Patents

Literature

94results about How to "Short release time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

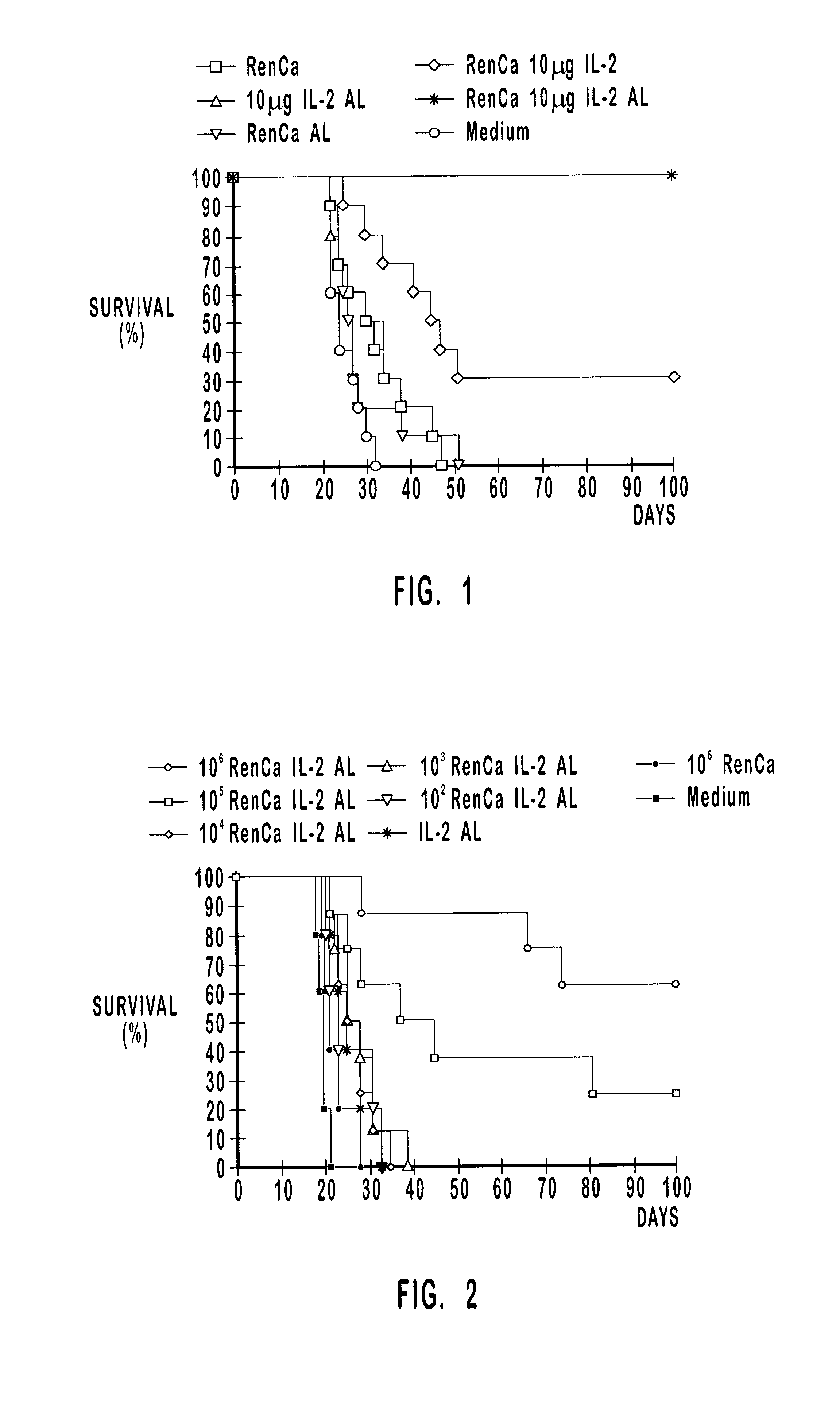

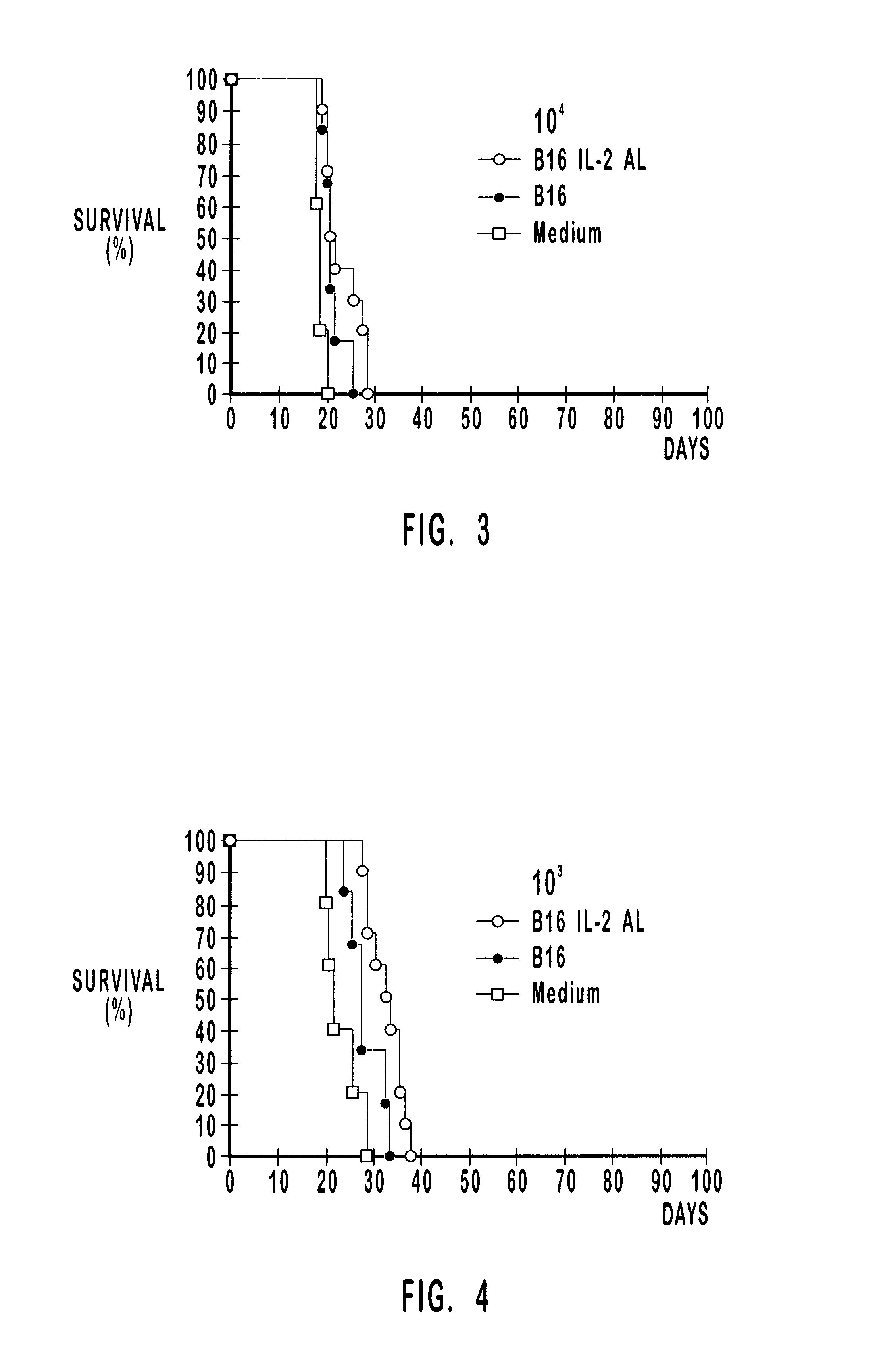

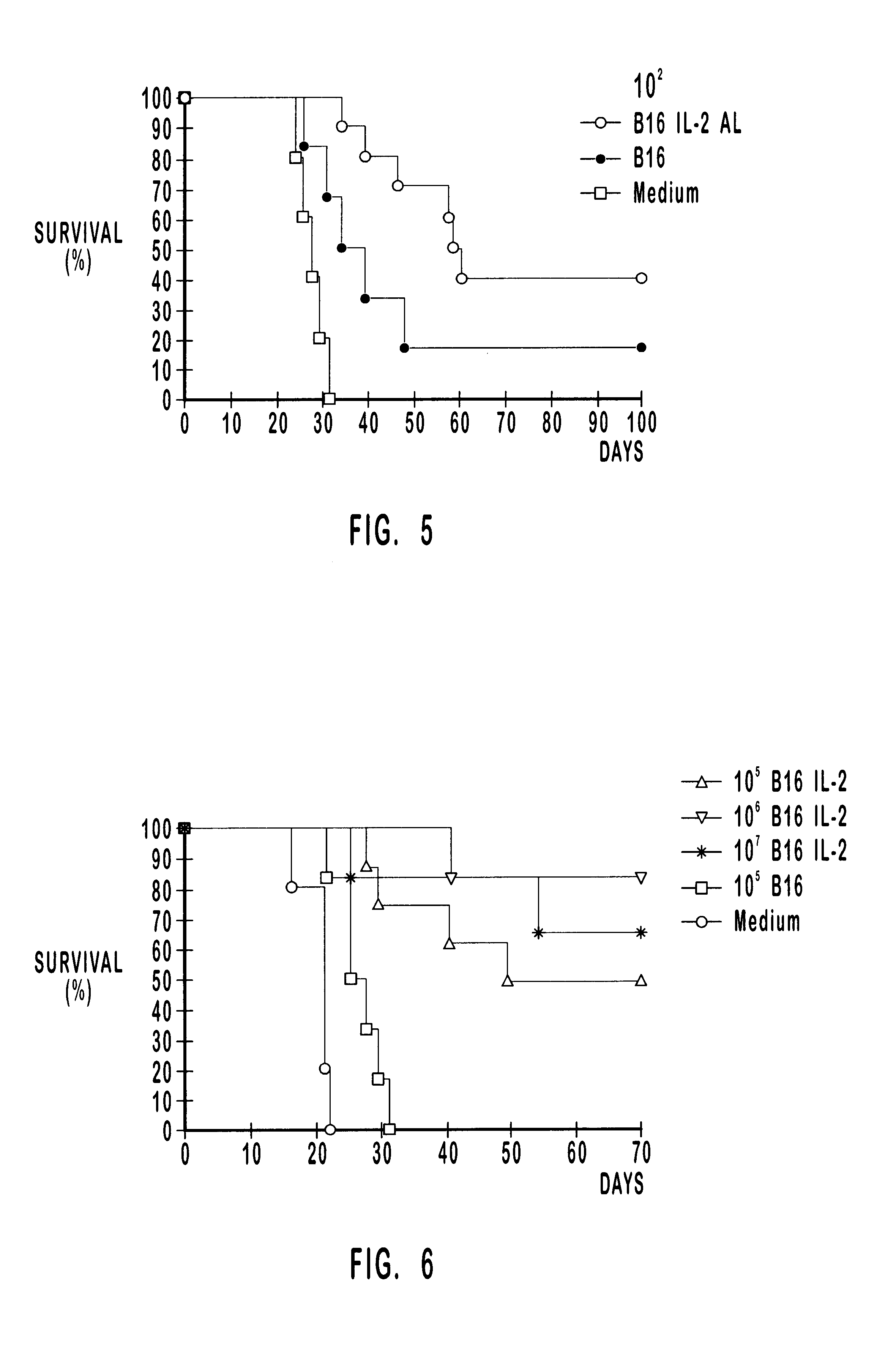

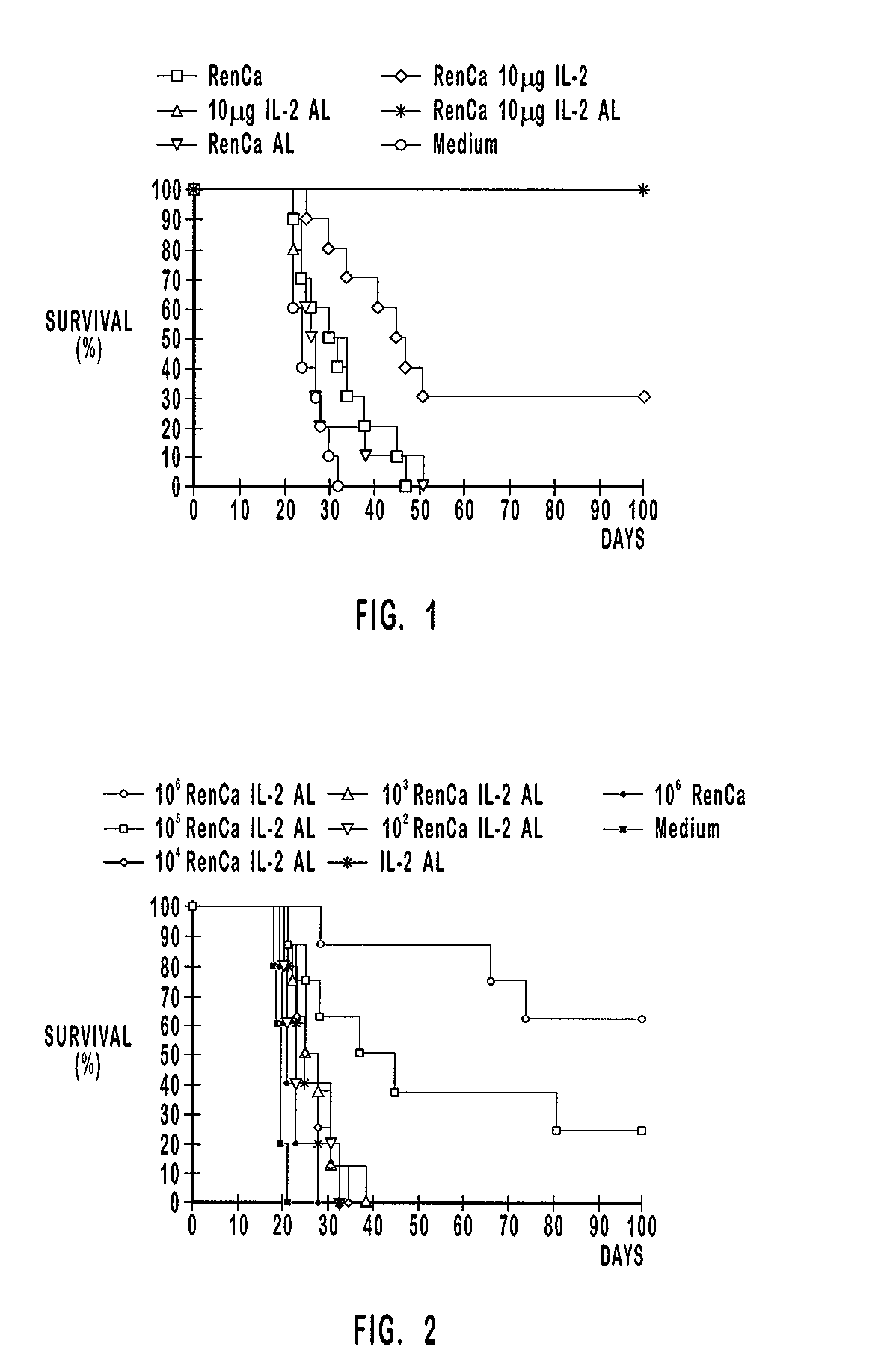

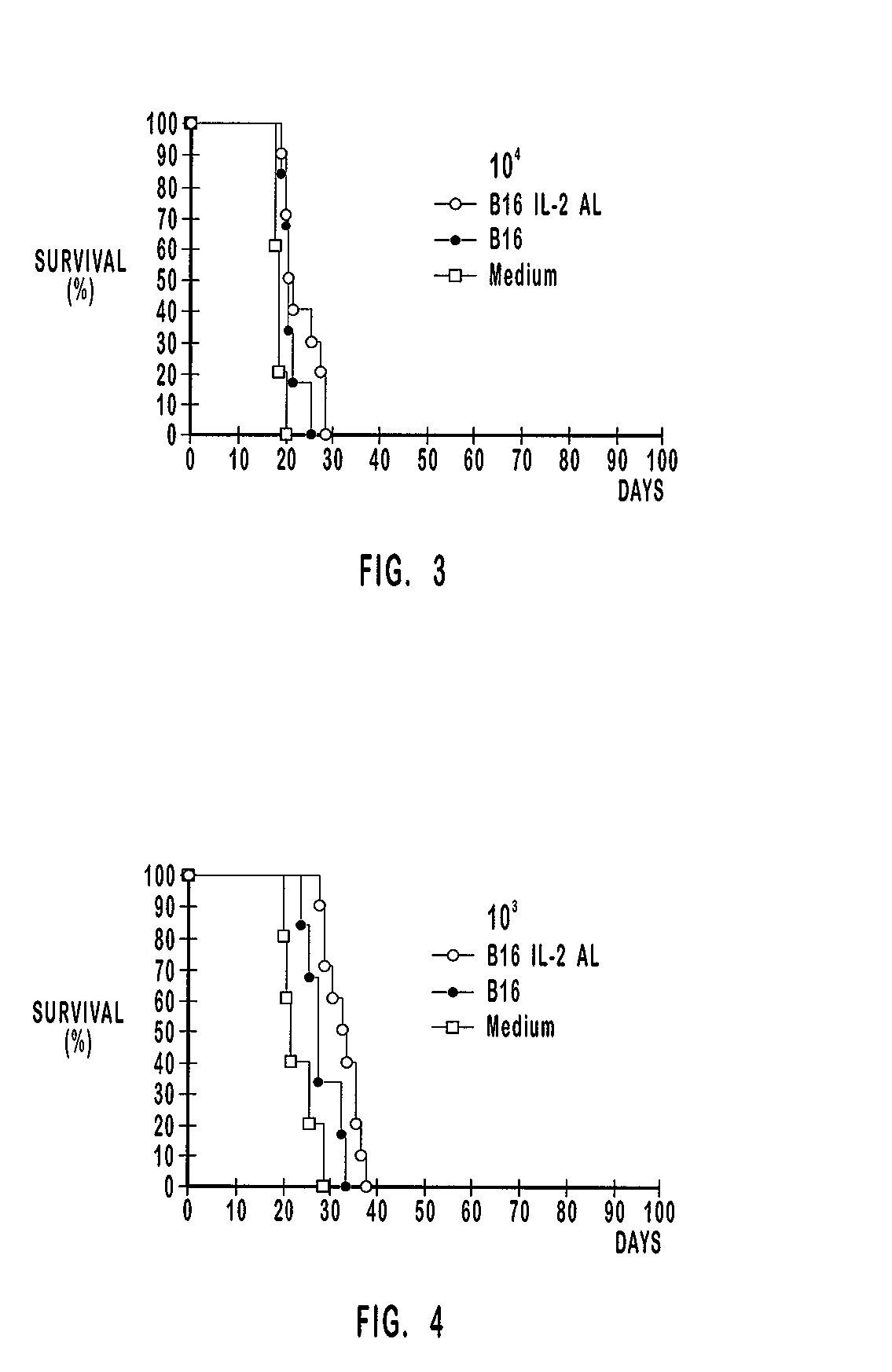

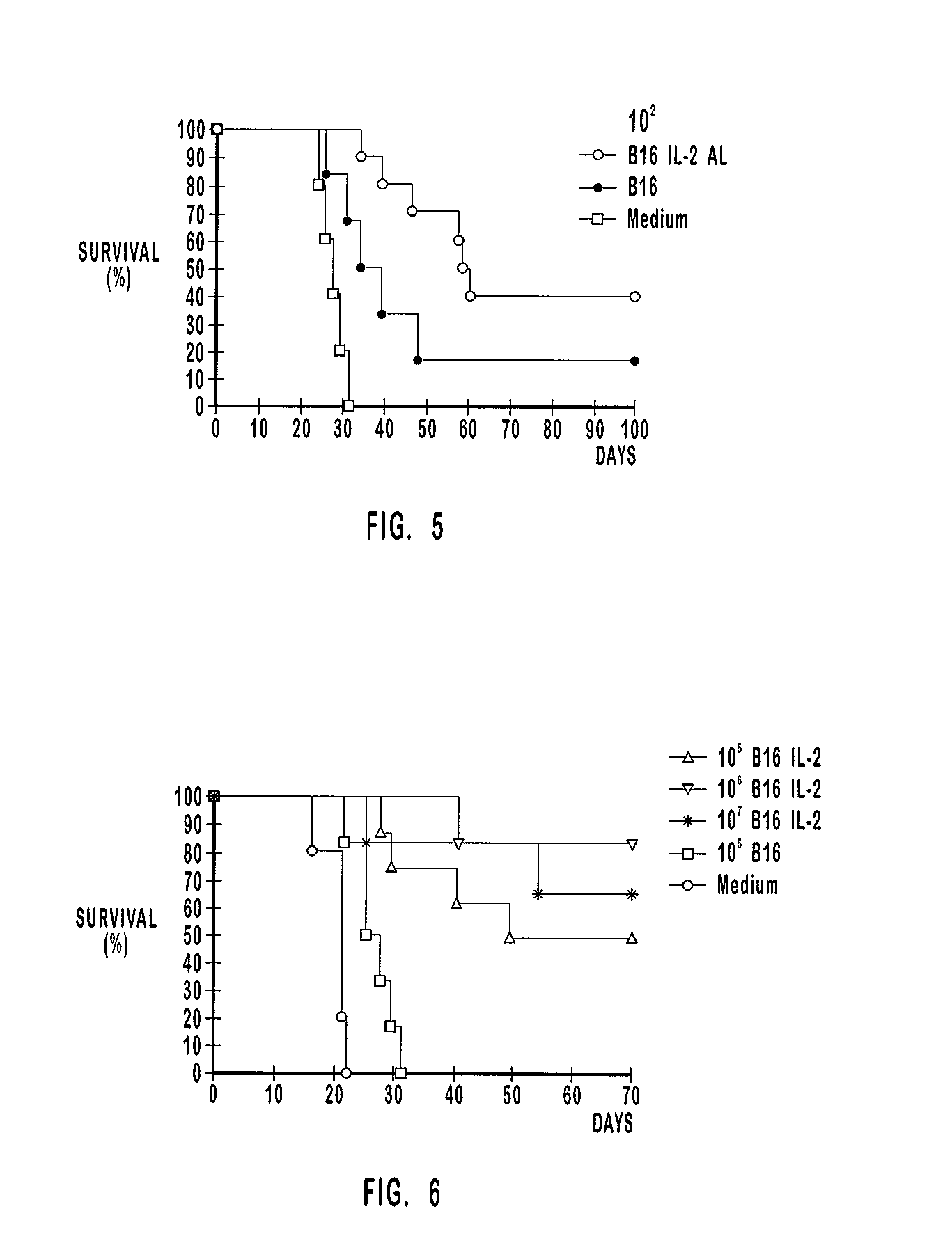

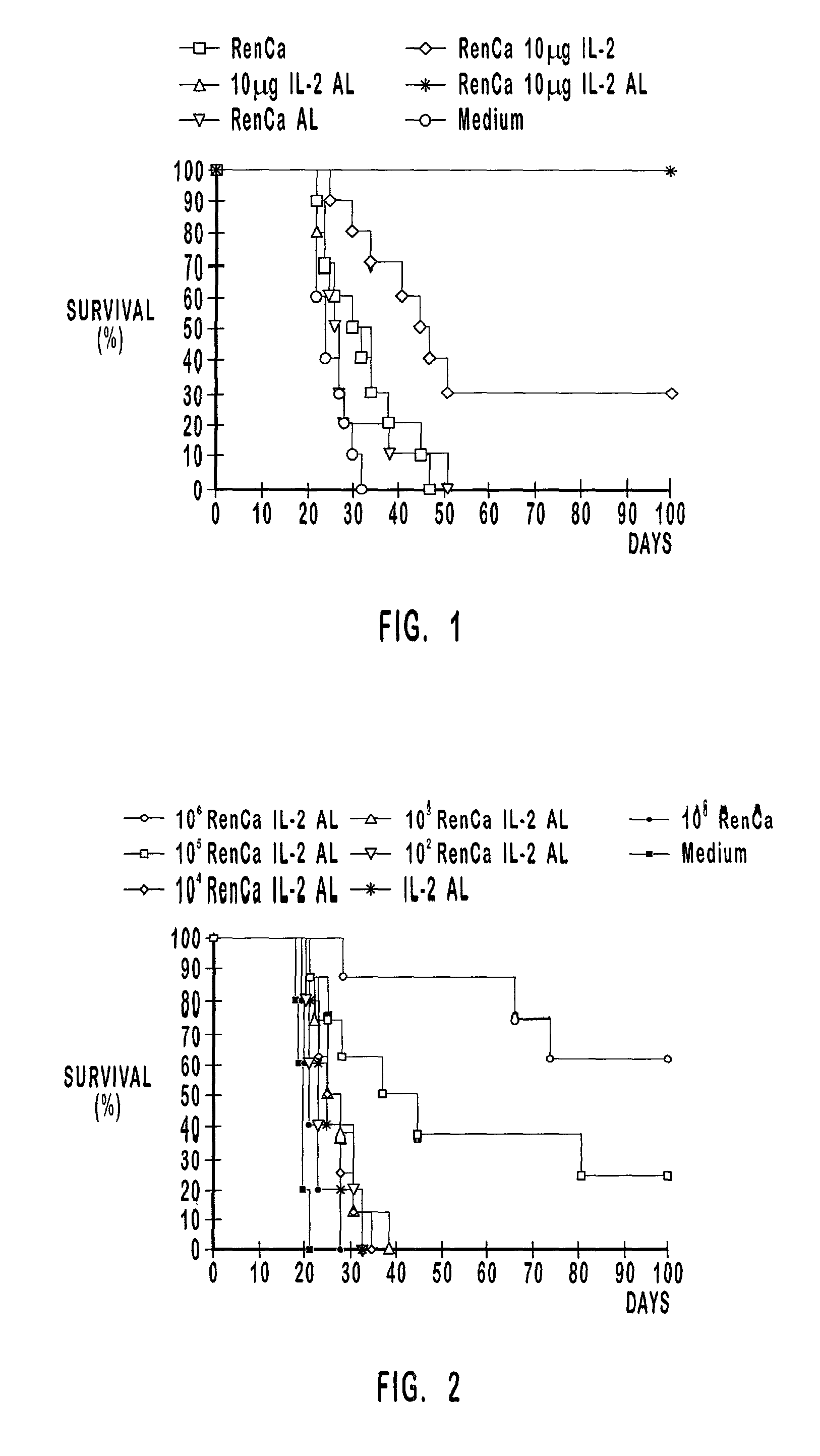

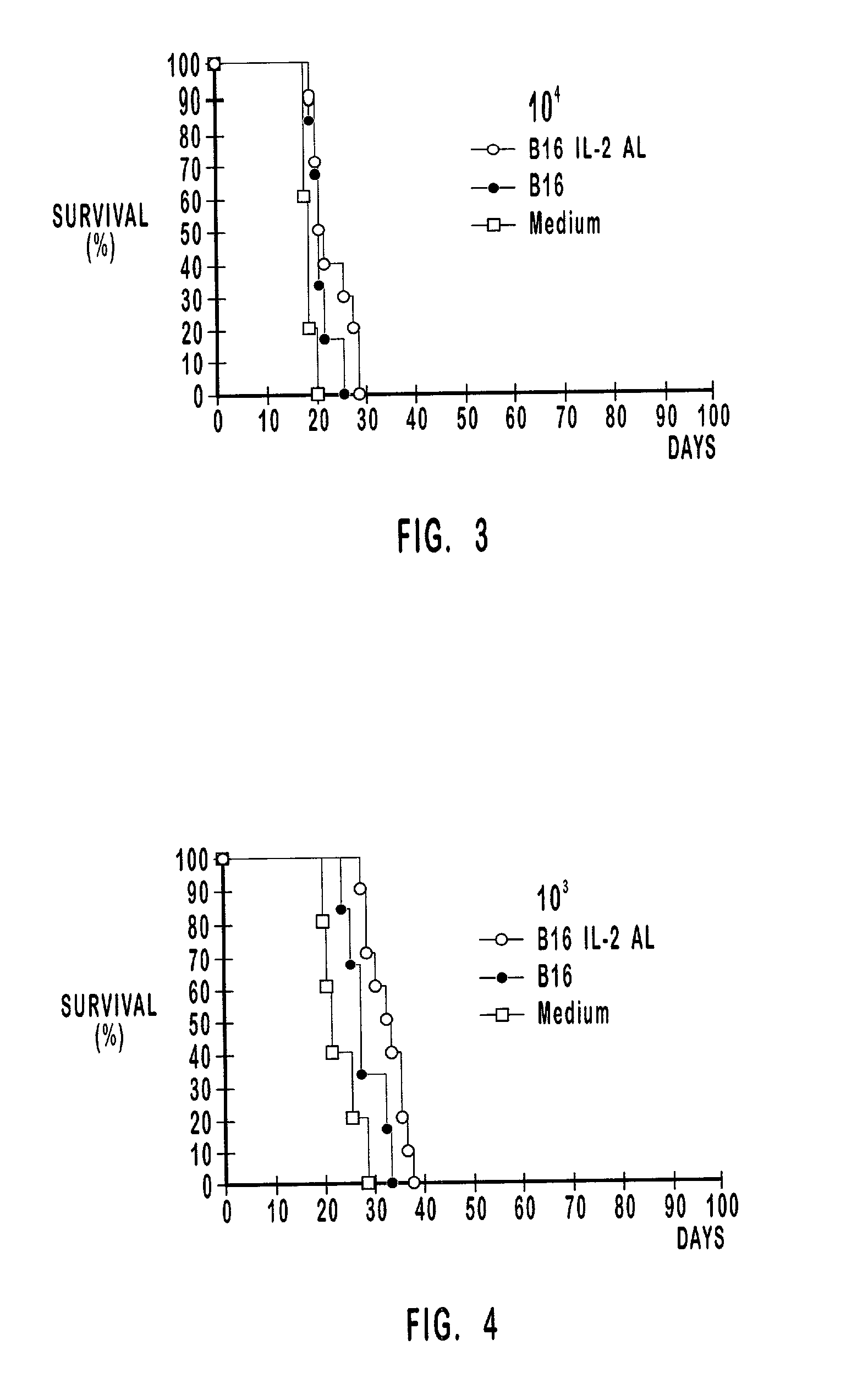

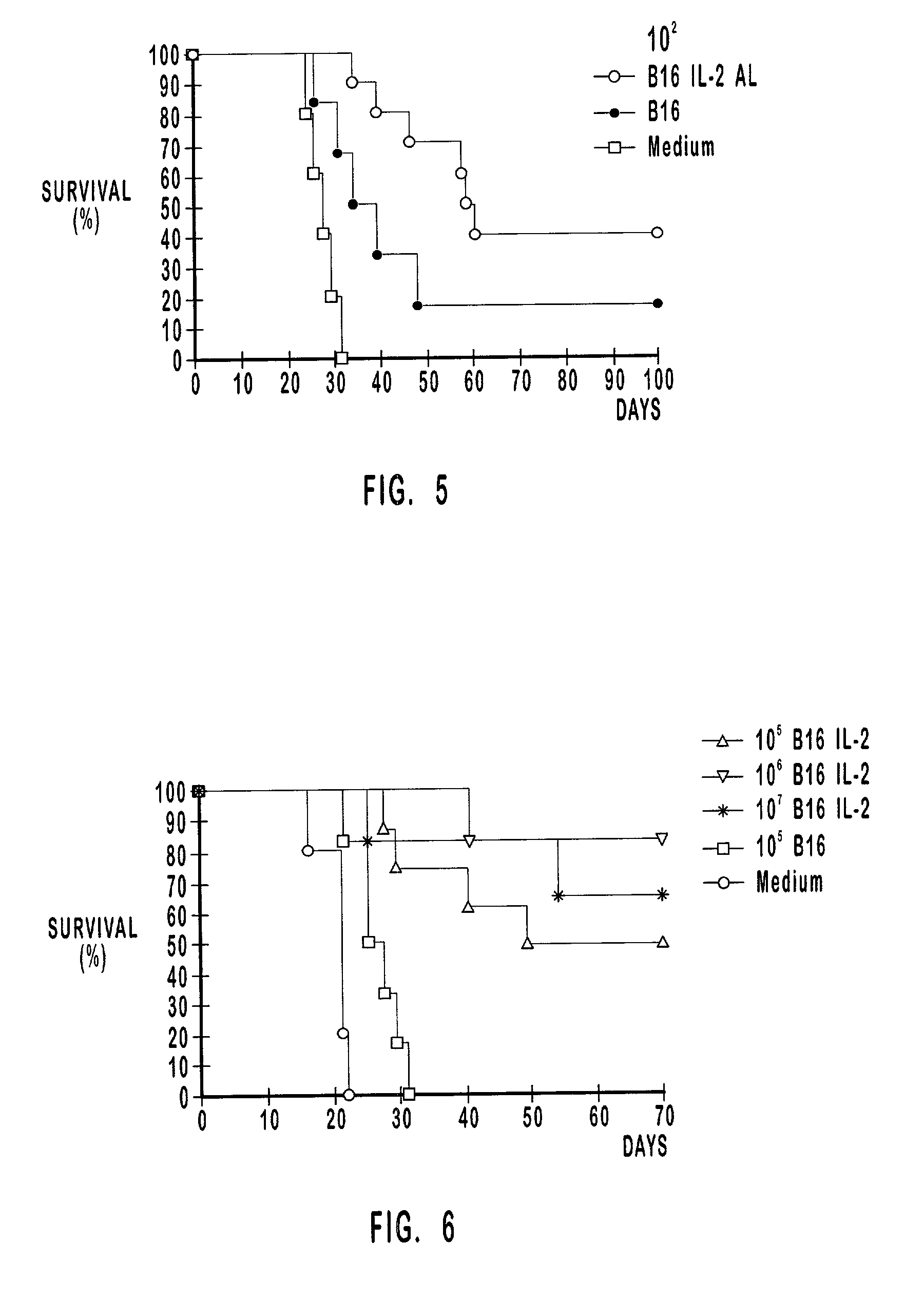

Compositions and methods for treatment of tumors and metastatic diseases

InactiveUS6406689B1Stimulate immune responseSimple and reliable to useBiocideSnake antigen ingredientsDiseaseActive immunization

Owner:FALKENBERG FR W

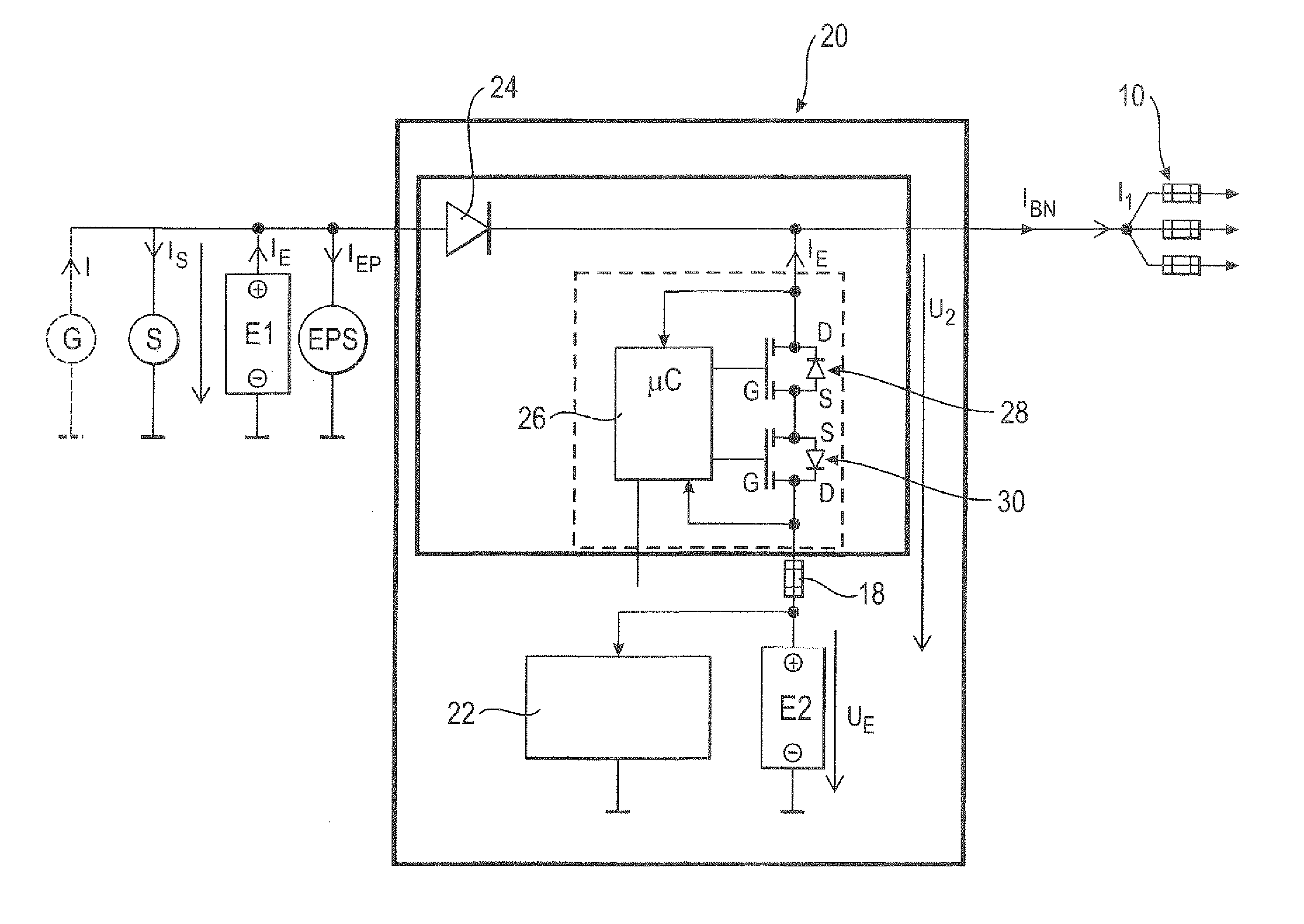

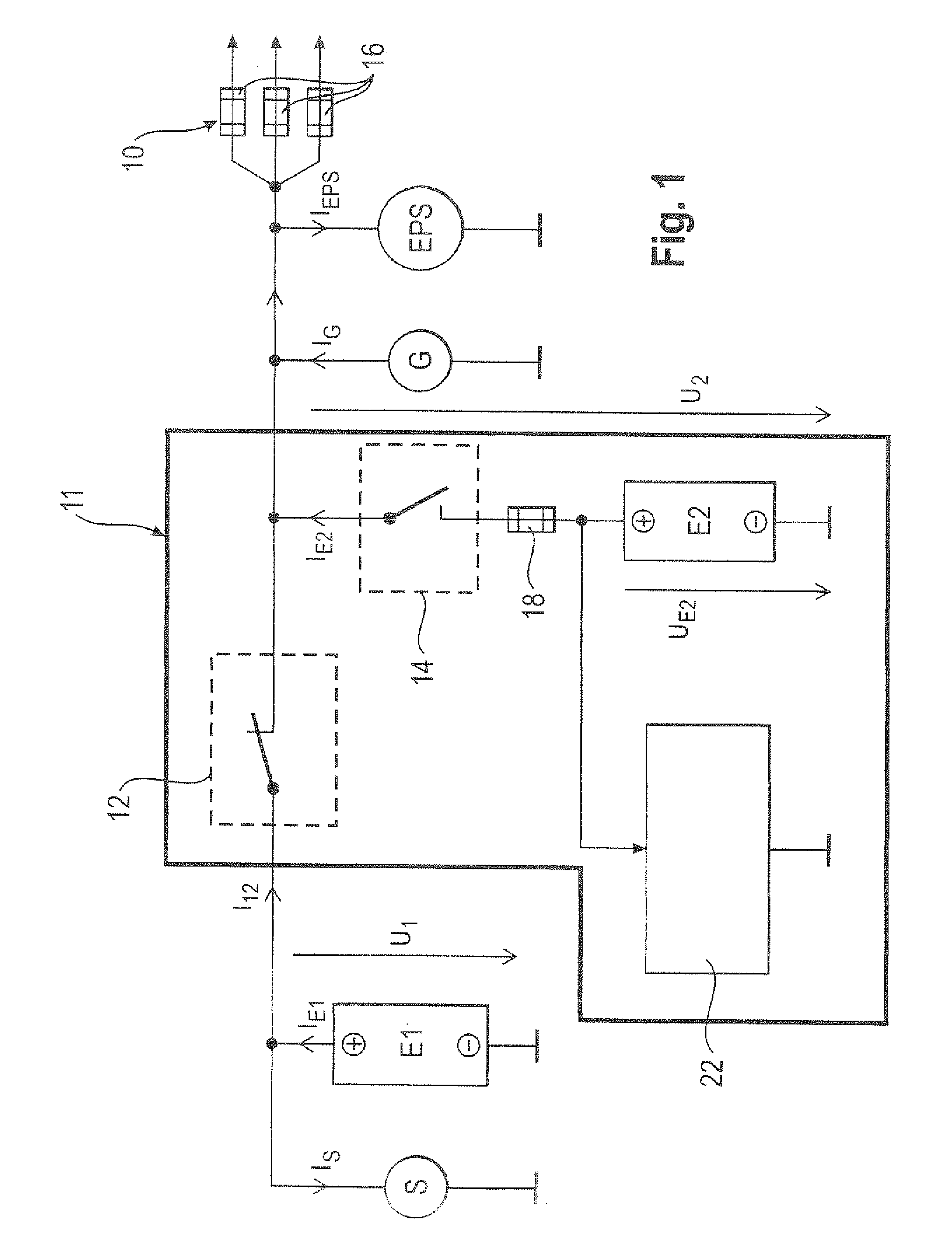

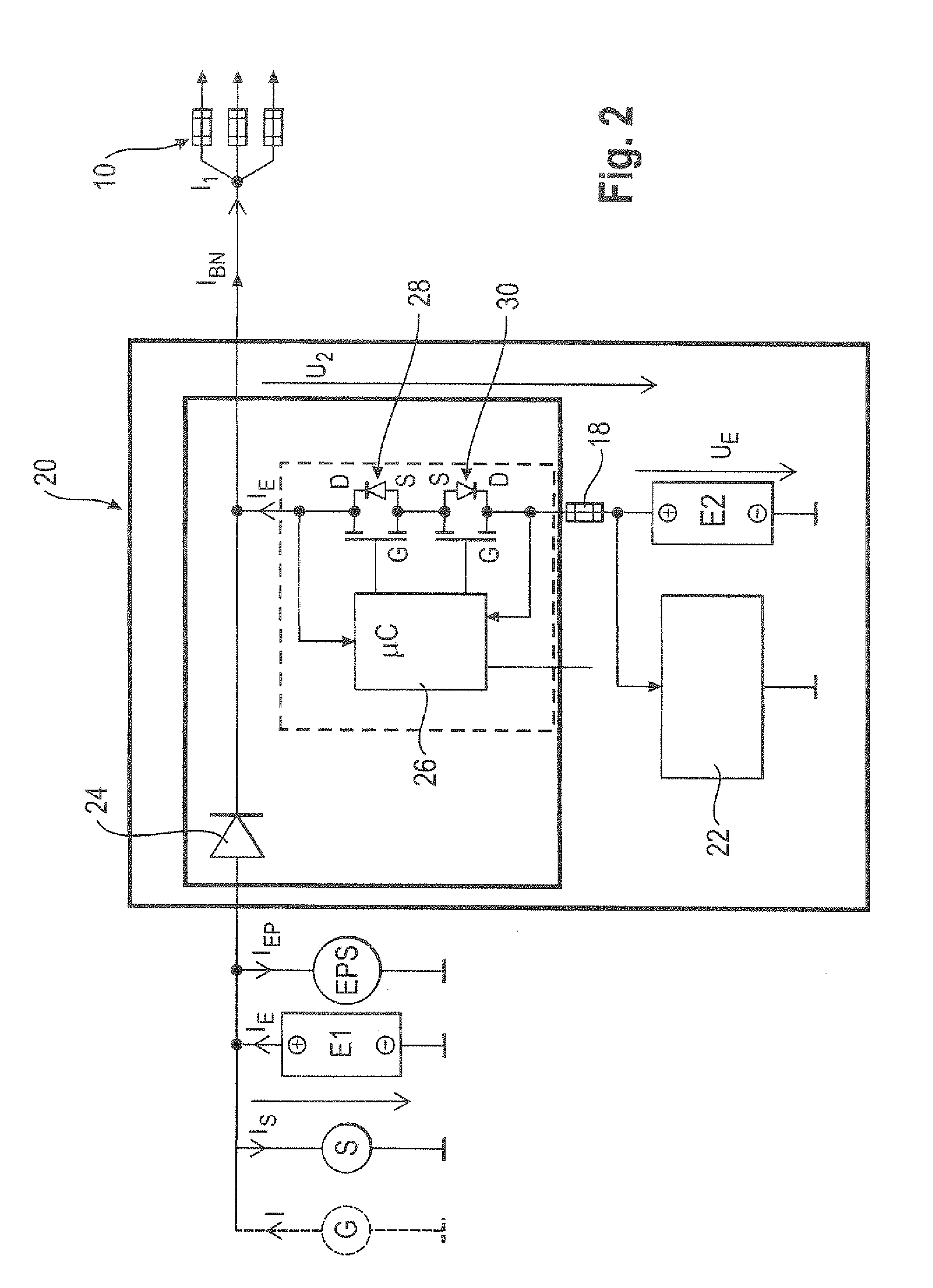

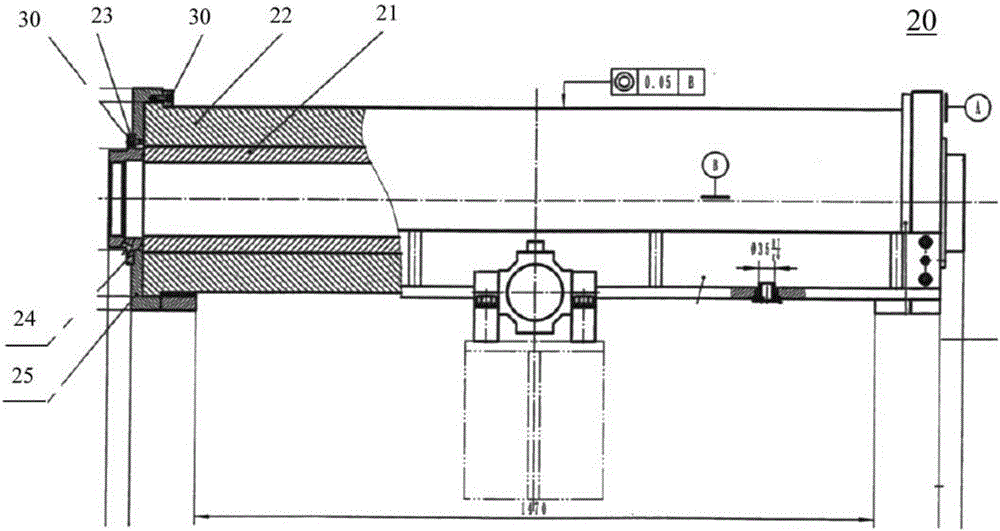

Circuit for voltage stabilization in an onboard power supply

ActiveUS20110012424A1Improve storage densityShort release timeBatteries circuit arrangementsElectric devicesMobile vehicleElectricity

The invention relates to a circuit (20, 50) for voltage stabilization in an onboard power supply (10), particularly for motor vehicles, which is electrically connected between the onboard power supply (10) to be stabilized and a first energy store (E1). The circuit (20, 50) comprises a diode element (24) which contains a plurality of semiconductor switches (34) connected in parallel, a pilot and control circuit (33) which determines the level of a current flowing through the diode element (24) and controls the semiconductor switches (34) of the diode element (24) on the basis of the determined current level, and a second energy store (E2) which is electrically connected to the diode element (24) and to the onboard power supply (10).

Owner:LISA DRAXLMAIER GMBH

Trace element-doped porous calcium carbonate ceramic, and preparation method and application thereof

