Patents

Literature

45results about How to "Efficiently arranged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

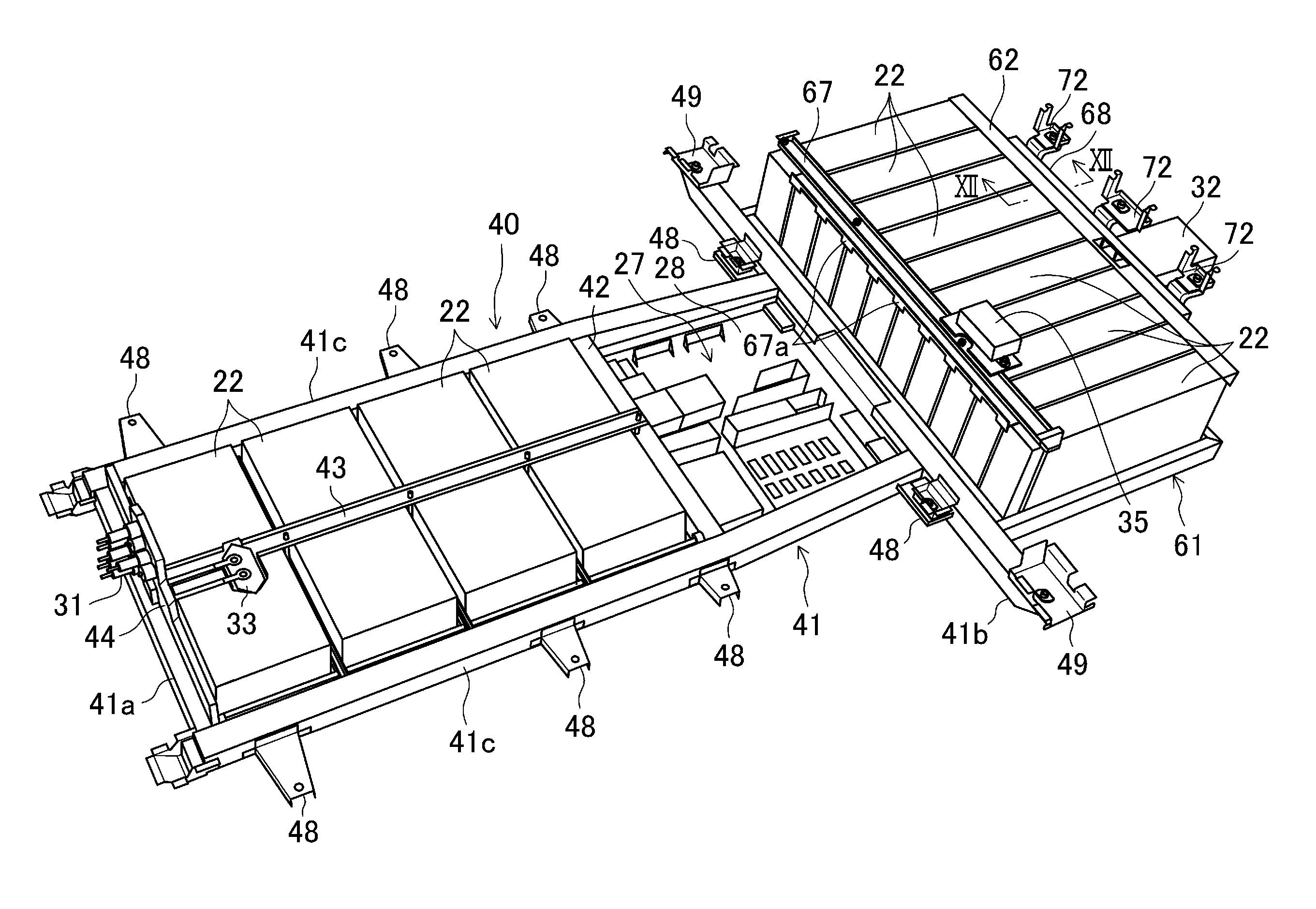

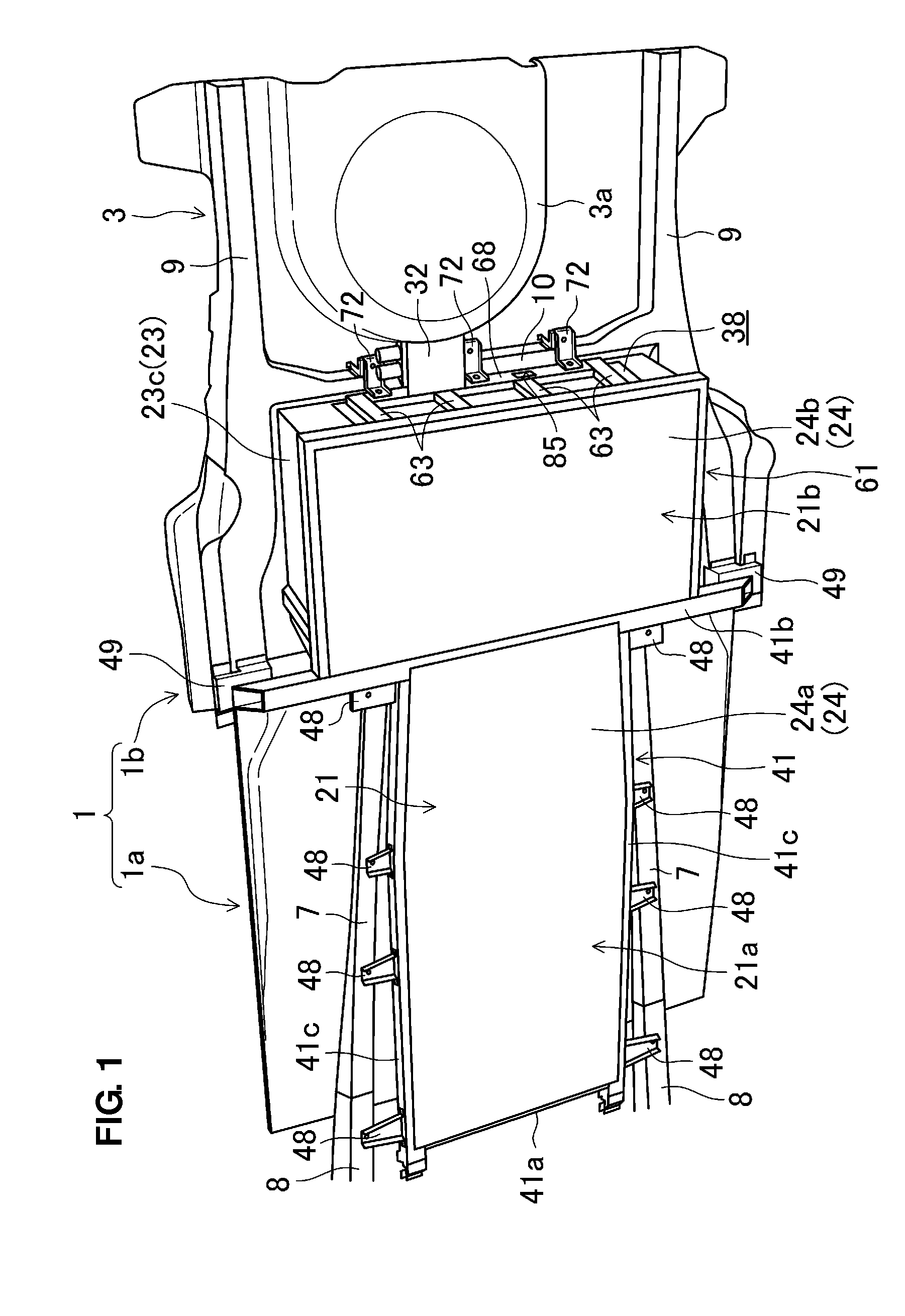

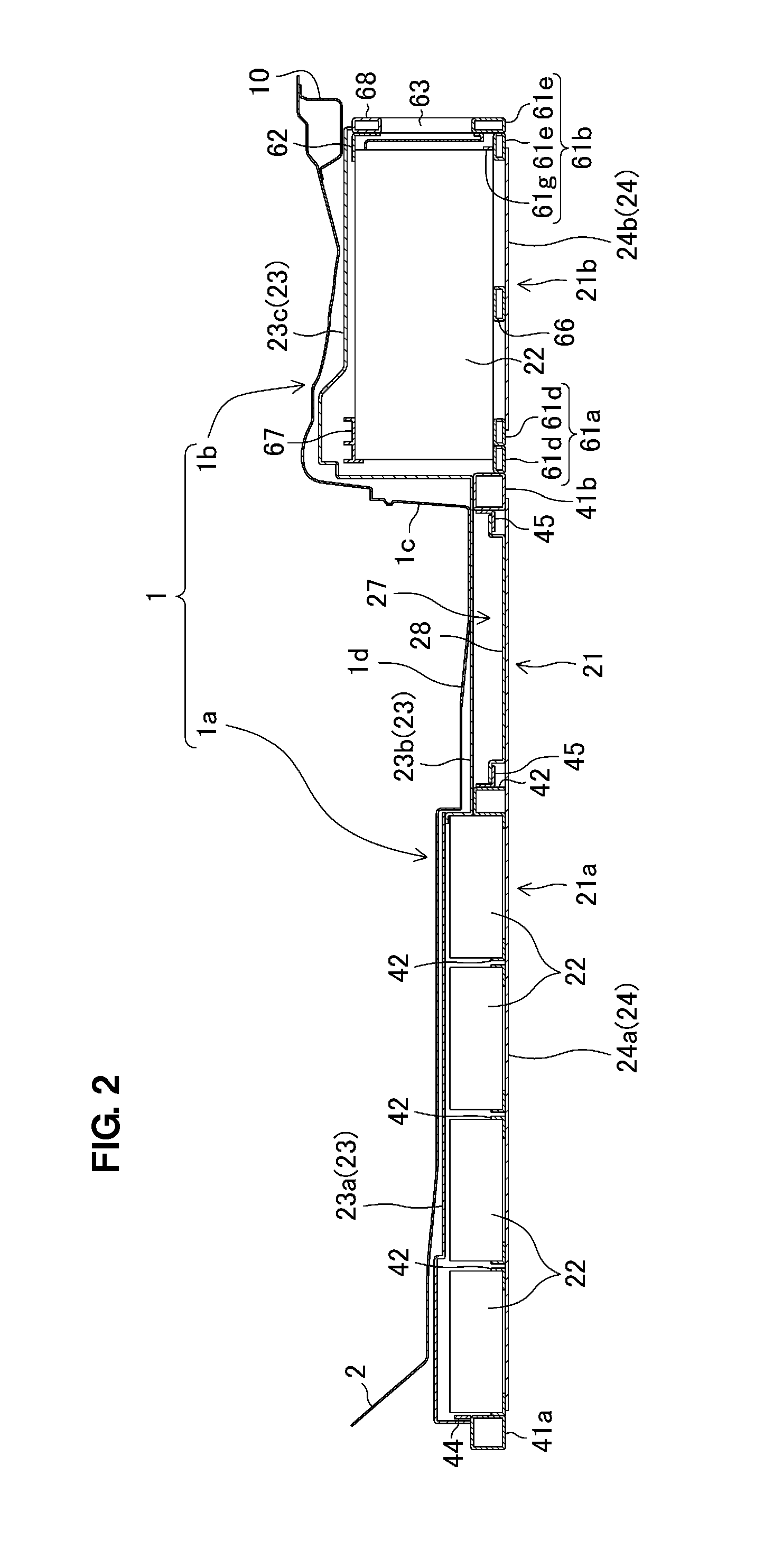

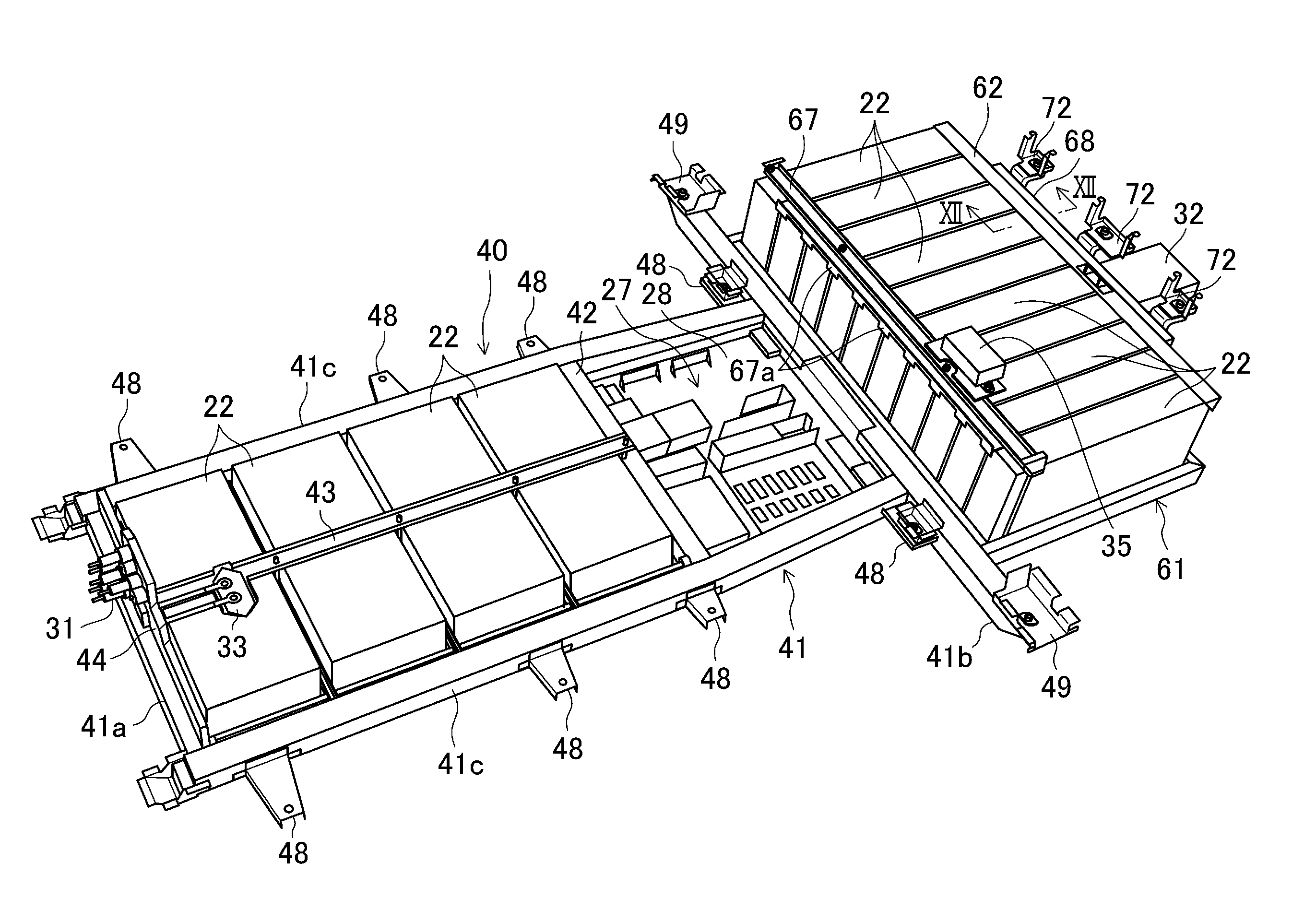

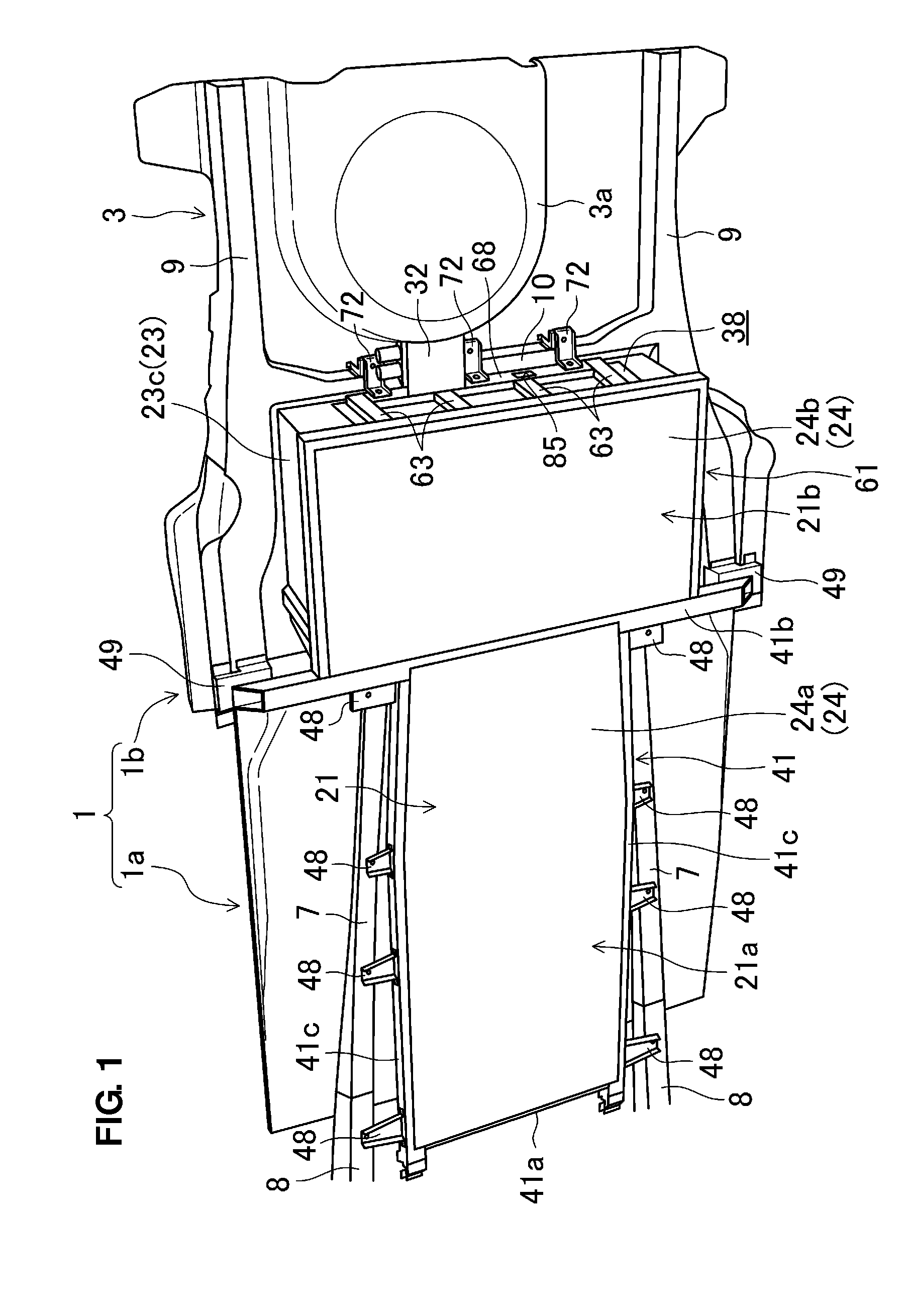

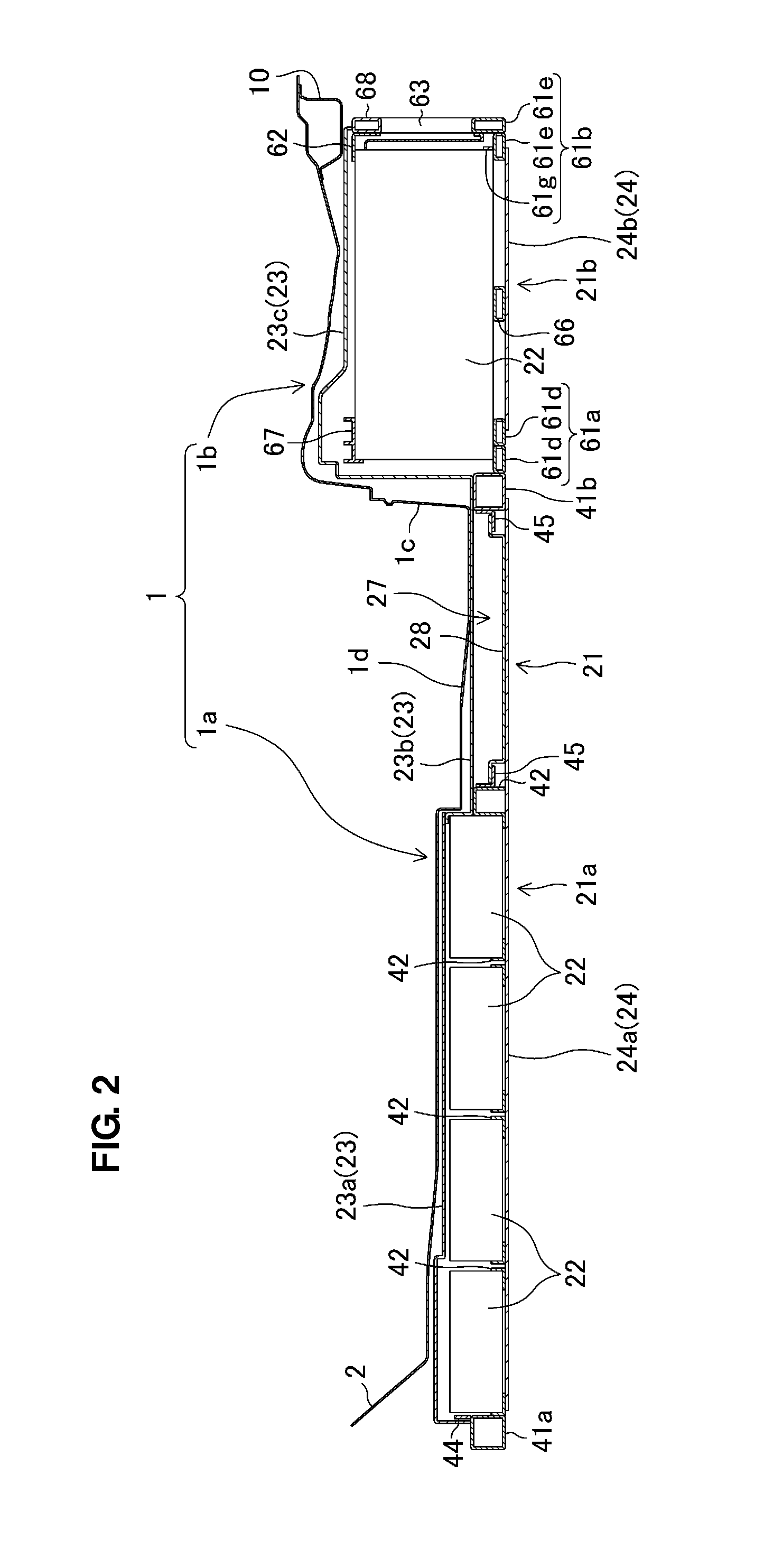

Battery mounting structure of electromotive vehicle

InactiveUS20110297469A1Efficiently arrangeEfficiently arrangedElectric propulsion mountingCell component detailsEmbedded system

Plural battery modules mounted on a first mount portion of a battery unit which is positioned below a front floor portion are arranged in a vehicle longitudinal direction such that the longitudinal direction of each of the battery modules matches a vehicle width direction and the short side of a rectangular section of each of the battery modules extends in a vehicle vertical direction, and plural battery modules mounted on a second mount portion which is positioned below a rear floor portion are arranged in the vehicle width direction such that the longitudinal direction of each of the battery modules matches the vehicle longitudinal direction and the long side of the rectangular section of each of the battery modules extends in the vehicle vertical direction. Accordingly, the plural battery modules can be arranged efficiently.

Owner:MAZDA MOTOR

Battery mounting structure of electromotive vehicle

InactiveUS8464817B2Efficiently arrangedElectric propulsion mountingCell component detailsEmbedded system

