Semi-automatic tank car loading arm and control method thereof

A semi-automatic, loading and unloading arm technology, applied in container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve the problems of frequent operation, time-consuming, low efficiency, etc. time, improve the efficiency of loading and unloading vehicles, and reduce the difficulty of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

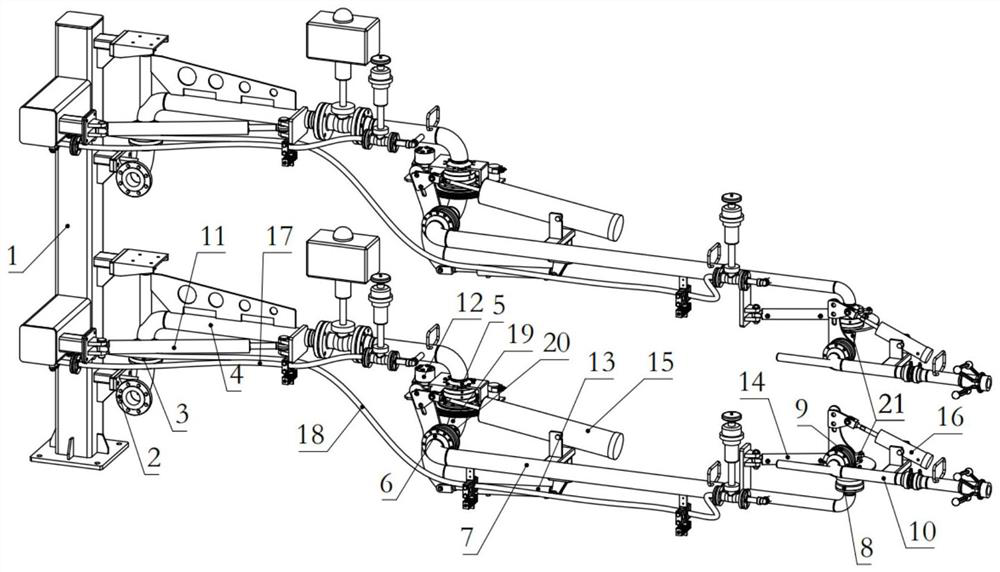

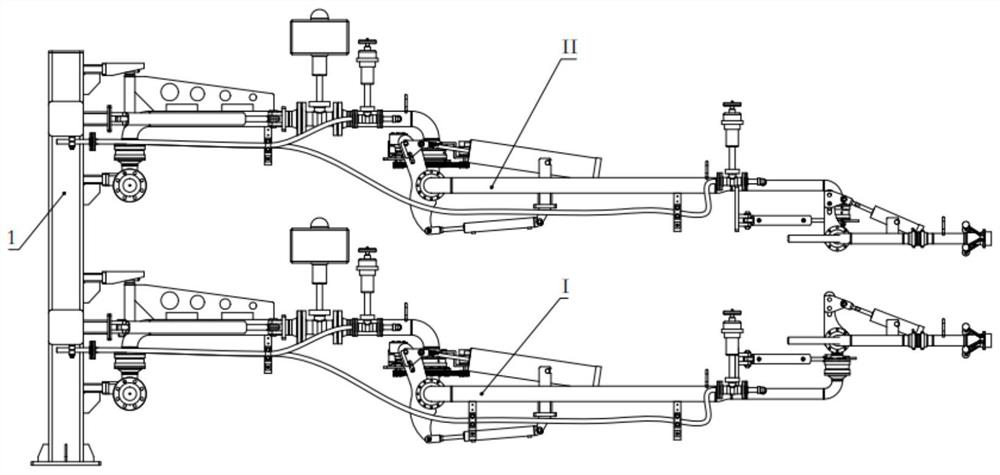

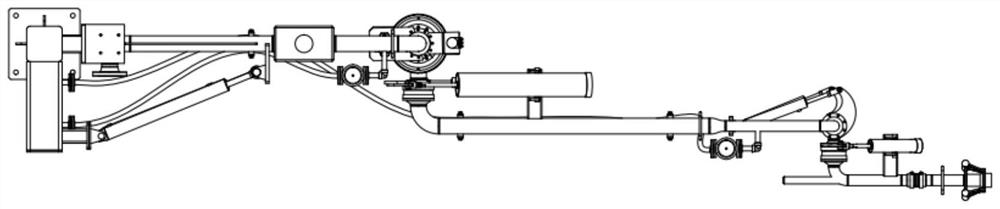

[0033] combine Figure 1-Figure 3 , a semi-automatic tank truck loading and unloading arm and its control method of the present invention, comprising a column 1, a liquid phase arm I and a gas phase arm II; Inner arm 4, outer arm 7, vertical pipe 10, four hydraulic drive mechanisms 11-14, two spring balance mechanisms 15-16, nitrogen purge system 17, exhaust system 18, five cryogenic rotary joints 3 / 5 / 6 / 8 / 9.

[0034] The inlet connector 2 is fixed on the column 1, and the inlet connector 2 is connected to one end of the inner arm 4 through the first rotary joint 3; the inner arm 4 is rotatably connected to the column 1 through the connector; the inner arm 4 The other end is connected to one end of the three-inch right-angle elbow 19 by the second rotary joint 5; the other end of the three-inch right-angle elbow 19 is connected to the eleven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com