The invention discloses a trace element-doped porous calcium carbonate ceramic, and a preparation method and application thereof, belonging to the field of medical materials for bone repair. The preparation method disclosed by the invention comprises the following steps: doping Mg, Sr, Zn, Si, Cu and other trace elements in a human body into calcium carbonate through a chemical precipitation method, or doping trace elements into low-temperature phosphate bioglass used as a sintering binder, uniformly mixing the trace element-doped calcium carbonate powder, the glass binder and pore forming agent, then forming, performing isostatic pressing treatment, sintering, and removing the pore forming agent to obtain the trace element-doped porous calcium carbonate ceramic. The trace element-doped porous calcium carbonate ceramic prepared by the invention has high strength and porosity, controllable degradation rate, long-term slow release of the doped trace element ions and favorable bone conductibility and inductivity, and is a novel artificially synthesized bone repair material.

Owner:GUANGZHOU MEDICAL UNIV

Compositions and methods for treatment of tumors and metastatic diseases

InactiveUS20020176845A1Effective treatmentStimulate immune responsePeptide/protein ingredientsCancer antigen ingredientsDiseaseActive immunization

Compositions and methods are provided which can be utilized in active immunization as a prophylactic treatment or a therapeutic treatment for tumors. The compositions are employed as injectable tumor vaccines or as preparations for intratumoral administration and are capable of stimulating immune responses to specific tumor antigens. The tumor vaccines are composed of an antigenic cellular material including a plurality of inactivated tumor cells or tumor cell portions, a depot material, and an immunostimulant adsorbed to the depot material. The depot material with absorbed immunostimulant is mixed with the tumor cells or tumor cell portions to form the vaccine compositions. The preparations for intratumoral administration include the depot material adsorbed immunostimulant without the antigenic cellular material. The immunostimulant adsorbed to the depot material permits release of biologically active quantities of the immunostimulant over a period of time rather than all at once.

