Light splitting pupil confocal Raman-LIBS-mass spectrum detection-based femtosecond laser machining and monitoring method and device

A femtosecond laser processing and monitoring device technology, used in measurement devices, analytical materials, thermal excitation analysis, etc., can solve the problems of easy axial drift of samples, in-situ detection of complex morphological performance parameters of samples, etc., and achieve high precision. Real-time fixed focus problem, improve axial position monitoring ability and axial dimension detection ability, and solve the effect of drift problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

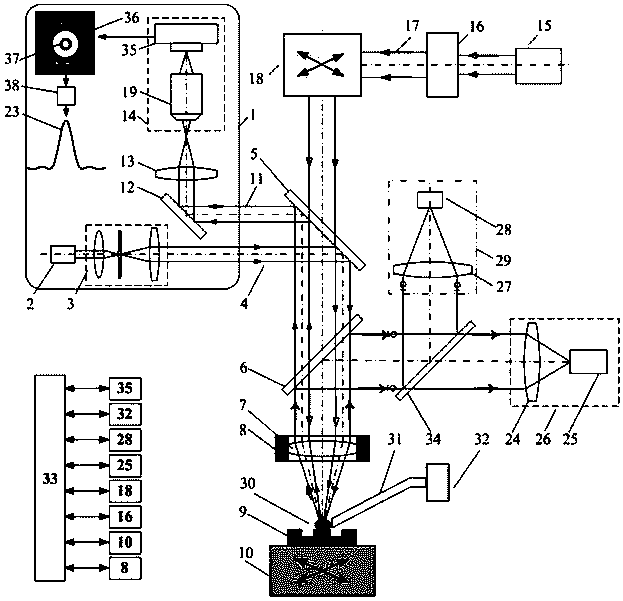

[0051] Such as figure 1 , using the split-pupil confocal axial monitoring module 1 to monitor the surface position of the sample 9 before processing and the axial position of the sample 9 during processing, the computer 33 monitors the two-dimensional scanner 18, the precision table 10, and the axial scanner 8 performs feedback control to realize three-dimensional scanning and position adjustment of the processing and monitoring of the sample 9;

[0052] The split pupil detector 14 is composed of a spot magnifying objective lens 19 , a pinhole 20 and a light intensity detector 21 . The implementation steps of the femtosecond laser processing monitoring method with split-pupil confocal Raman-LIBS-mass detection are as follows:

[0053] Step 1: Place the sample 9 on the precision workbench 10, and the precision workbench 10 drives the sample 9 to scan;

[0054] Step 2: Before processing, use the split-pupil confocal axial monitoring module 1 to scan and measure the surface of ...

Embodiment 2

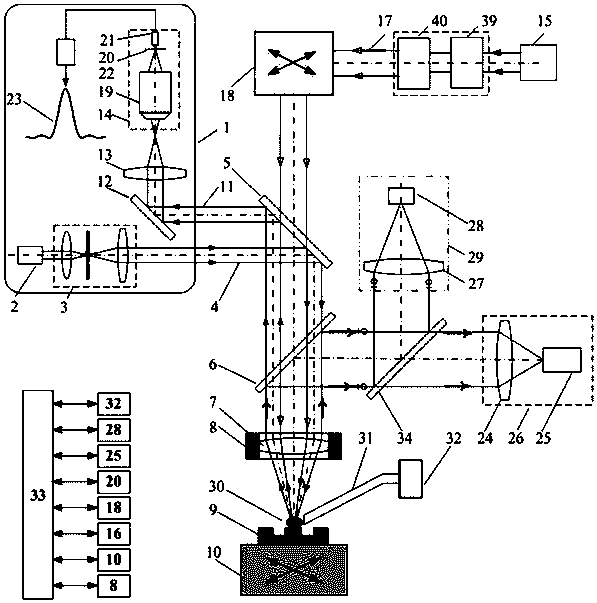

[0063] Such as figure 2 As shown, the split pupil detector 14 is composed of a spot enlargement objective lens 19, a detection CCD35, a detection area 37 and an image signal processor 38, wherein the detection area 37 is located at the center of the image plane of the detection CCD35; 1 When monitoring the axial position and axial size of the sample 9 during processing, the axial monitoring parallel beam 4 is reflected by the dichroic mirror A5 and transmitted by the dichroic mirror B6, and then focused onto the sample 9 by the objective lens 7, The reflected axial monitoring light beam 11 reflected by the sample 9 is converged on the detection CCD35 by the reflector 12, the detection objective lens 13, and the spot magnification objective lens 19, and the image signal processor 38 processes the signal of the detection area 37 on the image surface of the detection CCD35 , to obtain the split-pupil confocal signal of a point on the surface of sample 9.

[0064] All the other ...

Embodiment 3

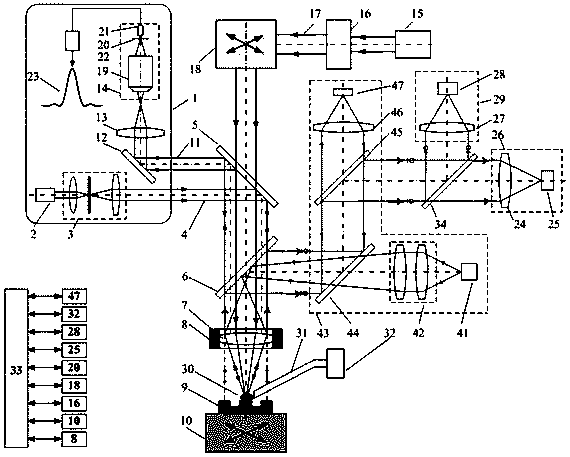

[0066] Such as image 3 As shown, the laser space-time shaping module 16 is composed of a space shaper 39 and a time shaper 40, and adjusts the time domain and space domain parameters of the light beam emitted by the femtosecond laser 15, so as to optimize the femtosecond laser processing performance.

[0067] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com