Owner:MAZDA MOTOR CORP

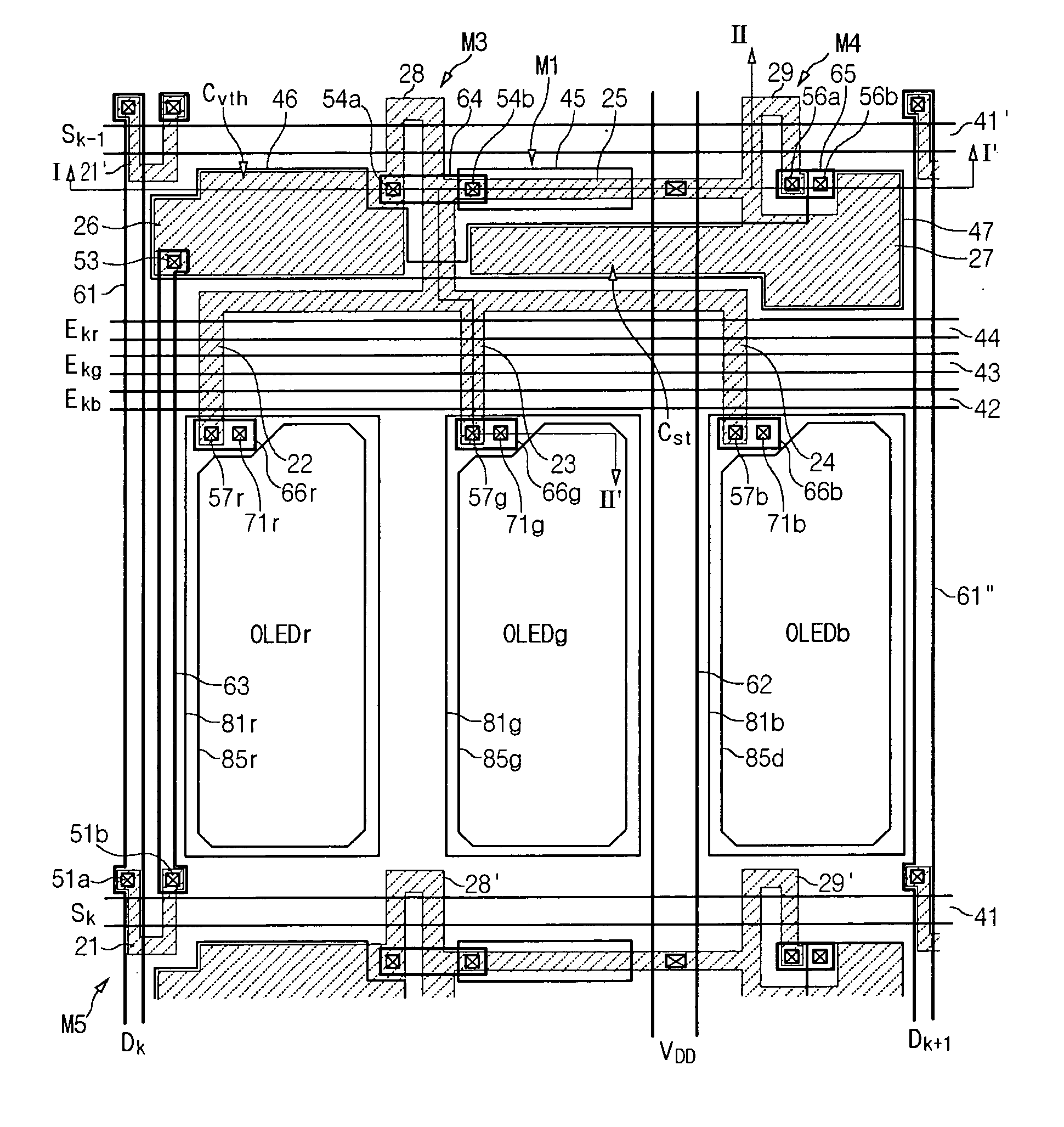

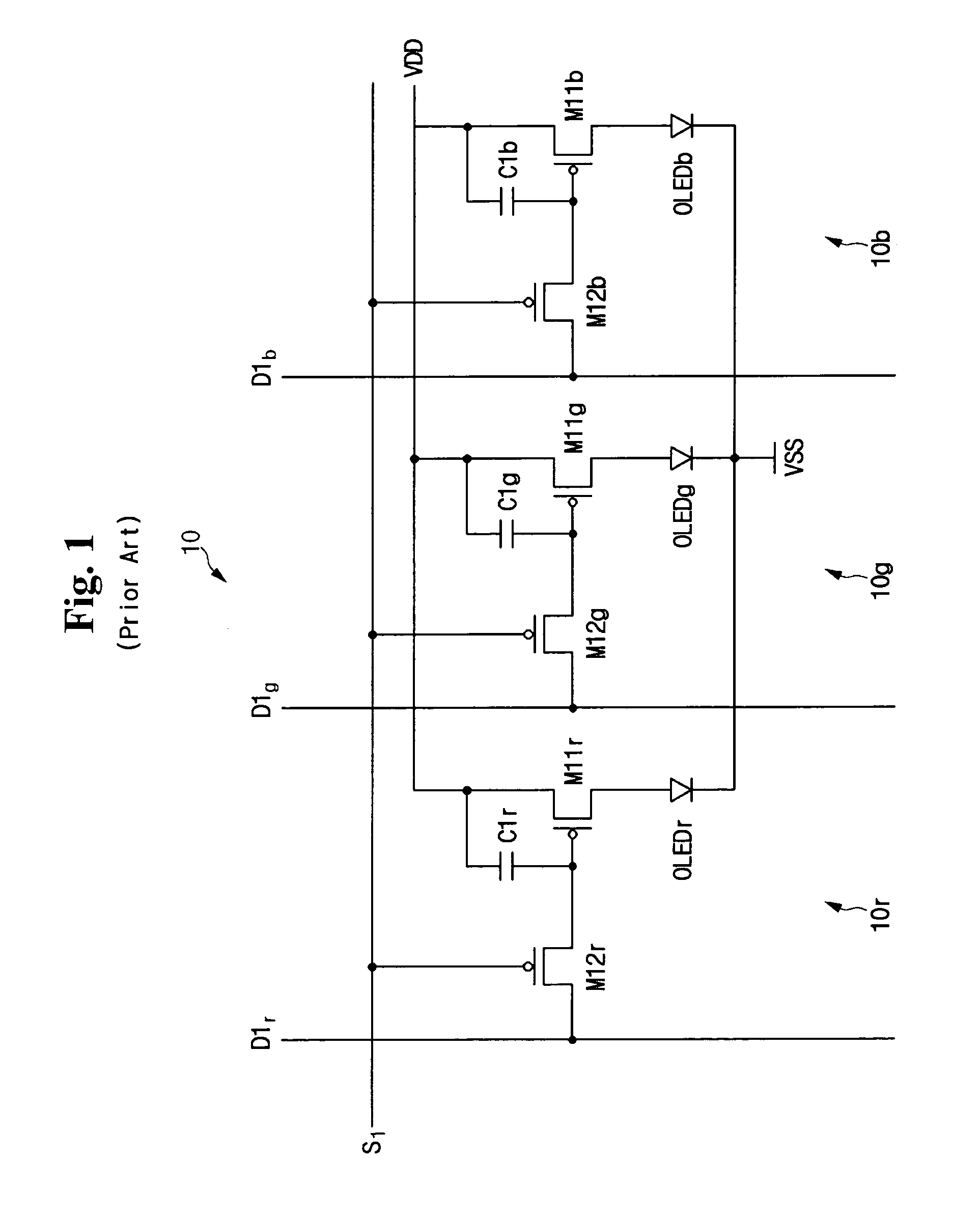

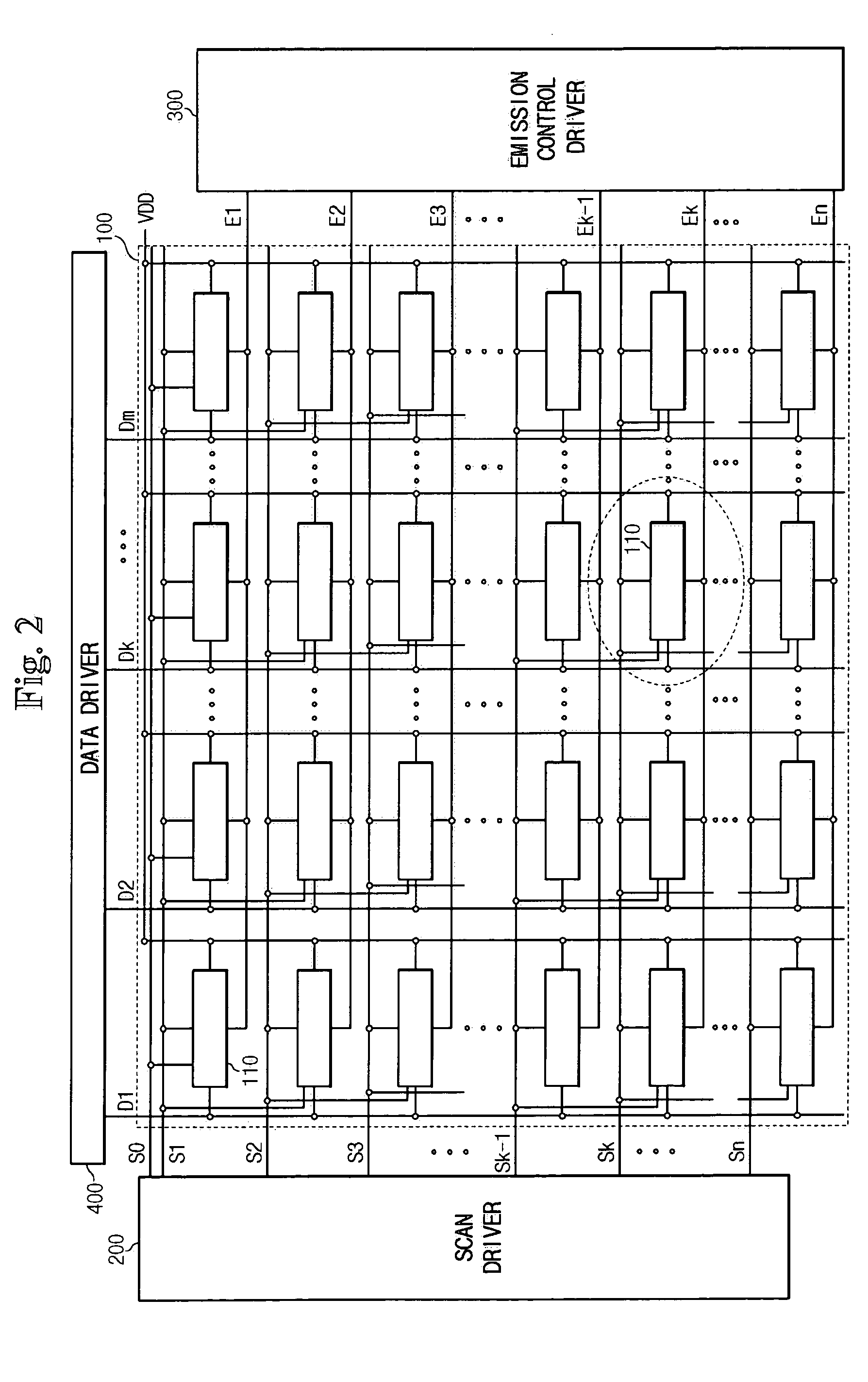

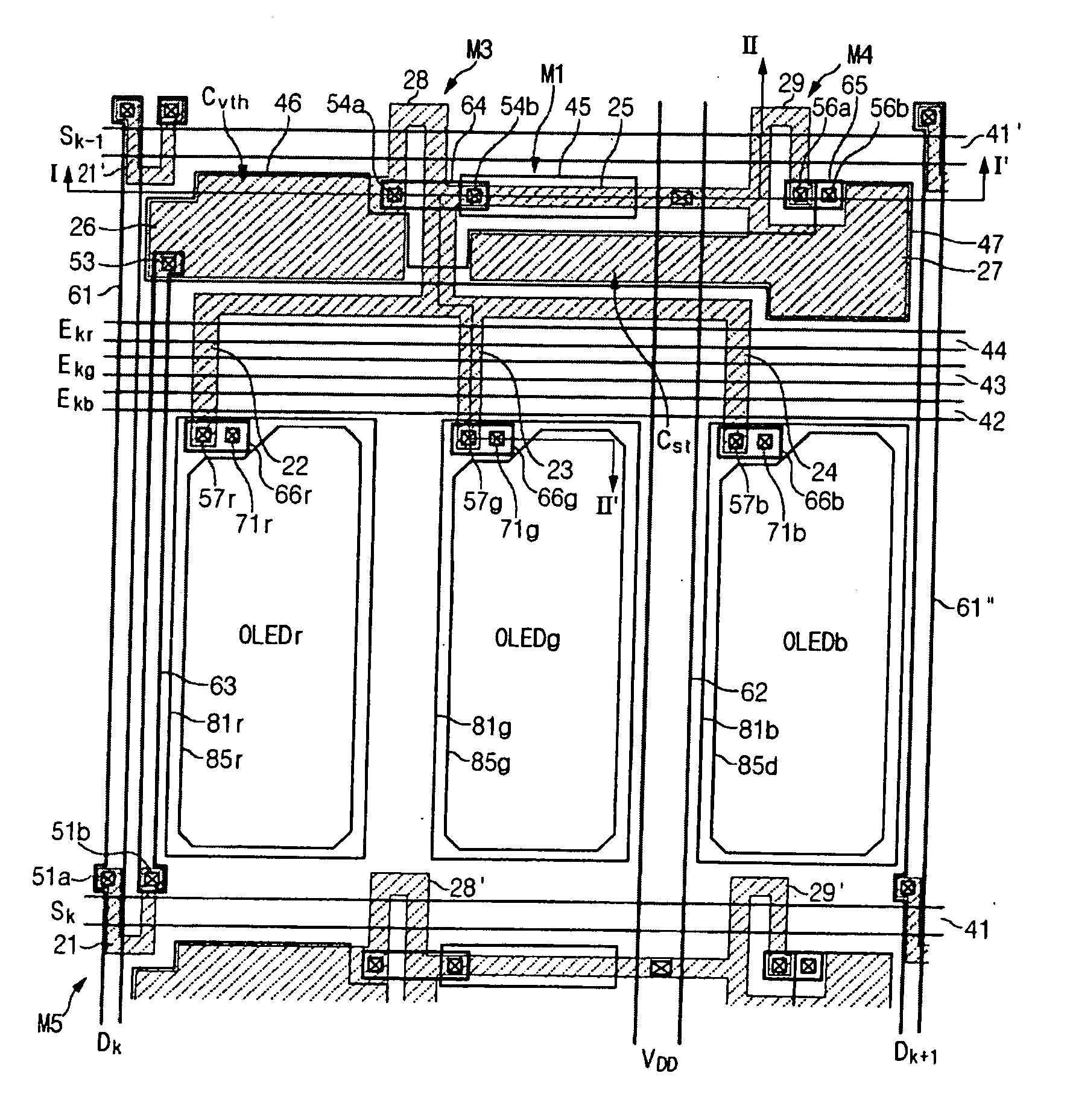

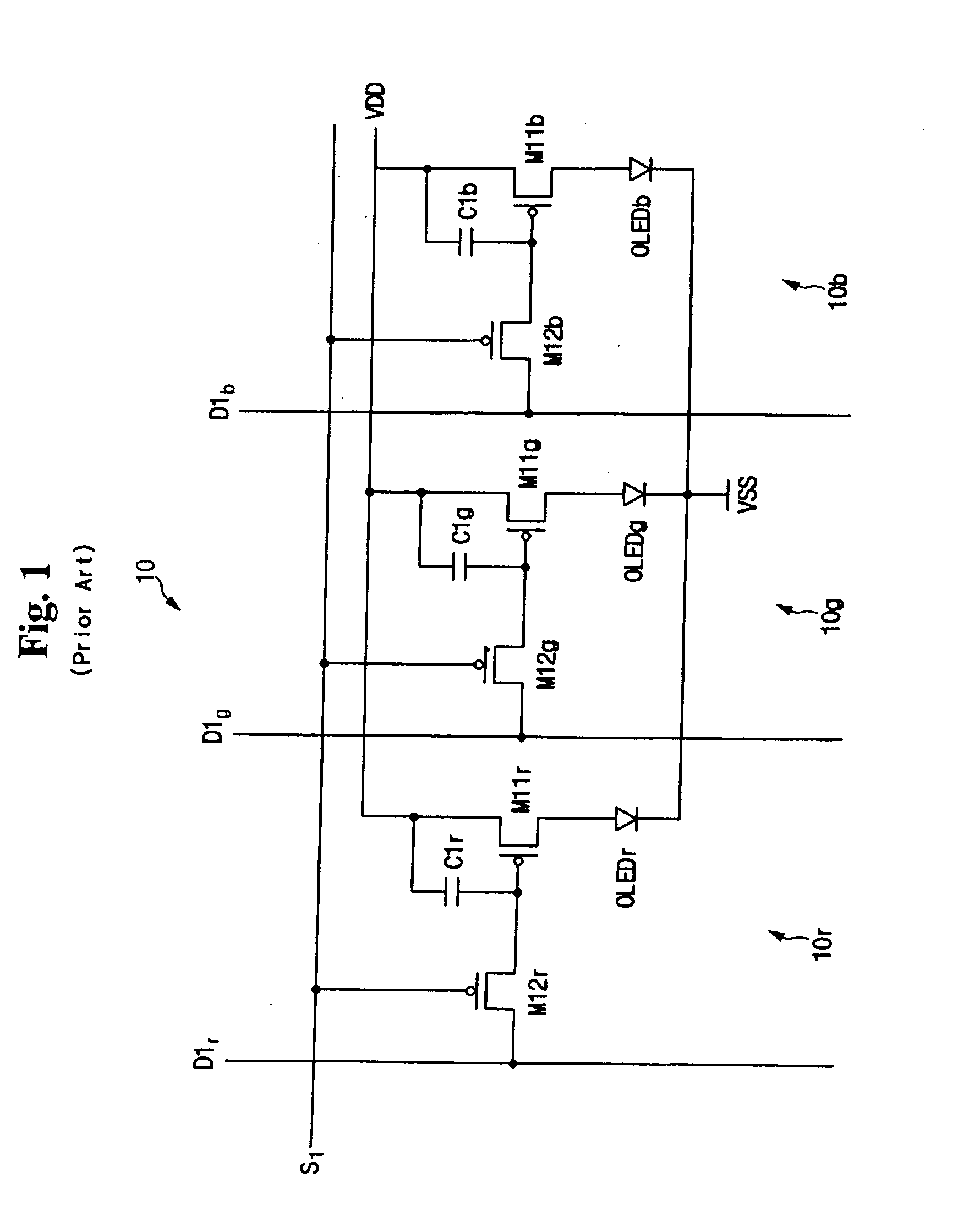

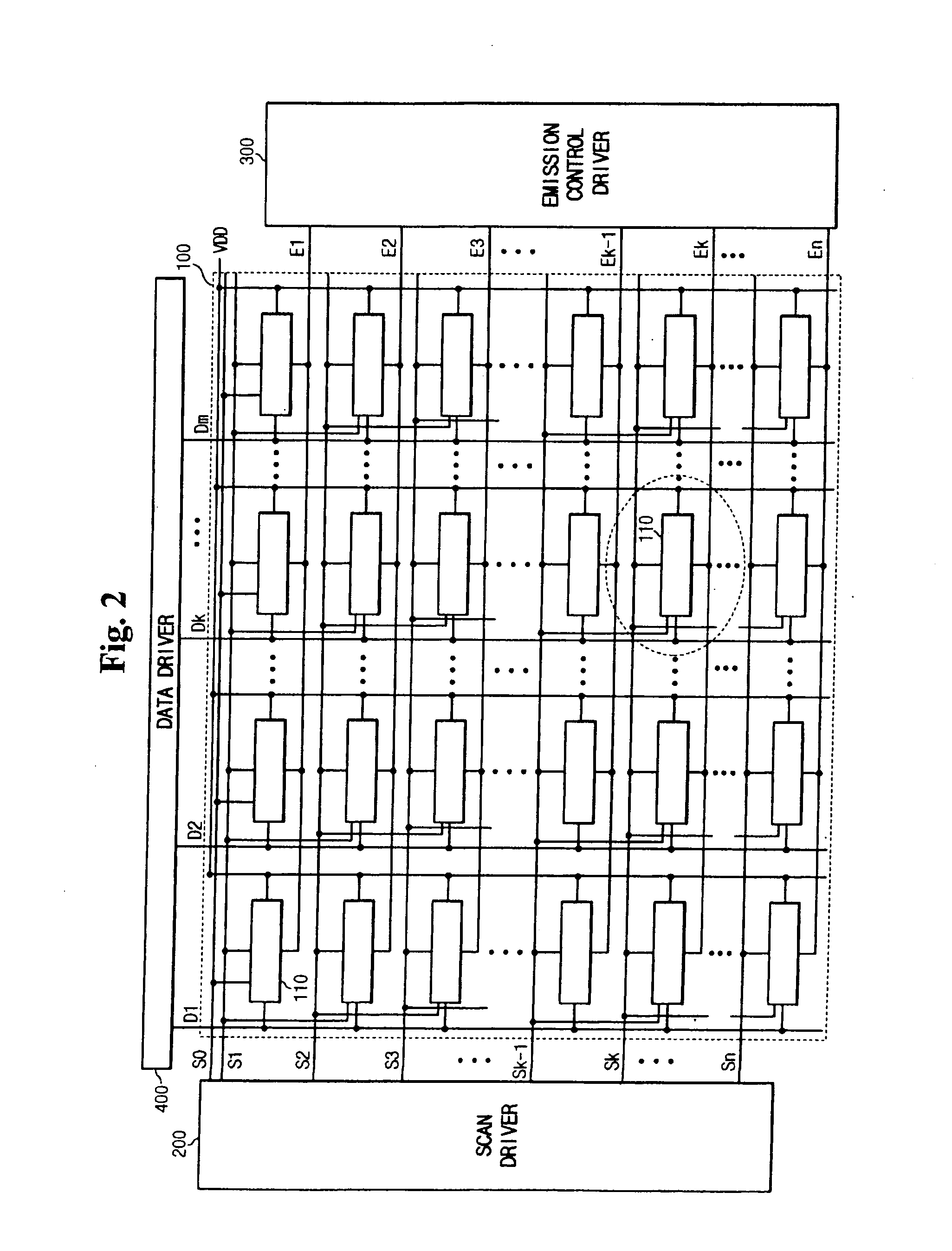

Display device

ActiveUS20050259142A1Efficient arrangementEfficiently arrangedStatic indicating devicesDigestive systemScan lineData signal

A current pixel circuit of a display device includes a switching transistor which may be turned on in response to the current selection signal to transfer a data signal, a driving transistor for outputting a current corresponding to the data signal, and first and second transistors being turned on in response to the previous selection signal. In the display device, the gate electrodes of the switching transistor of a previous pixel and the first and second transistors of the current pixel are coupled to one scan line for transferring the previous selection signal. Accordingly, the transistors are arranged in the order of the switching transistor of the previous pixel and the first and second transistors of the current pixel on the scan line at an area between two adjacent data lines.