Owner:FRANK W FALKENBERG

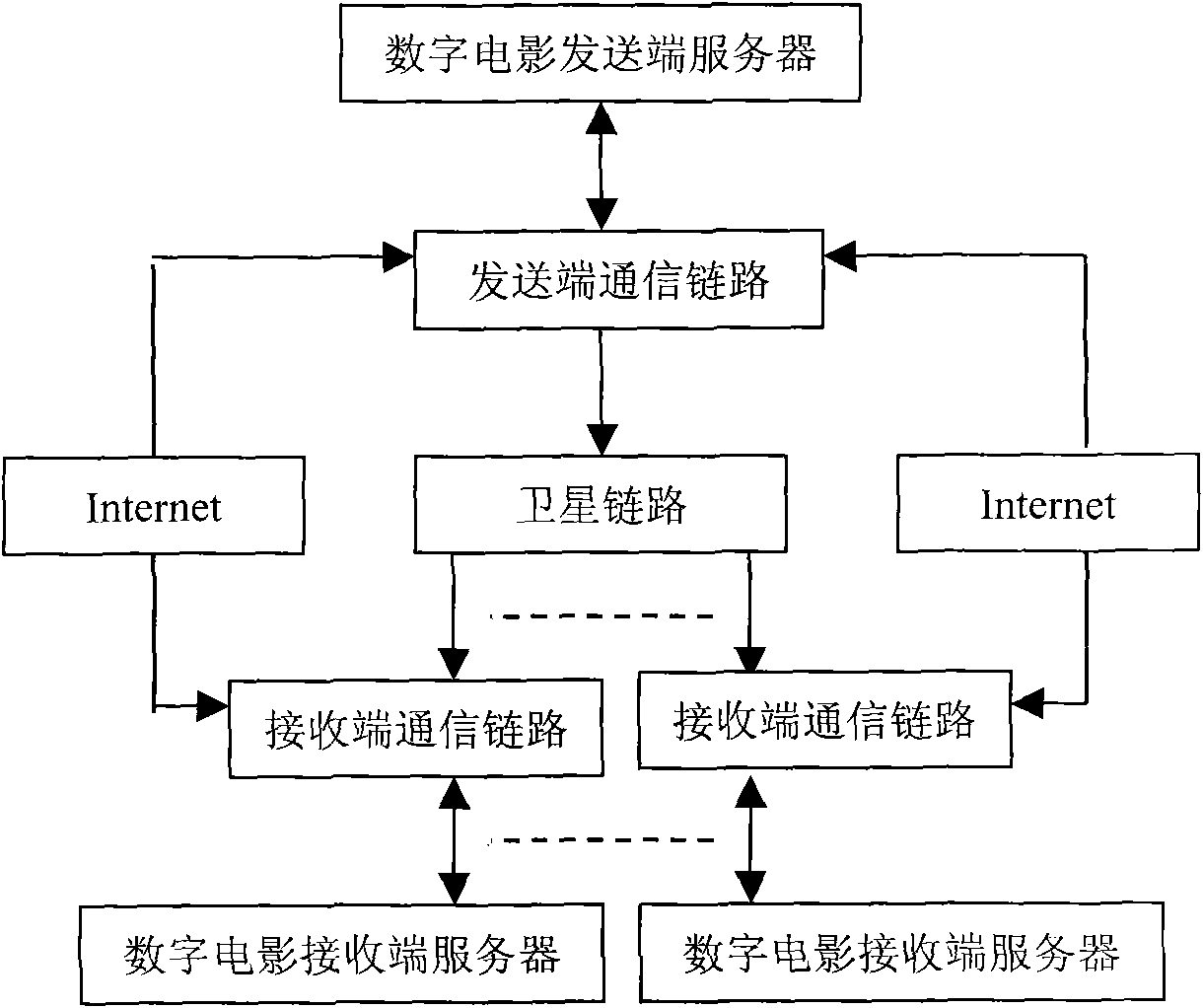

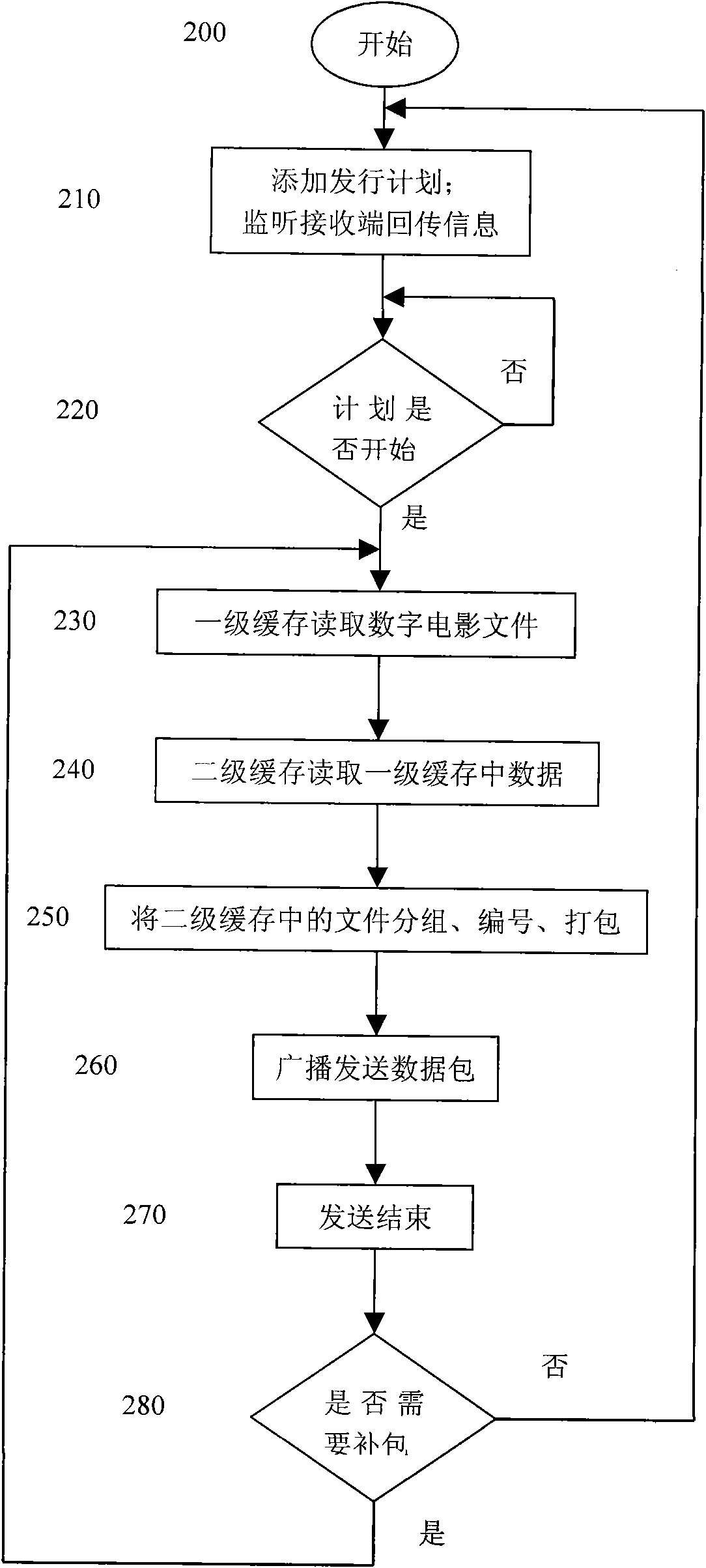

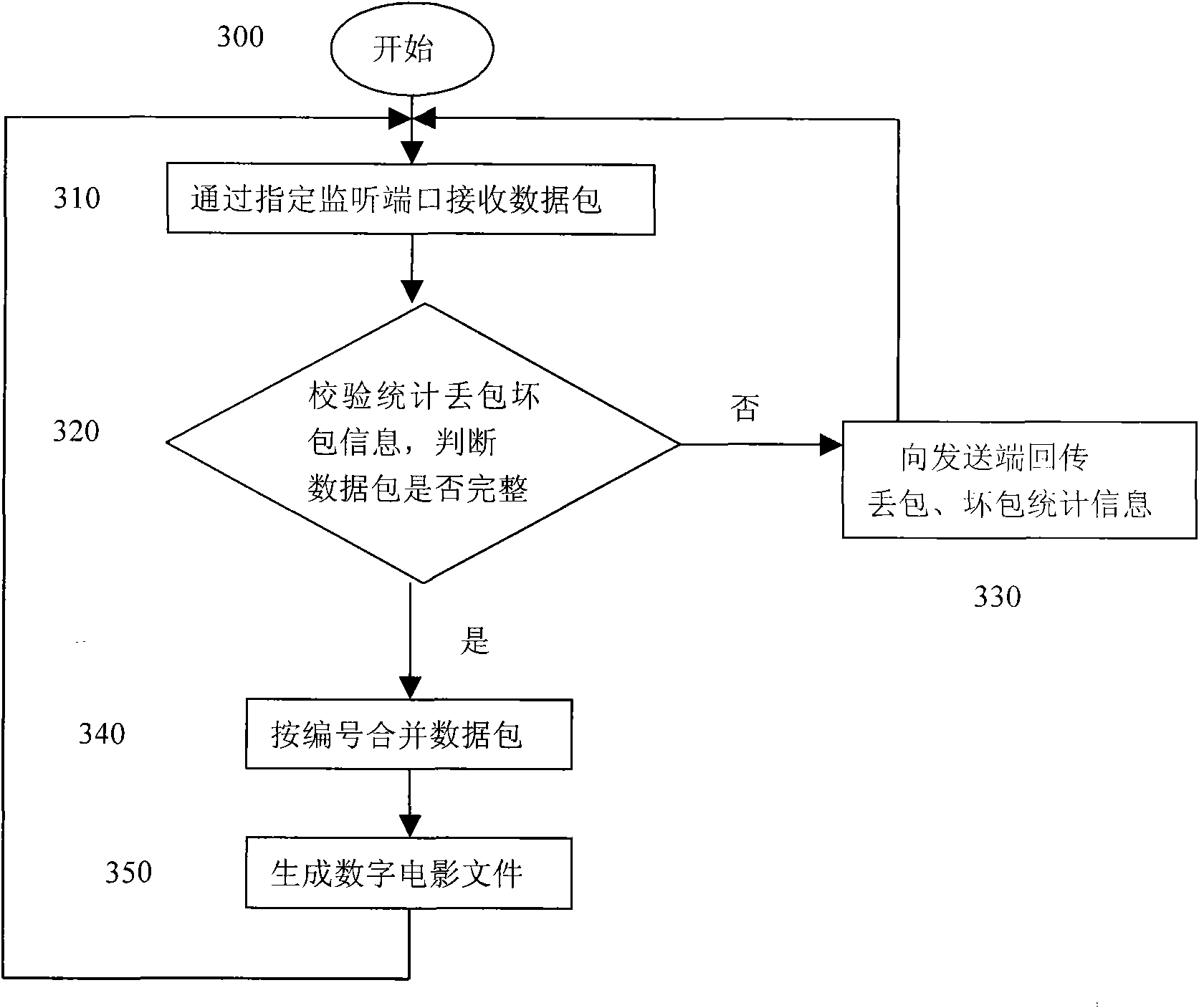

Method and device for network transmission of digital movie

InactiveCN101567794AImprove reading speedImprove efficiencySpecial service provision for substationPulse modulation television signal transmissionComplete dataNetwork packet

The invention relates to a method and a device for network transmission of a digital movie. A read digital movie file is grouped, numbered and packed by a sending terminal and is sent to a receiving terminal by a satellite link; after receiving data packets, the receiving terminal counts the number of wrong packets and transmits the information of the wrong packets back to the sending terminal; and the sending terminal complementally sends lost or damaged data packets to the receiving terminal according to the transmitted information of the wrong packets until the receiving terminal generates a complete digital movie file after receiving a complete data packet. The invention starts an L2 cache in a memory of a server of the sending terminal. An L1 cache with larger capacity reads the original digital movie file, and the L2 cache with smaller capacity reads data from the L1 cache and groups, numbers and packs the data read by the L2 cache. The invention can enhance the speed and the stability to read the file of the sending terminal and improves the use ratio of the network bandwidth and the transmission efficiency of the data.

Owner:CHINA BROADCASTING TELECOMM

Industrialized jasmine tea processing method

ActiveCN104872344AQuality improvementIncrease productionTea substituesActivated carbonCamellia oleifera

The invention discloses an industrialized jasmine tea processing method. The industrialized jasmine tea processing method adopting a sectional industrialized technical process includes: jasmine fragrance release with temperature, humidity and air controlled, fragrance gathering by means of negative-pressure air suction and activated carbon adsorption, and subcritical extraction of initial essential oil and flower residue essential oil (in a first blossom stage); tea leaf fragrance adsorption with essential oil temperature controlled, constant-temperature hermetic fragrance curing and low-temperature drying (in a second non-blossom stage). The industrialized jasmine tea processing method has the advantages that automatic and precise control of a jasmine fragrance release environment is realized, and fragrance release time is prolonged; effectiveness in collection of fragrant substances is realized by means of fragrance adsorptive gathering techniques, and owing to subcritical extraction, essential oil quality is improved, and industrial production is facilitated; by means of 'jasmine essential oil-tea' scenting, a traditional scenting mode of mixture of jasmine flowers and tea leaves is broken, possibility of production of scented tea in non-blossom seasons is realized, and automation and industrialization in production of scented tea are realized.

Owner:闽榕茶业有限公司

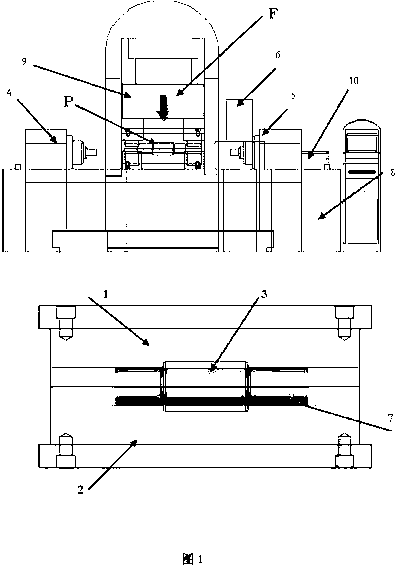

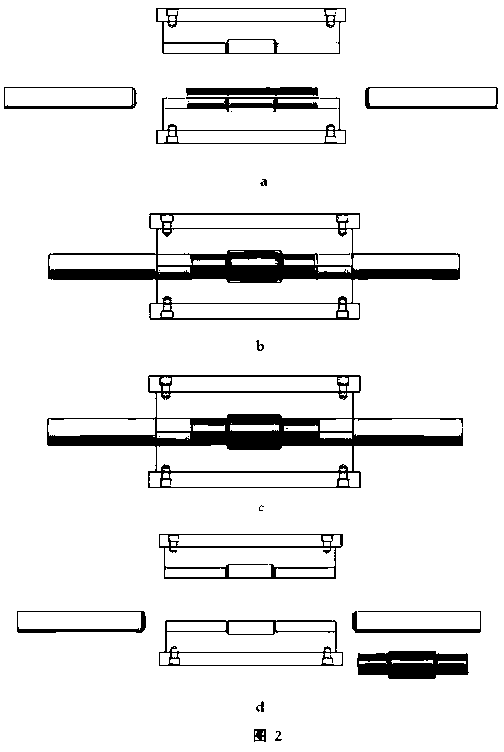

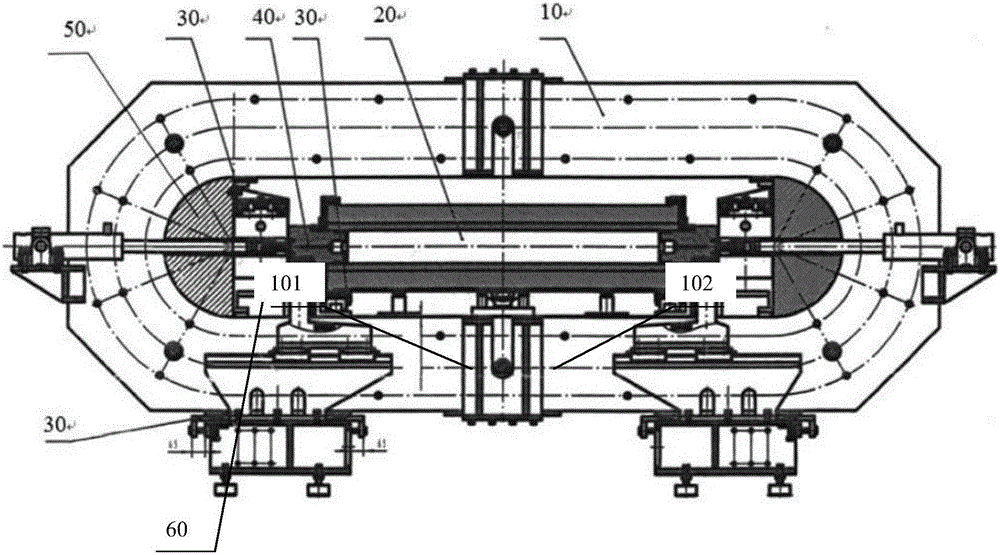

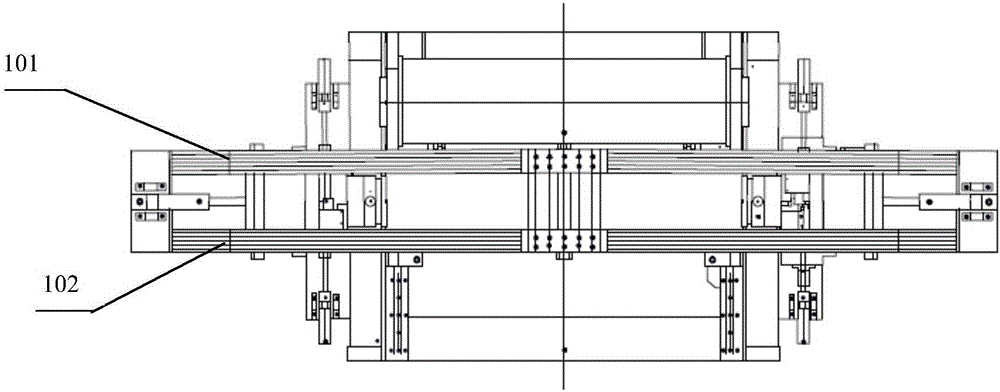

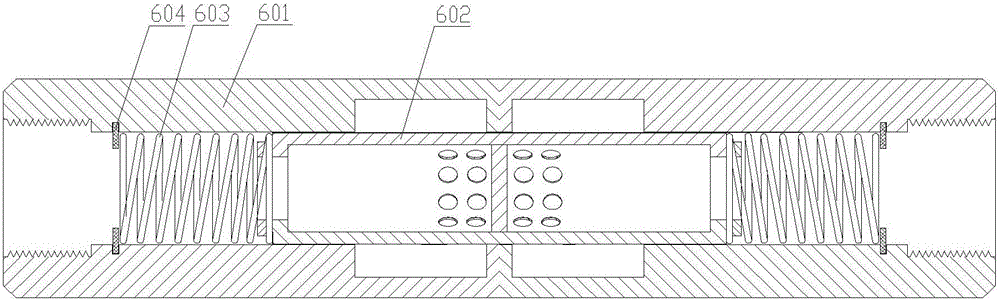

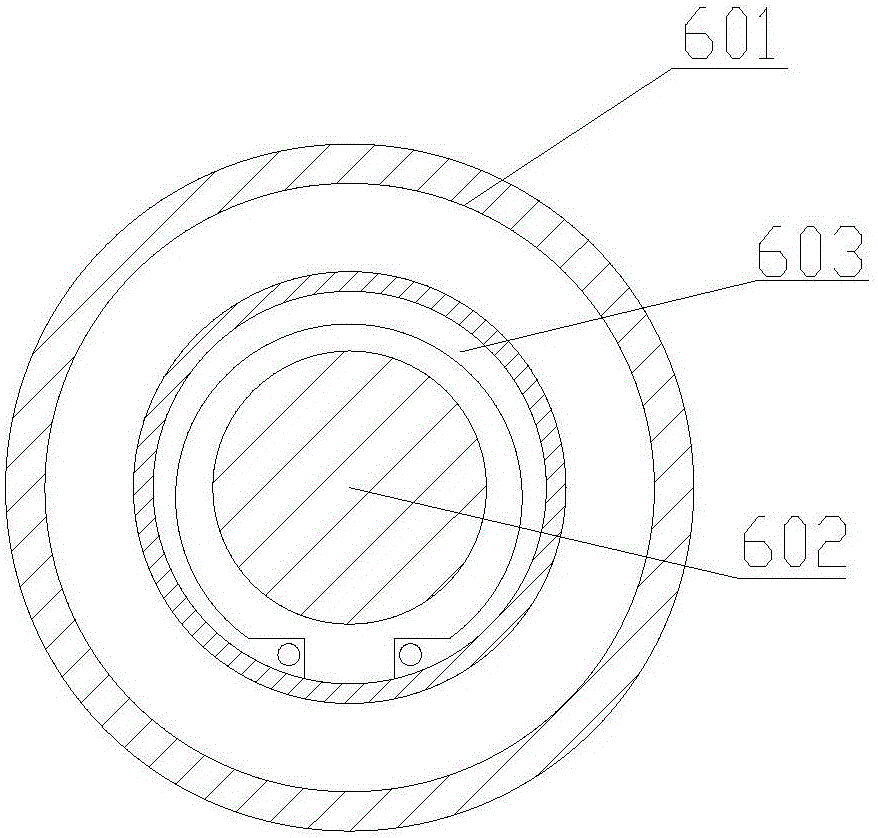

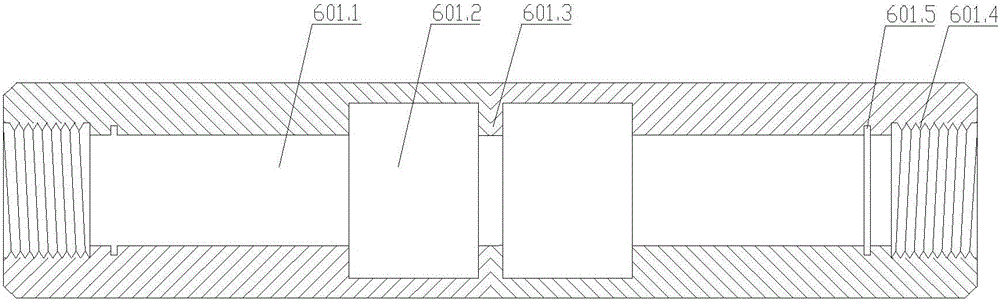

Variable-mold-clamping-force pipe internal high-pressure forming device and method

ActiveCN103212619AReduced pressure holding performance requirementsSmall tonnageEngineeringAxial force

The invention relates to a variable-mold-clamping-force pipe internal high-pressure forming method, which comprises the steps that after an upper mold and a lower mold are clamped, forming media with certain pressure is filled into a mold cavity, pushing heads on a left side and a right side simultaneously push pipe blanks into the mold cavity from the left side and the right side, the pipe blanks are pressed into the mold cavity to be formed through internal pressurization and axial force application and material compensation under the joint effect of the pressure of the forming media and the material compensation of the pushing heads, and finally the pipe blanks are in fit with the mold cavity to realize part formation. Since different mold clamping forces are adopted at different stages, the defects that the pressure required by the traditional constant-mold-clamping-force tube internal high-pressure forming method is high, the requirements on machine performance, mold performance, sealing performance and mold lubricating performance are high, the machine cost is high, the situation of mold lifting is apt to occur, the part forming pressure is high, large-deformation complex parts cannot be formed, the working efficiency is low and the like are overcome.

Owner:NINGBO POWER PRECISION HYDRAULIC MACHINERY

Compositions and methods for treatment of tumors and metastatic diseases

InactiveUS20020039571A1Stimulate immune responseSimple and reliable to useBiocideGenetic material ingredientsDiseaseActive immunization

Compositions and methods are provided which can be utilized in active immunization as a prophylactic treatment or a therapeutic treatment for tumors. The compositions are employed as injectable tumor vaccines or as preparations for intratumoral administration and are capable of stimulating immune responses to specific tumor antigens. The tumor vaccines are composed of an antigenic cellular material including a plurality of inactivated tumor cells or tumor cell portions, a depot material, and an immunostimulant adsorbed to the depot material. The depot material with absorbed immunostimulant is mixed with the tumor cells or tumor cell portions to form the vaccine compositions. The preparations for intratumoral administration include the depot material adsorbed immunostimulant without the antigenic cellular material. The immunostimulant adsorbed to the depot material permits release of biologically active quantities of the immunostimulant over a period of time rather than all at once.

