Adjustable mounting frame and unmanned aerial vehicle thereof

A mounting frame and adjustable technology, which is applied in the layout/installation of power units, aircraft parts, transportation and packaging, etc., can solve the problems of low adjustment and positioning efficiency, poor installation and maintenance flexibility, and cumbersome operation, so as to improve the adjustment and positioning efficiency , Improve the flexibility of installation and maintenance, and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

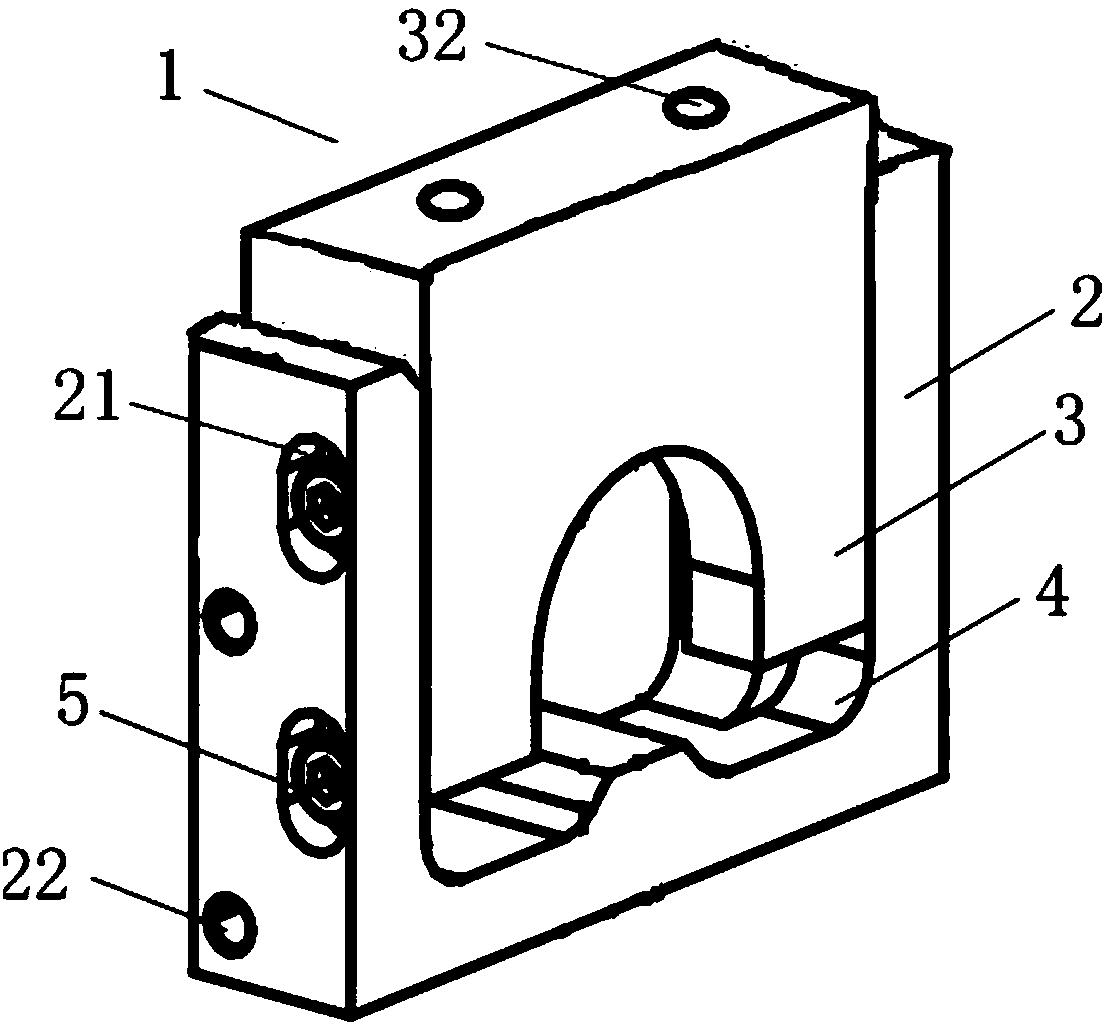

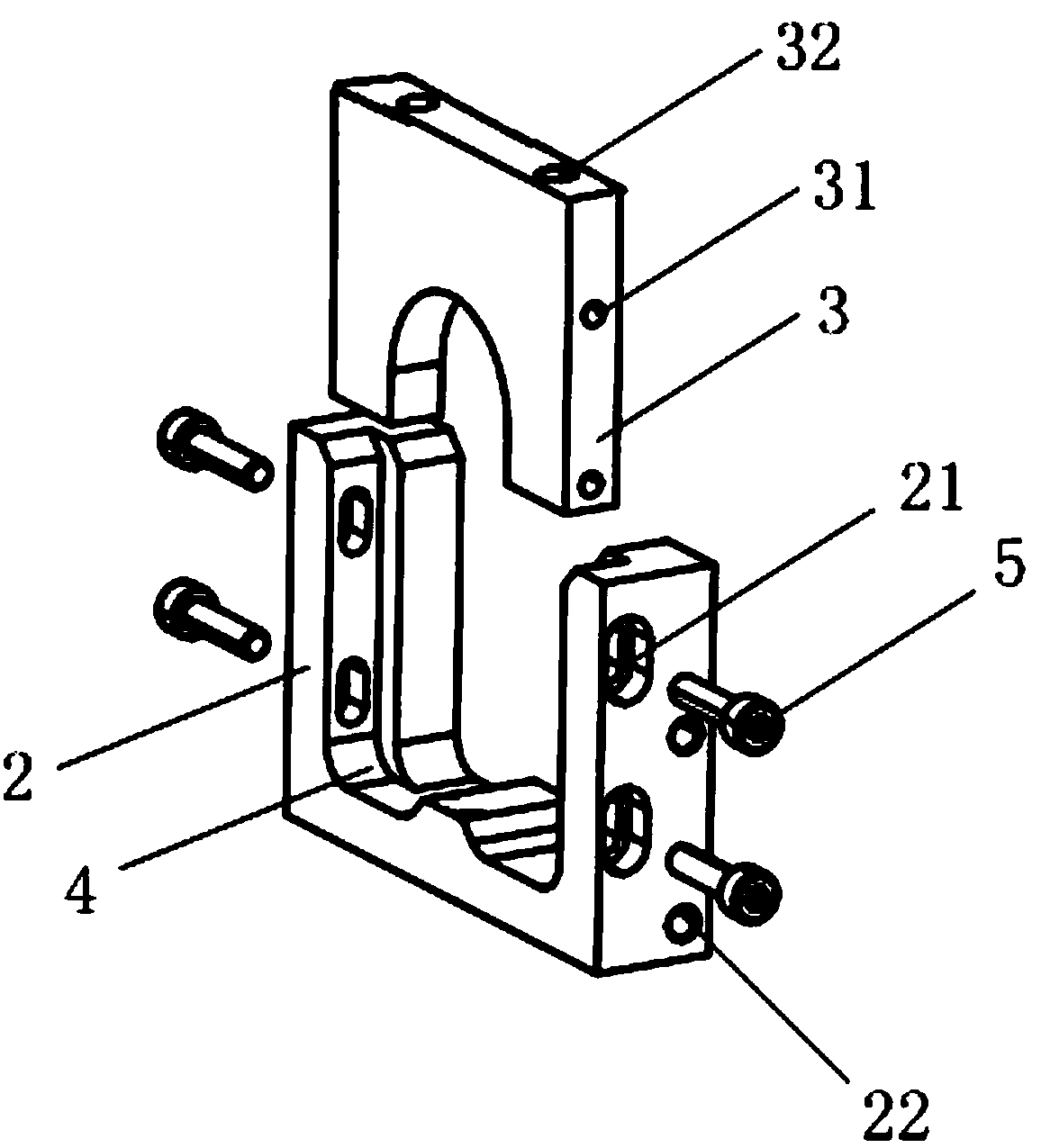

[0032] figure 1 The structural schematic diagram of the adjustable mounting frame 1 provided for the first embodiment of the present invention is shown by figure 1 It can be seen that the adjustable mounting frame 1 provided in this embodiment includes: a fixed support 2, a mounting part 3 and a longitudinal locking mechanism, the fixed support 2 is provided with an accommodating groove 4, and the thickness of the mounting part 3 is smaller than that of the accommodating groove 4 Width, so that the mounting part 3 is adapted to the accommodating groove 4; during installation, the mounting part 3 is placed in the accommodating groove 4, and moves longitudinally along the accommodating groove 4 relative to the fixed support 2; and through the longitudinal locking mechanism Fix the mounting part 3 at any height position in the longitudinal direction of the accommodating groove 4 .

