Large-span steel truss arch construction method

A construction method and long-span technology, applied in arch bridges, erection/assembly bridges, bridge forms, etc., can solve the problems of high cost of arch frames, single node structure of section form, etc., to meet construction requirements, small deformation, and large economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

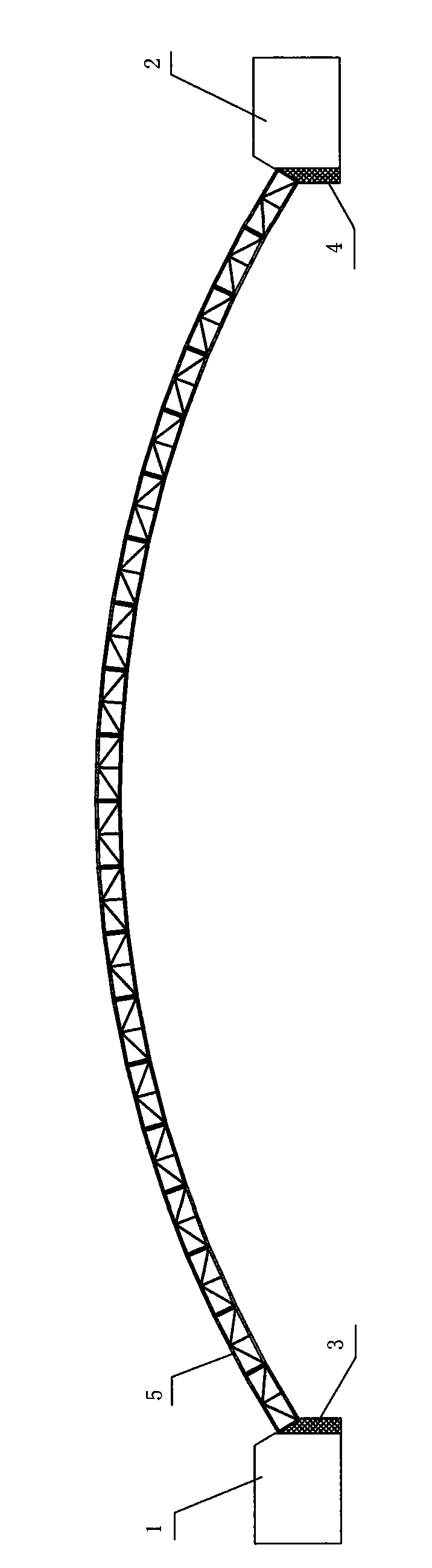

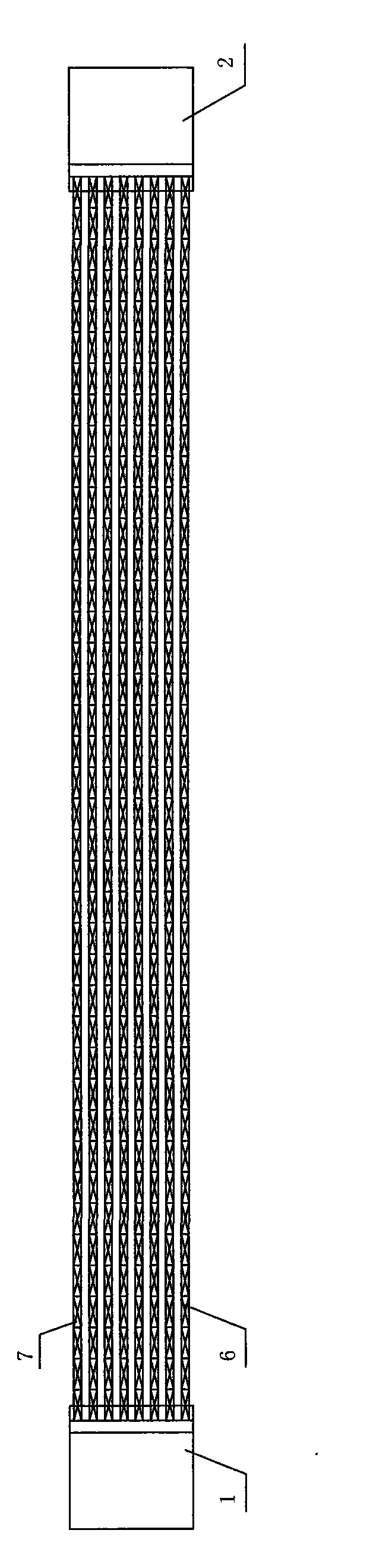

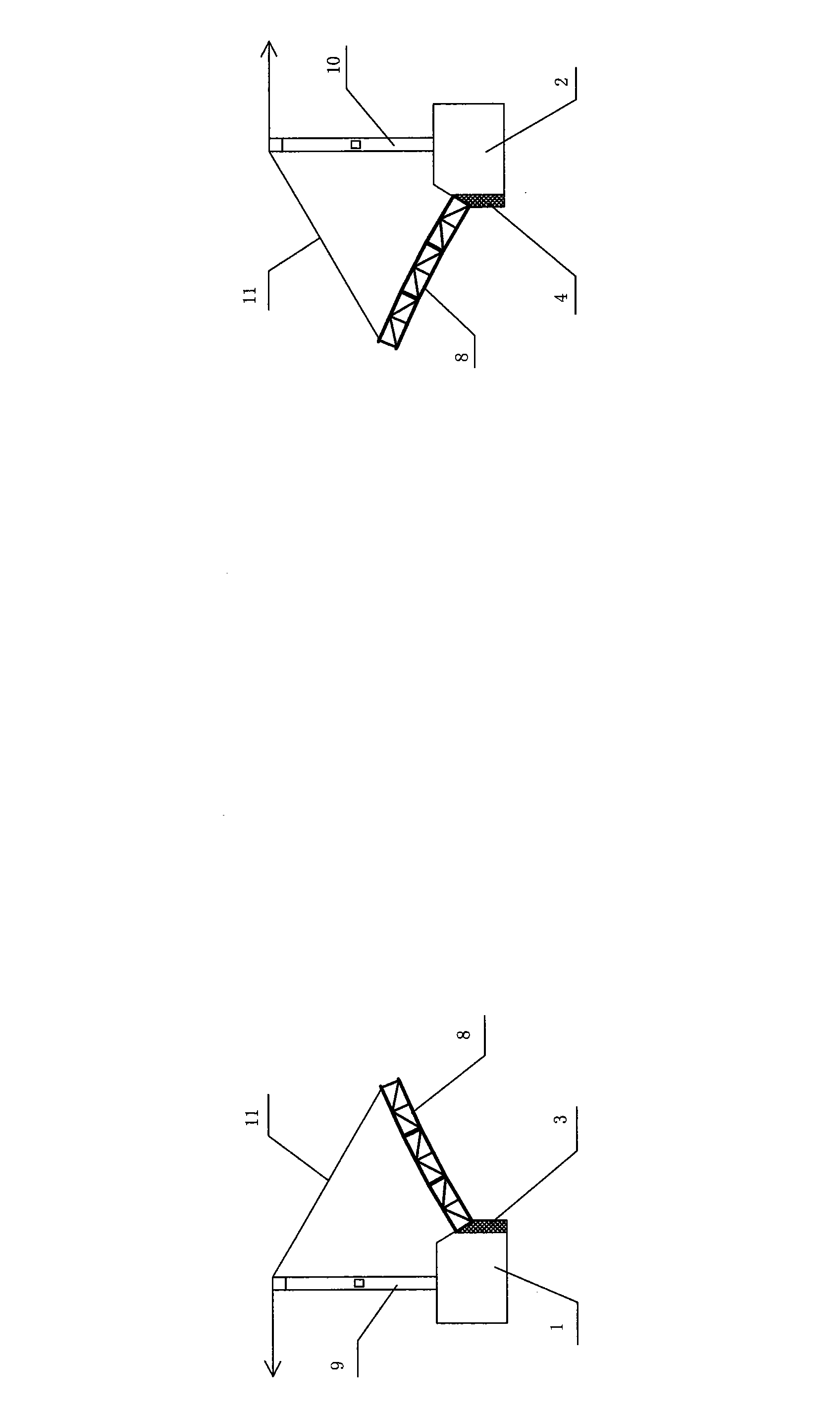

[0042] Such as figure 1 , figure 2 As shown, the construction method of the long-span steel truss arch includes the following steps:

[0043] 1) According to the design line shape of the main arch circle of the reinforced concrete arch bridge, a reasonable line shape of the arch axis of the steel truss arch is selected, in order to reduce the height of the pad between the steel truss arch and the soffit of the concrete arch box, and it is required to select The linear shape of the steel truss arch must satisfy the linear shape of the designed main arch circle as much as possible in space. For reinforced concrete arch bridges with a main arch span of no more than 100m, considering the convenience of steel truss arch in the factory and the ease of workers setting out the arch axis accurately, the arc line can be used as the line shape of the arch axis of the steel truss arch , so that the line shape of the arch axis of the steel truss arch is close to the design line shape of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com