Owner:FALKENBERG FR W

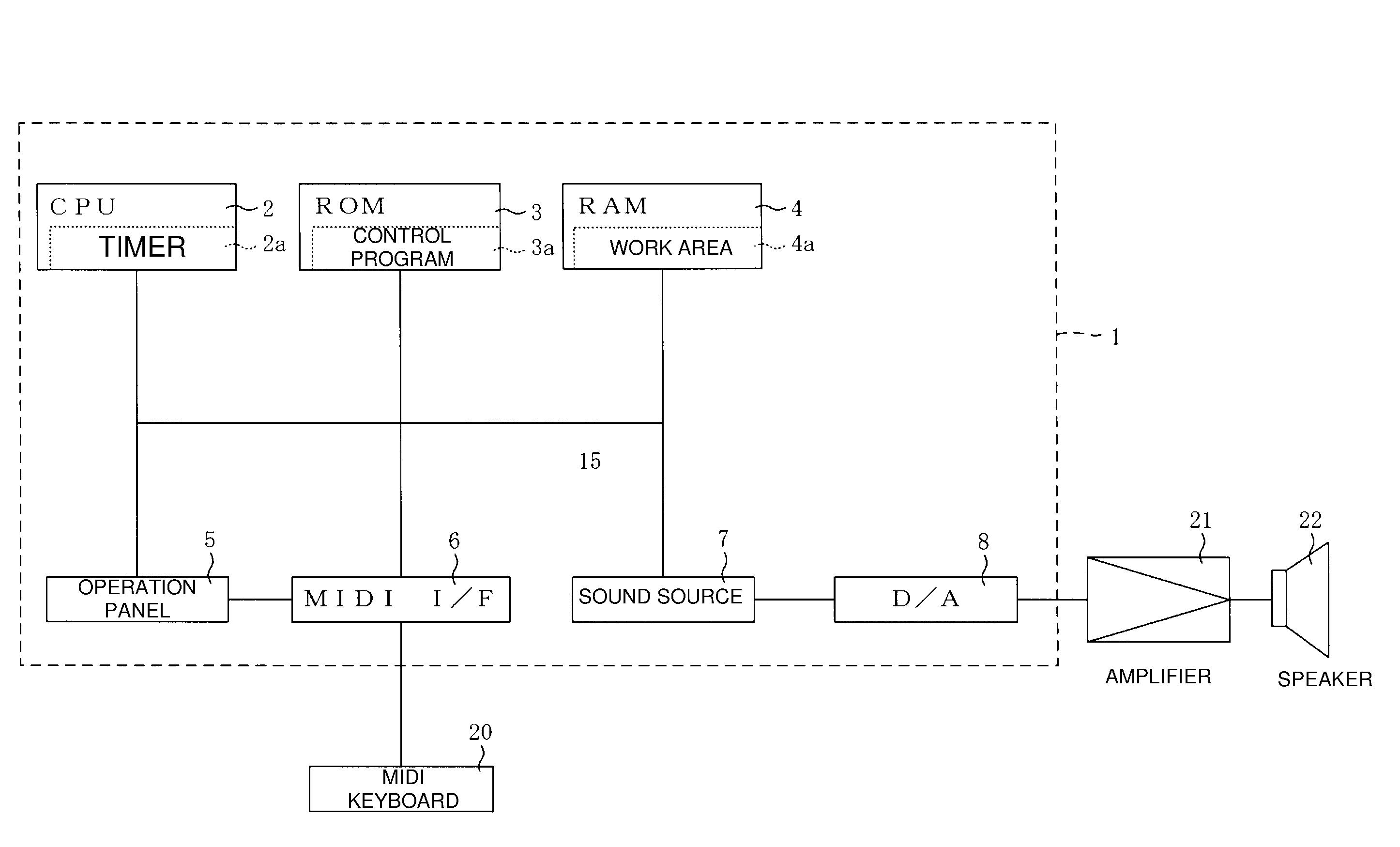

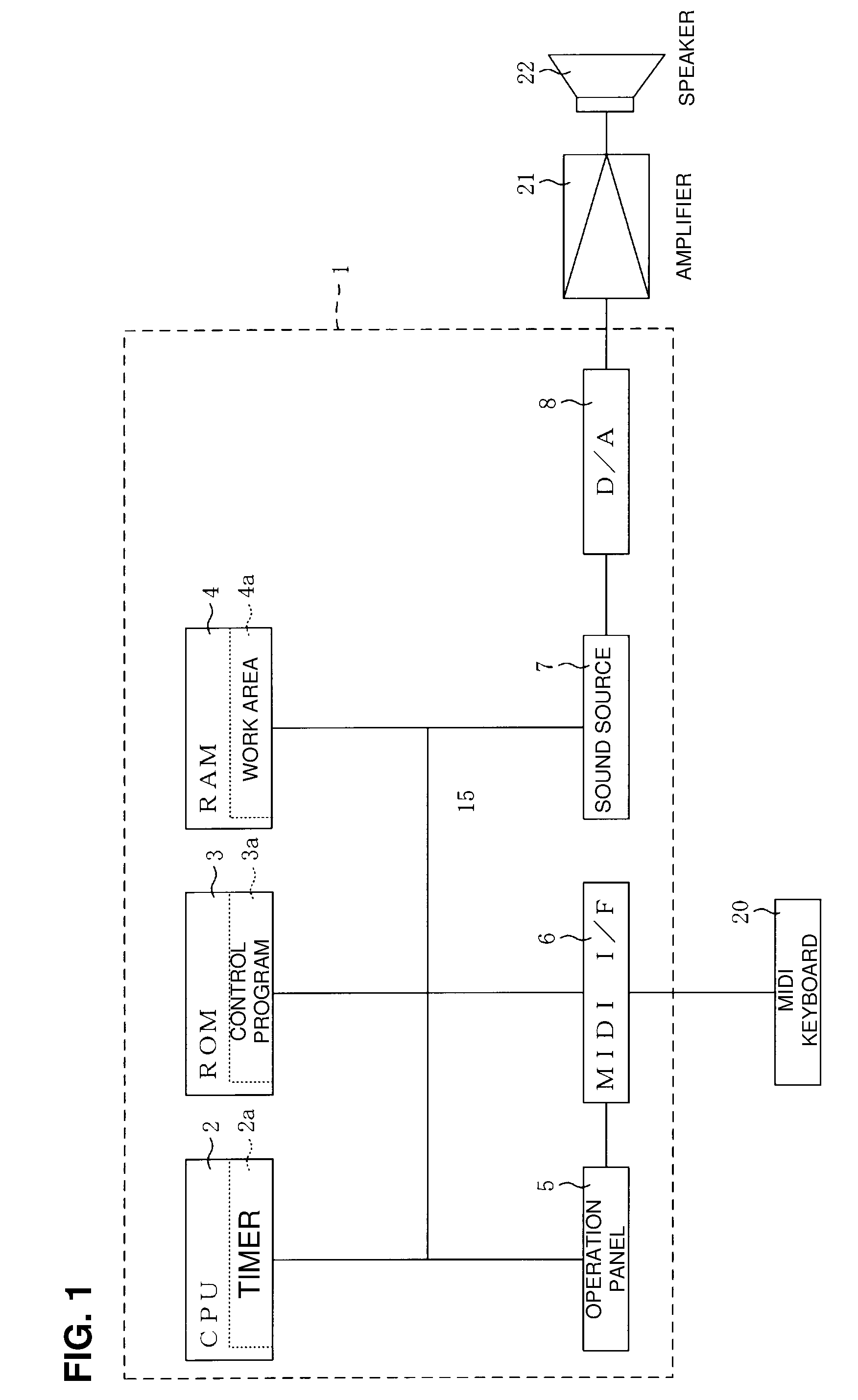

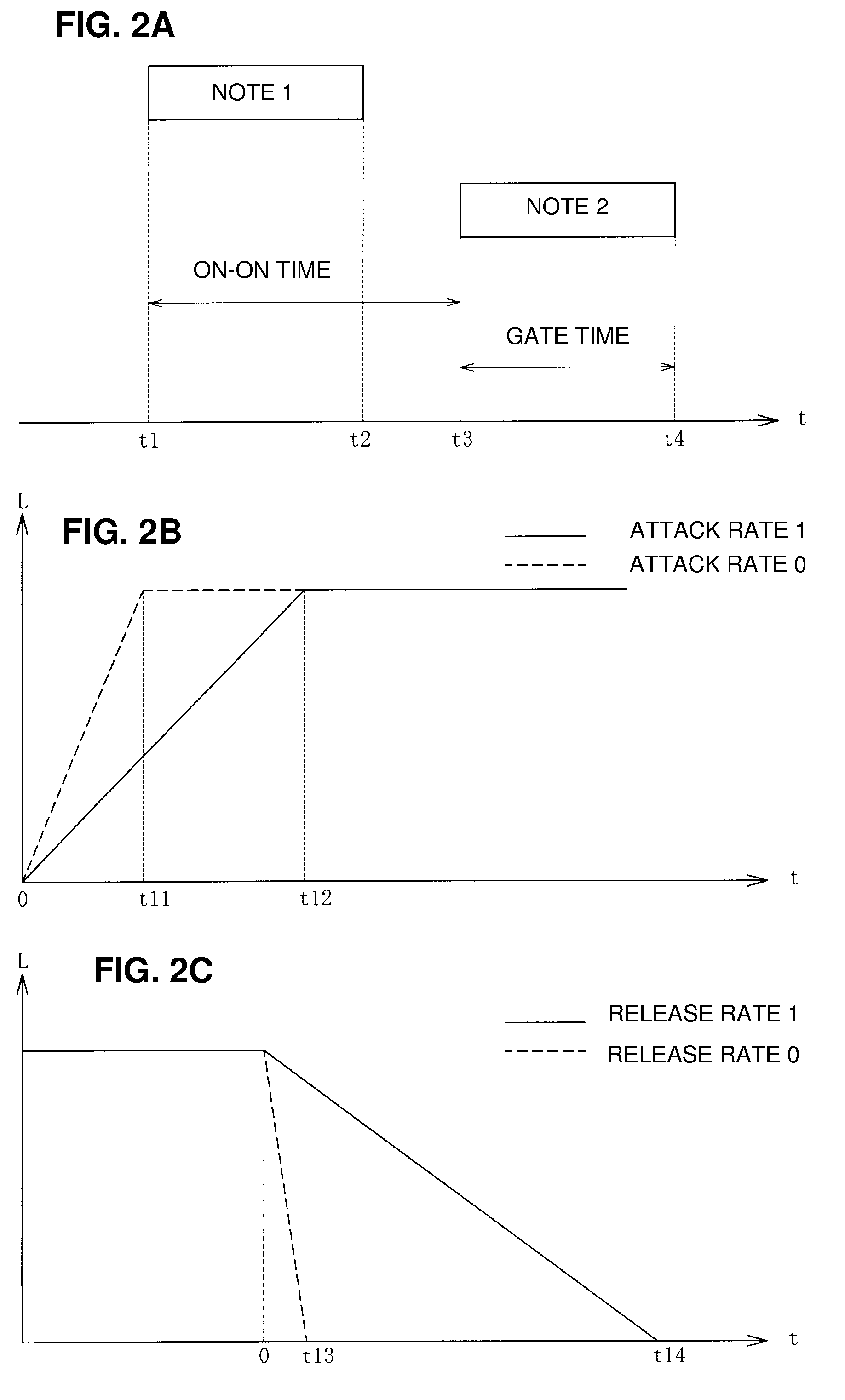

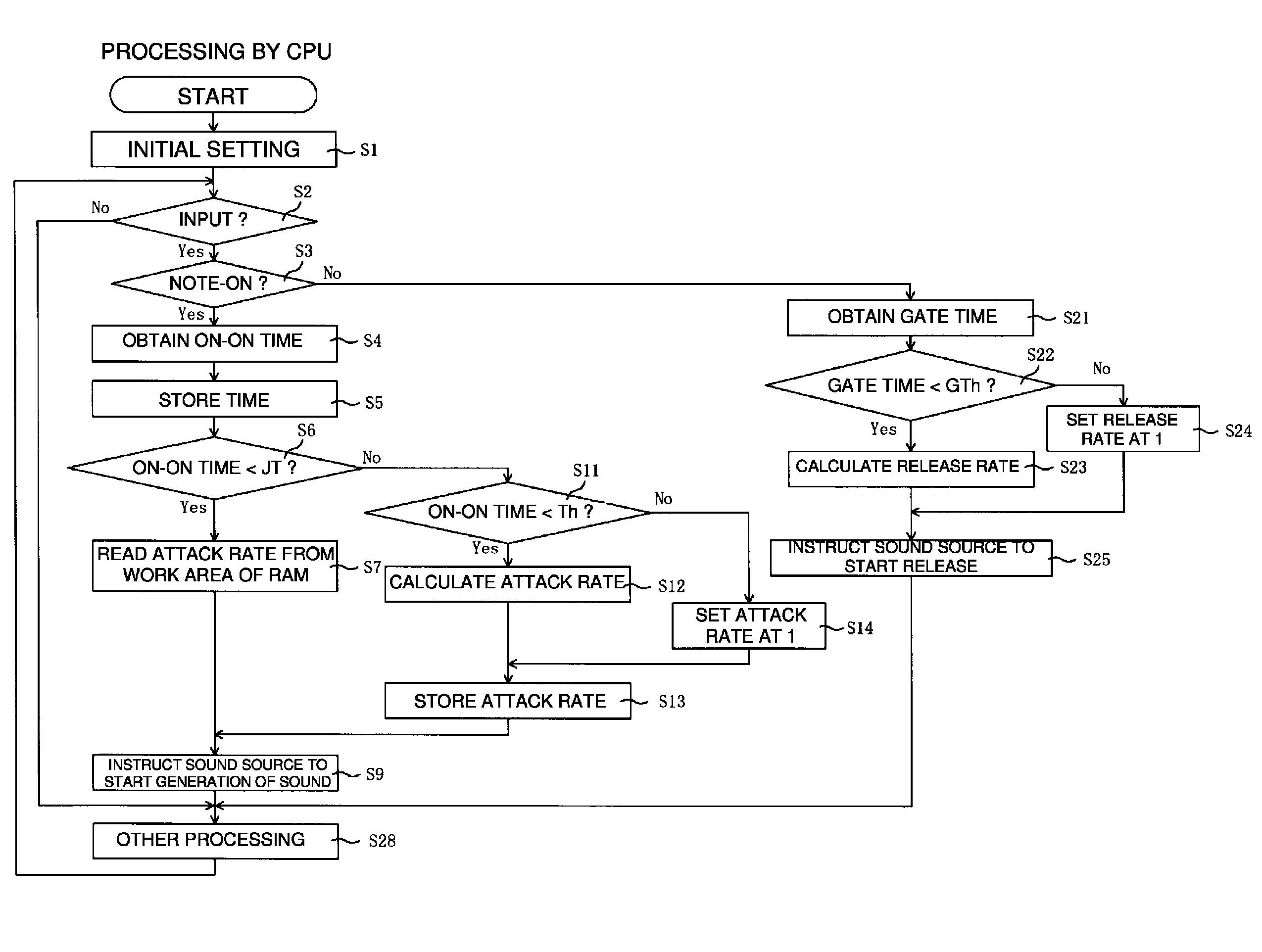

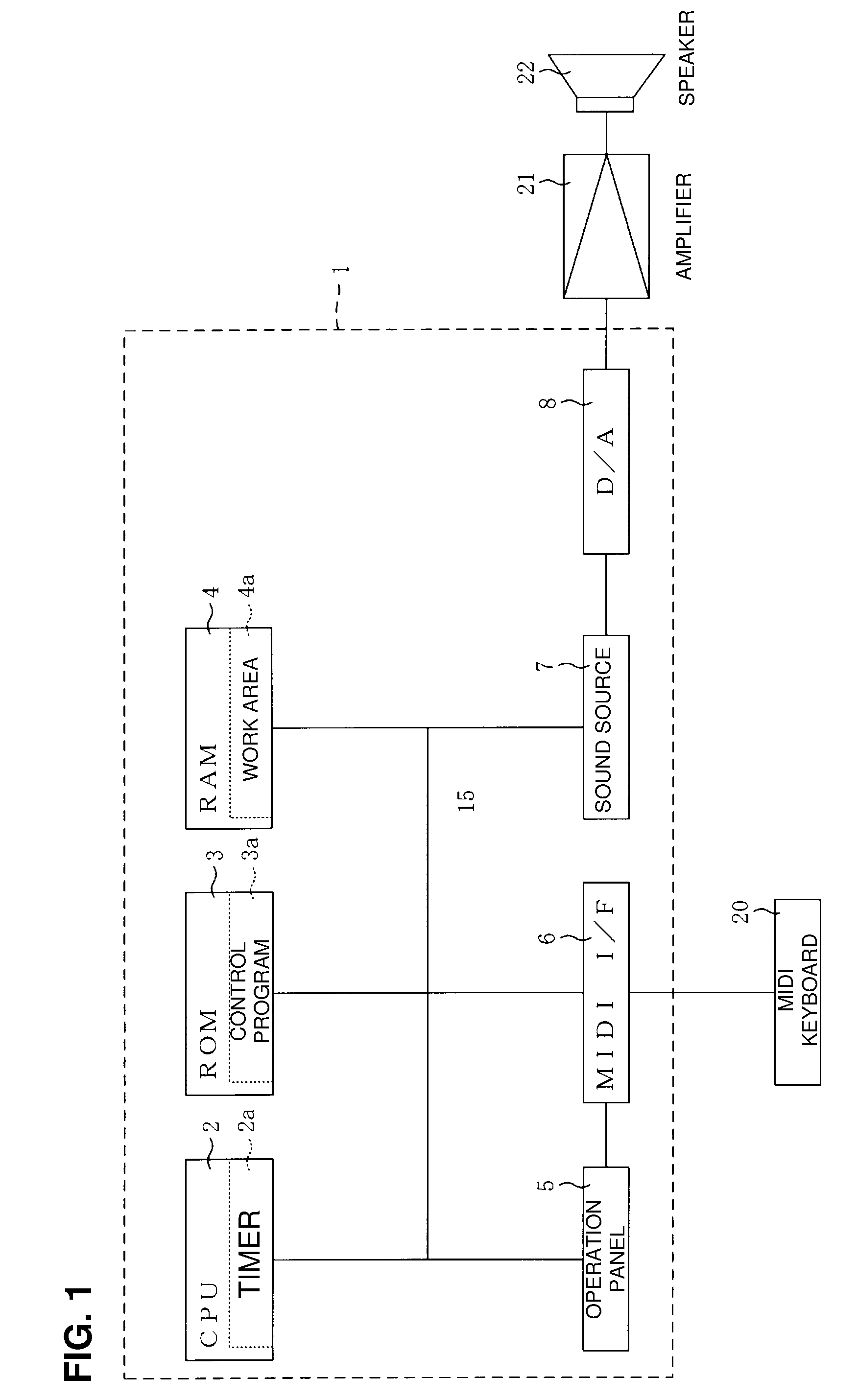

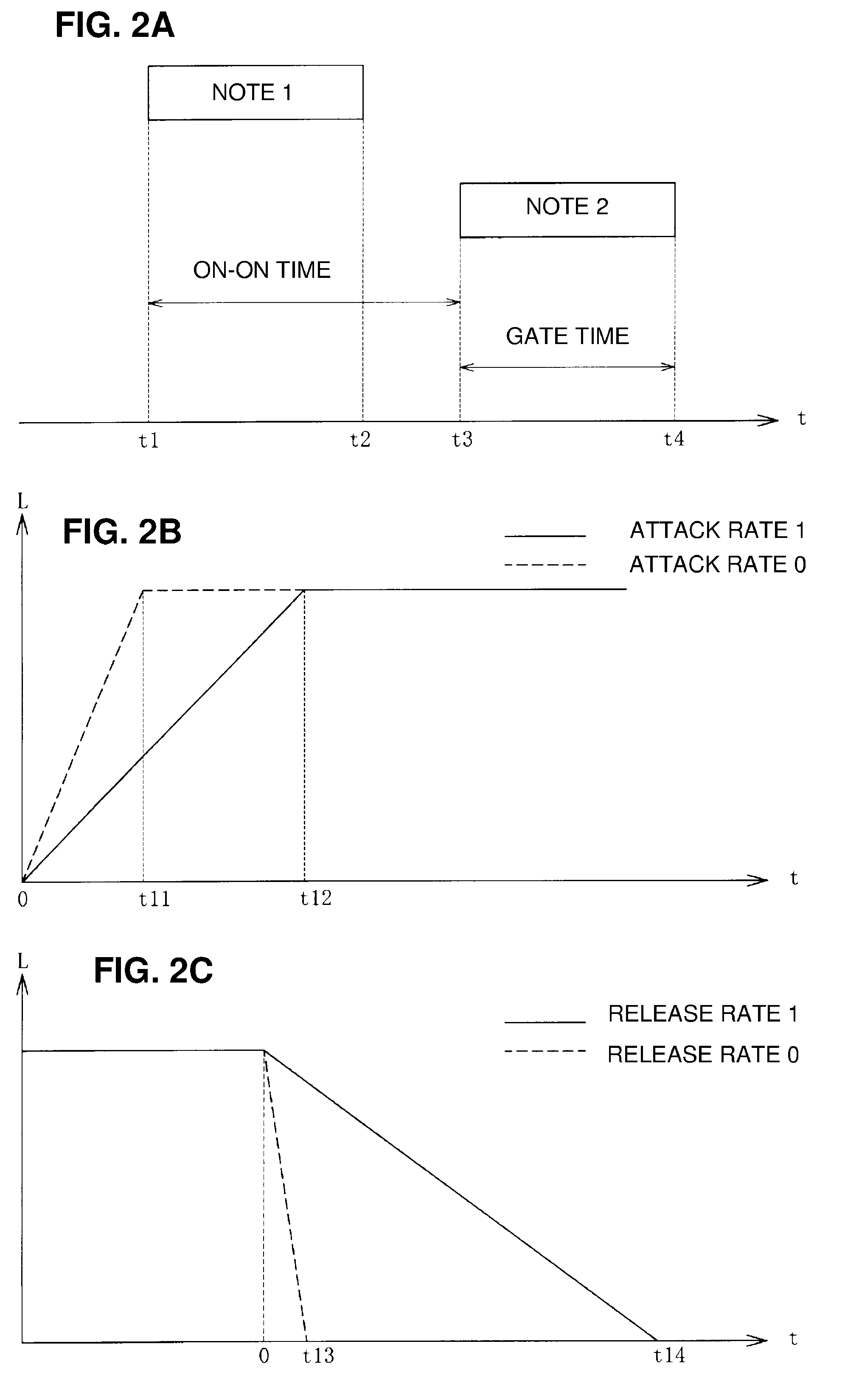

Electronic musical instrument

ActiveUS20090249943A1Short startup timeClear processGearworksMusical toysSound generationSound sources

An electronic musical instrument includes: an input device that inputs a sound generation instruction that instructs to start generating a musical sound and a stop instruction that instructs to stop the musical sound being generated by the sound generation instruction; a sound source that starts generation of a musical sound in response to the sound generation instruction, and stops generation of the musical sound in response to the stop instruction; an on-on time timer device that measures a time difference between a first sound generation instruction inputted by the input device and a second sound generation instruction inputted next to the first sound generation instruction; a gate time timer device that measures a time difference between the second sound generation instruction and a stop instruction that instructs to stop a musical sound generated in response to the second sound generation instruction; an attack characteristic setting device that sets an attack characteristic of the musical sound generated in response to the second sound generation instruction to have a shorter attack time as the time difference measured by the on-on time timer device becomes shorter; a release characteristic setting device that sets a release characteristic of the musical sound generated in response to the second sound generation instruction to have a shorter release time as the time difference measured by the gate time timer device becomes shorter; and an instruction device that instructs the sound source to start generation of a musical sound with an attack characteristic set by the attack characteristic setting device in response to an input of the second sound generation instruction by the input device, and instructs the sound source to stop generation of a musical sound with a release characteristic set by the release characteristic setting device in response to an input of the stop instruction by the input device.

