Extrusion blow molding machine-head-and-die-orifice gap electrical adjustment device and realization method and application thereof

An extrusion blow molding and electric adjustment technology is applied in the field of electric adjustment devices for the die gap of extrusion blow molding parison die, which can solve the problems of shortened service life, high production and manufacturing costs, heat generation, etc. Cost reduction and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

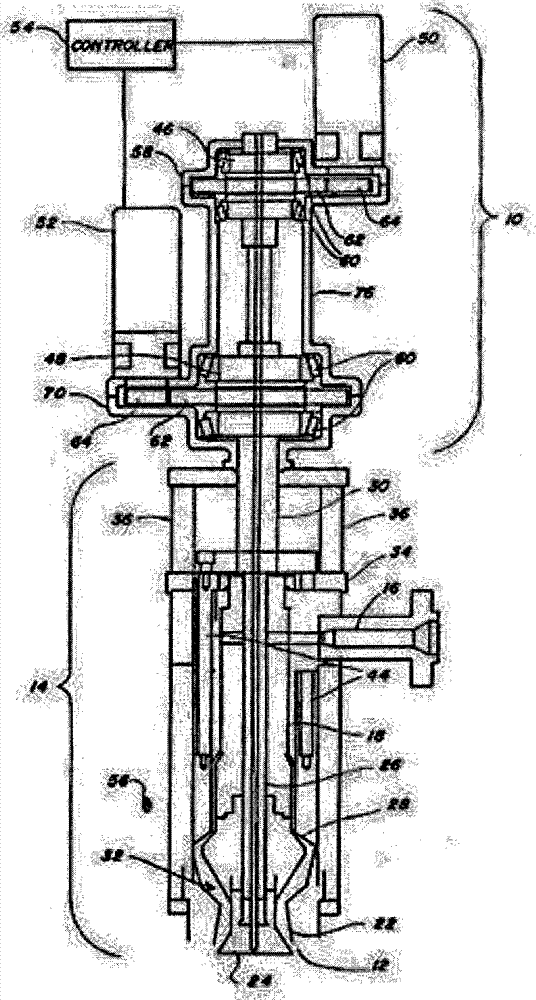

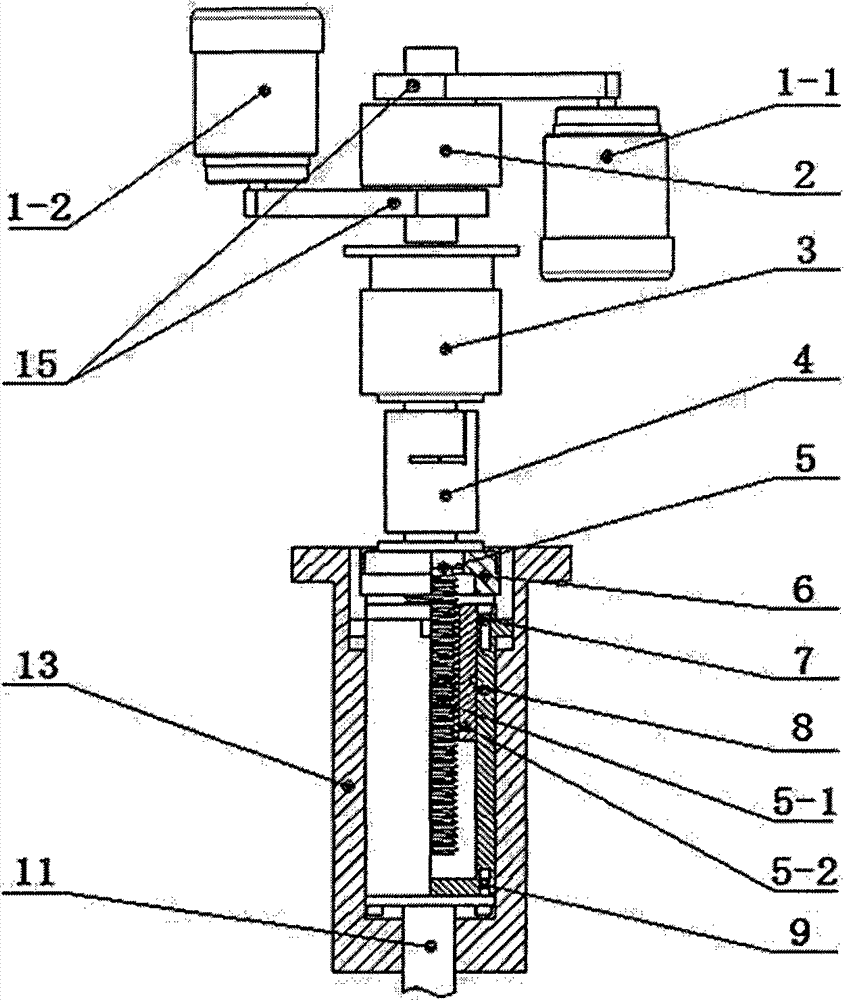

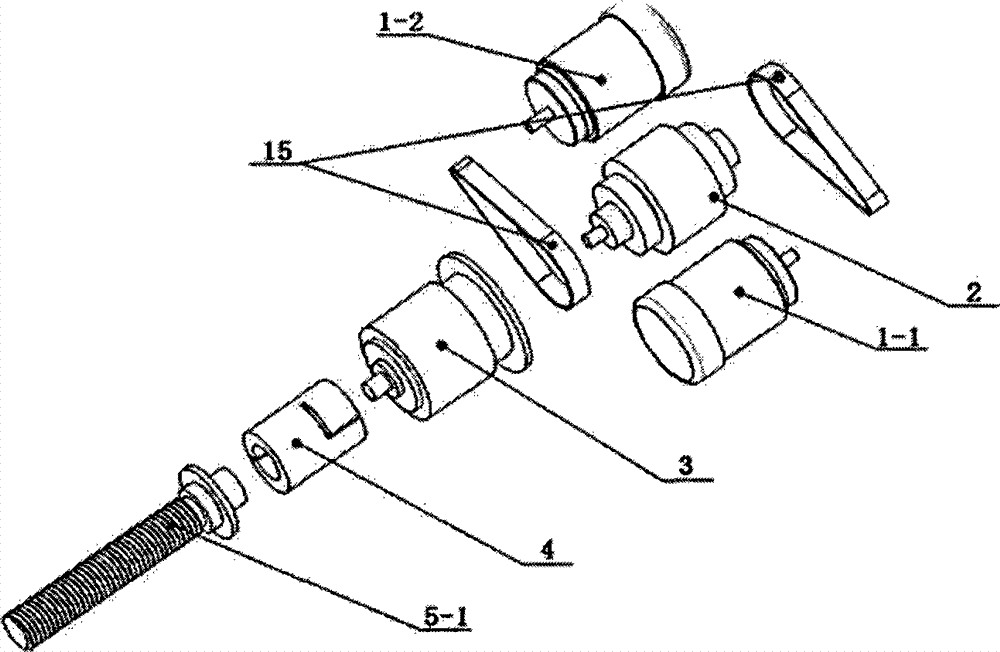

[0026] Concrete structure of the present invention sees Figure 2-7 . Figure 2-7 It is shown that the electric adjustment device for the gap between the die and mouth of the extrusion blow molding machine includes motors 1-1 and 1-2, a synchronous belt 15, a clutch reversing device 2, a reducer 3, a coupling 4, a ball screw pair 5, Thrust roller bearing 6, sleeve 13 with chute, sleeve 8 with Oldham slider, and mandrel 11 connected thereto.

[0027] The clutch reversing device 2 adopts a clutch assembly composed of a forward clutch 2-4, a reverse clutch 2-5 and a brake clutch 2-6, and its forward input end cover 2-2 and reverse input end cover 2-3 are respectively connected to the motors 1-1 and 1-2 through the synchronous belt 15, when the forward clutch 2-4 or the reverse clutch 2-5 is energized and engaged, the output shaft 2-1 and the input end cover 2- 2 or 2-3 are connected to form forward or reverse output; when the brake clutch 2-6 is energized and engaged, the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com