Owner:SAMSUNG DISPLAY CO LTD

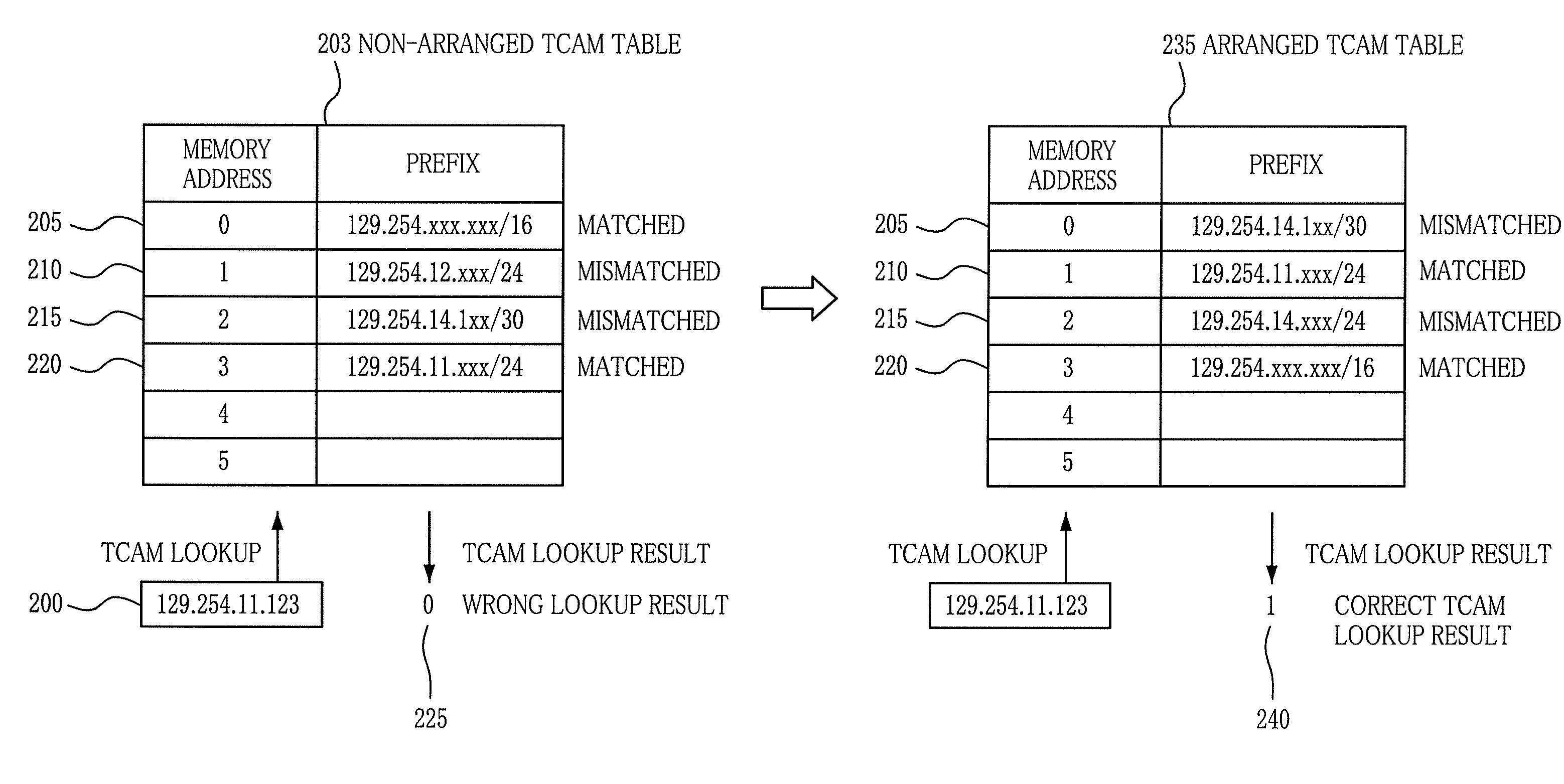

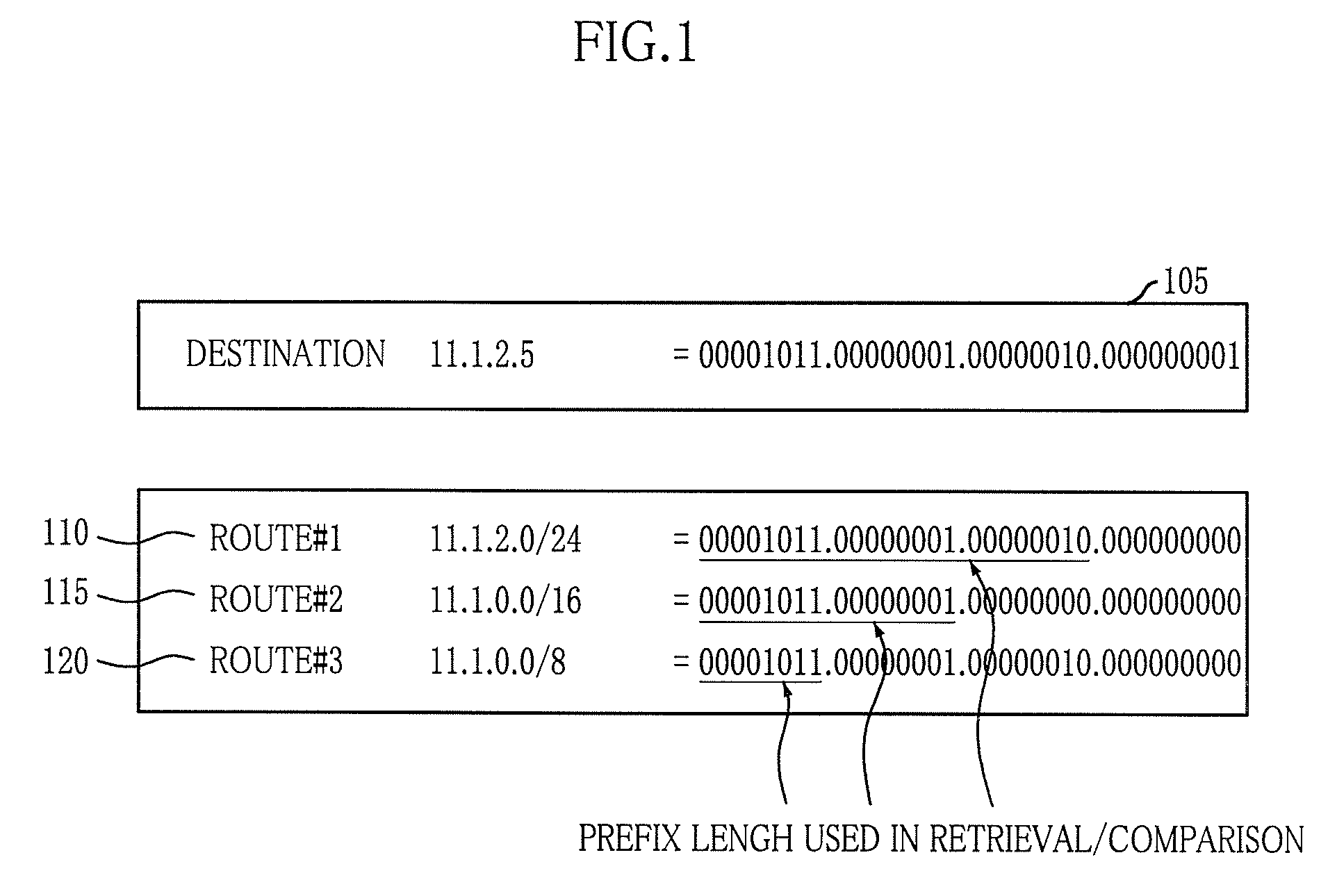

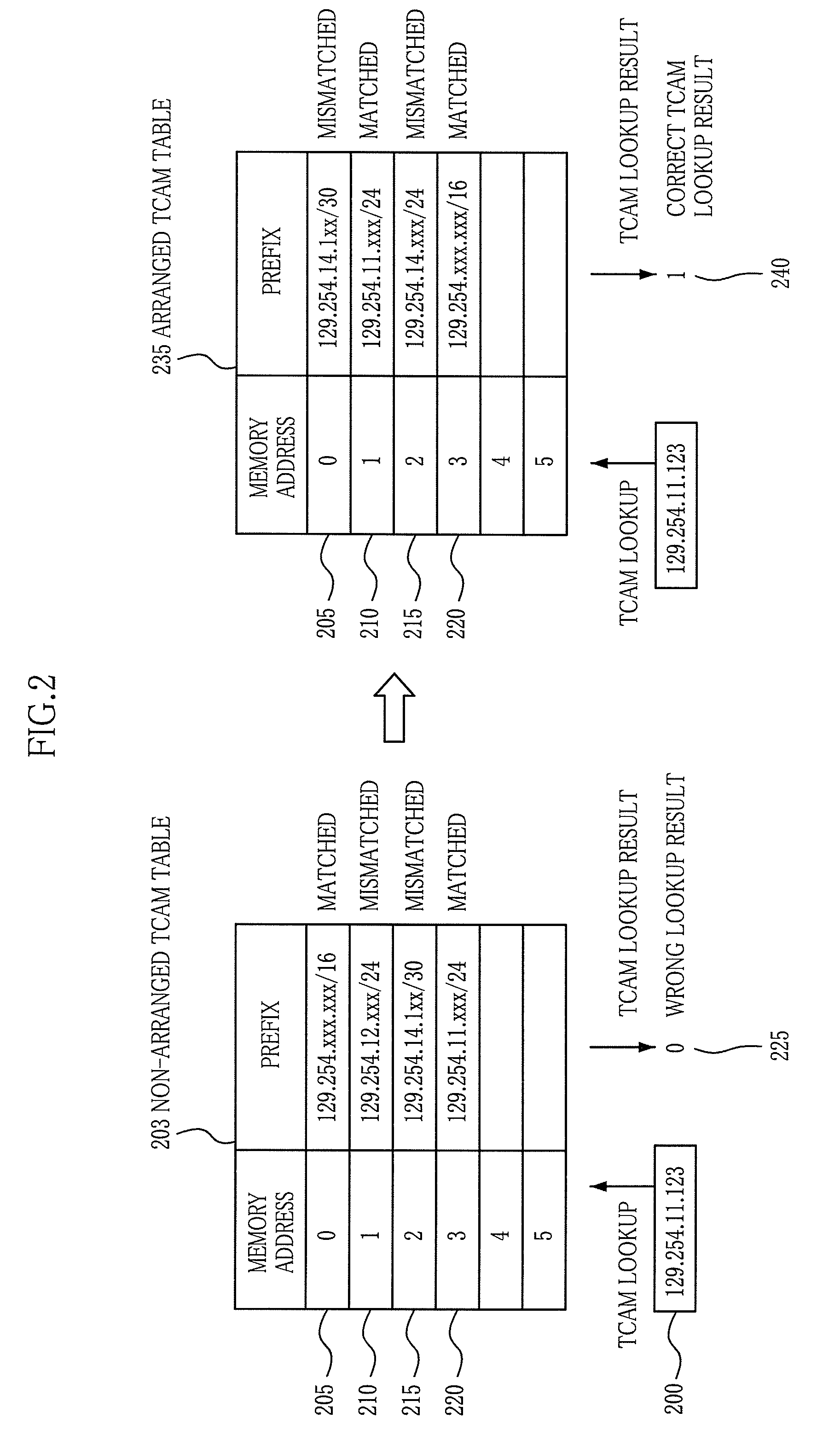

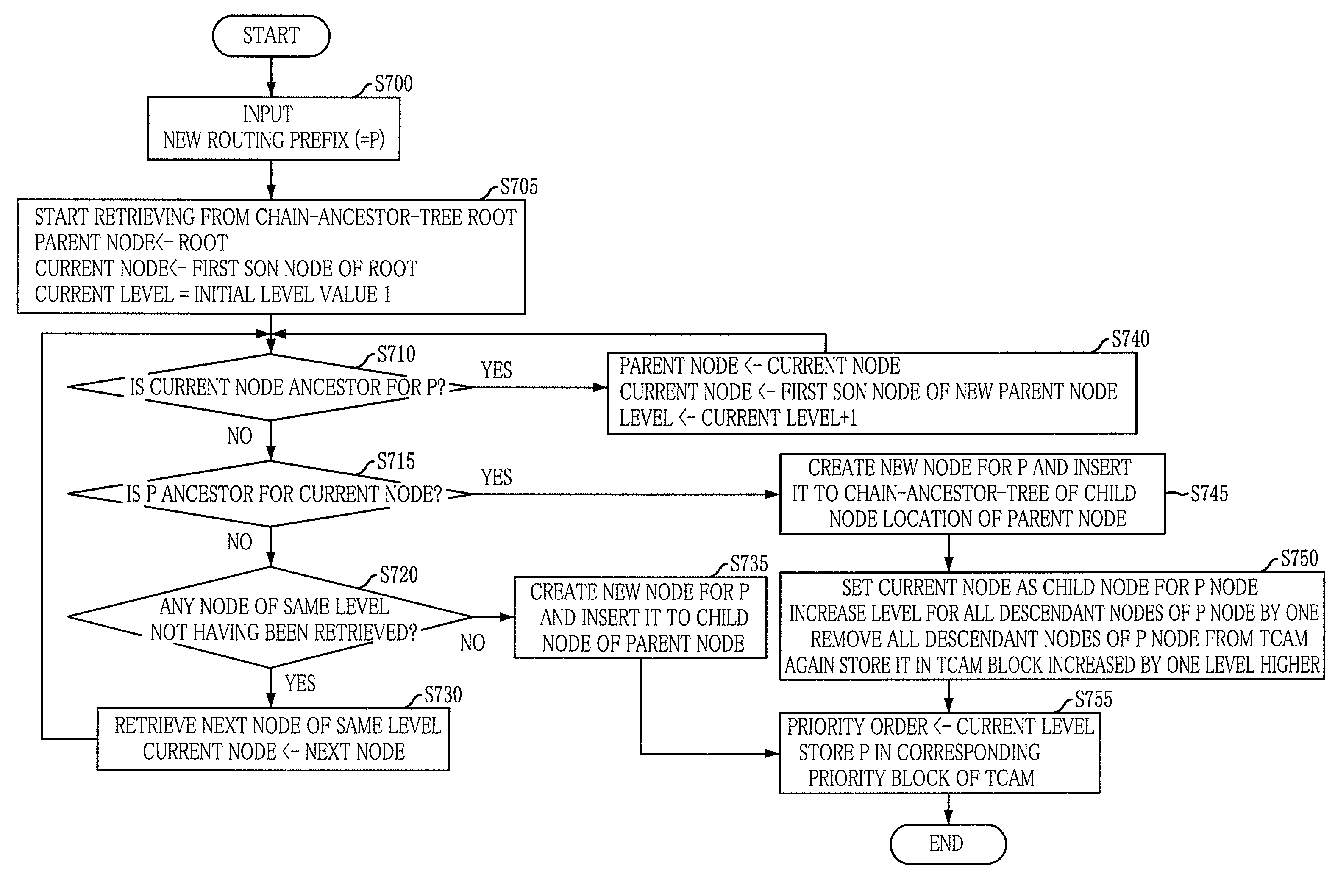

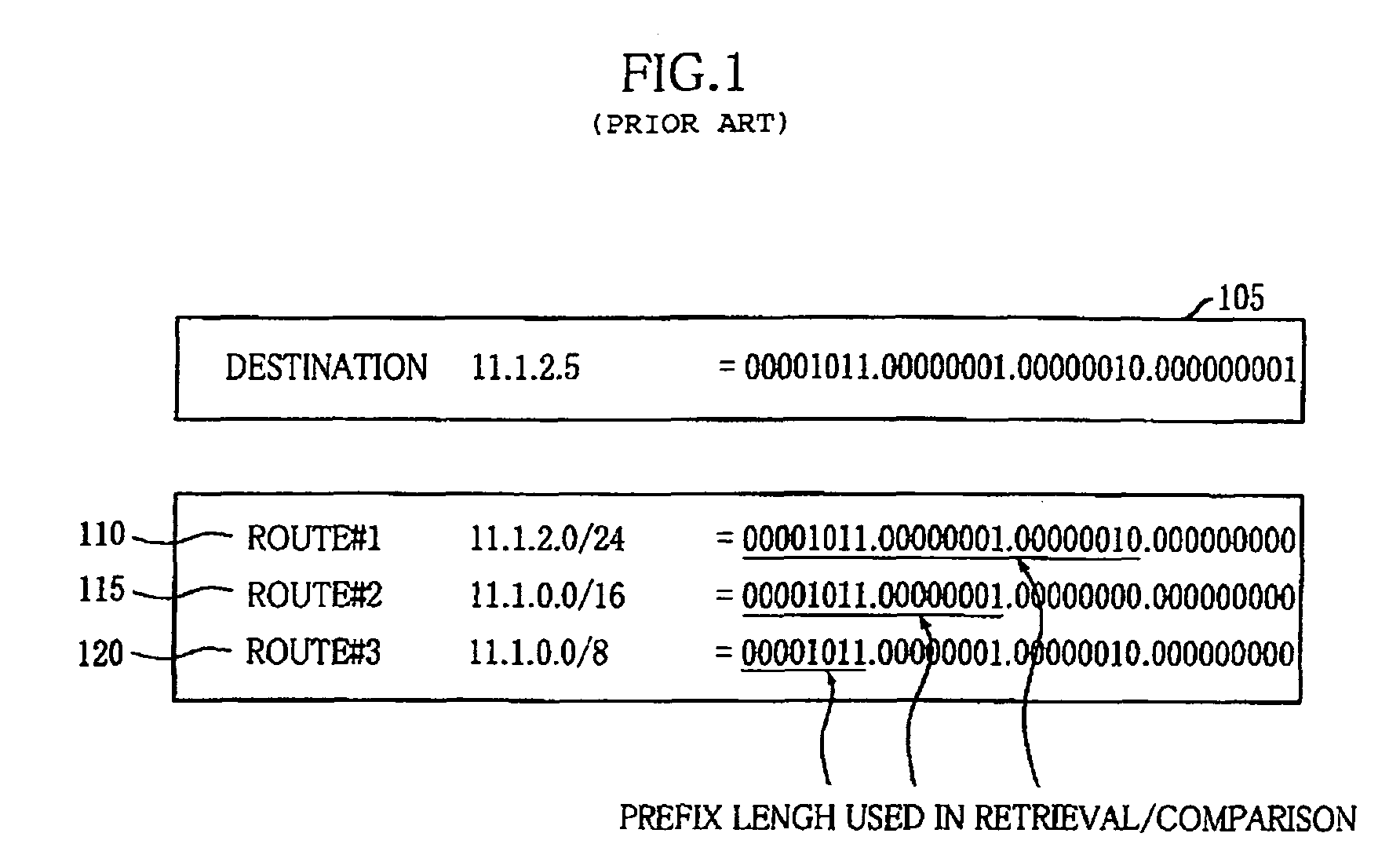

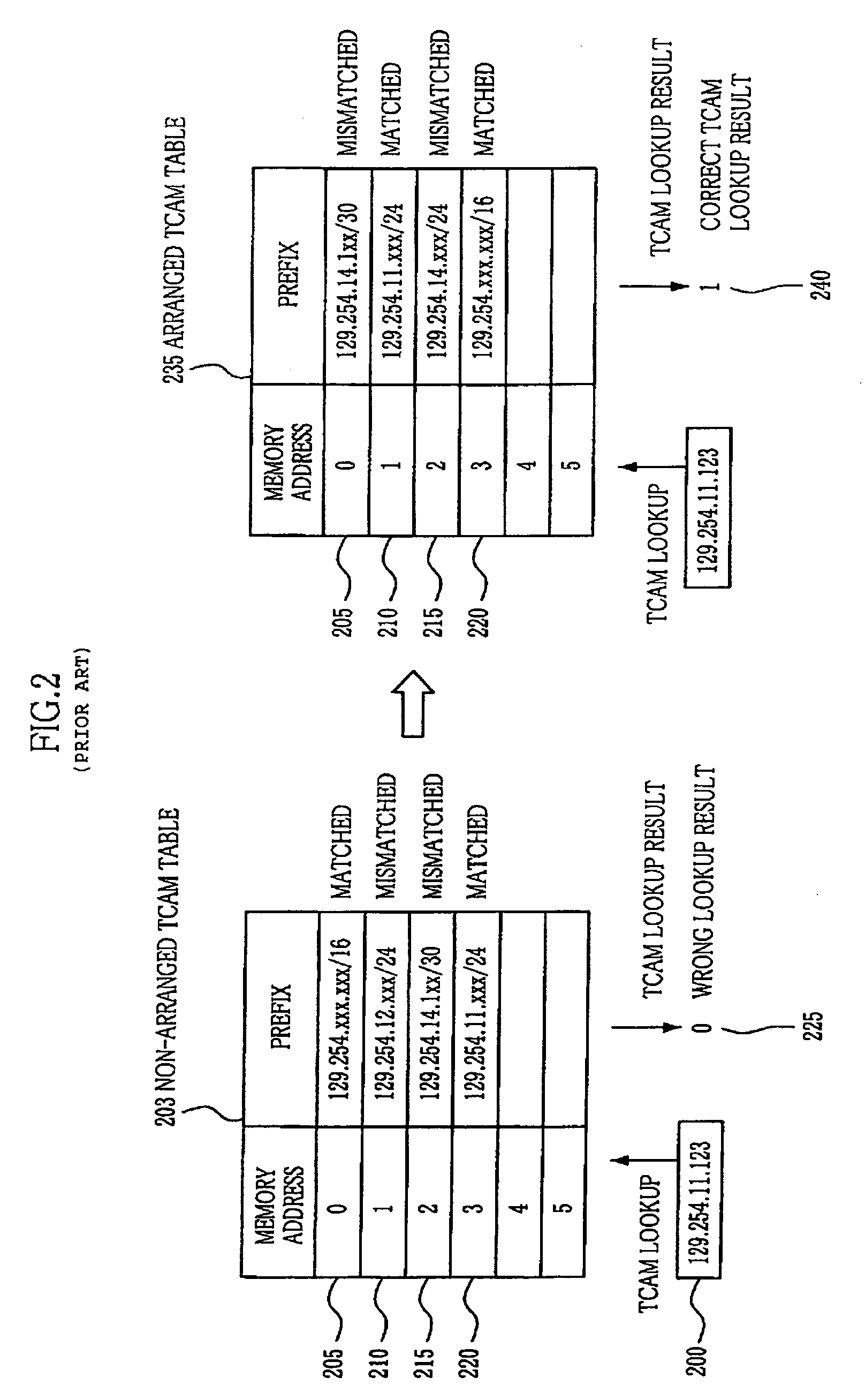

Method for ternary contents address memory table management

InactiveUS20080080539A1Efficiently arrangedNo wasteData switching by path configurationSecuring communicationLongest prefix matchLookup table

Provided are a method for Ternary Contents Address Memory (TCAM) table management and a computer-readable recording medium for recording a program that implements the method. The method includes the steps of: a) dividing a memory area of TCAM into fixed-size blocks depending on priority to configure a lookup table; b) assigning a priority to each routing entry being inputted to the lookup table based on prefix length; c) storing the routing entry having been assigned with the priority in a lookup table block of a corresponding priority; and d) when a modification occurs in the lookup table, modifying the lookup table to maintain an arranged state for a longest prefix match.