Owner:ROLAND CORP

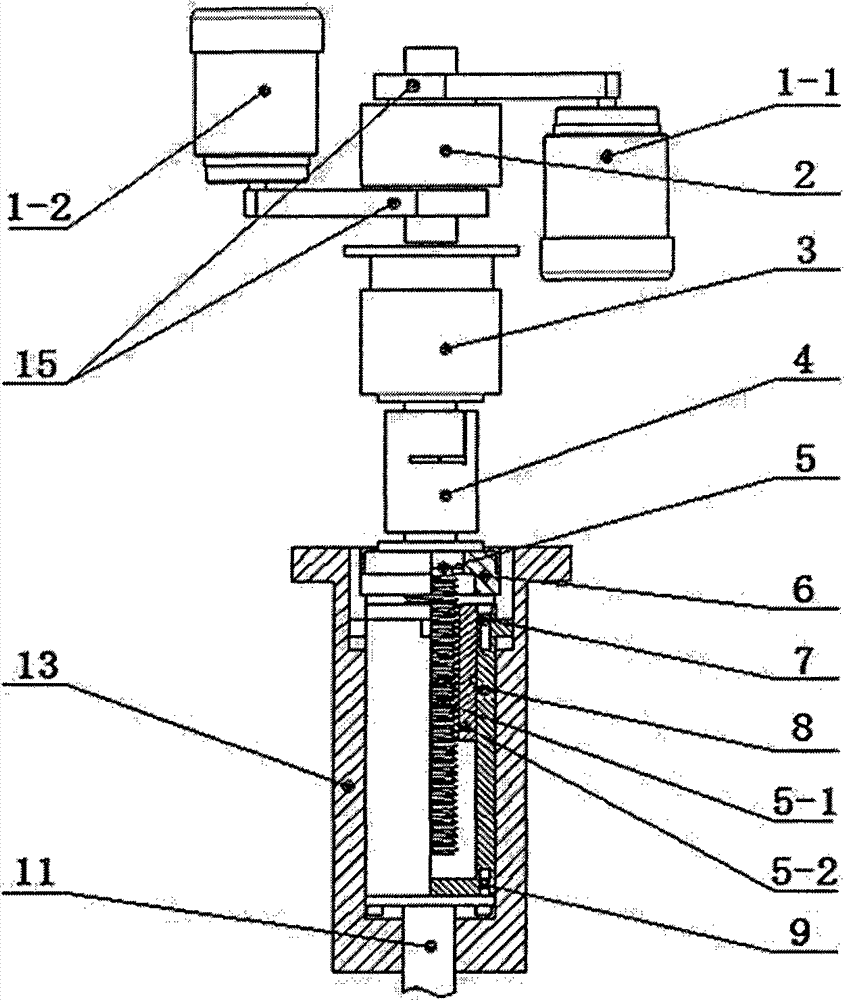

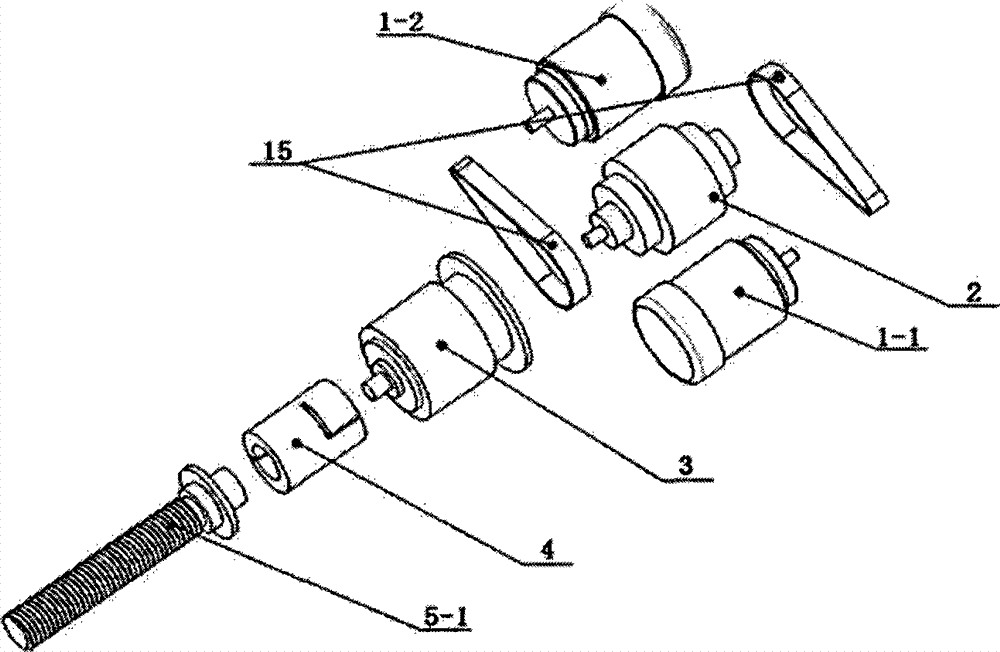

Extrusion blow molding machine-head-and-die-orifice gap electrical adjustment device and realization method and application thereof

Owner:SOUTH CHINA UNIV OF TECH

Acidification and profile control integrated method

InactiveCN104213885AMake sure to fill with waterWater injection pressure does not riseFluid removalAbsorption capacityEngineering

The invention relates to an acidification and profile control integrated method. The method includes the following steps of analyzing the development history of oil deposit and the current situation of a water injection well, and screening a high-pressure water injection well; conducting acidification processing, wherein acid liquid matched with a target stratum is rapidly injected into the stratum through a high-pressure pump truck on the premise of the pressure lower than the stratum breakage pressure, the acid liquid is made to permeate the stratum to corrode blocking objects in hole gaps, hole space is enlarged, the diversion capacity of the stratum is restored or improved, and the water injection pressure is reduced; conducting profile control processing, wherein acid-resistant profile control agents are injected into the target stratum, highly-permeable bands with the high water absorption capacity are blocked, and a permeation channel where water is injected is changed. By means of the acidification and profile control integrated method, profile control is conducted on high-pressure water injection caused by pollutant blockage in the immediate vicinity of wellbore, the aim of improving water injection developing effect is achieved, and it is ensured that water injection can still be normally executed after profile control.

Owner:PETROCHINA CO LTD

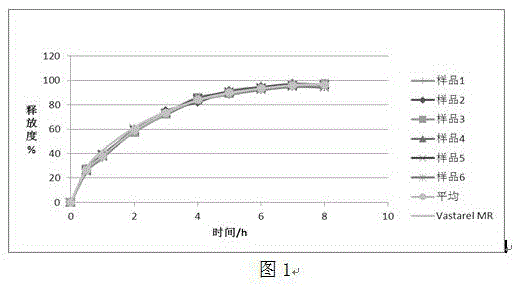

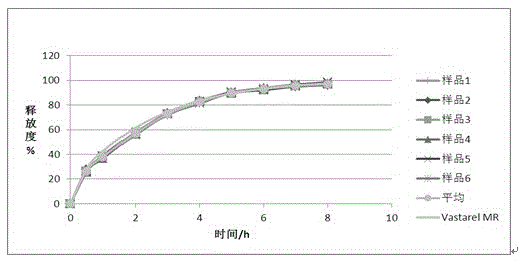

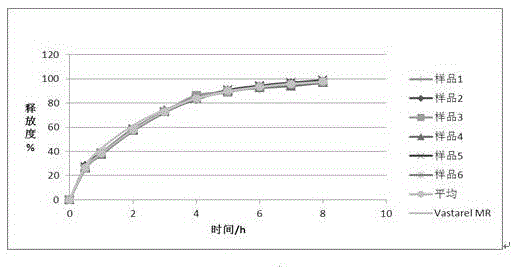

Trimetazidine sustained-release mini-pill composition and method for preparing same

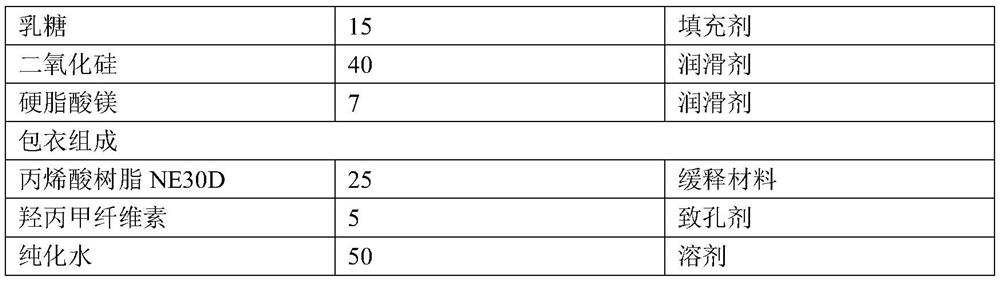

ActiveCN105616358AImprove solubilityPoor sustained releaseOrganic active ingredientsSenses disorderMedicineTrimetazidine

The invention discloses a trimetazidine sustained-release mini-pill composition. The trimetazidine sustained-release mini-pill composition comprises sustained-release pills A and C or sustained-release pills A, B and C. The sustained-release pills A, B and C have different increased weights. The trimetazidine sustained-release mini-pill composition has the advantages that two or three types of film-controlled sustained-release mini-pills with different increased weights are proportionally mixed with one another to obtain the trimetazidine sustained-release mini-pill composition, accordingly, zero-order release effects can be realized by the trimetazidine sustained-release mini-pill composition, and the trimetazidine sustained-release mini-pill composition can be released in a long-acting and sustained manner.

Owner:南京卓康医药科技有限公司

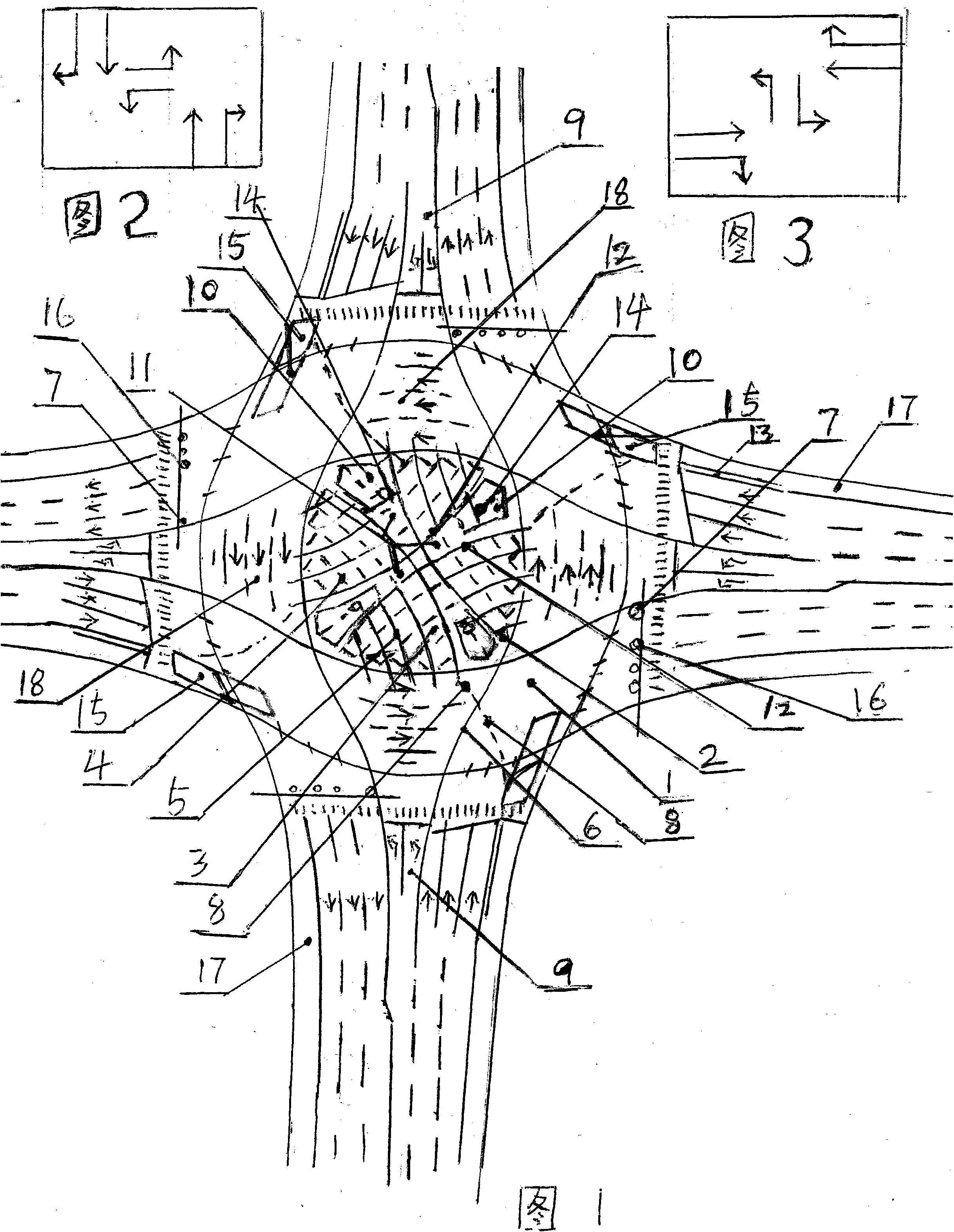

Advance left-hand steering and its driving method

InactiveCN102733275AEase congestionShort waiting time for green lightRoadwaysRoad T junctionEngineering

The invention relates to advance left-hand steering and its driving method. According to the invention, two bidirectional-lane level crossings are arranged. Four unidirectional-lane separated roads (1) are disposed at the crossroad of the two level crossings. An advance left-hand steer waiting zone (2) is arranged at the level center of the separated level crossings. Steer waiting lanes for (3) are arranged in the steer waiting zone (2). A left-turn driving signal lamp (6) is mounted over a lamppost at each exit road. When driving at the entrance roads at the traffic light, through left-and-right-hand turning traffic flows can park to wait for green lights. When facing green lights, through right-hand turning traffic flows enter the crossings. After left-hand turning traffic flows wait to enter through right-hand steering crossings for 10-15 seconds and when the left-turn driving signal lamp turns green, the left-hand turning traffic flows enter the crossings and drive into the advance left-hand steer waiting zone (2), so as to wait for through traffic flows at another level crossings drive away from the crossings at the same time. There is no intersection conflict point when through left-hand turning traffic flows are at the same phased crossing. Through the design provided by the invention, the waiting time for green lights is short when vehicles are at the entrance roads, blowdown flow rate of automobiles is minimized, and it is safe for driving.

Owner:胡昌碰

Preparation method of slow-release fertilizer

InactiveCN106380311AShort release timeNo pollution in the processSuperphosphatesBioloigcal waste fertilisersManufacturing technologyRoom temperature

The invention discloses a preparation method of the slow-release fertilizer and belongs to the field of fertilizer manufacture technology. The preparation method comprises the following steps: a) mixing sodium alginate, lecithin, plant oil and dodecylbenzenesulfonic acid, potassium salt, and carrying out ultrasonic dispersion to obtain mixed liquor; b) uniformly coating the surface of fertilizer master batch A with the mixed liquor by a vacuum spray mode, drying and cooling to room temperature so as to prepare fertilizer granules; c) mixing fertilizer master batch B and gelatinized starch and the fertilizer granules so as to prepare composite fertilizer granules; and d) mixing beta-cyclodextrin and composite fertilizer water and stirring to obtain a paste, adding the composite fertilizer granules, stirring, drying and cooling to room temperature so as to prepare the slow-release fertilizer. The method is suitable for preparation of a water-soluble slow-release fertilizer. The coating material is a degradable material and is pollution-free to soil. The technology of the invention is simple and convenient to operate. The period of the technological process is short, and no waste is generated. The method accords with the idea of atom economy and environment protection. The invention is beneficial to industrial promotion and application.

Owner:ZHEJIANG JULONG FERTILIZER CO LTD

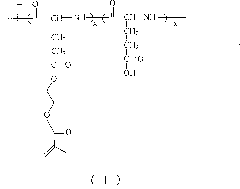

Poly (L-glutamic acid)/polyacrylic acid hydrogel and preparation method thereof

The invention provides a poly (L-glutamic acid) / polyacrylic acid hydrogel and preparation method thereof. The hydrogel contains poly (L-glutamic acid-g-hydroxy ethyl acrylate), polyacrylic acid and water. The preparation method includes the following steps: pH value of acrylic acid buffer solution is regulated to be 8-9, so as to obtain a first reaction solution; poly (L-glutamic acid-g-hydroxy ethyl acrylate) buffer solution is added into the first reaction solution, so as to obtain a second reaction solution; initiator is added into the second reaction solution to obtain a third reaction solution, the third reaction solution is subject to heating or irradiation to obtain reaction product; and the reaction product is placed into deionized water to be soaked, thus obtaining the poly (L-glutamic acid) / polyacrylic acid hydrogel. The poly (L-glutamic acid) / polyacrylic acid hydrogel prepared by the preparation method has biodegradability and high pH sensibility and is especially suitable for being used as oral drug release carrier.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

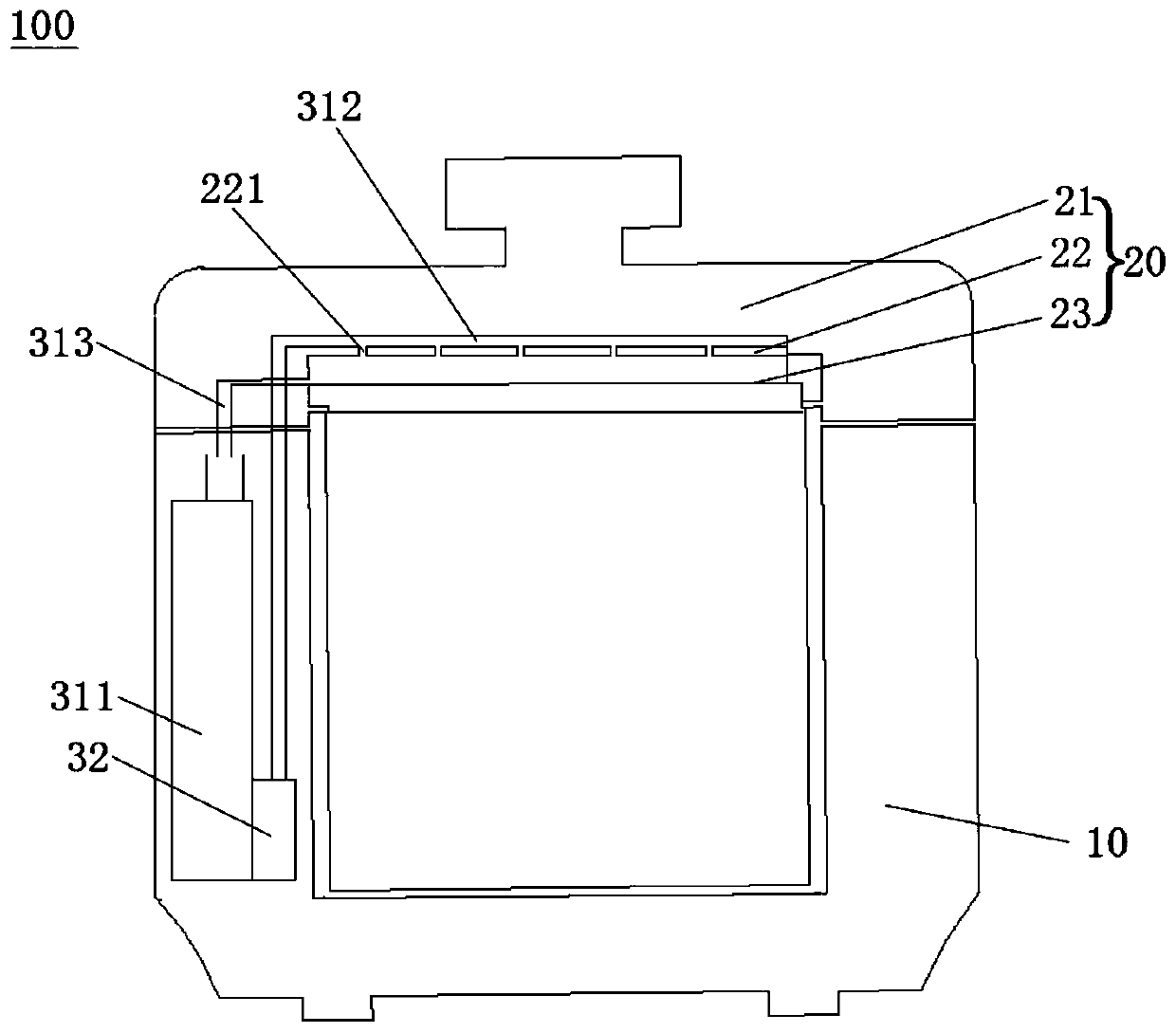

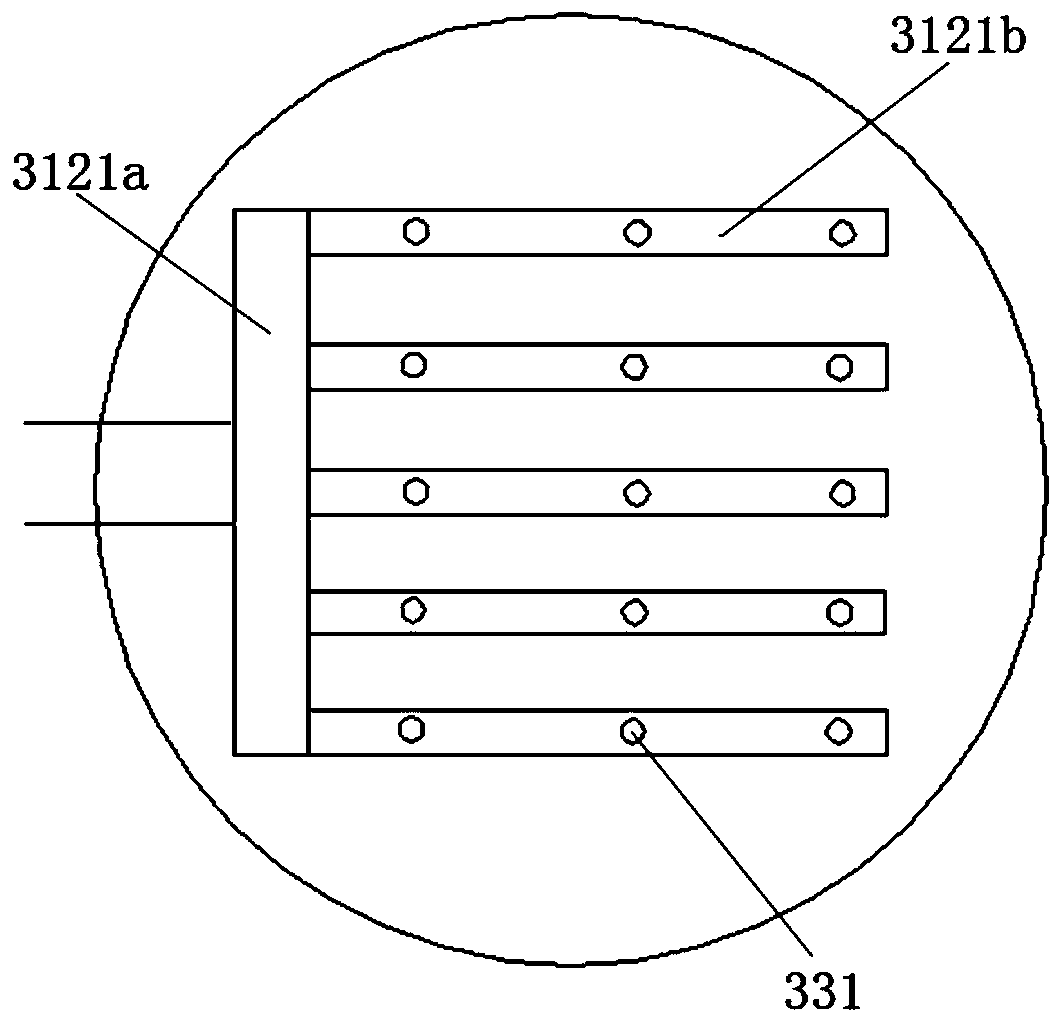

Electric pressure cooker with pressure relieving function

PendingCN110720826AReduce the temperatureSpeed up pressure dropPressure-cookersWater storageThermodynamics

The invention relates to an electric pressure cooker with a pressure relieving function. The electric pressure cooker comprises a cooker body, a cooker cover and a jet flow impact cooling device, wherein the cooker cover is matched with the cooker body to be used; the jet flow impact cooling device comprises a circulation water path, a jet flow pump connected onto the circulation water path and aspraying device arranged in the pot cover; and the spraying device communicates with the circulation water path. The temperature in the cooker is fast lowered by using the jet flow impact cooling cooker cover; the reduction speed of the pressure in the cooker is further accelerated; the pressure relieving time is shortened; by using strong heat exchange capability of the jet flow impact cooling, the demanding quantity of the cooling water can be reduced; and the size of a water storage device and the size of the whole electric pressure cooker are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

