Vacuum treatment system valve assembly and chemical vapor deposition system

A chemical vapor deposition, valve assembly technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of sealing between processing chamber and transmission chamber, difficult conduction control, complex sealing valve structure, etc. , to achieve strong corrosion resistance, improve sealing and conduction effects, and improve work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

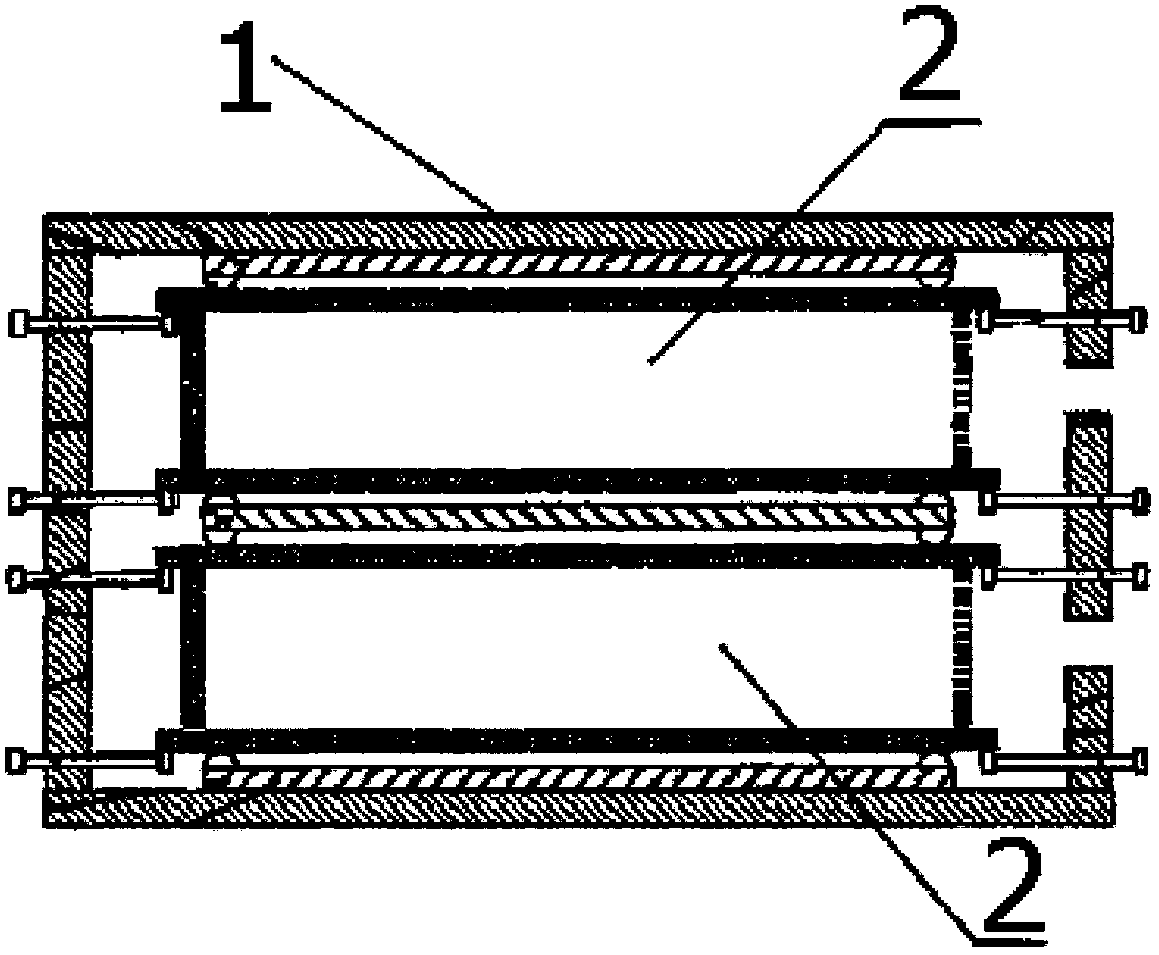

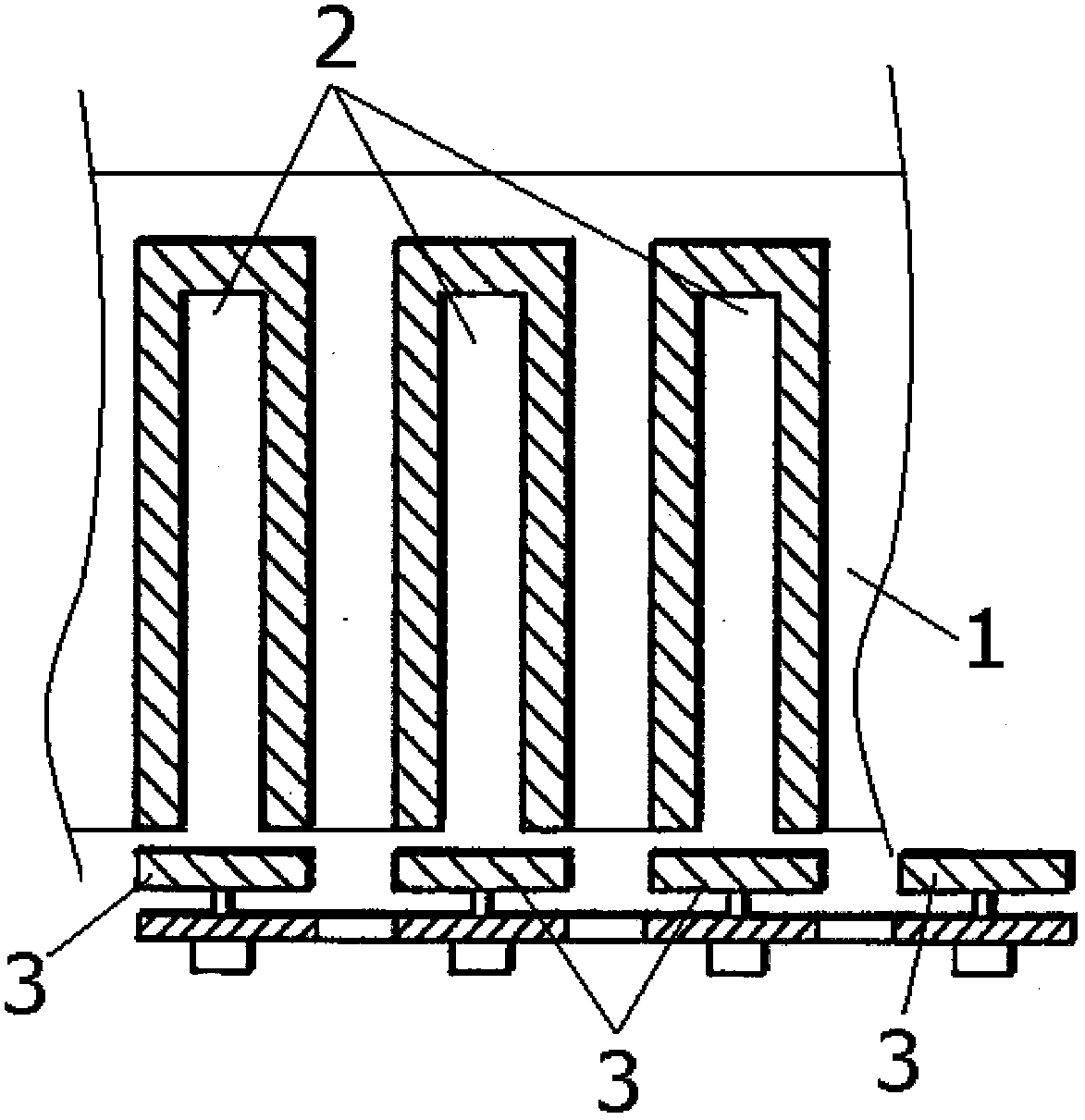