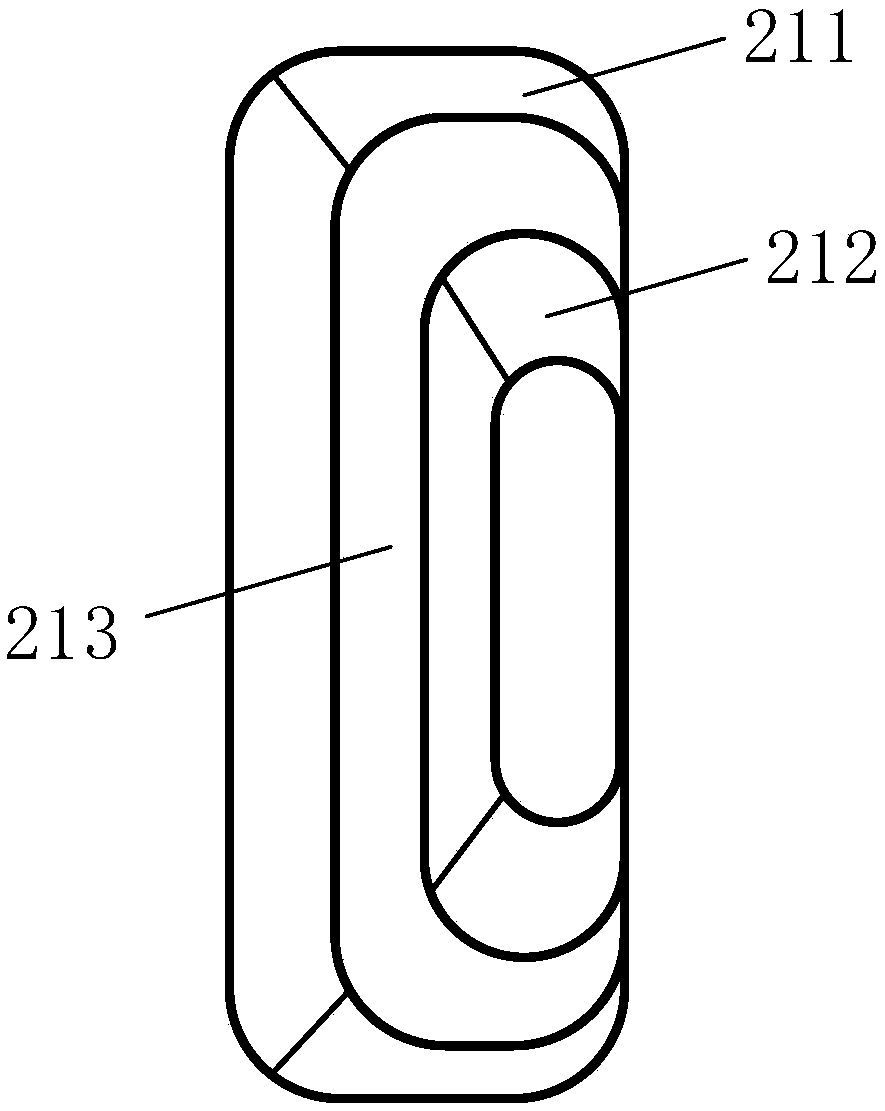

[0033] Specifically as figure 2 As shown, the shape of the accommodating groove 4 in this embod...

Embodiment 2

[0041] Figure 5 The three-dimensional structure schematic diagram of the adjustable mounting frame provided for the second embodiment of the present invention is different from the foregoing embodiments in that, on the basis of the foregoing embodiments, the adjustable mounting frame 1 also includes a function for driving the mounting part 3 in the An elevating adjustment mechanism that moves vertically relative to the fixed support 2 in the accommodating groove 4 . specific as Figure 6 As shown in , the lifting adjustment mechanism in this embodiment includes a second threaded through hole 24 arranged on the bottom edge of the fixed support 2 and a stud 6 matched with the second threaded through hole 24, and the stud 6 can pass through The second threaded through hole 24 enters the accommodation groove 4 and abuts against the mounting part 3. When the stud 6 is screwed in the second threaded through hole 24, the abutting mounting part 3 will be vertically Carry out jackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com