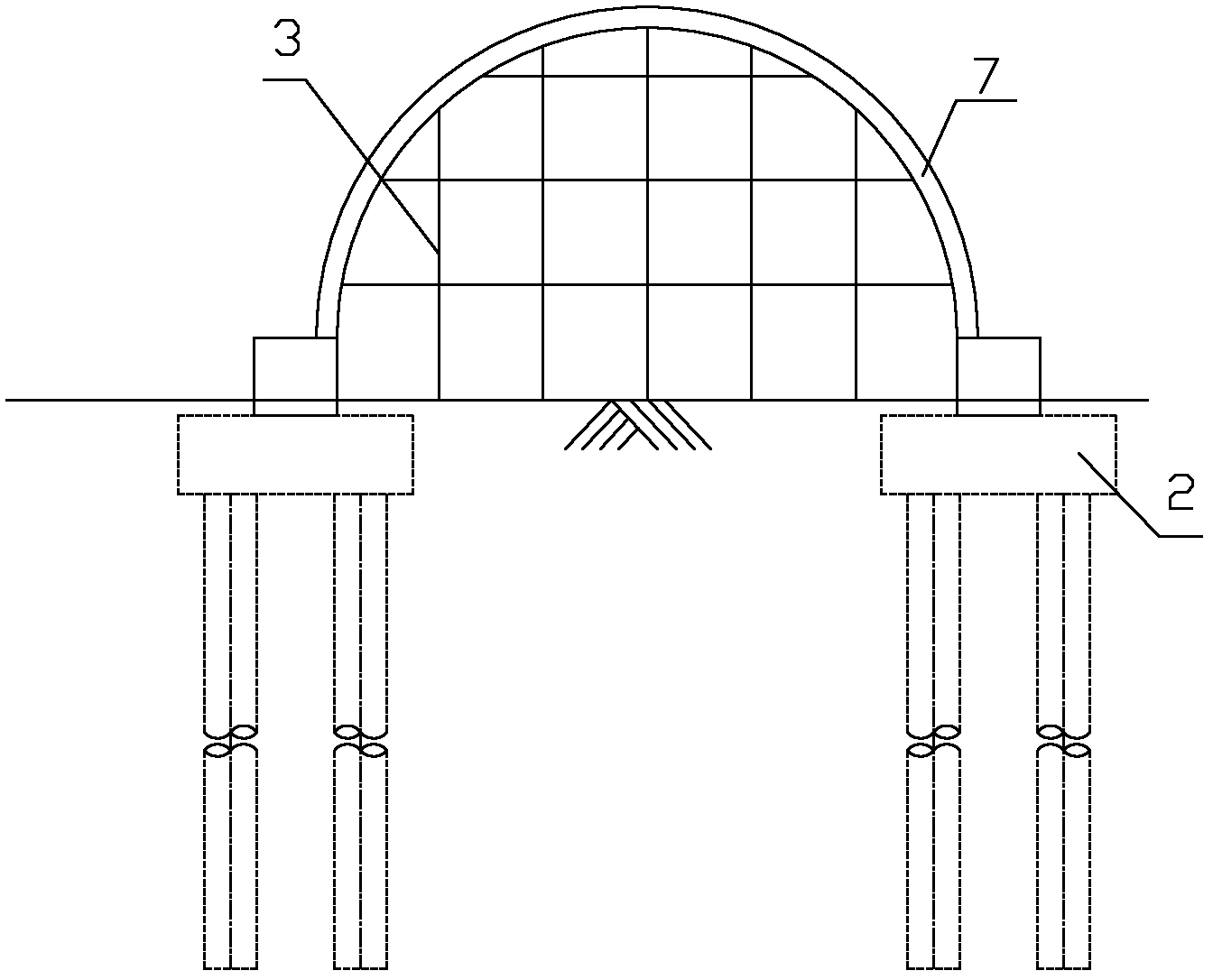

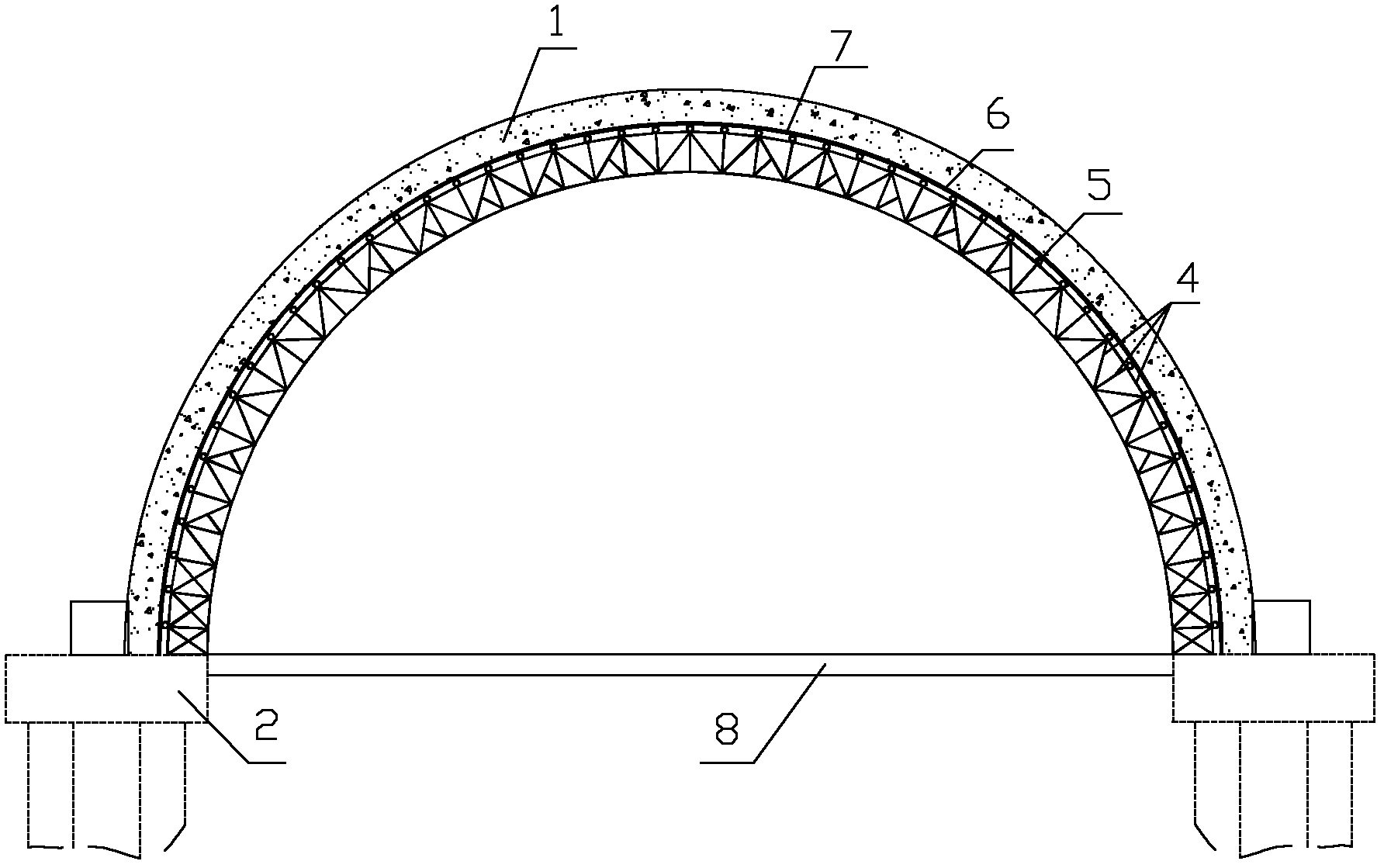

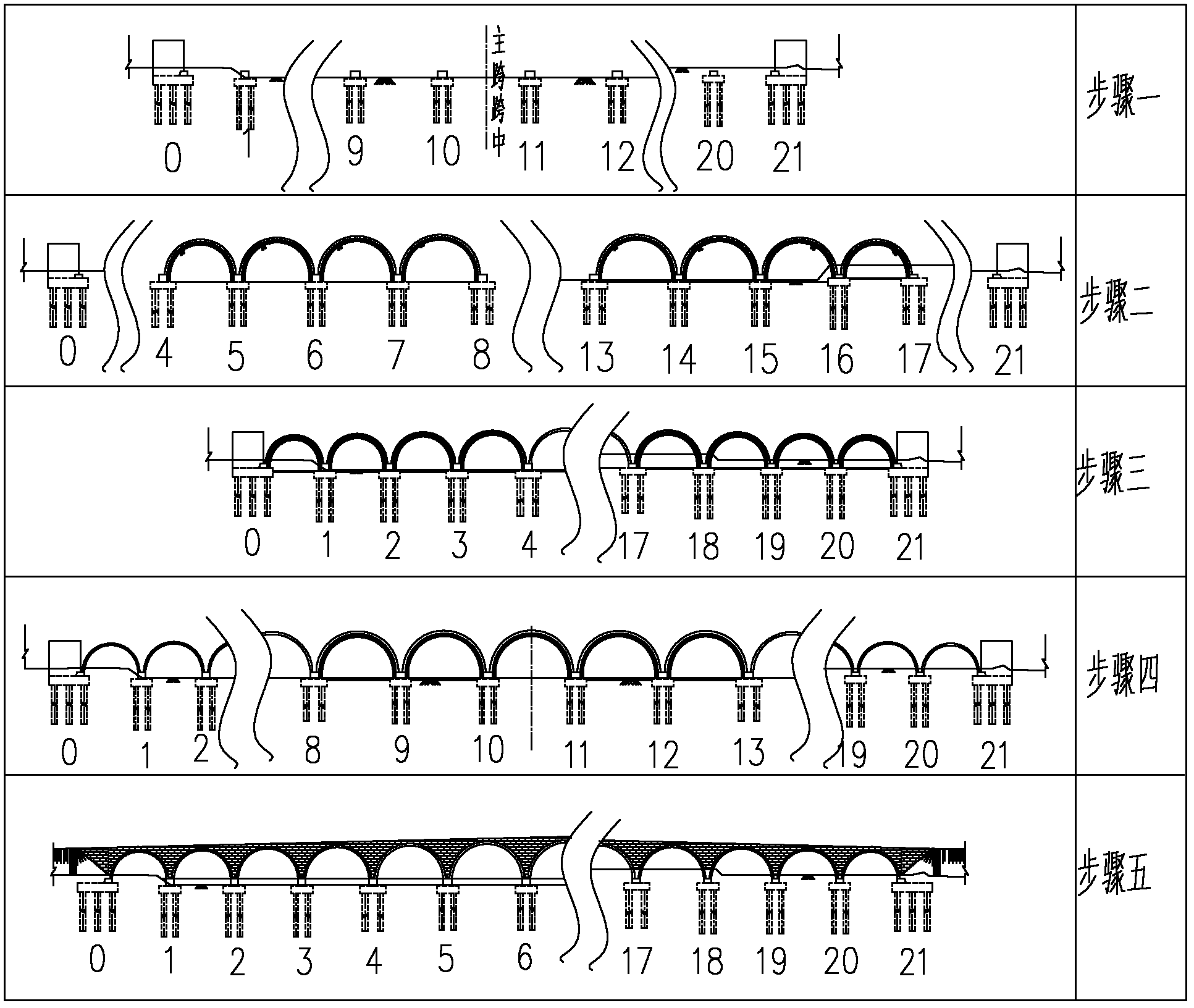

[0034] combine figure 2 and image 3 The embodiment of the present invention is described in detail,

[0035] Such as figure 2 As shown, the arch ring support used in the construction process of the reinforced concrete arch bridge includes the arch truss 4, the bottom of both sides of the arch truss is supported on the consolidation support 2, and the construction formwork 7 is laid on the upper plane of the arch truss for the reinforced arch Concrete ring 1 pouring. There are also longitudinal steel bars 6 and building steel pipes 5 between the upper plane of the arched truss and the building formwork, wherein the building steel tubes are arranged horizontally at the nodes of the upper plane of the arched truss, and the vertical steel bars and the building steel tubes are vertically crossed and tiled in one layer as Building formwork support. The arched truss is HRB400 steel bar truss. The longitudinal reinforcement is threaded reinforcement. The two consolidation sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com