Owner:ELECTRONICS & TELECOMM RES INST

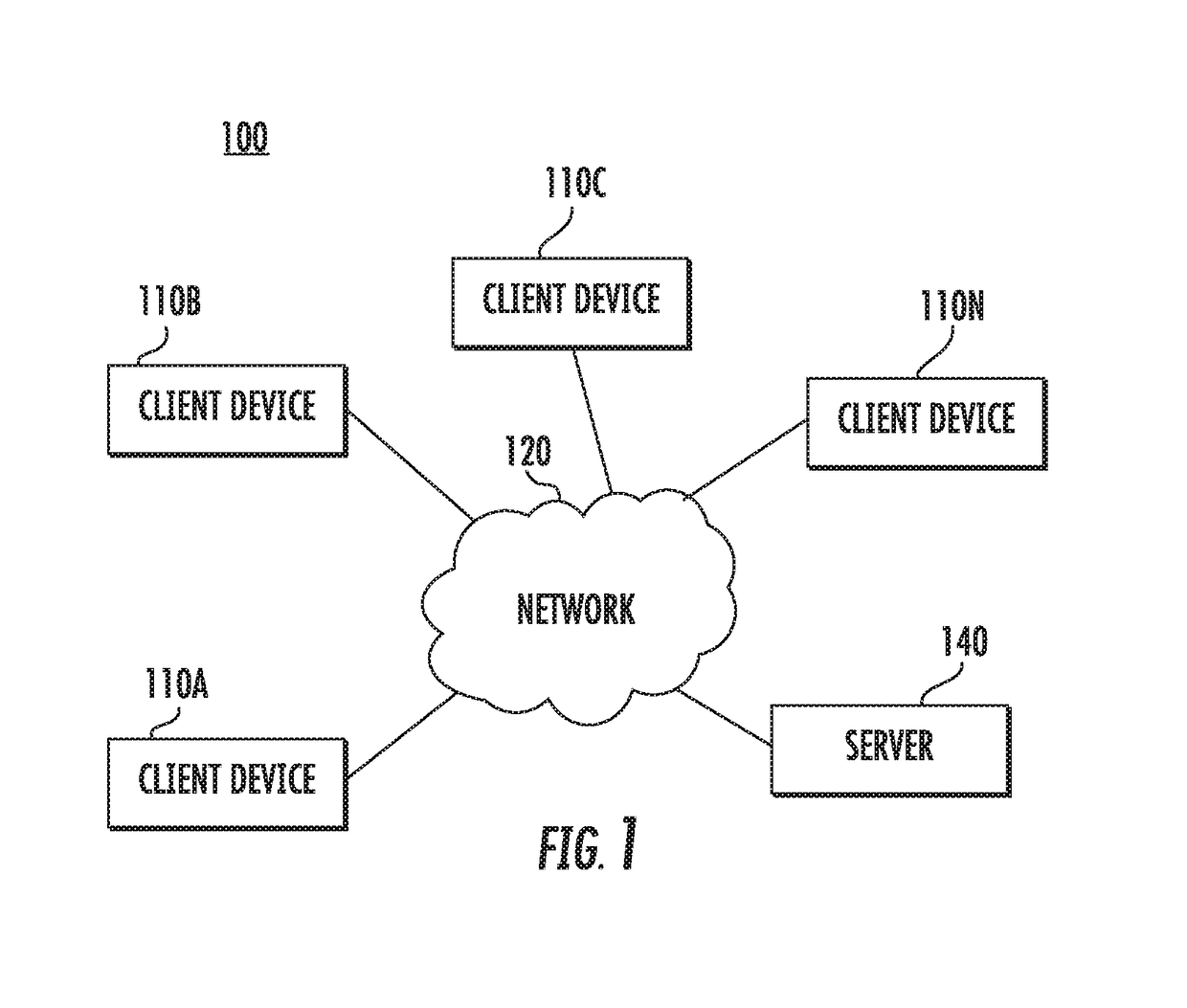

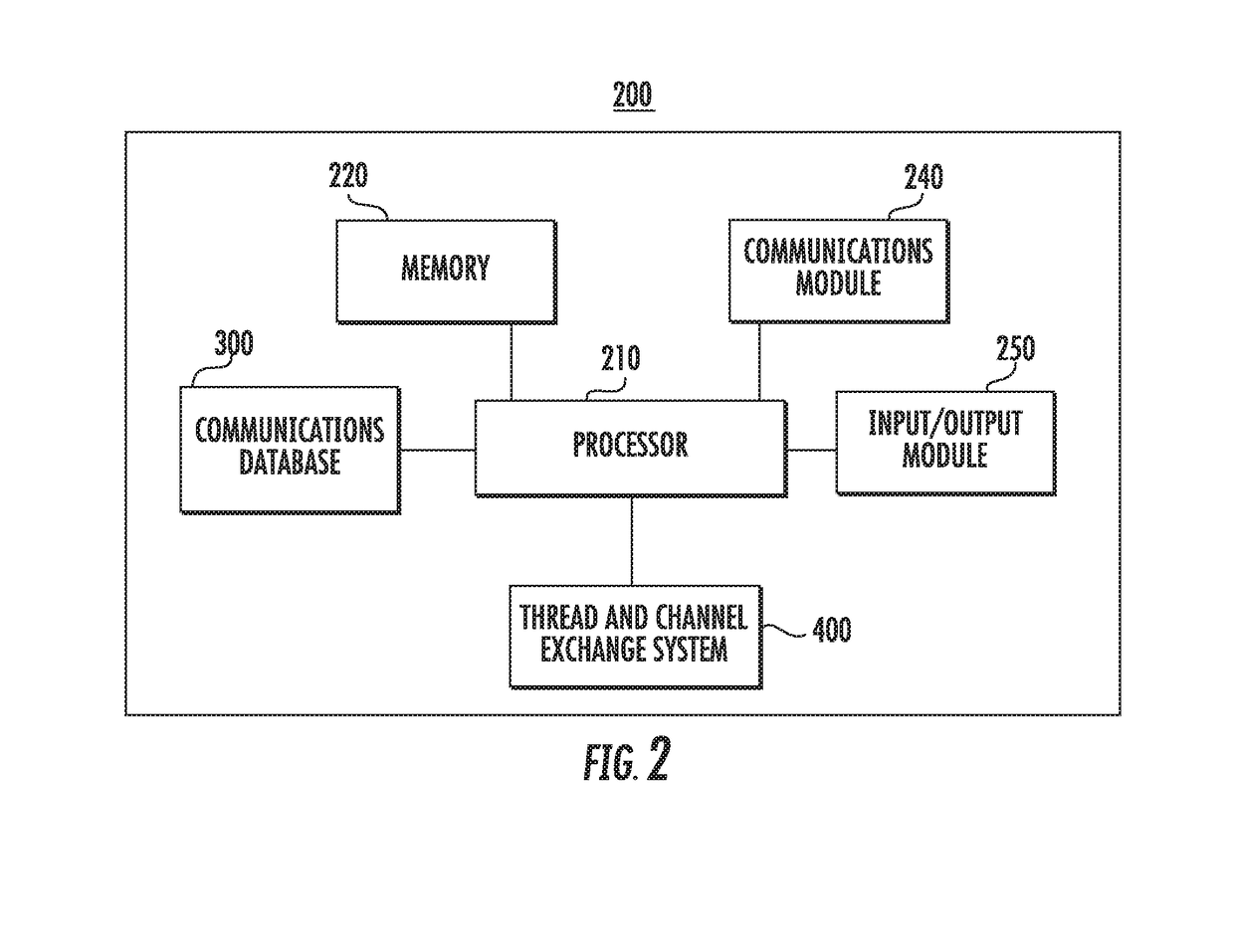

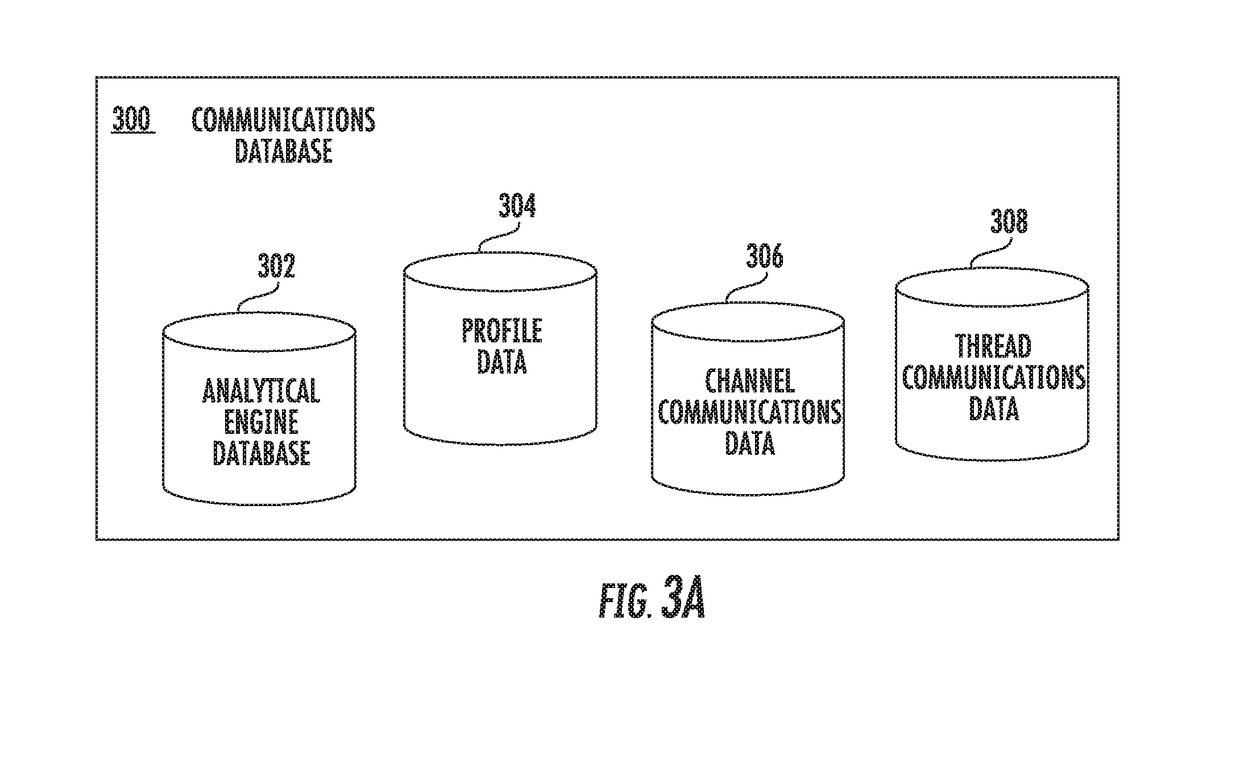

Group-based communication interface with subsidiary channel-based thread communications

ActiveUS20190058680A1Efficiently arrangedEfficient arrangementData switching networksMessage passingCommunication interface

Provided is a group-based communication interface configured to allow members of the interface to communicate within group-based communication channels. The group-based communication interface is configured to relegate selected group-based messaging communications to a separate display pane, where additional messaging communications can be received, thereby maintaining a focused selected group-based communication channel. The selected group-based communication channel is updated to indicate that the selected group-based messaging communications was relegated to a separate display pane, informing the channel members while also allowing the channel members to access the separate display pane if desired. Accordingly, the selected group-based communication interface provides for efficient and focused group-based communications.