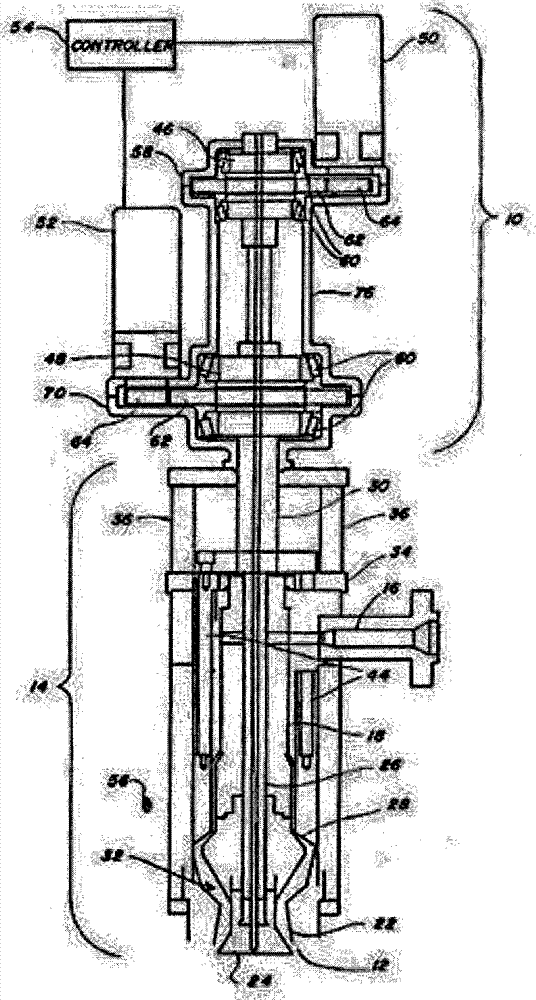

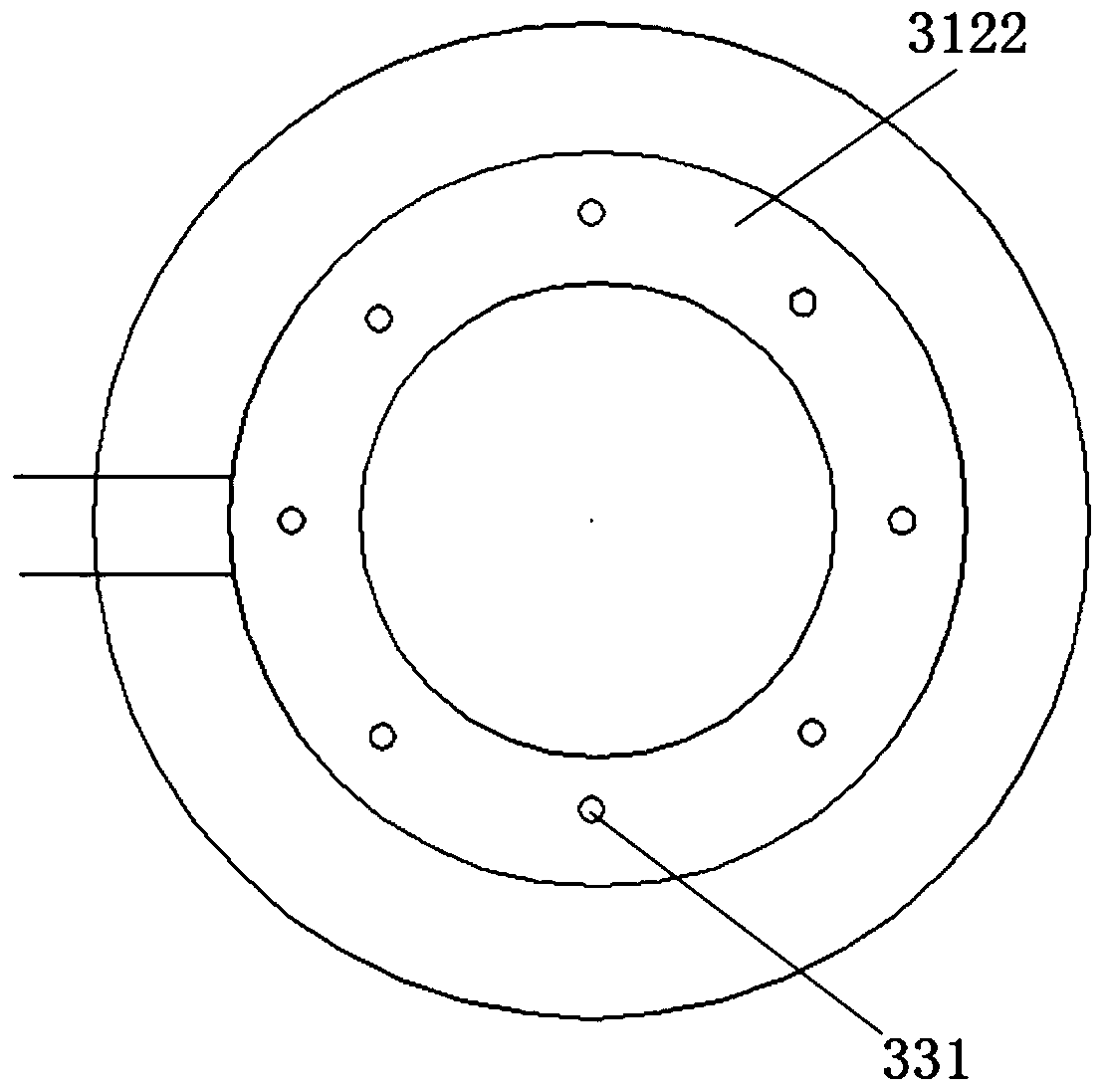

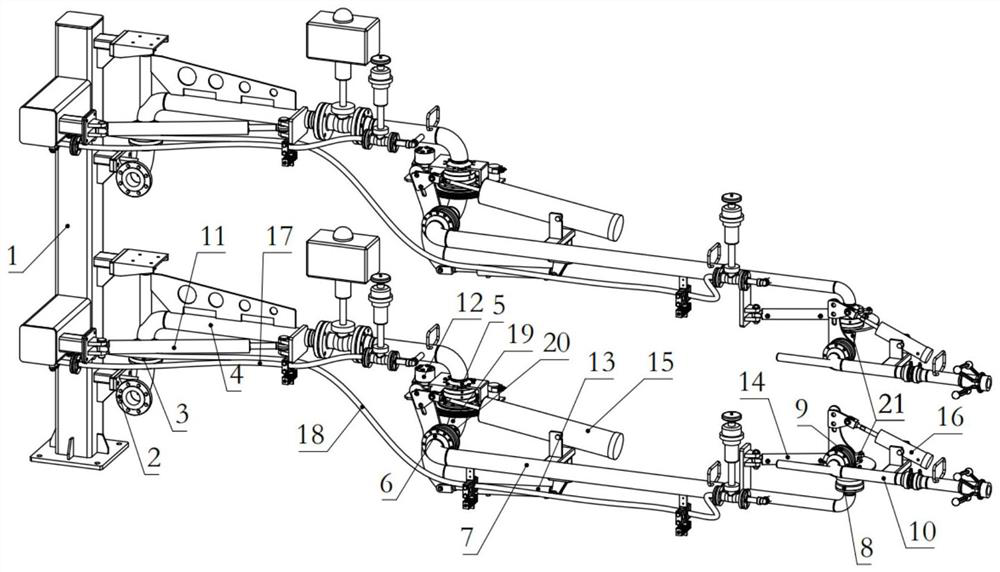

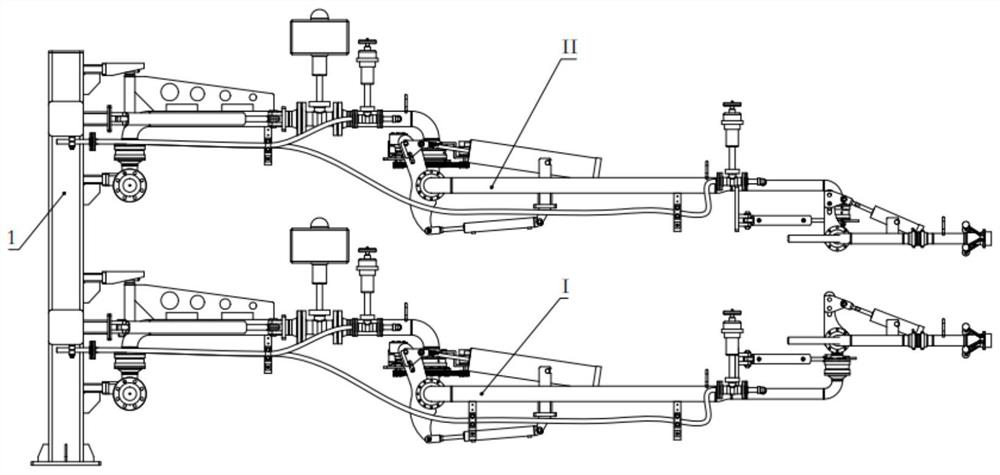

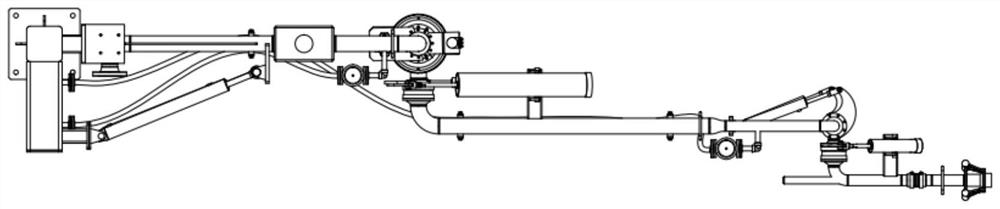

Semi-automatic tank car loading arm and control method thereof

ActiveCN112178451AReduce labor intensityHigh speedContainer filling methodsContainer discharging methodsBalancing machineControl engineering

Owner:JARI AUTOMATION CO LTD CHINA

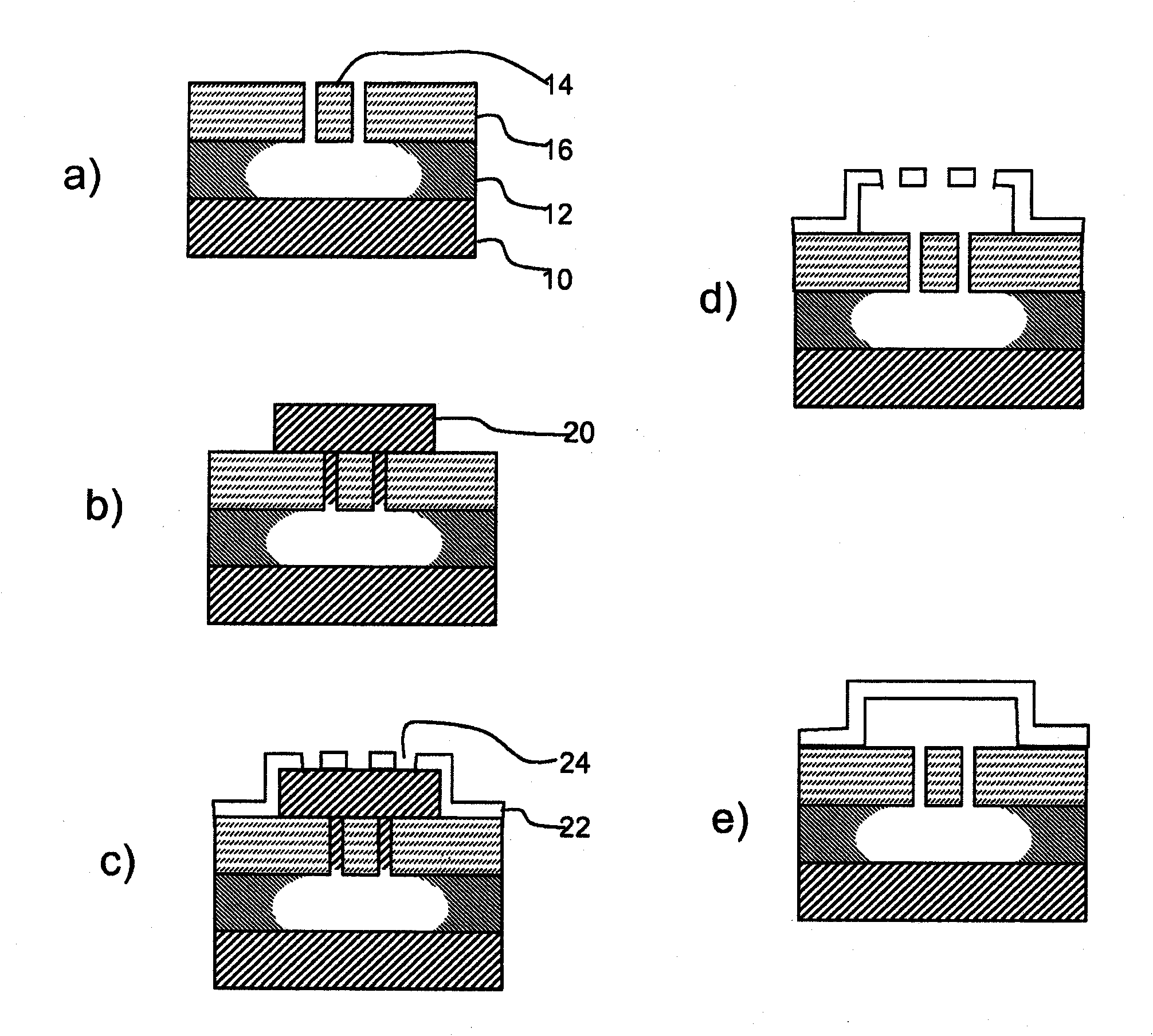

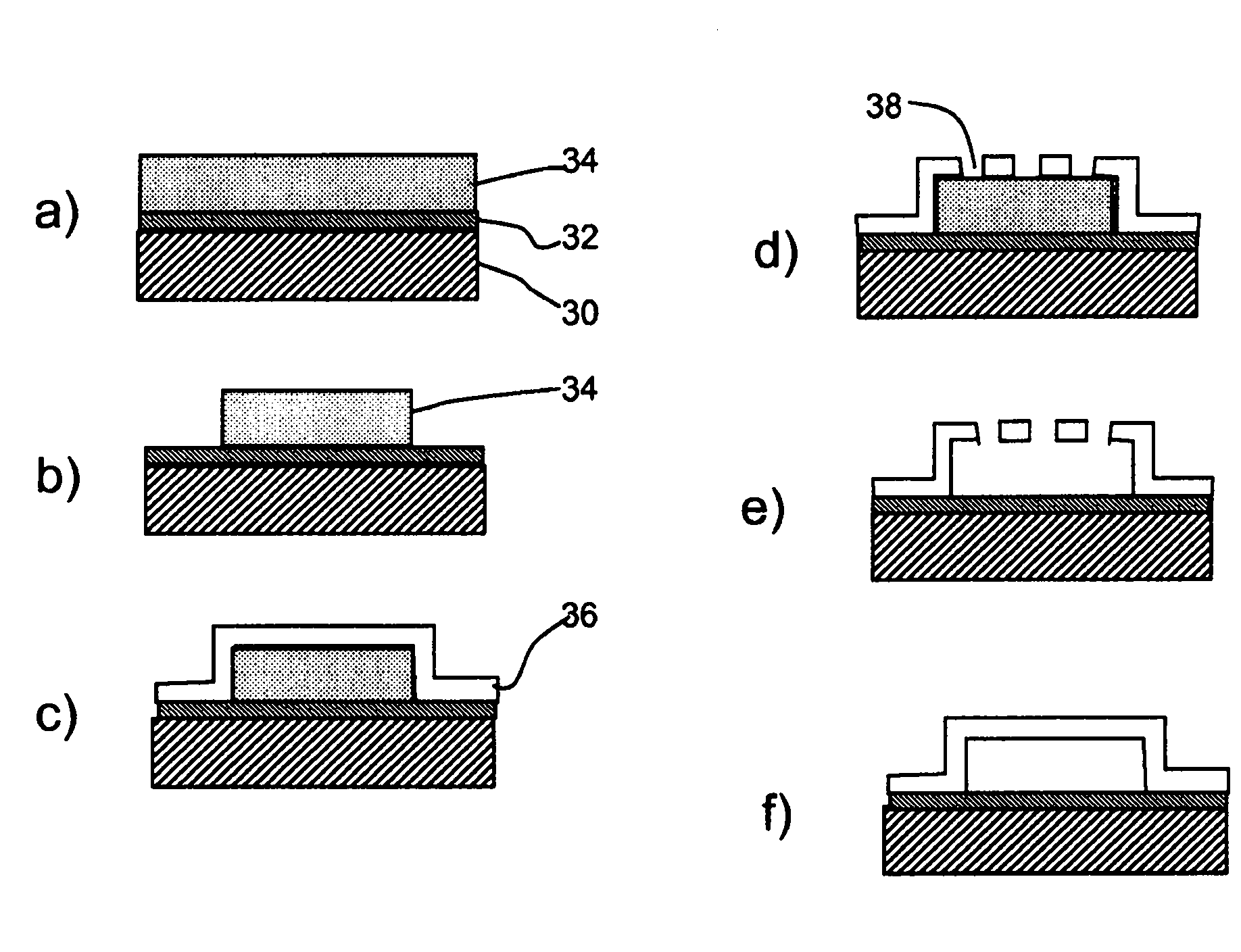

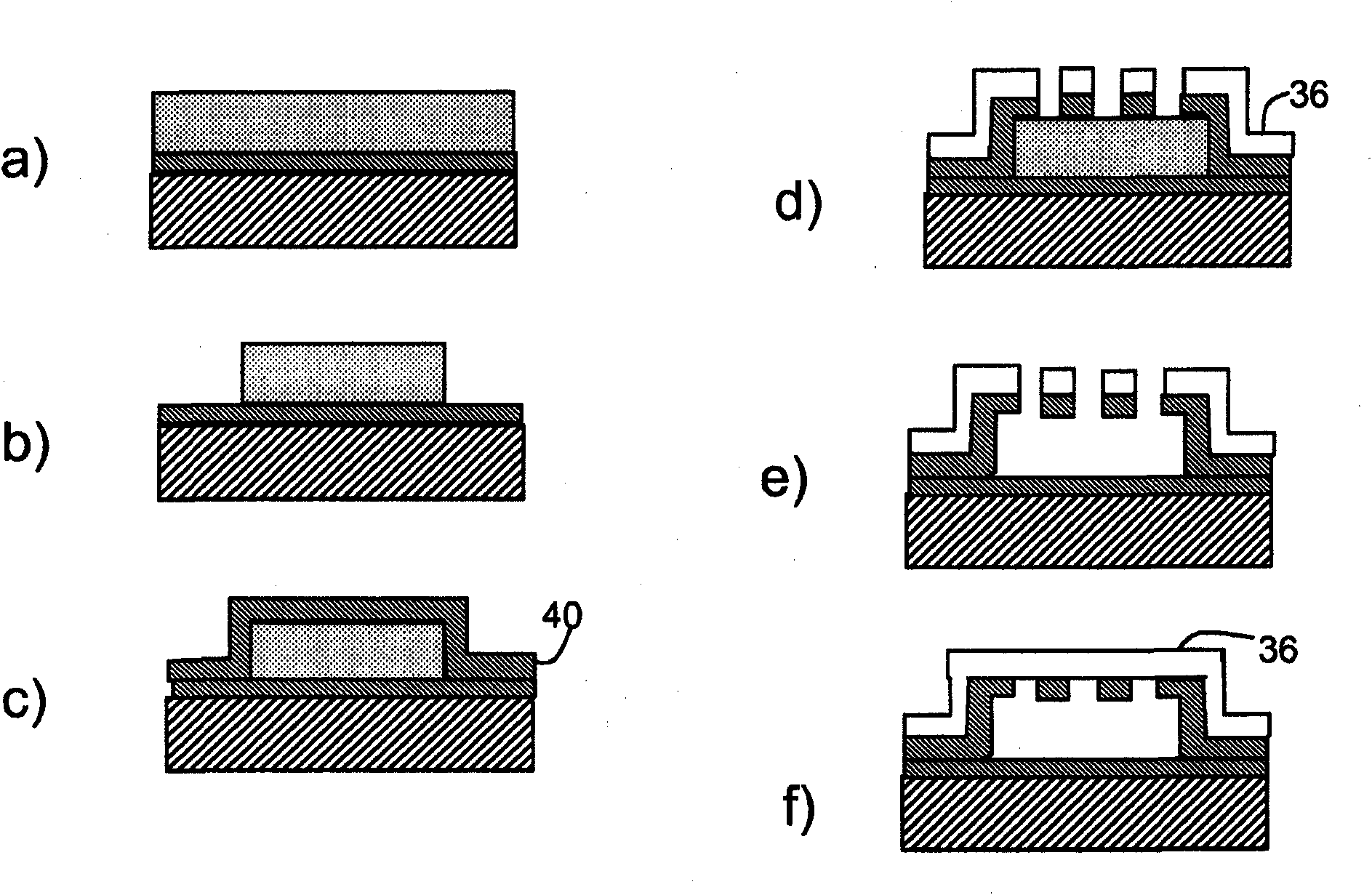

MEMS devices

InactiveCN102105389ASmall packageShort release timeDecorative surface effectsForming microstructural systemsEngineering

A method of manufacturing a MEMS device comprises forming a MEMS device element (14). A sacrificial layer (20) is provided over the device element and a package cover layer (22) is provided over the sacrificial layer. The sacrificial layer is removed using at least one opening (22) in the cover layer and the at least one opening (24) is sealed by an anneal process.

Owner:NXP BV

Preparation method of biodegradable nitrogen and phosphorus slow-release fertilizer

InactiveCN106380310AShort release timeNo pollution in the processSuperphosphatesAlkali orthophosphate fertiliserCarrageenanSodium stearate

The invention discloses a preparation method of a biodegradable nitrogen and phosphorus slow-release fertilizer and belongs to the field of fertilizer preparation technology. The preparation method comprises the following steps: a) mixing carrageenan, soyabean lecithin, rapeseed oil, a potassium dihydrogen phosphate solution, expanded vermiculite, fish protein powder and sodium stearate, and carrying out ultrasonic dispersion; b) coating a fertilizer master batch A with the mixed liquor, drying and cooling to room temperature so as to prepare fertilizer granules; c) mixing a fertilizer master batch B, expanded corn flour and the fertilizer granules so as to prepare compound fertilizer granules; and d) obtaining beta-cyclodextrin and a potassium nitrate solution, adding the compound fertilizer granules, stirring, drying and cooling to room temperature so as to prepare the biodegradable nitrogen and phosphorus slow-release fertilizer. The method is suitable for preparation of a water-soluble slow-release fertilizer. The coating material is a degradable material and is pollution-free to soil. The technology of the invention is simple and convenient to operate, has short technological cycle, causes no wastes, accords with the ideal of atom economy and environmental protection, and is beneficial to industrial promotion and application.

