Aluminum alloy low-pressure casting device and process

A low-pressure casting and aluminum alloy technology, applied in the field of aluminum alloy low-pressure casting devices, can solve the problems of material consumption, liquid lifting, long pressure relief time, inability to adapt to the fiercely competitive environment, and high production costs, saving pressure relief time, The effect of saving liquid liter time and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

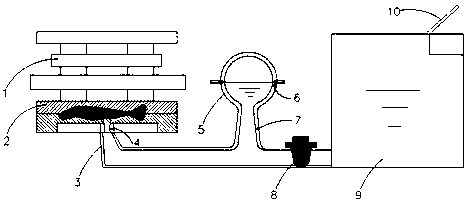

[0015] An aluminum alloy low-pressure casting process, the check plug 8 is opened after the mold 2 is closed, the aluminum alloy liquid in the holding furnace 9 is injected through the diversion groove 3, and the check plug is closed after the aluminum liquid in the pressure kettle 5 reaches the upper limit of the limited liquid level 8. Open the central plunger 11 at the same time, and inject compressed air into the autoclave 5 to implement the filling and pressure maintaining process of low-pressure casting. After the casting in the mold cavity is completely solidified, remove the pressure in the autoclave and empty the compressed air , open the mold and pick up the parts, and complete the entire low-pressure casting process.

[0016] Aluminum alloy low-pressure casting process device, the non-return plug 8 placed on the diversion groove 3 separates the low-pressure casting host 1 and the holding furnace 9, and can continuously add aluminum liquid to the holding furnace 9. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com