Owner:SALESFORCE COM INC

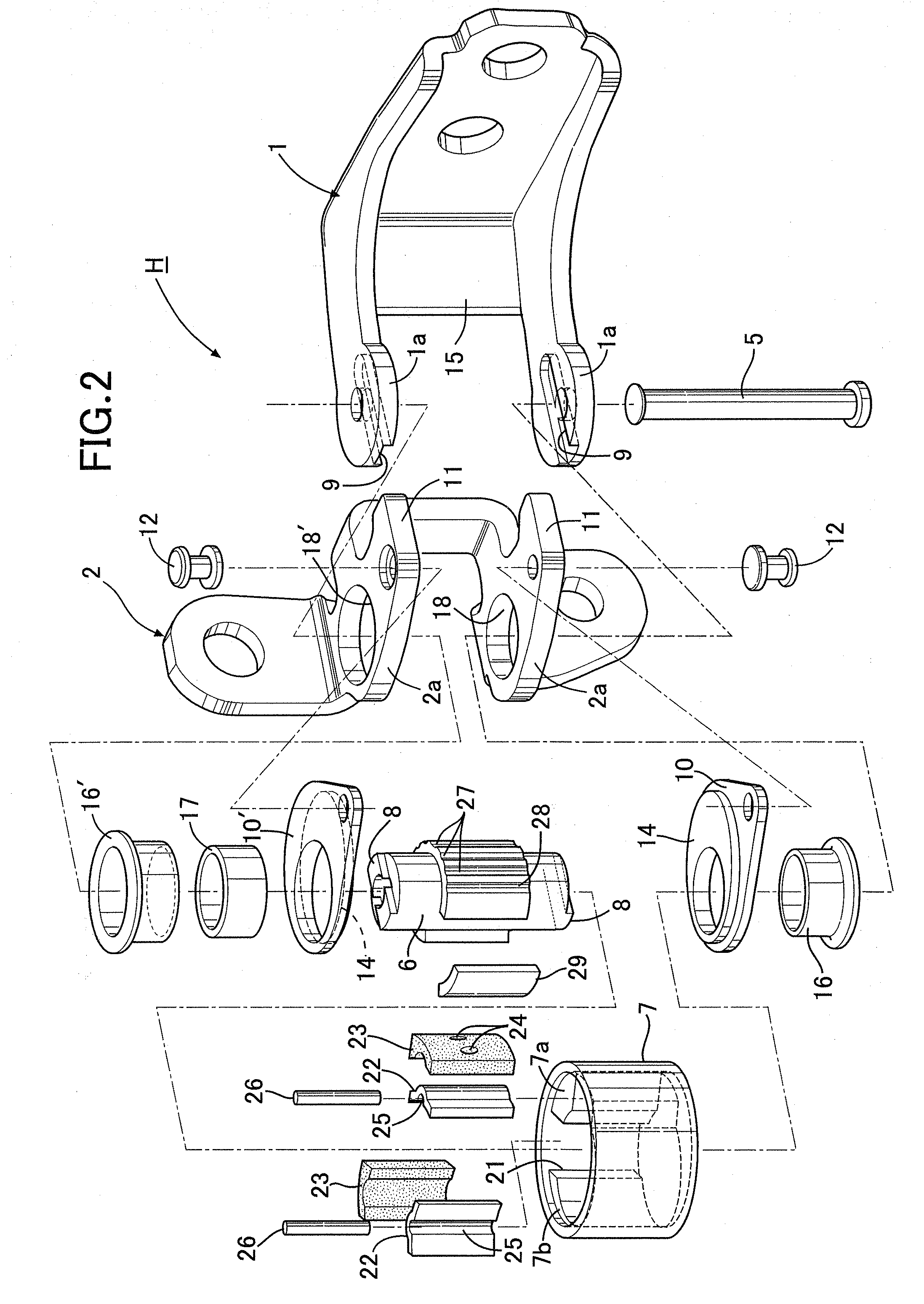

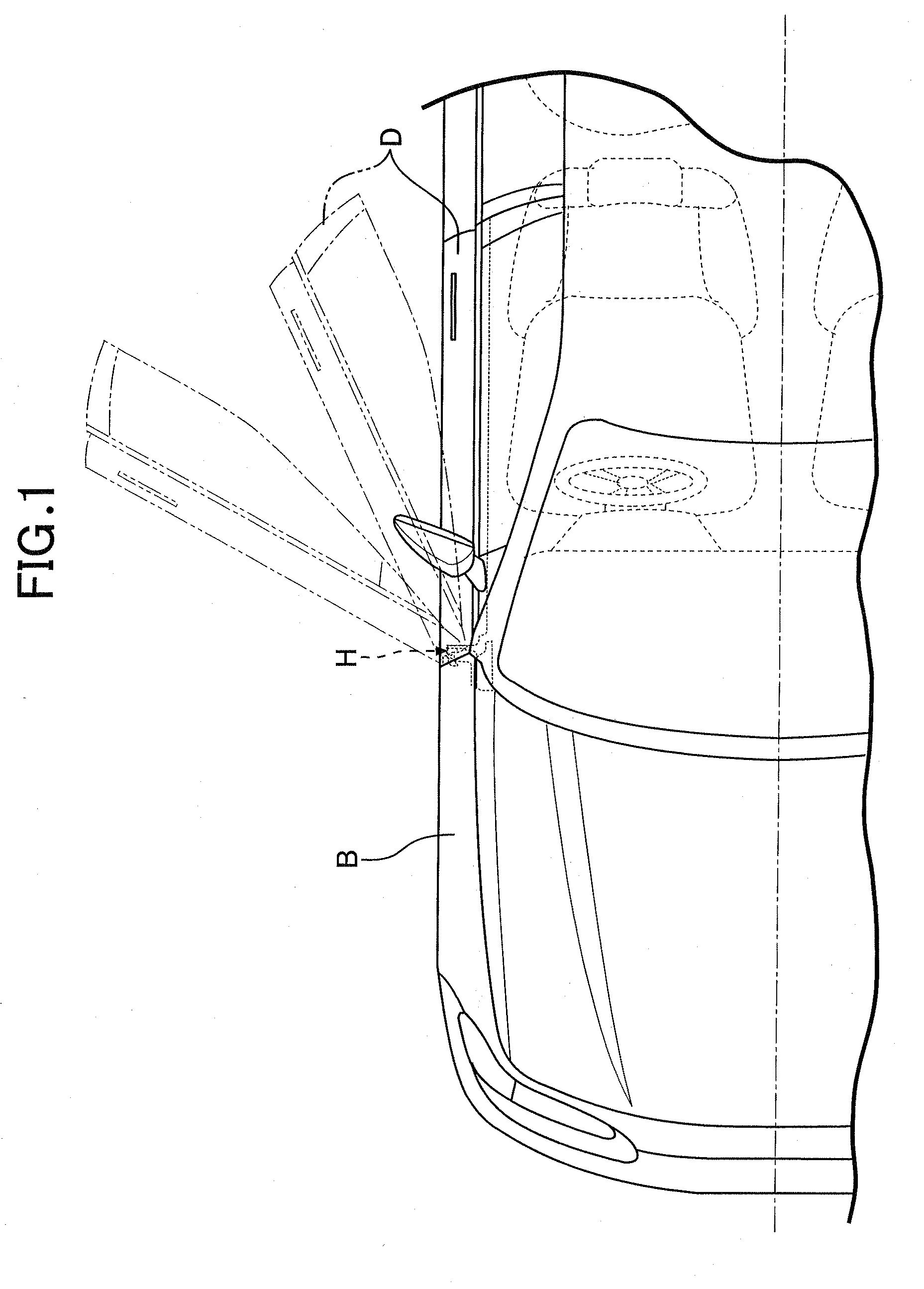

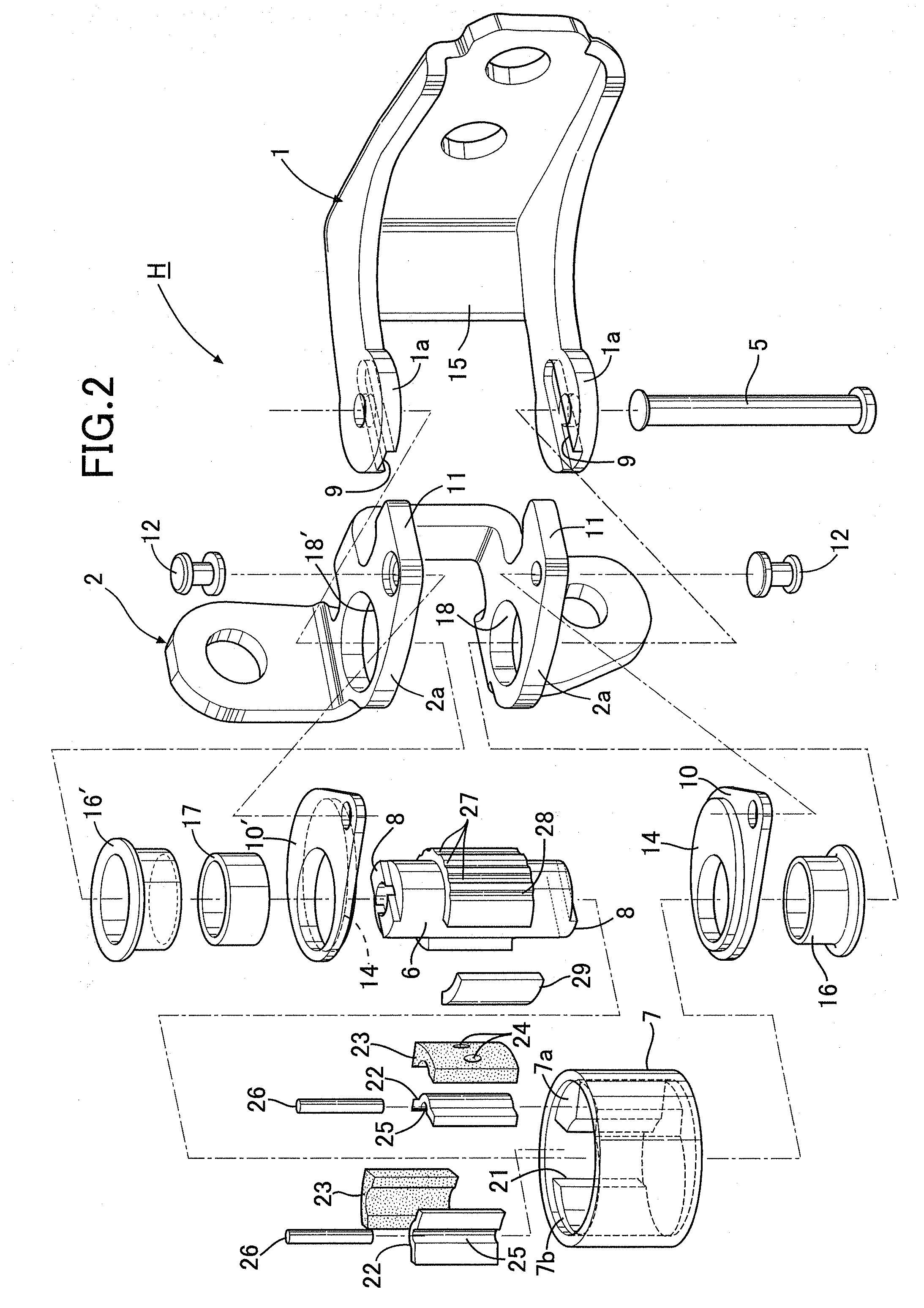

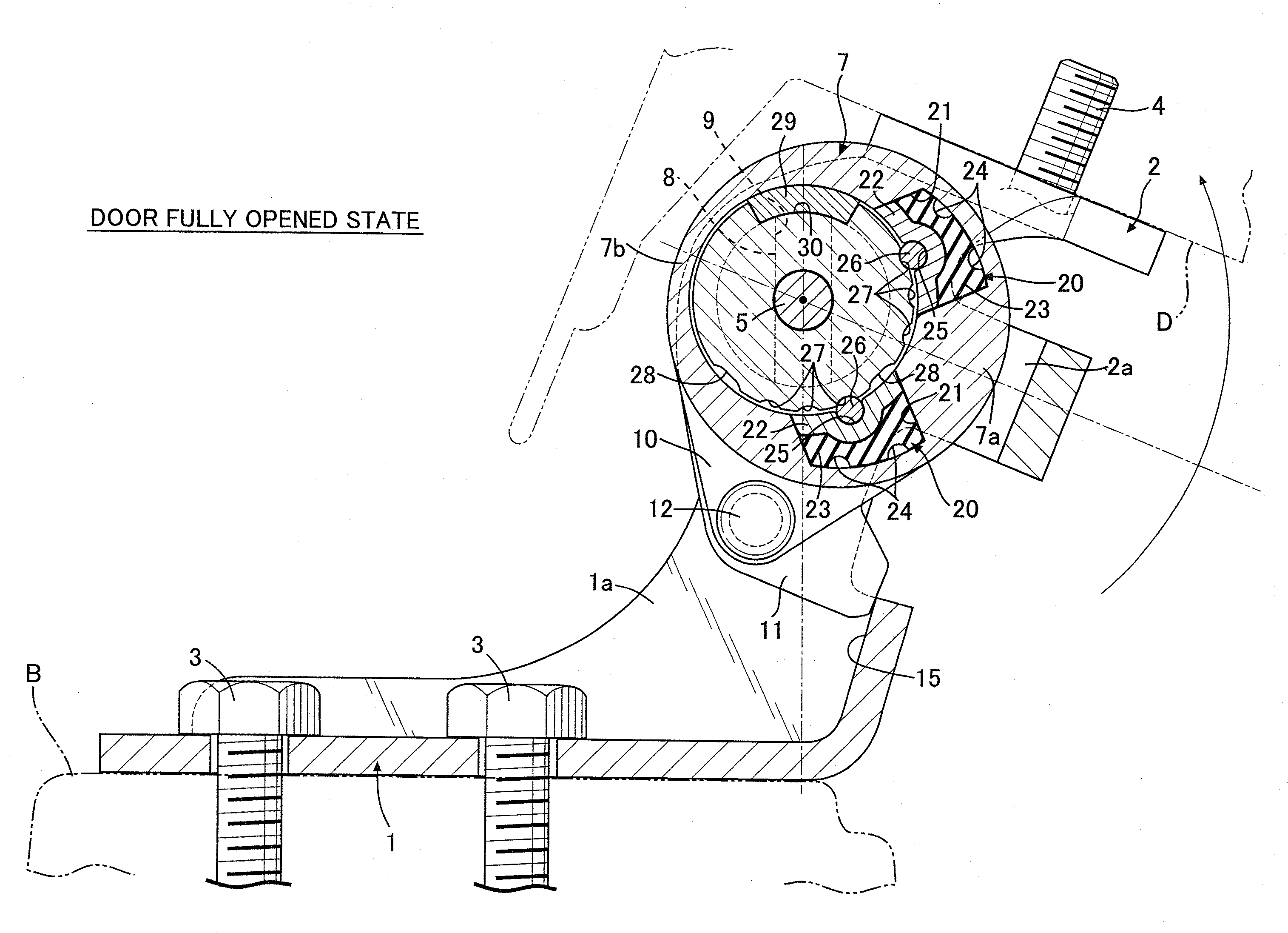

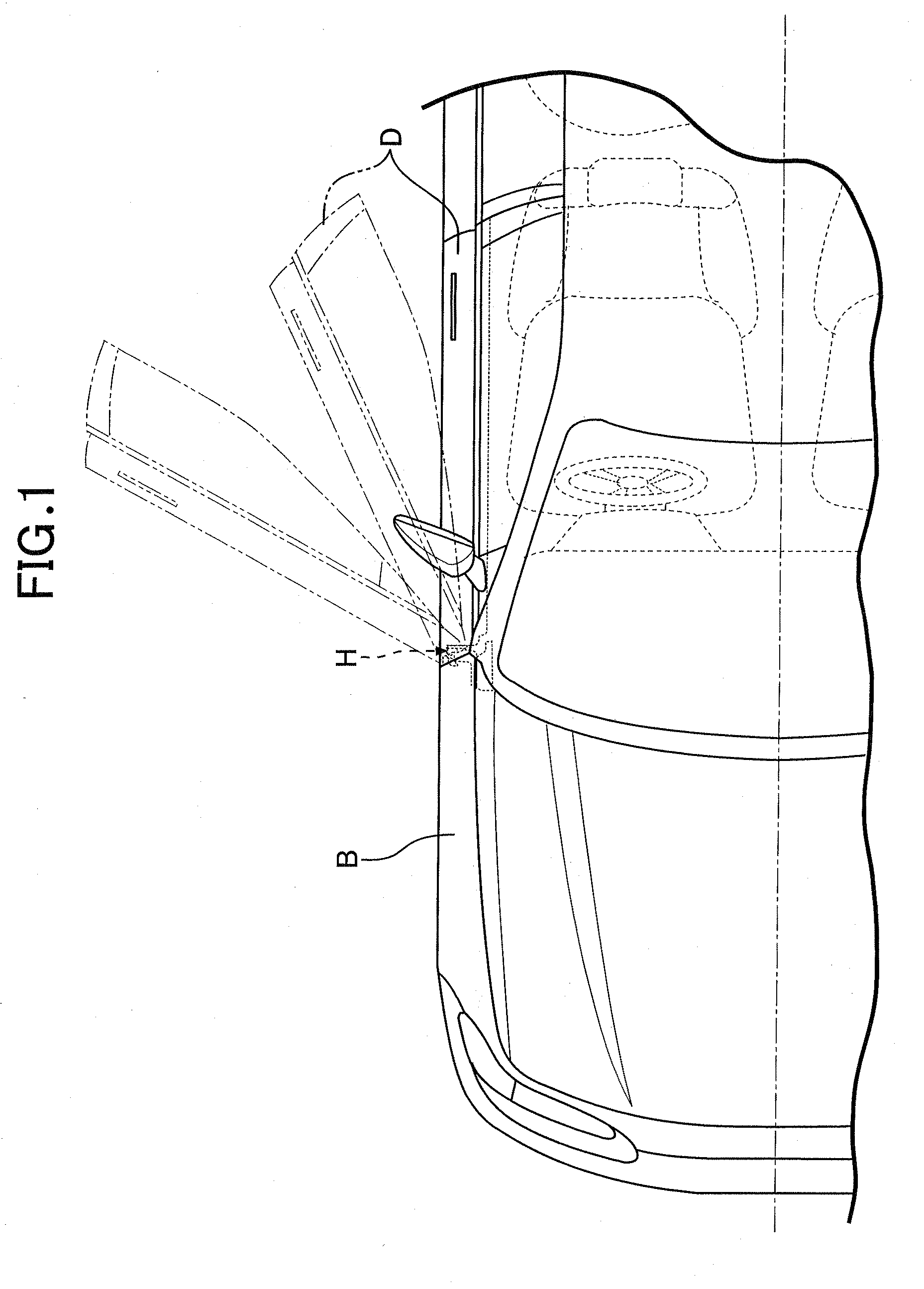

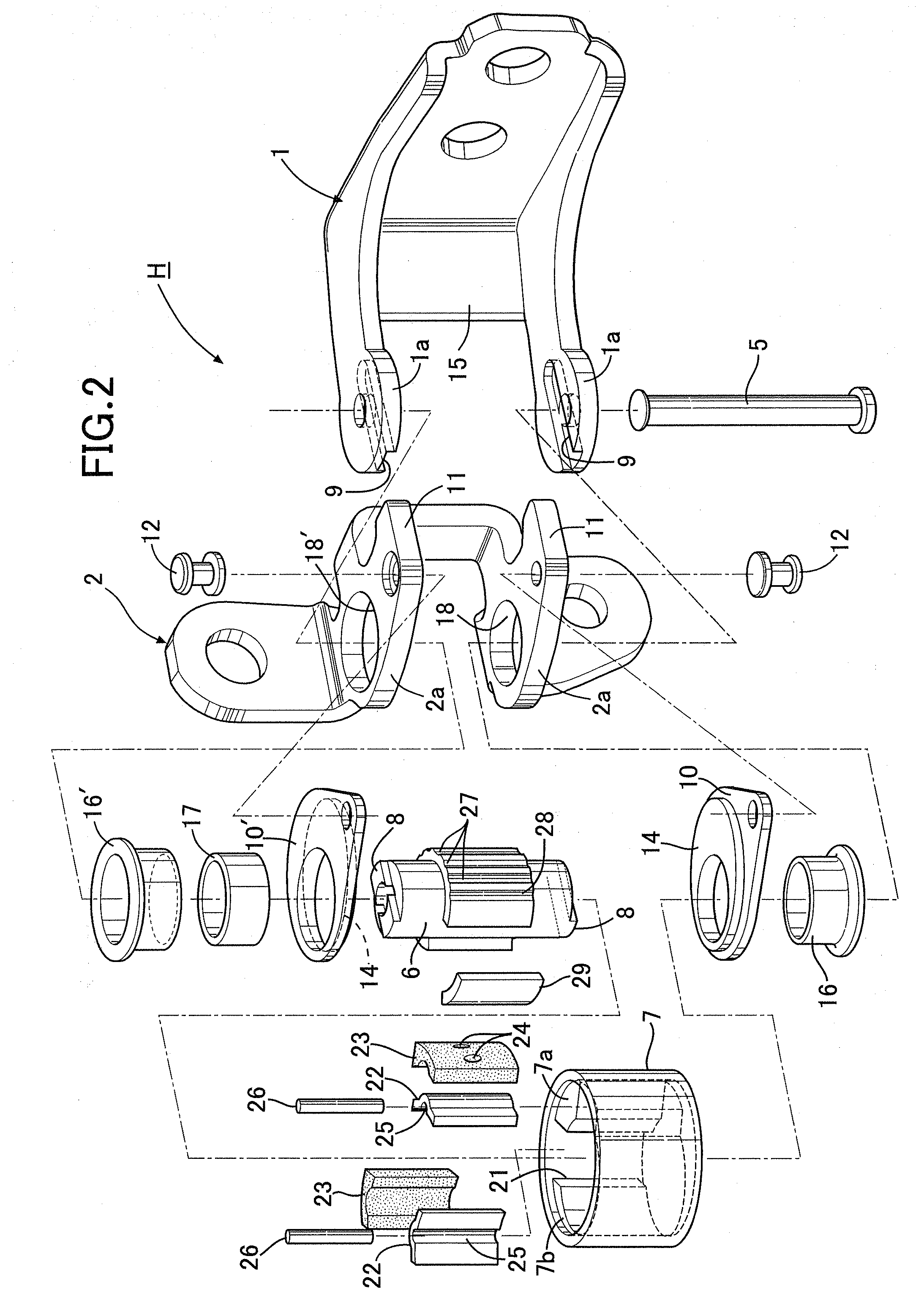

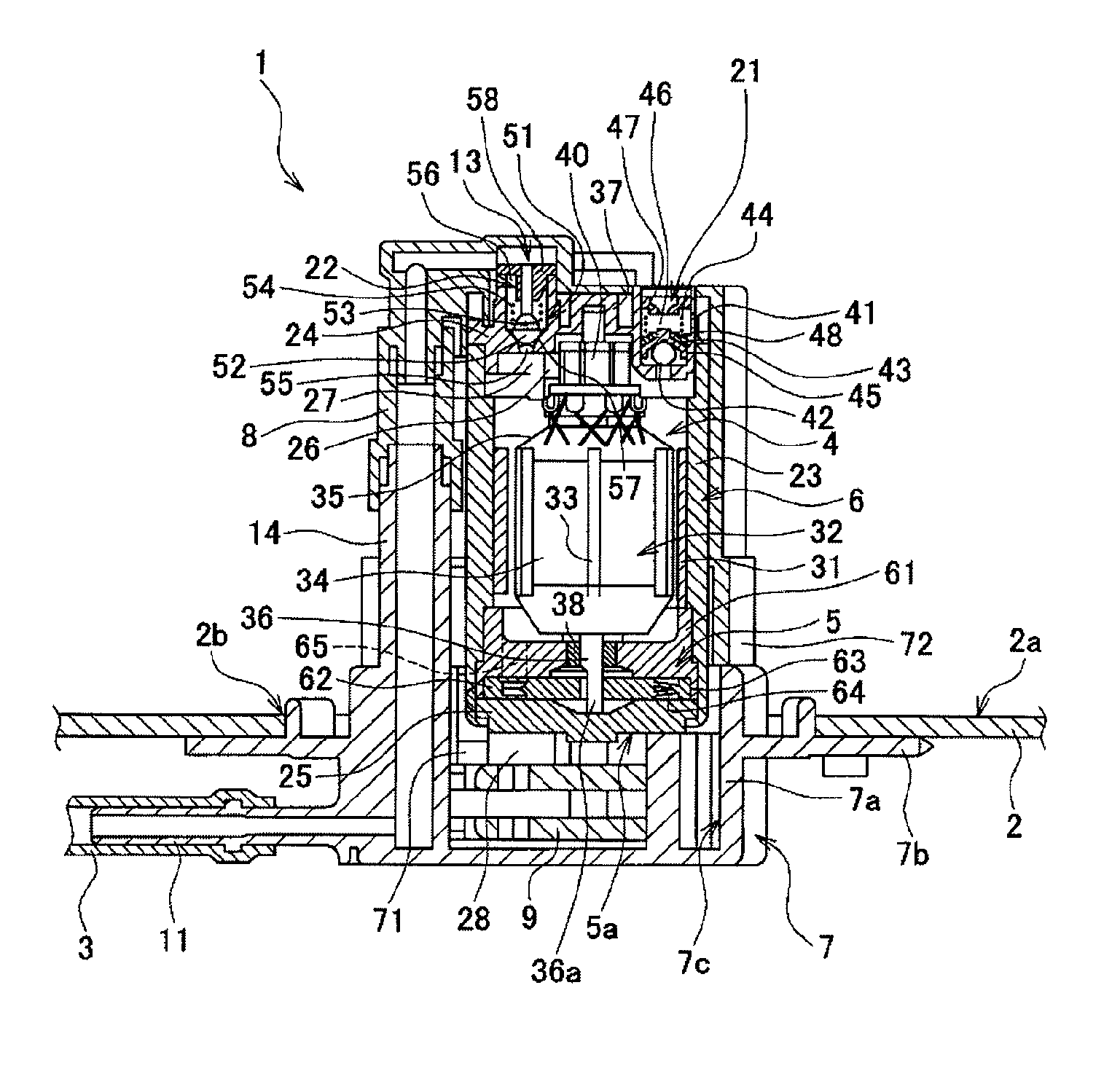

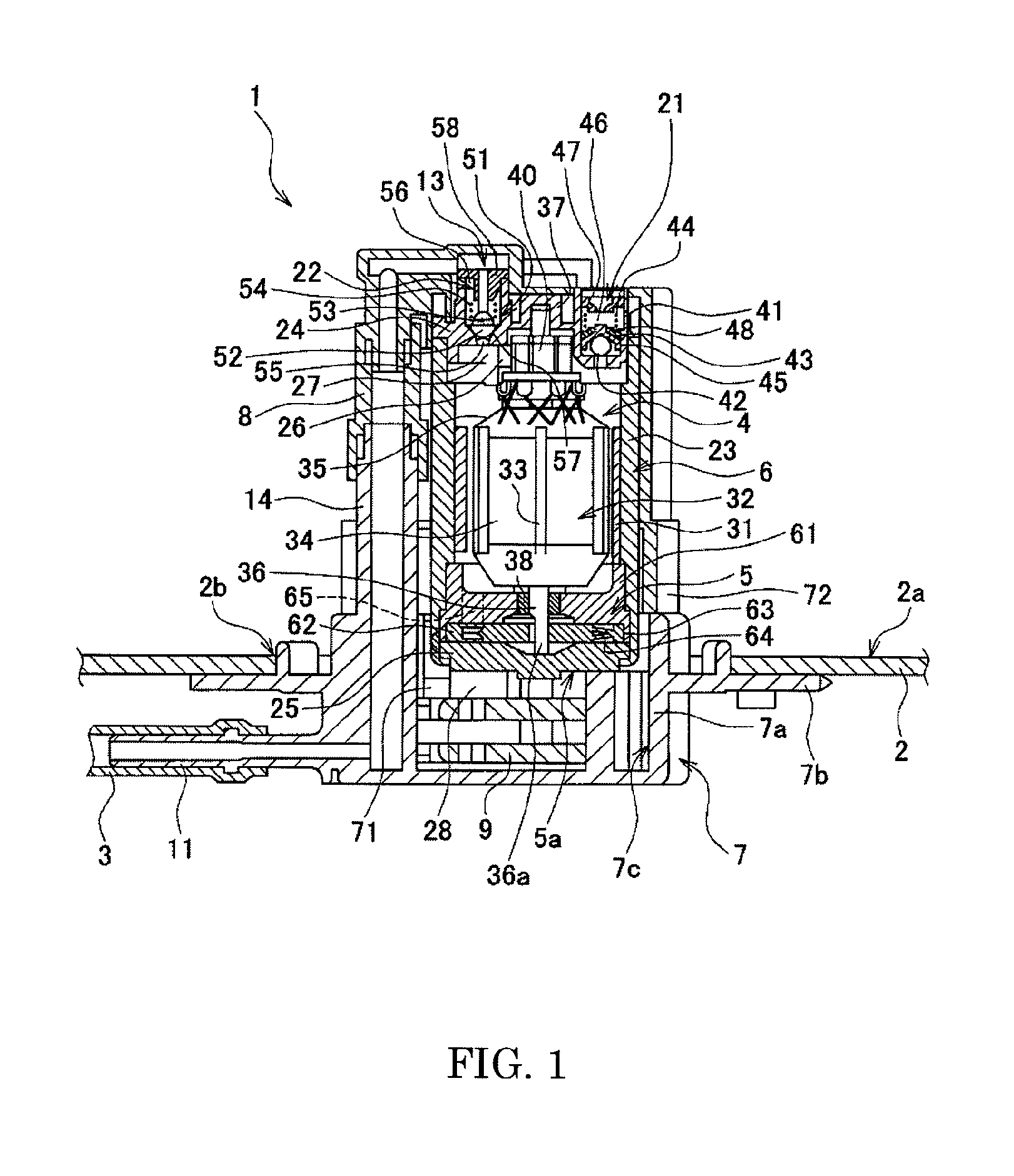

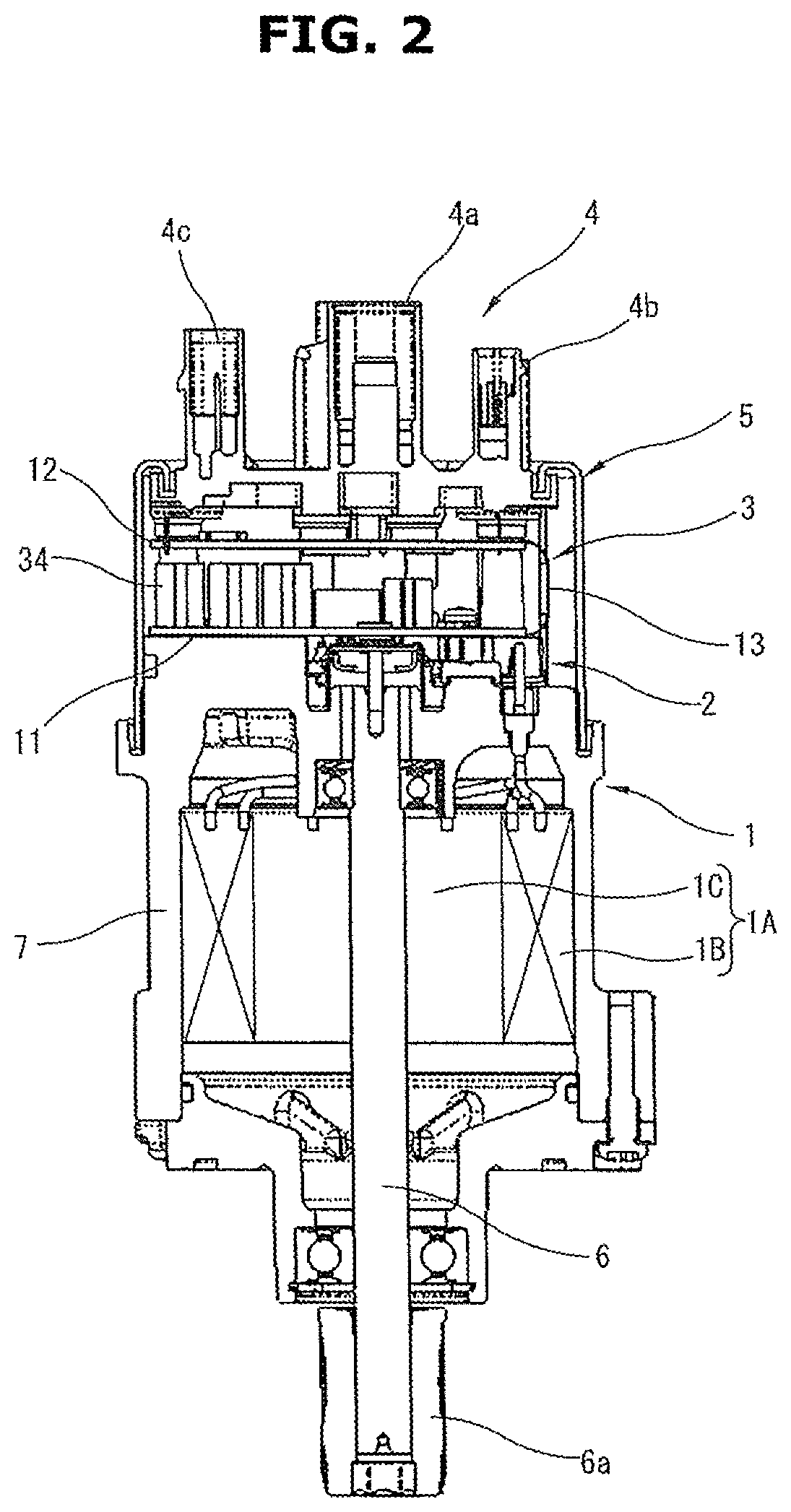

Checker-equipped door hinge device for vehicle

InactiveUS8108969B2Efficiently arrangedConvenient ArrangementBuilding braking devicesWing fastenersThick wallEngineering

A checker-equipped door hinge device for vehicle includes: a first bracket fixed to one of a body and a door; a second bracket fixed to another one of the body and the door; a hinge pin connecting the first and second brackets to each other, and allowing the brackets to be relatively rotatable; an inner cylinder connected integrally to the first bracket and disposed coaxially with the hinge pin; an outer cylinder connected integrally to the second bracket and disposed so as to surround the inner cylinder in a manner of being rotatable relative to the inner cylinder; and a checking-force generating mechanism provided between the inner cylinder and the outer cylinder, the checking-force generating mechanism generating a checking force against the door at a predetermined opening position of the door, wherein an inner peripheral surface and an outer peripheral surface of the outer cylinder are eccentric to each other, so that a thick wall portion having a large distance between the inner peripheral surface and the outer peripheral surface is formed in the outer cylinder, and the checking-force generating mechanism is provided in the thick wall portion. Thereby the door hinge device can be compact, in which the checking-force generating mechanism can be disposed in the outer cylinder without increasing the diameter of the outer cylinder.