Owner:ZHEJIANG JULONG FERTILIZER CO LTD

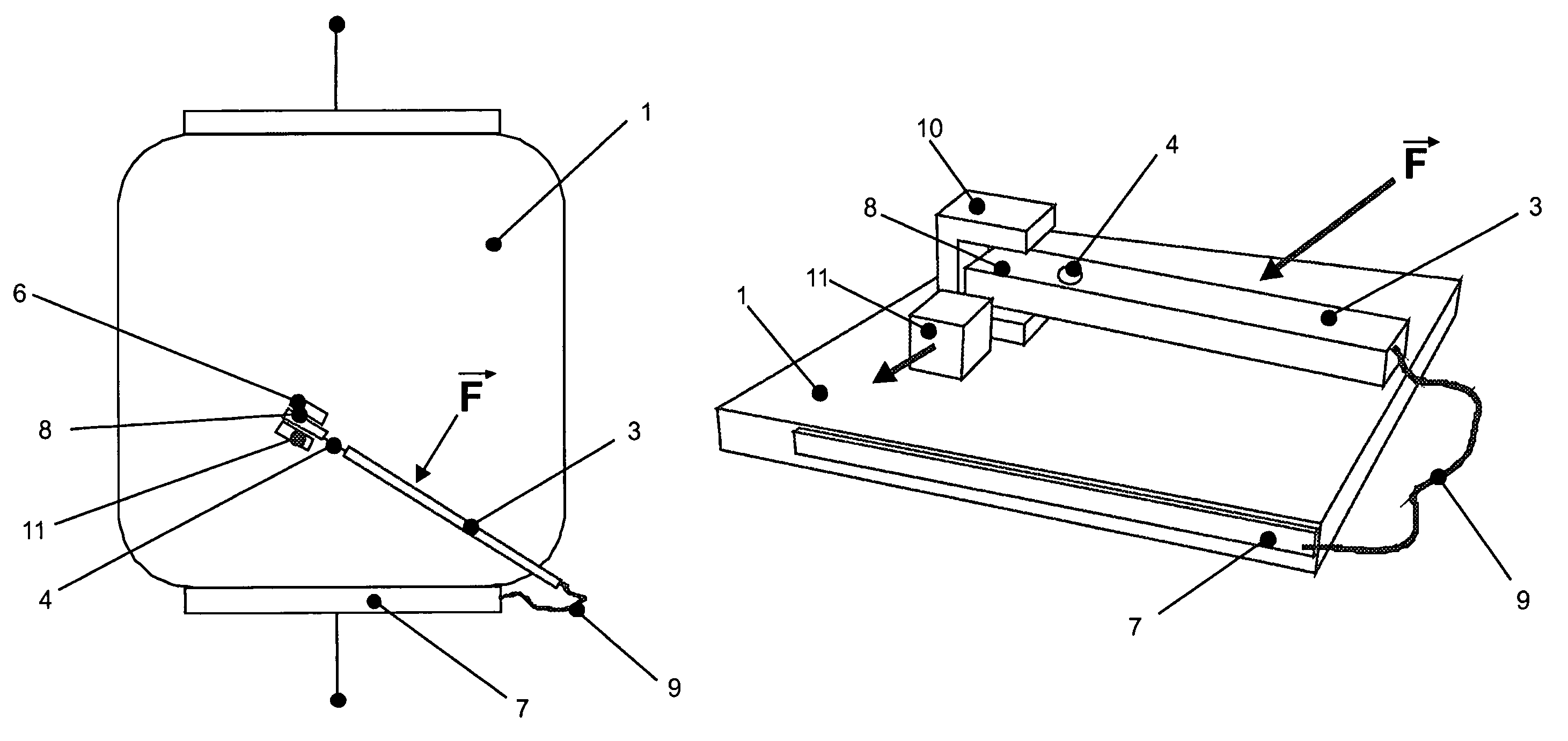

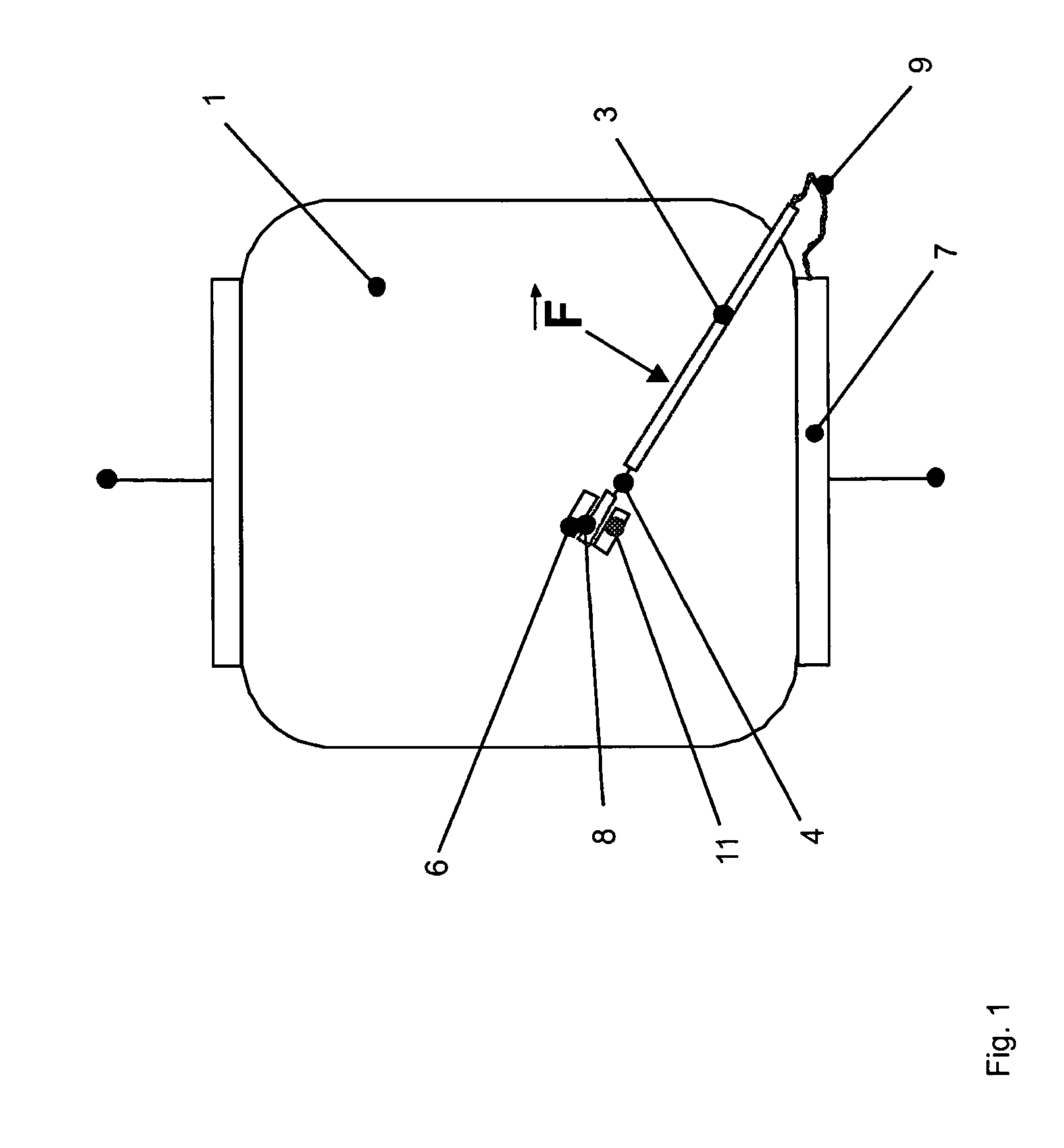

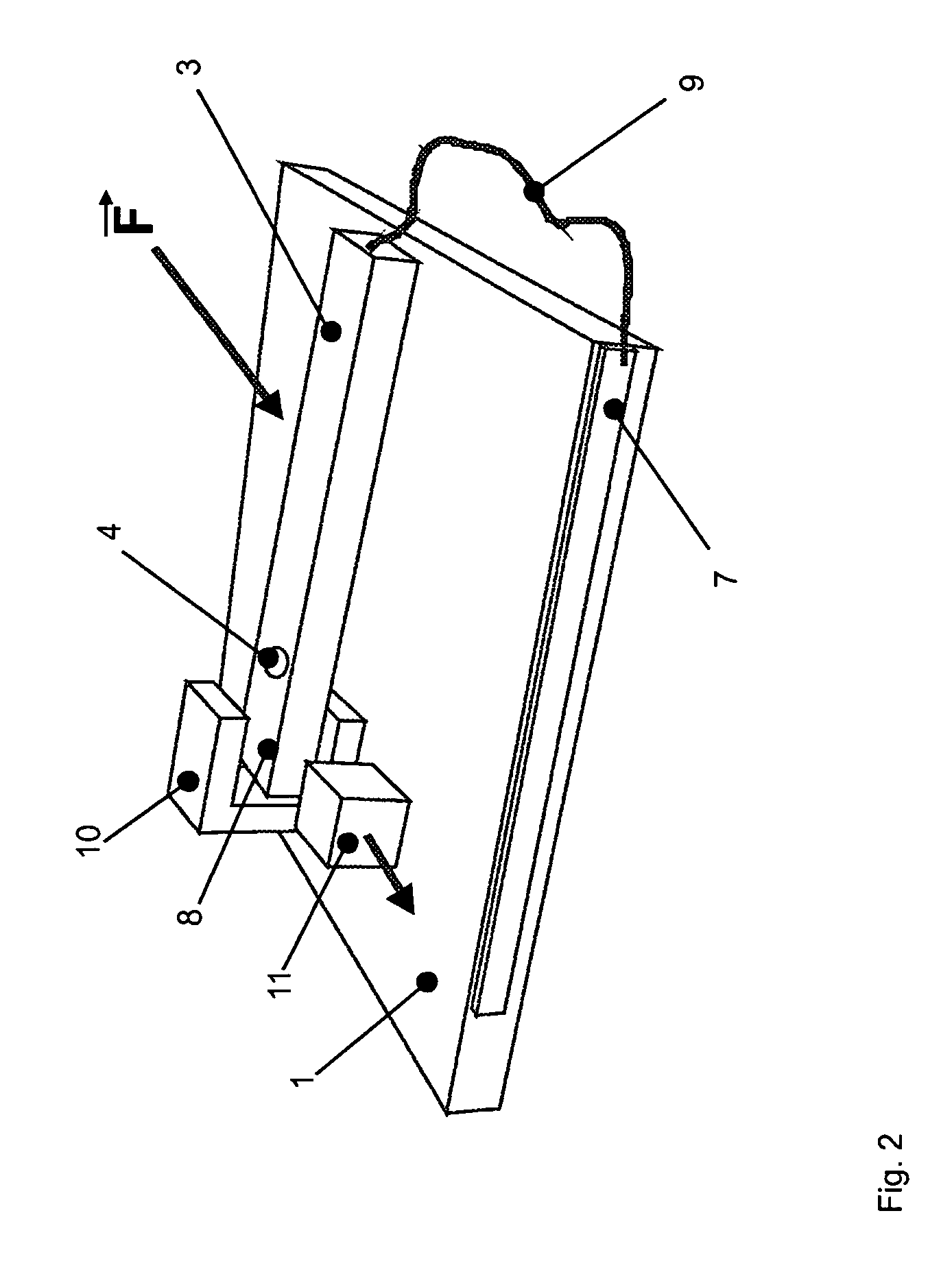

Rapid disconnect device

ActiveUS9130354B2Rapid disconnectionSimple meansSwitches with electrothermal openingSpark gap detailsElectricityPower grid

The invention relates to a rapid disconnect device for surge arrestors, in particular plate-type or flat varistors, comprising at least one element that is maintained under a mechanical stress, and a disconnection point for disconnecting the surge arrestor from the respective power grid upon thermal overload, wherein the disconnection point comprises contacts, the positions of which vary relative to one another, wherein one of said contacts is designed to be fixed. According to the invention, the contacts of varying positions relative to one another are electrically connected without the use of solder in such a way that incident current forces act primarily in the contact force direction and such that the moving contacts of the positionally-variable contacts of a lost element located at the surge arrestor and thermally detachable therefrom can be moved from a closed position to the disconnected position.

Owner:DEHN SOHNE GMBH CO KG

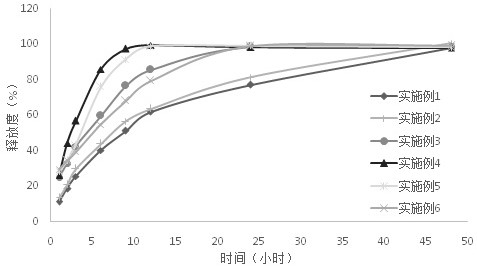

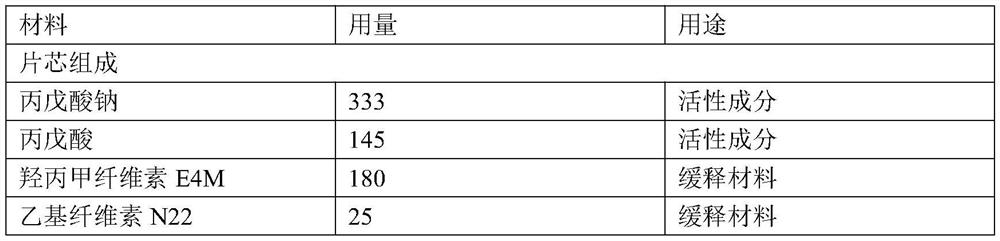

Sustained release tablet containing sodium valproate and preparation method thereof

PendingCN113616607AHigh production process technical control requirementsShort release timeNervous disorderPharmaceutical non-active ingredientsSustained Release TabletDrug utilisation

The invention aims to provide a sodium valproate sustained release tablet which is stable in drug release and safer in medication. The sodium valproate sustained release tablet is characterized by consisting of sodium valproate, valproic acid and physiologically acceptable auxiliary materials. The sustained release tablet provided by the invention has the characteristics of cheap and easily available prescription composition, simple process equipment, constant and lasting drug release and the like.