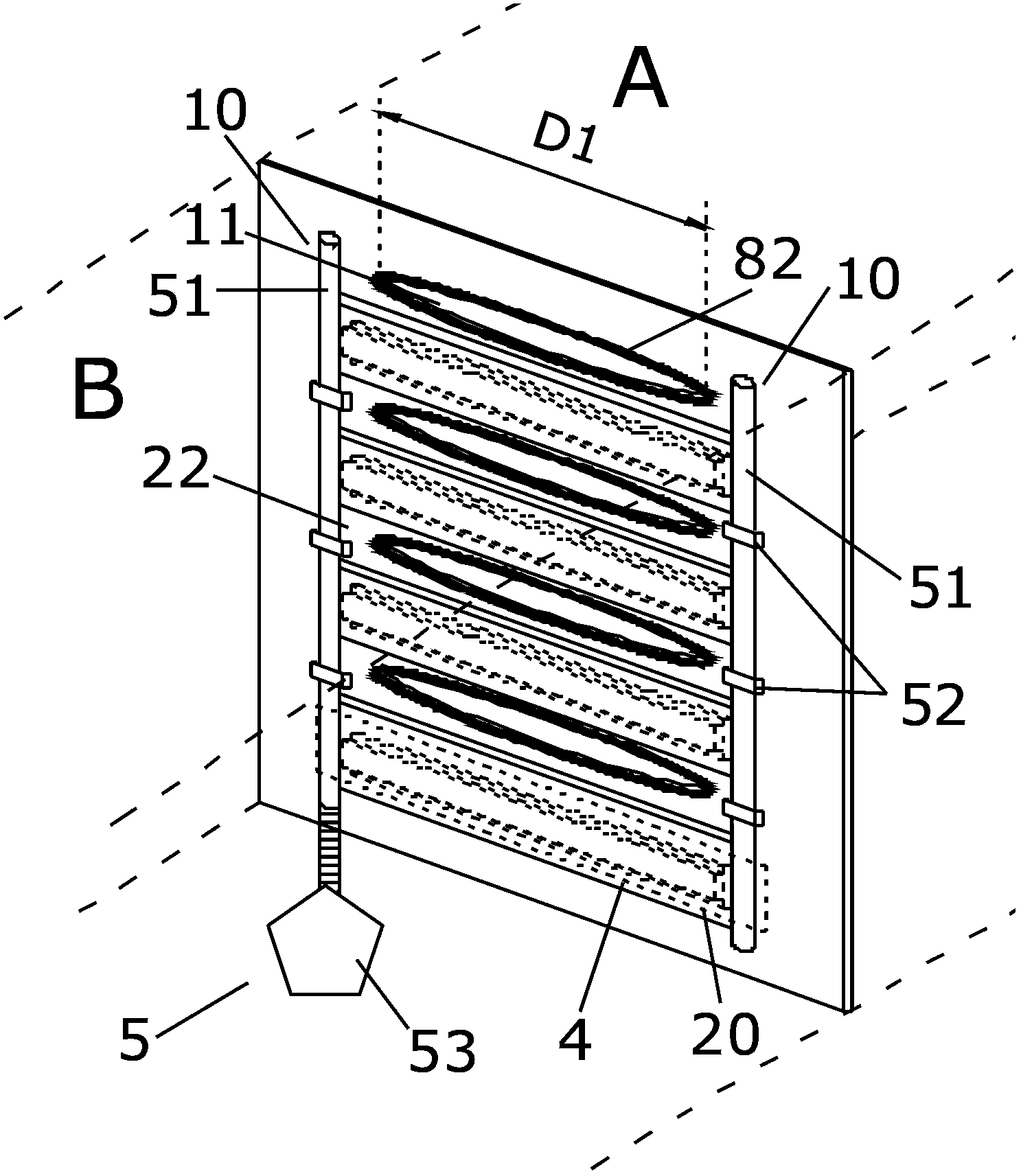

[0053] As described in the background art, in the PECVD process, in order to improve the production efficiency of PECVD film deposition, the PECVD processing chamber includes a plurality of reaction sub-chambers. However, as in the solar panel substrate film deposition process, the length of the opening between each reaction sub-chamber and the transfer chamber is large, and both sides of the sealing valve (between the transfer chamber and each reaction sub-chamber) during the PECVD film deposition process Due to the large pressure difference and the pressure difference between the reaction sub-chambers, it is difficult to ensure the tightness of each reaction sub-chamber 2 in the thin film deposition process by using a single sealing valve. Therefore, in the existing PECVD system, an independent sealing valve is generally arranged between each reaction sub-chamber and the transmission chamber, and the sealing or opening linkage control between the sealing valves is realized thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com