Owner:RIKEN KAKI KOGYO CO LTD

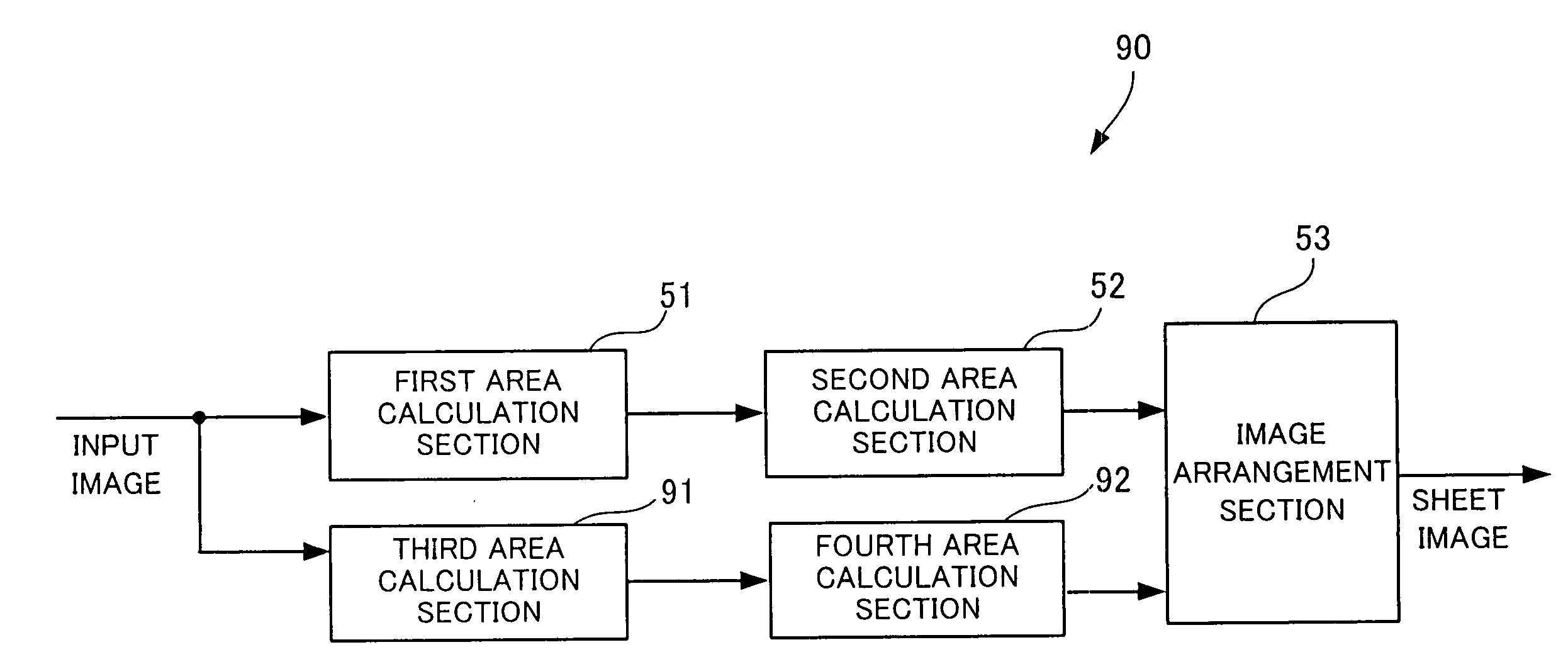

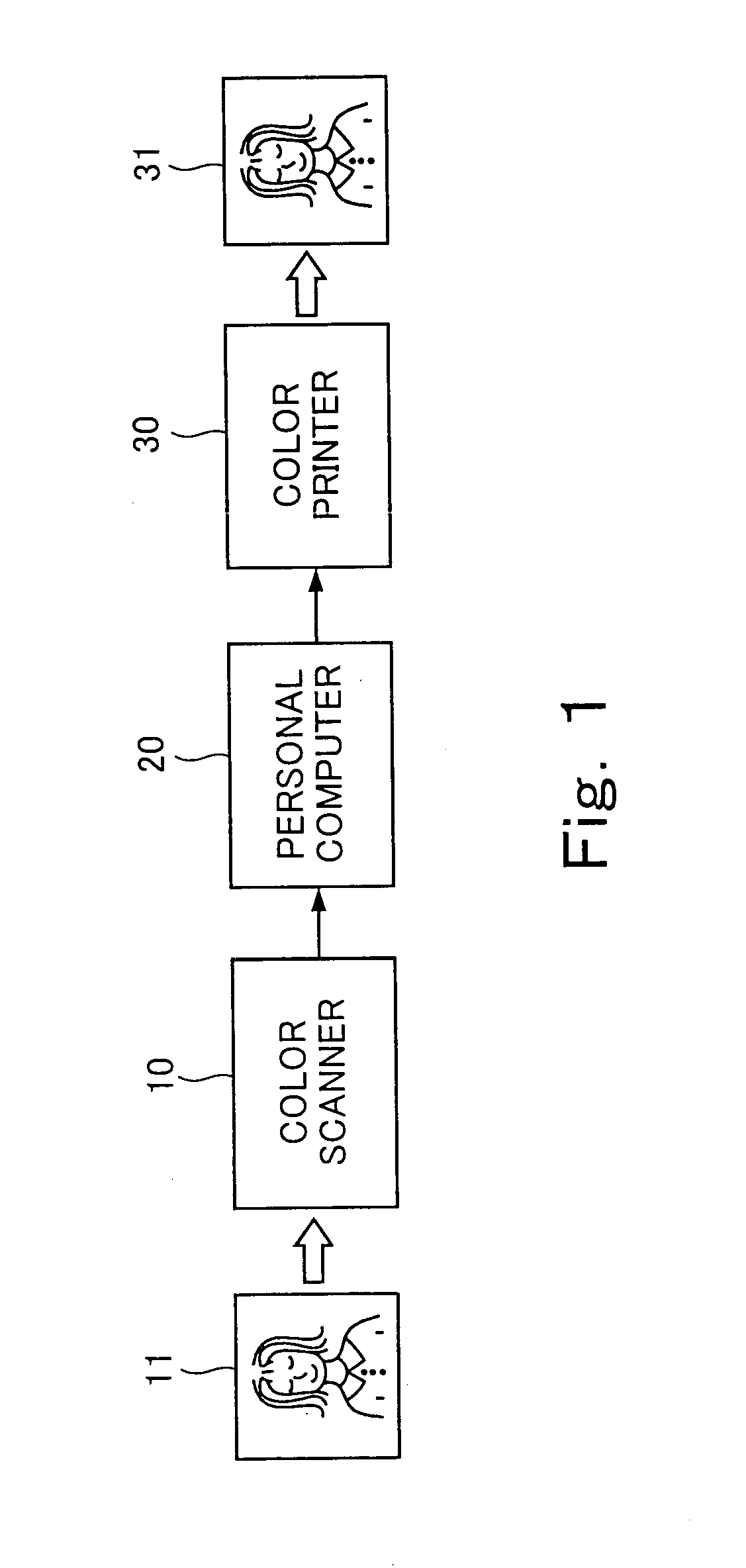

Image arrangement method, image arrangement device, and image arrangement program storage medium

InactiveUS20040109201A1Efficiently arrangedEasy to useVisual presentation using printersOriginals for photomechanical treatmentComputer science

Owner:FUJIFILM CORP +1

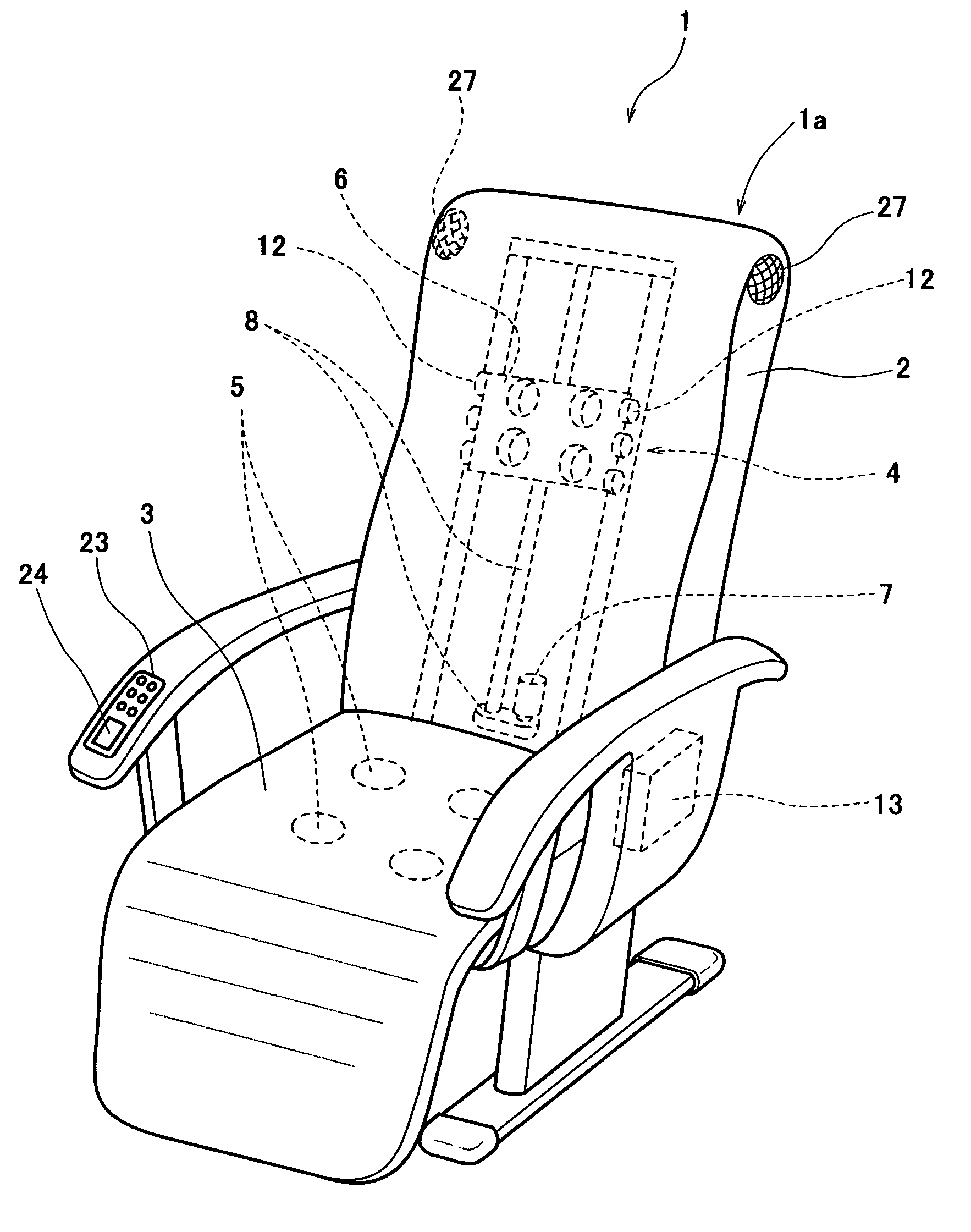

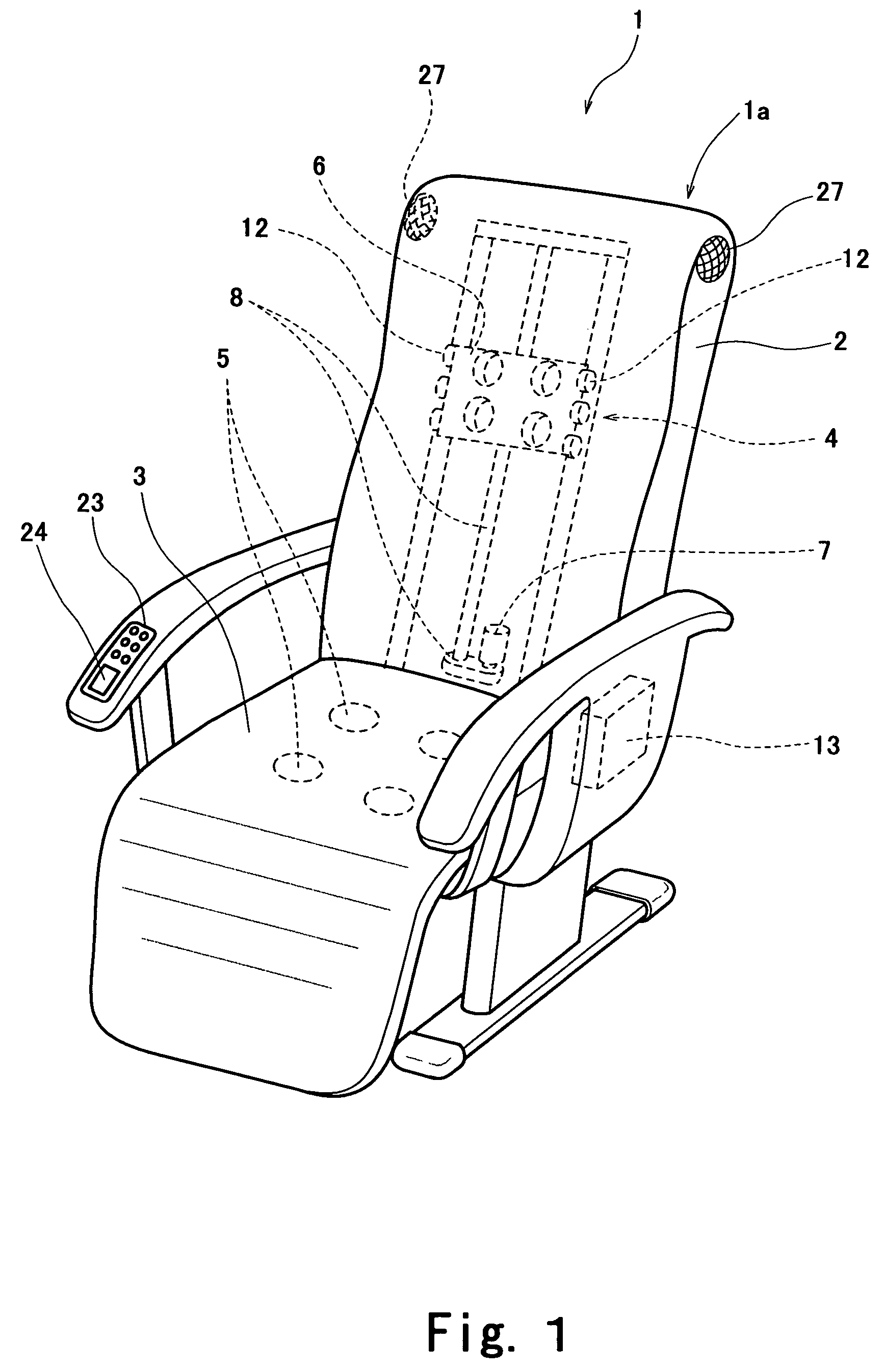

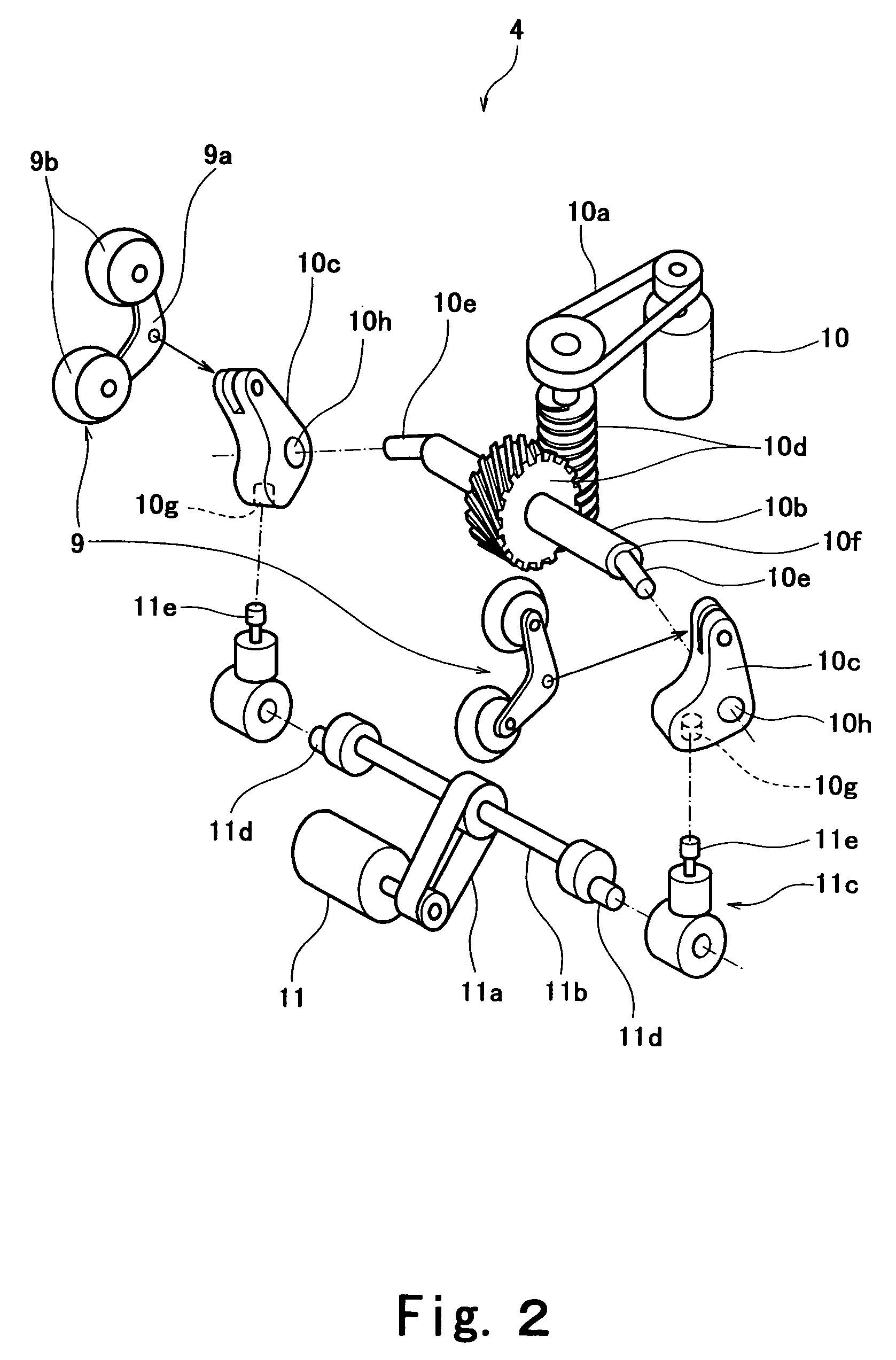

Massage machine, information recorded medium, program writing method

An object of the present invention is to provide a massaging apparatus that faithfully incorporates the rhythm or melody of a music source and performs massage with accents arranged more effectively based on these. A massaging apparatus of the present invention comprises massaging mechanisms (4, 5) that give mechanical impulses to a body by driving motors (5a, 10, 11), and a control device (13) that controls operations of the motors. The control device (13) comprises a waveform converter (18) having a waveform converting circuit for converting a waveform of an audio signal input from a sound source (A), such as a smoothing circuit, a differentiating circuit, or an integrating circuit, and a specific frequency band signal selecting unit (17) having a low pass filter, a high pass filter, and a band pass filter. In accordance with a control signal output from the waveform converter (18) and the specific frequency band signal selecting unit (17), the operations of the motors are controlled.