Owner:南京泽恒医药技术开发有限公司

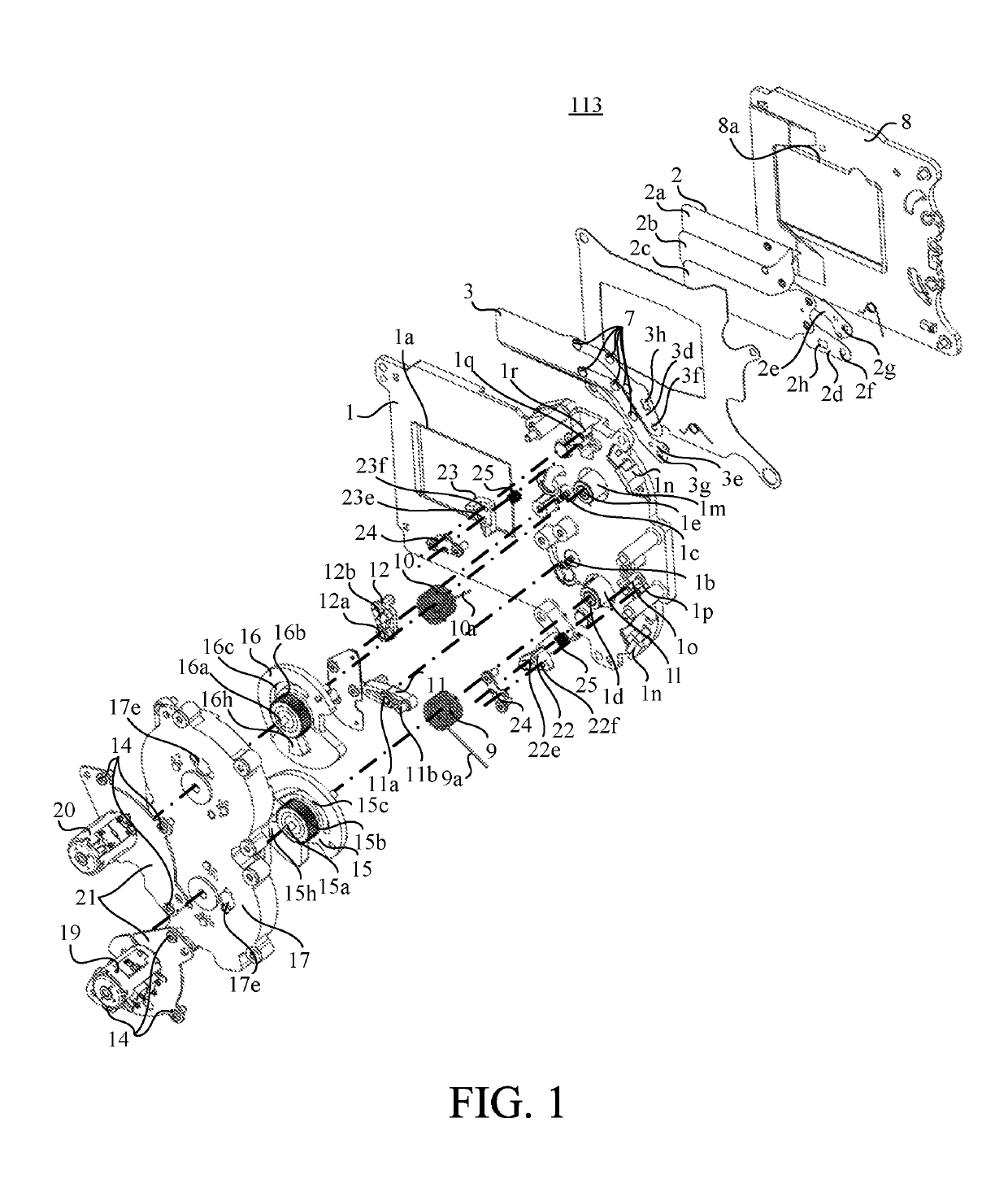

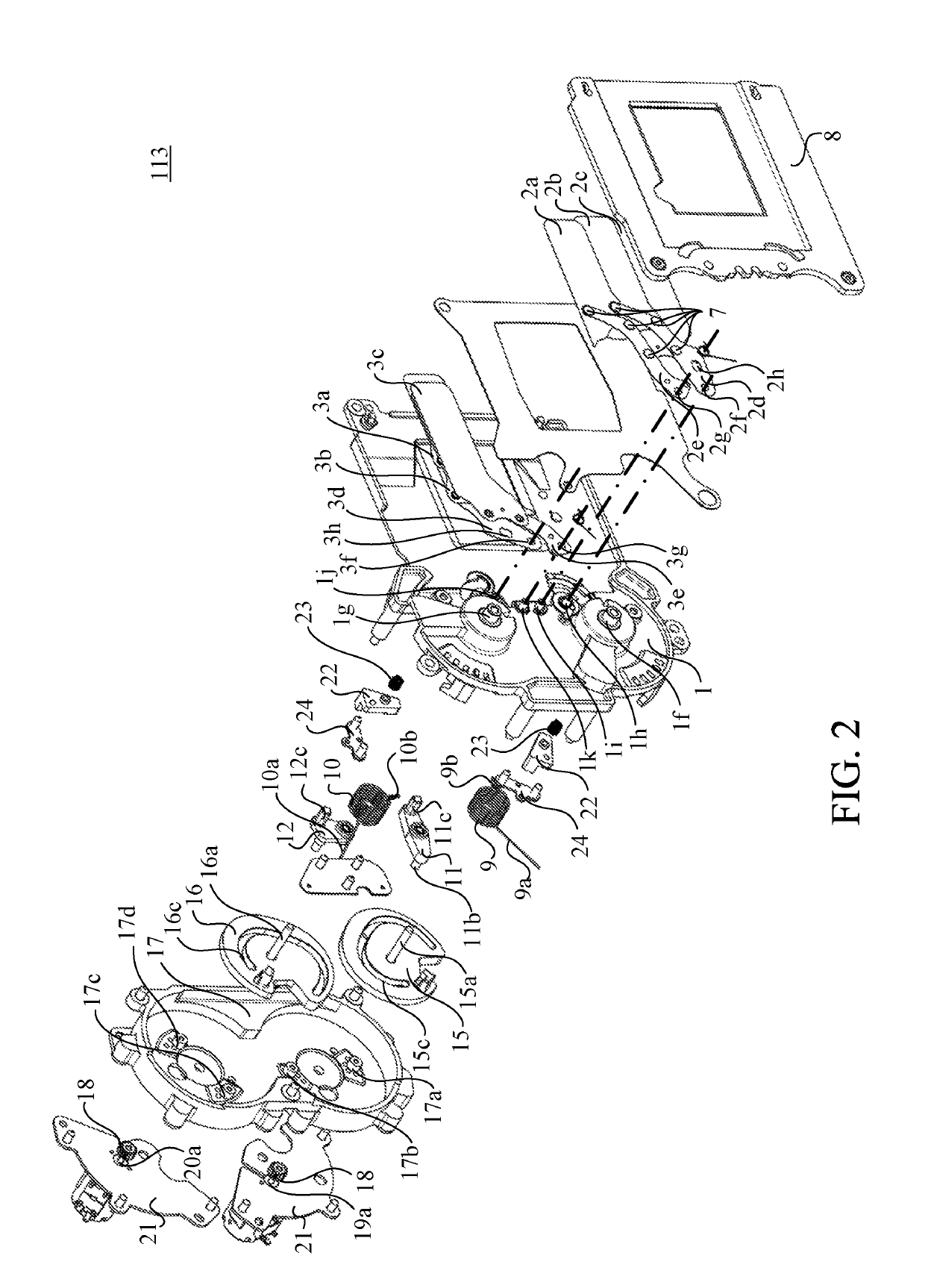

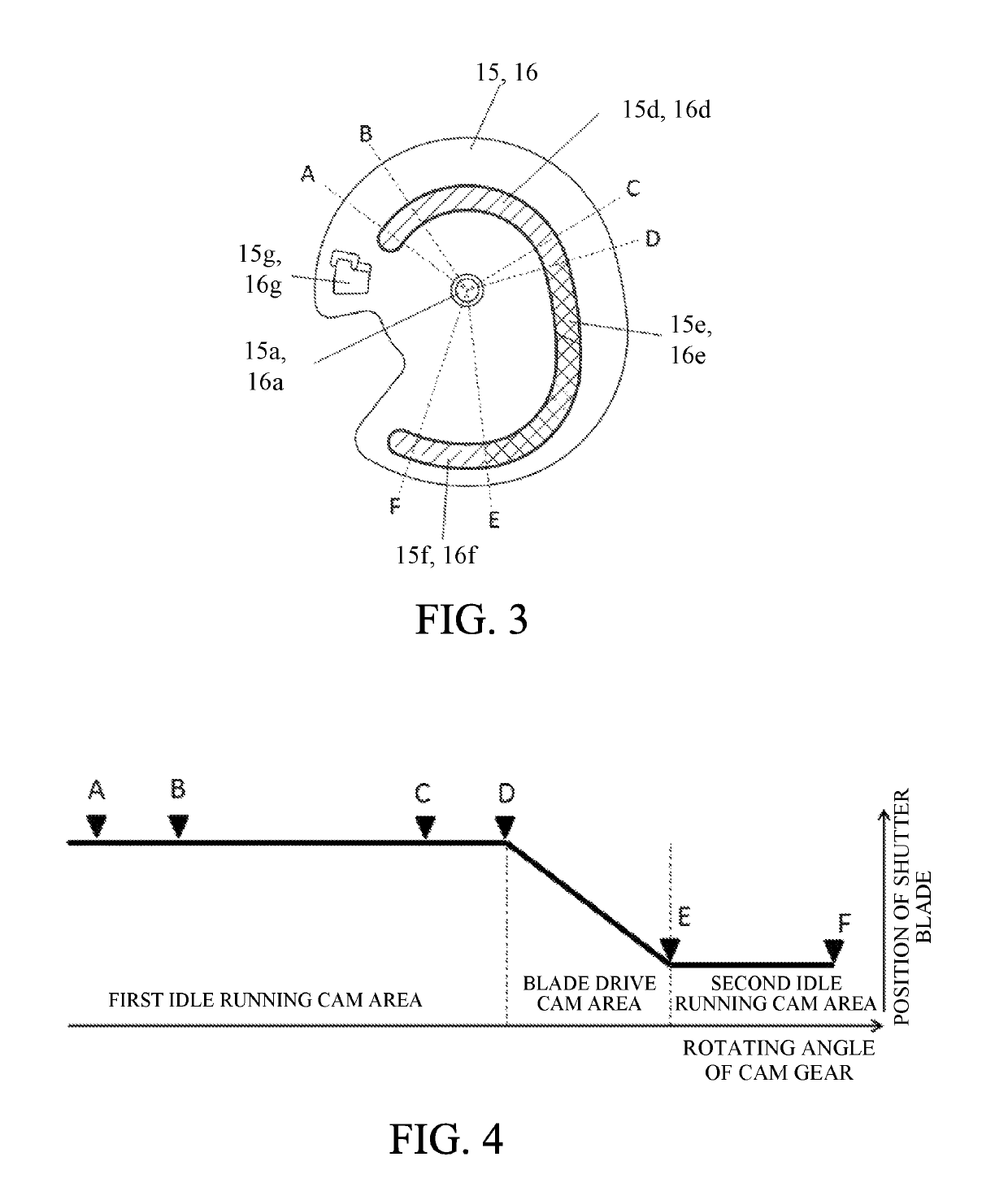

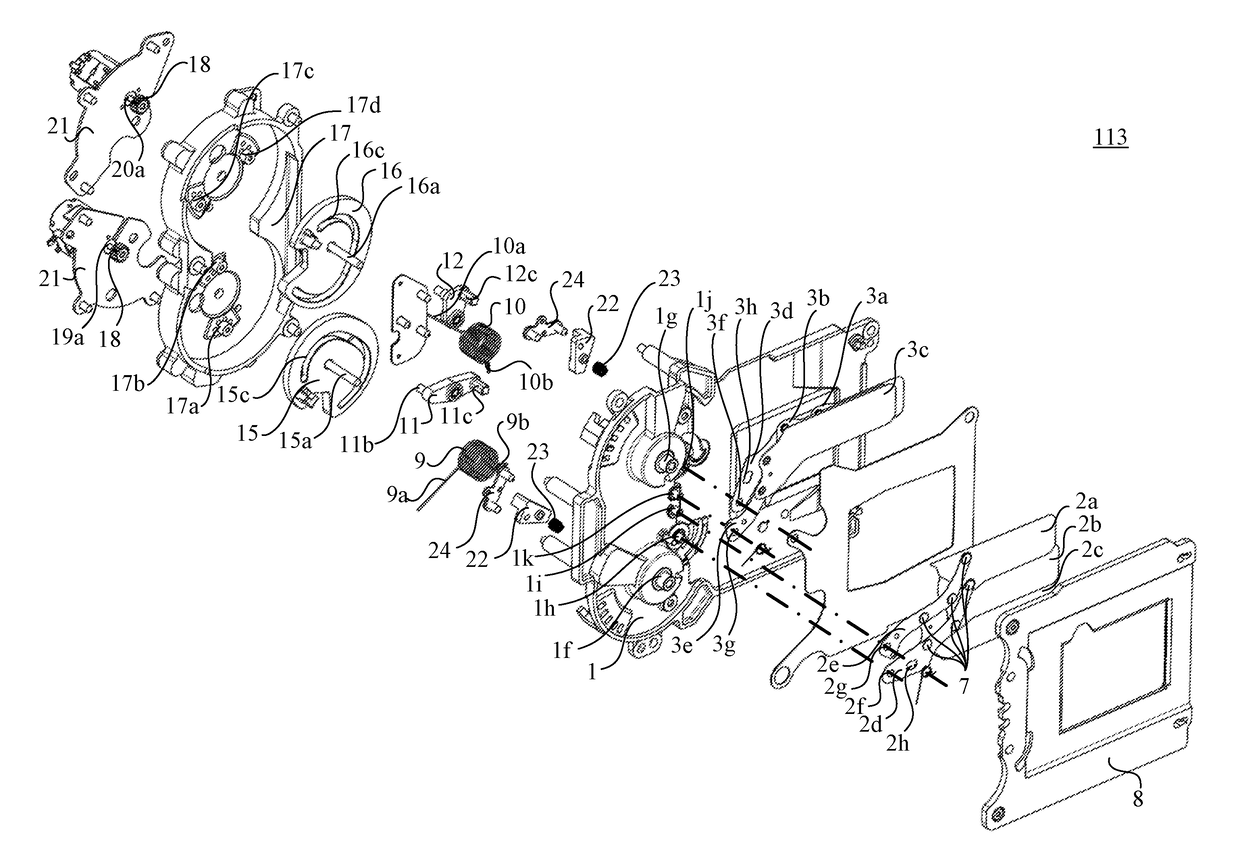

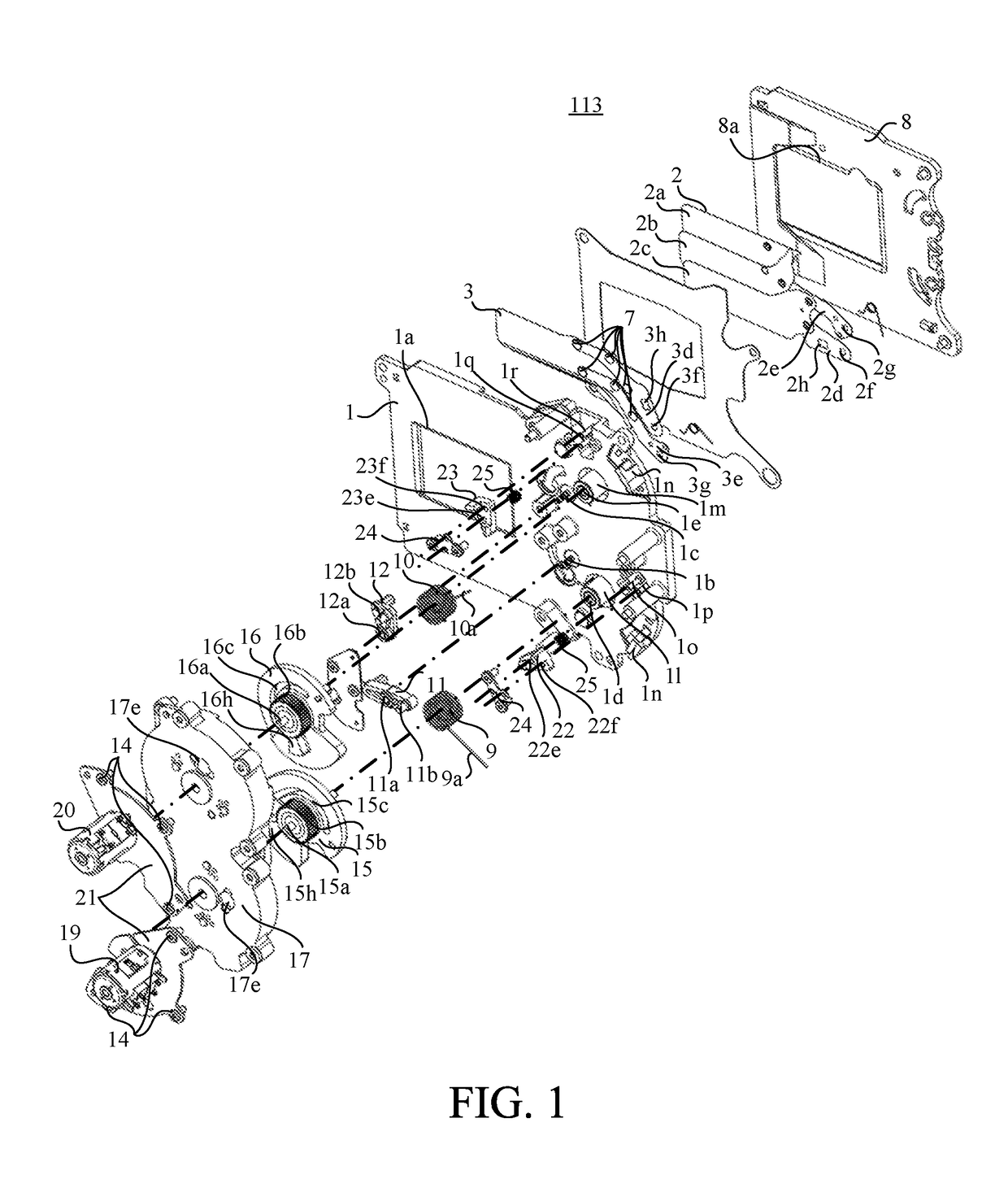

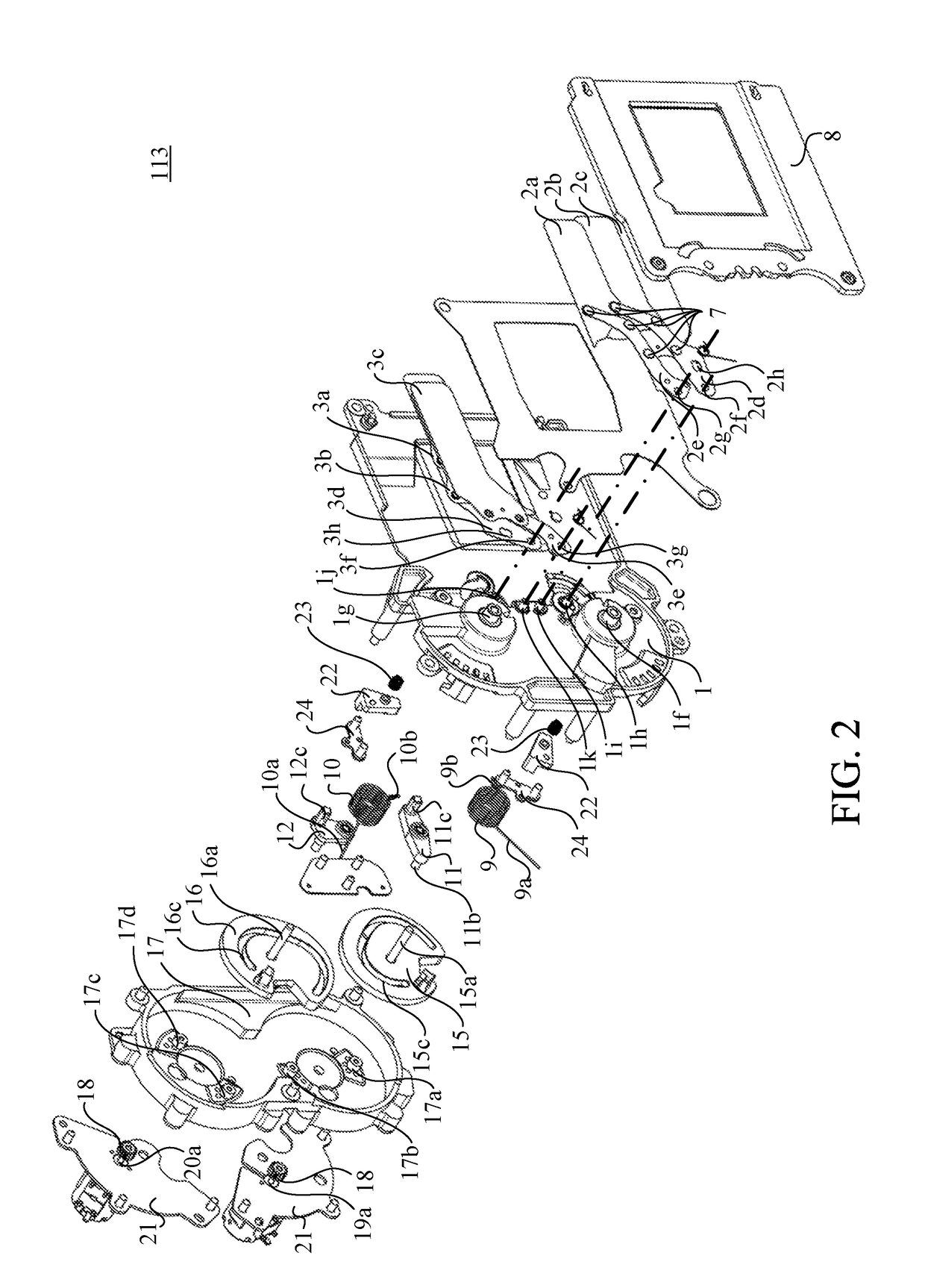

Shutter apparatus and image capturing apparatus

A shutter apparatus includes a shutter base plate having an opening, a light shield movable between a closed state for closing the opening and an open state for opening the opening, a cam member rotatable in a first angle range, a second angle range, and a third angle range between the first angle range and the second angle range, the cam member that rotates in the third angle range rotating the light shield, a motor configured to drive the cam member, a forcing member configured to force the cam member so as to rotate the cam member from the first angle range to the third angle range, and a restricting member configured to restrict the forcing member from forcing the cam member in at least part of the first angle range.

Owner:CANON KK

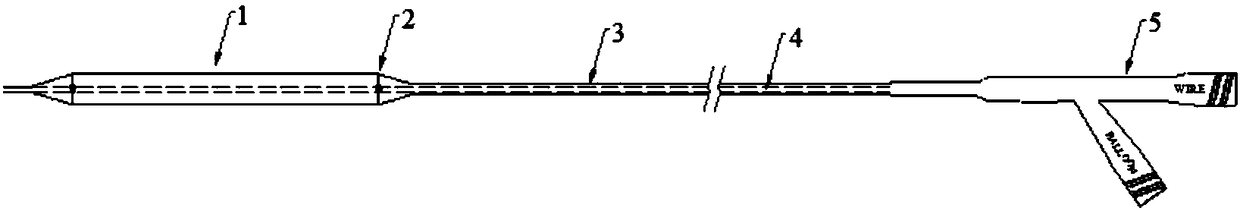

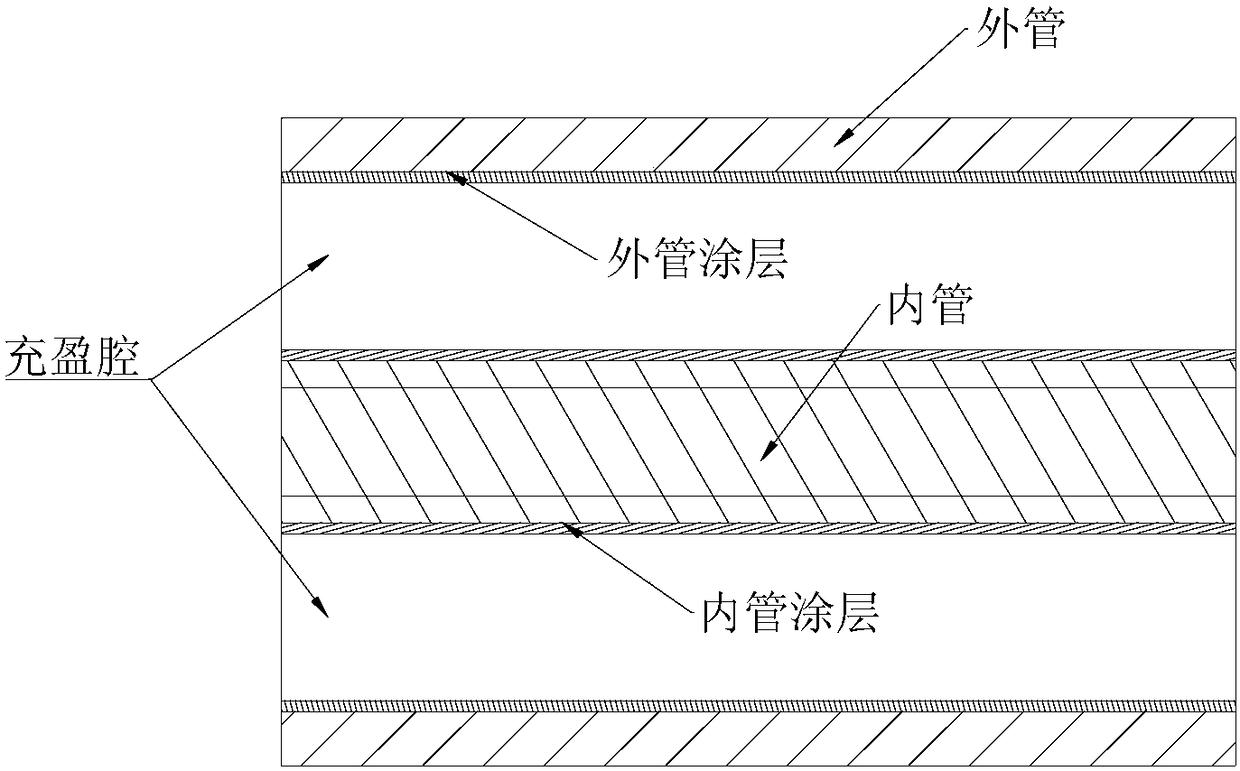

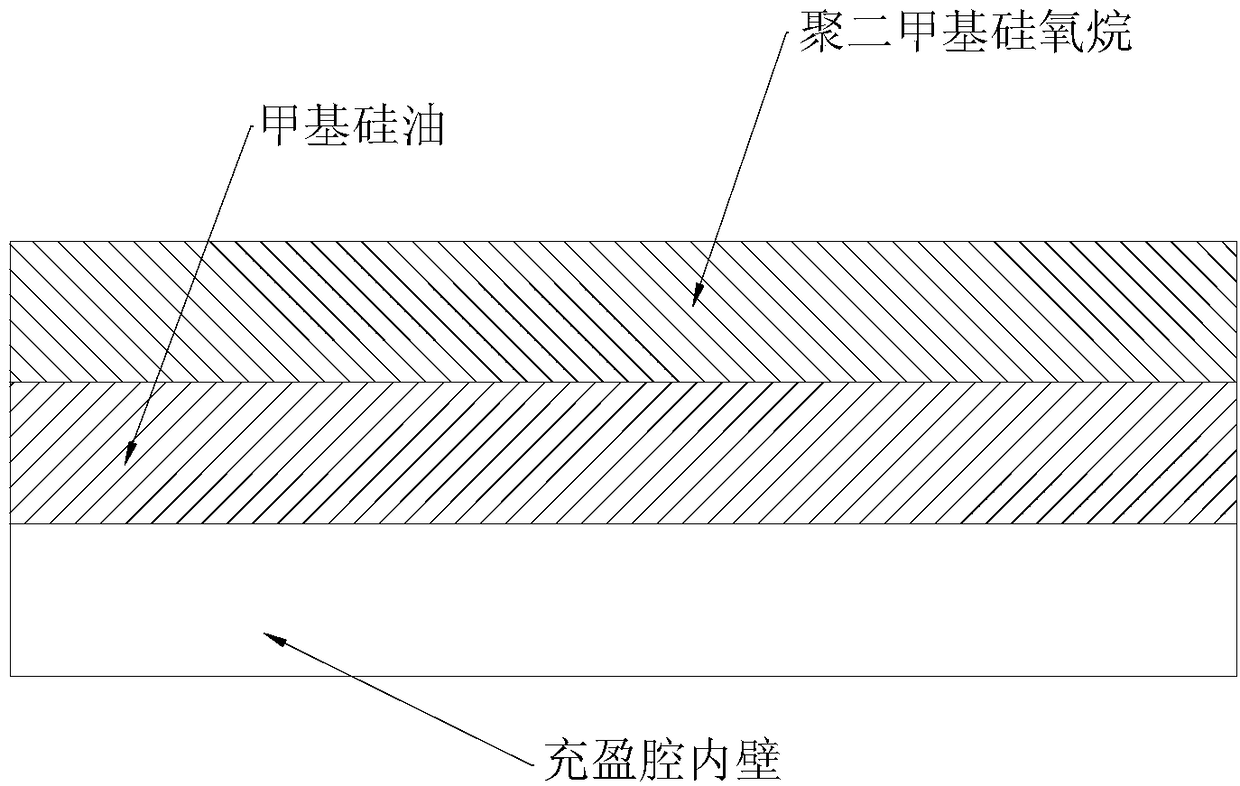

Balloon catheter

ActiveCN108211092AImprove surface smoothnessShort release timeBalloon catheterPretreated surfacesBalloon catheterSilicone oil

The invention discloses a balloon catheter. The balloon catheter comprises an inner tube, a balloon, a developing ring, an outer tube and a catheter base, wherein the developing ring is embedded in the inner tube through pressing, and the far end of the inner tube is fixed in a distal part of the balloon; the far end of the outer tube is fixed in the near end of the balloon, and the near end of the outer tube is fixed in the catheter base; the inner wall of the outer tube and the outer wall of the inner tube are both coated with a coating. Each coating comprises a methyl silicon oil layer anda polydimethylsiloxane layer, wherein the methyl silicon oil layer is arranged between the inner wall of the outer tube / the outer wall of the inner tube and the polydimethylsiloxane layer. A filling cavity of the balloon catheter is coated with a coating, so that the surface smoothness of the filling cavity is improved on the basis that the original the original pushing property, traceability andcompressive strength of the balloon catheter are kept, then the friction between the filling cavity and contrast liquid is reduced, and the pressure relief time of the balloon is shortened.

Owner:BIOTYX MEDICAL SHENZHEN CO LTD

Pressure relief device for ultra-high pressure sterilization apparatus

The invention relates to a pressure relief device for an ultrahigh pressure sterilization apparatus. The pressure relief device comprises an ultrahigh pressure cabin, at least an ultrahigh pressure source, at least a pressure sensor, at least a decompression valve and a control module. the invention is characterized in that ultrahigh pressure in the ultrahigh pressure cabin reaches a preset threshold value under pressurization of the ultrahigh pressure source; the control module gives instructions to the decompression valves to carry out at least one fast pressure relief on the basis of the preset threshold value of the ultrahigh pressure in the ultrahigh pressure cabin monitored by the pressure sensor such that ultrahigh pressure inside the ultrahigh pressure cabin is suddenly reduced. The decompression valves are arranged inside end caps for sealing two sides of the ultrahigh pressure cabin. The decompression valve comprises at least two decompression disks which are coaxially arranged and close fit with each other. At least two of the decompression disks make decompression areas on the decompression disks to be superposed or separated in an independent rotating mode so as to carry out pressure relief or pressure sealing. Pressure in the ultrahigh pressure cabin changes stably, and service life is prolonged.

Owner:BEIJING SUYUAN ZHONGTIAN SCI

Shutter apparatus and image capturing apparatus

ActiveUS20180196333A1Restrain power consumption amountShort release time lagShuttersLens hoodEngineering

A shutter apparatus includes a shutter base plate having an opening, a light shield movable between a closed state for closing the opening and an open state for opening the opening, a cam member rotatable in a first angle range, a second angle range, and a third angle range between the first angle range and the second angle range, the cam member that rotates in the third angle range rotating the light shield, a motor configured to drive the cam member, a forcing member configured to force the cam member so as to rotate the cam member from the first angle range to the third angle range, and a restricting member configured to restrict the forcing member from forcing the cam member in at least part of the first angle range.

Owner:CANON KK

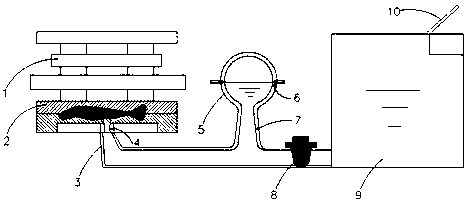

Aluminum alloy low-pressure casting device and process

The invention relates to an aluminum alloy low-pressure casting device and a process method of the aluminum alloy low-pressure casting device. According to the aluminum alloy low-pressure casting device and the process method of the aluminum alloy low-pressure casting device, a liquid lifting pipe is omitted, compressed air is injected into a pressure kettle instead of an original heat preservation furnace, the usage amount of the compressed air is saved, and the production efficiency of the low-pressure casting process is improved; a check plug is used to separate the low-pressure casting from the heat preservation furnace, so that aluminum alloy liquid can be added to the heat preservation furnace in real time without interrupting the low-pressure casting process, in this way, defectiveproducts influenced by the temperature field changes caused by continuous casting process interruption can be reduced, and the casting process yield is increased.

Owner:CITIC DICASTAL

Electronic musical instrument using on-on note times to determine an attack rate

An electronic musical instrument includes: an input device that inputs a sound generation instruction to start generating a musical sound and a stop instruction to stop the musical sound; an on-on time timer device that measures a time difference between a first and second sound generation instructions; a gate time timer device that measures a time difference between the second sound generation instruction and a stop instruction; an attack characteristic setting device that sets an attack characteristic of the musical sound to have a shorter attack time as the time difference measured by the on-on time timer device becomes shorter; and a release characteristic setting device that sets a release characteristic of the musical sound generated to have a shorter release time as the time difference measured by the gate time timer device becomes shorter.

Owner:ROLAND CORP

Preparation method of biological compound slow-release fertilizer

InactiveCN106336314AShort release timeNo pollution in the processSuperphosphatesAnimal corpse fertilisersEnvironmental resistanceSoybean Phospholipids

The invention discloses a preparation method of a biological compound slow-release fertilizer. The preparation method comprises the following steps: a) mixing bone glue, soybean phospholipids, soybean oil, soybean meal and iso-octyl palmitate, and then carrying out ultrasonic dispersion; b) uniformly coating a mixed solution on the surface of a fertilizer master batch A by using a way of vacuum spraying, then drying and cooling to room temperature to obtain fertilizer granules; c) taking a fertilizer master batch B and gelatinized starch to be mixed with the fertilizer granules, thus preparing compound fertilizer granules; d) taking starch sodium octenyl succinate and a potassium carbonate solution, mixing and stirring into paste, then adding to the compound fertilizer granules, stirring, drying and cooling to the room temperature to obtain the biological compound slow-release fertilizer. The preparation method disclosed by the invention is suitable for preparing the water-soluble slow-release fertilizer, and the material of a coating layer is a degradable material, so as to have no pollution to soil, furthermore, the preparation method is simple in process, convenient to operate and short in technical process cycle, and does not produce waste, so as to be in line with the concept of greenness and environmental protection of the atomic economy, and conducive to industrialized popularization and application.

Owner:ZHEJIANG JULONG FERTILIZER CO LTD

A kind of factory processing method of jasmine tea

The invention discloses an industrial processing method of jasmine tea, which adopts a segmented industrial process flow: jasmine fragrance exhalation with temperature control, humidity control and gas control, aroma capture of "negative pressure suction + activated carbon adsorption", and subcritical extraction Top aroma essential oil and flower dregs essential oil (the first stage of flowering season); essential oil temperature-controlled tea adsorption type aroma absorption, constant temperature airtight fragrance fixing, low-temperature drying (second stage of non-flowering season). The invention realizes automatic and refined control of the jasmine fragrance release environment, prolongs the fragrance exhalation time; effectively collects aroma substances through the aroma adsorption and capture technology, improves the quality of the essential oil with the subcritical extraction technology, and is easy for industrial production; finally, "jasmine flower Essential oil-tea scenting system breaks the traditional scenting mode of camellia mixing, realizes the possibility of scented tea production in non-flowering seasons, and realizes scented tea production towards automation and factory level.

Owner:闽榕茶业有限公司

Operating method of piston type two-way pressure relief valve

ActiveCN106051246ASimple structureImprove performanceEqualizing valvesSafety valvesEngineeringHigh pressure

The invention relates to an operating method of a piston type two-way pressure relief valve. The operating method is characterized in that when the pressure of the left and right ends of the piston type two-way pressure relief valve is the same, a piston is just in the center of a shell, the position of a partition of the piston corresponds to the position of a separating ring plate of the shell, and the piston does not move; when the pressure of the left end of the piston type two-way pressure relief valve is greater than that of the right end of the piston type two-way pressure relief valve, the partition is pushed to move rightwards by fluid, so that the piston moves rightwards, and the purpose of pressure relief is achieved; when the pressure of the right end of the piston type two-way pressure relief valve is greater than that of the left end of the piston type two-way pressure relief valve, the partition is pushed to move leftwards by the fluid, so that the piston moves leftwards, and the purpose of pressure relief is achieved. The operating method has the advantages of capability of achieving two-way pressure relief, simple structure, stable performance, short pressure relief time, high pressure relief speed, high precision and good sealing performance.

Owner:江苏金荣森制冷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com