Owner:FAMILY INADA

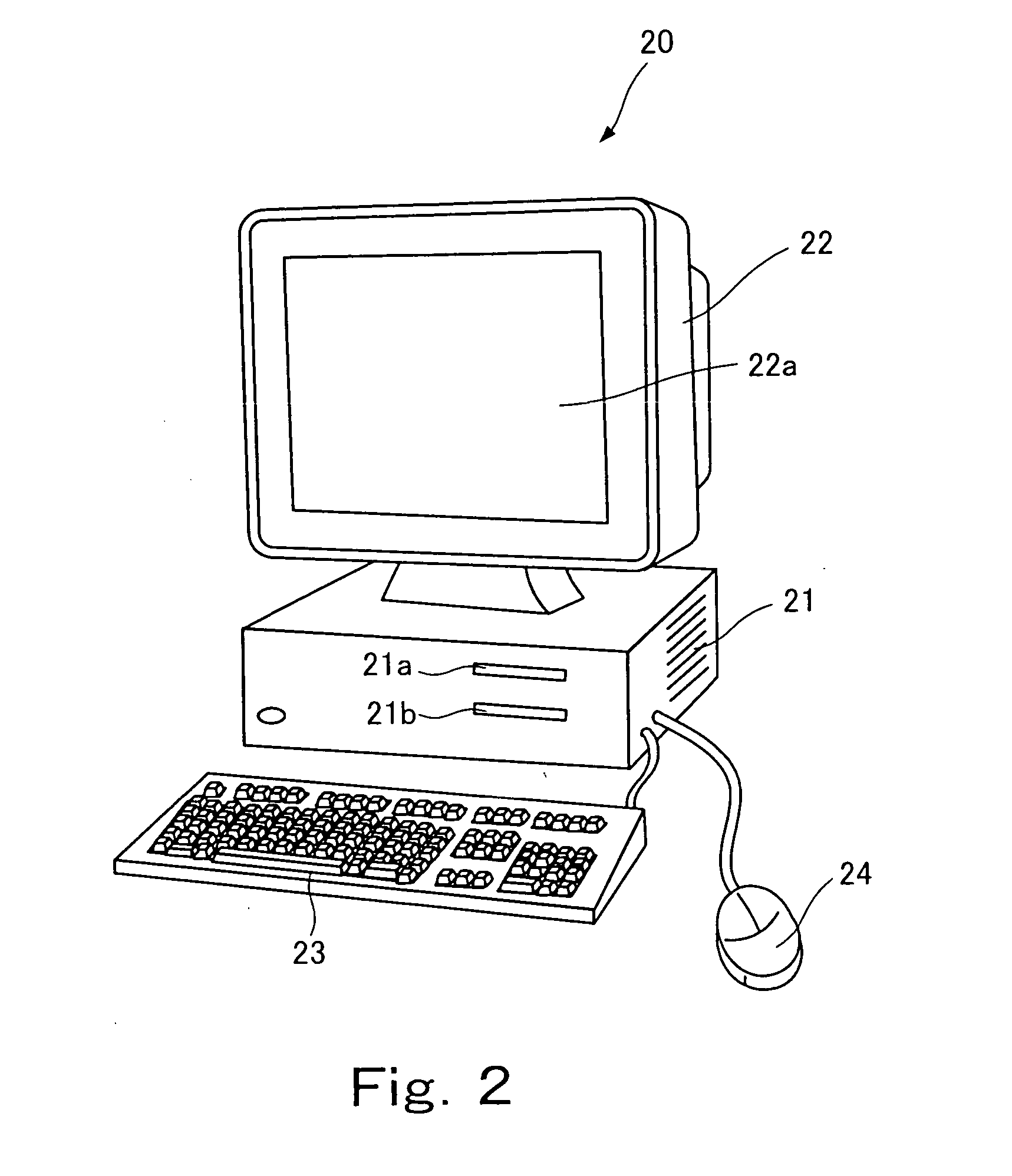

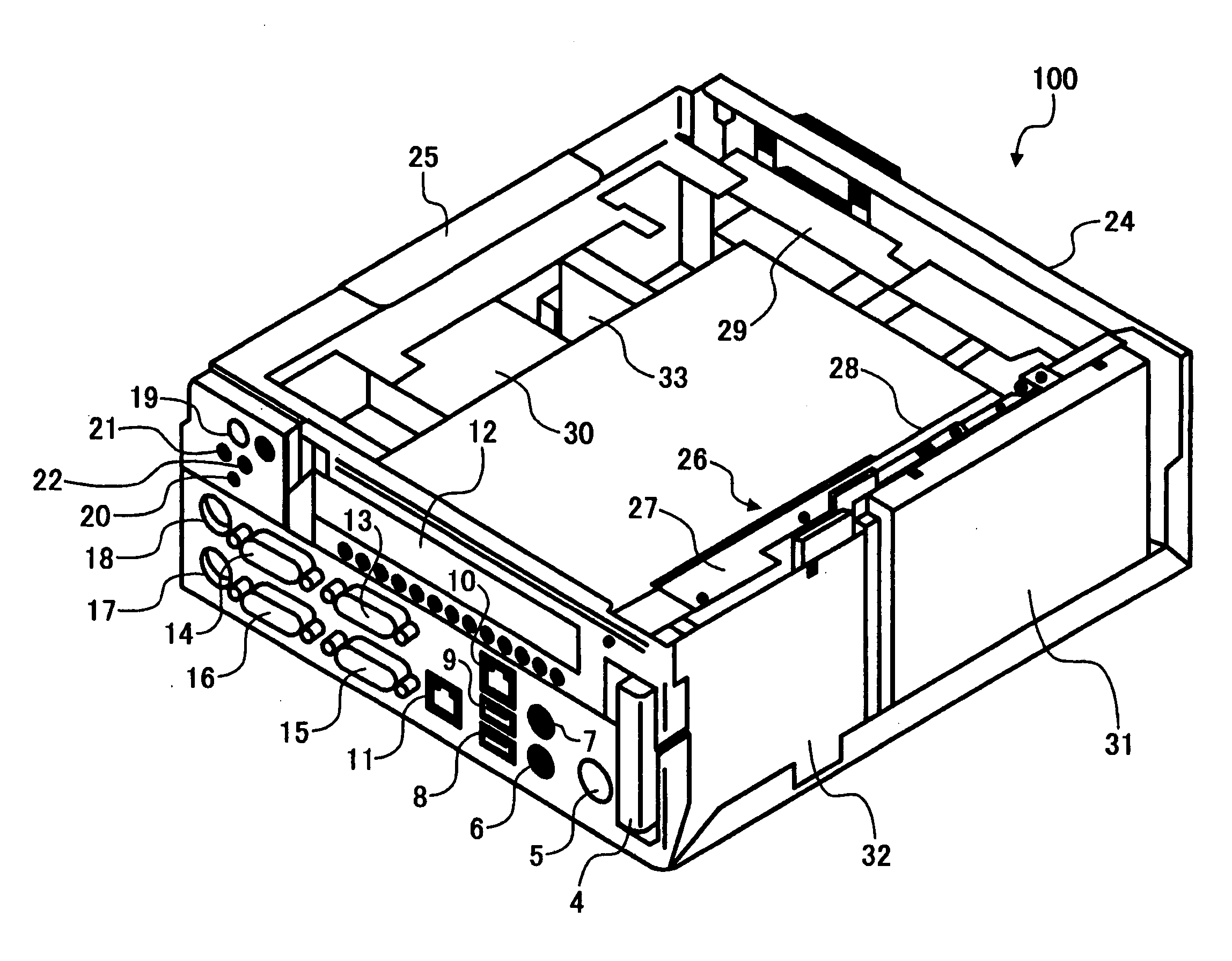

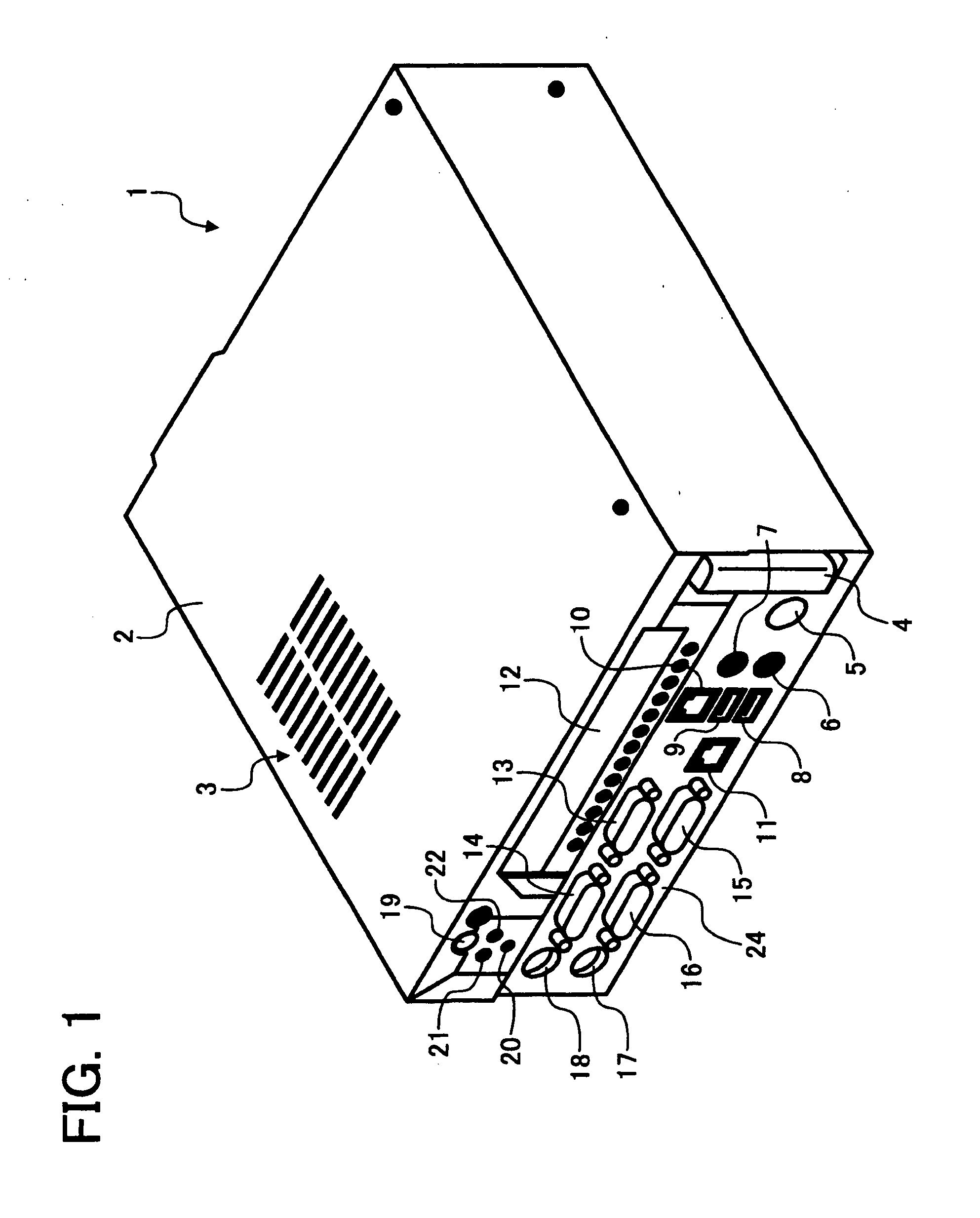

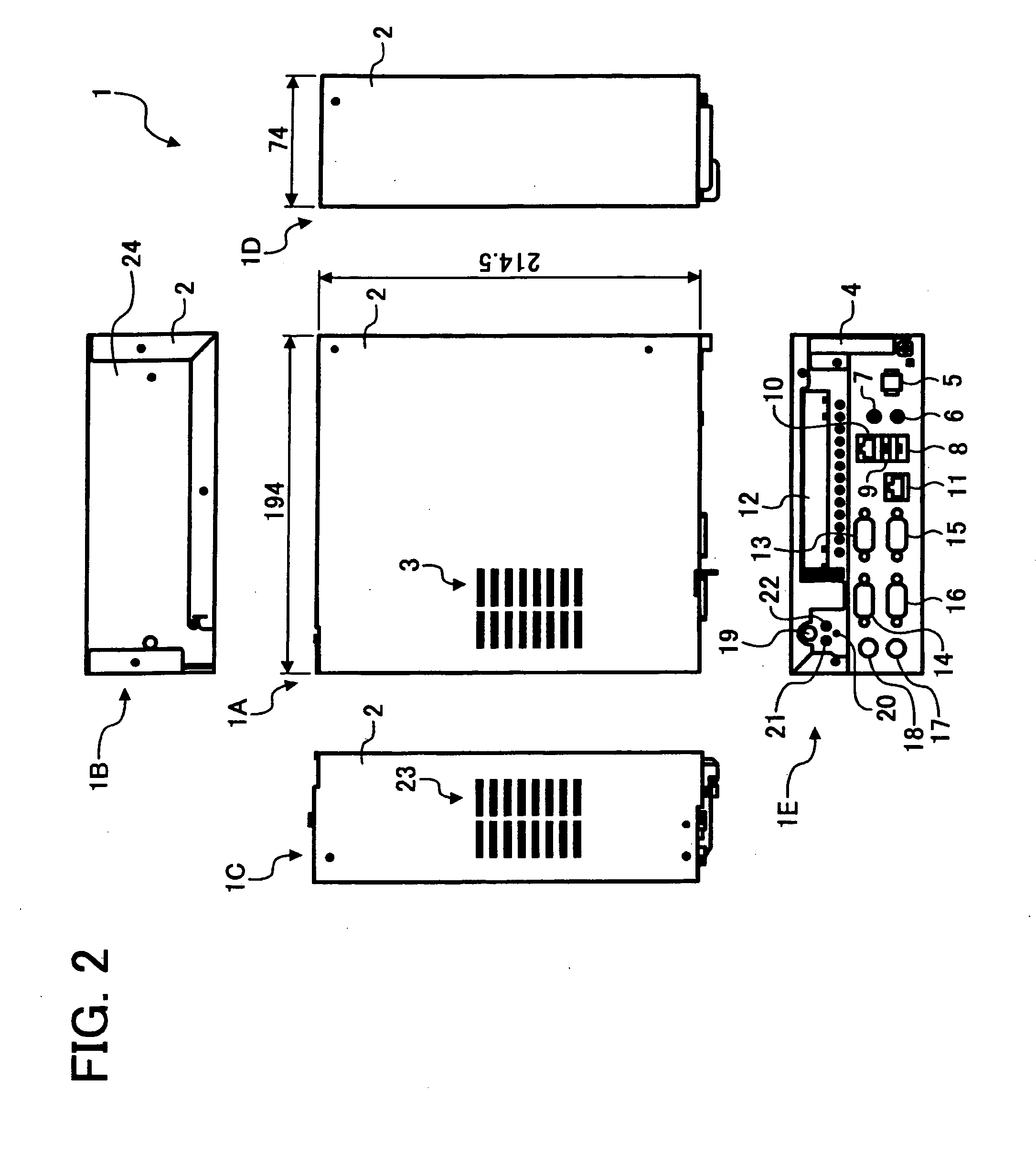

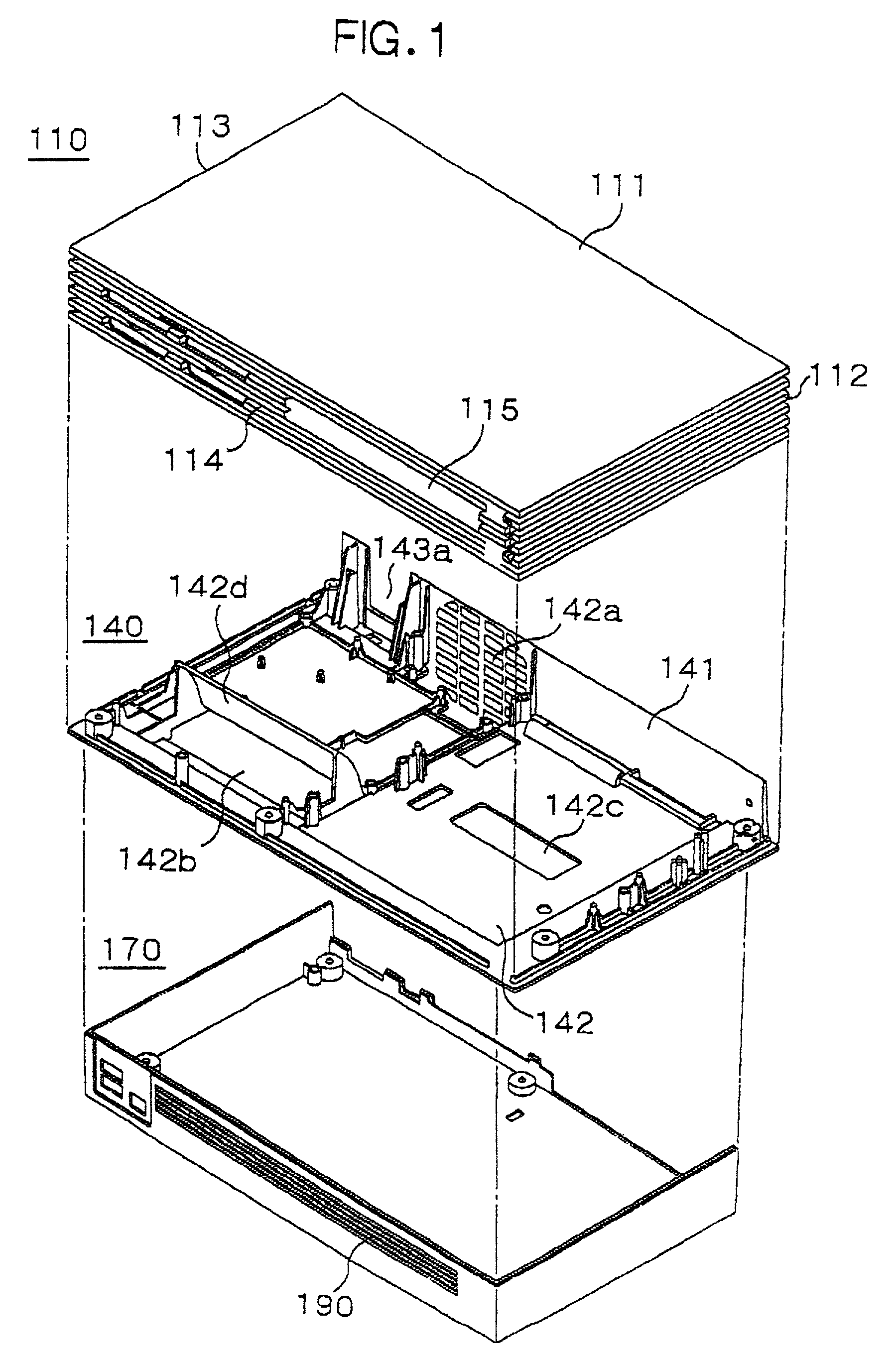

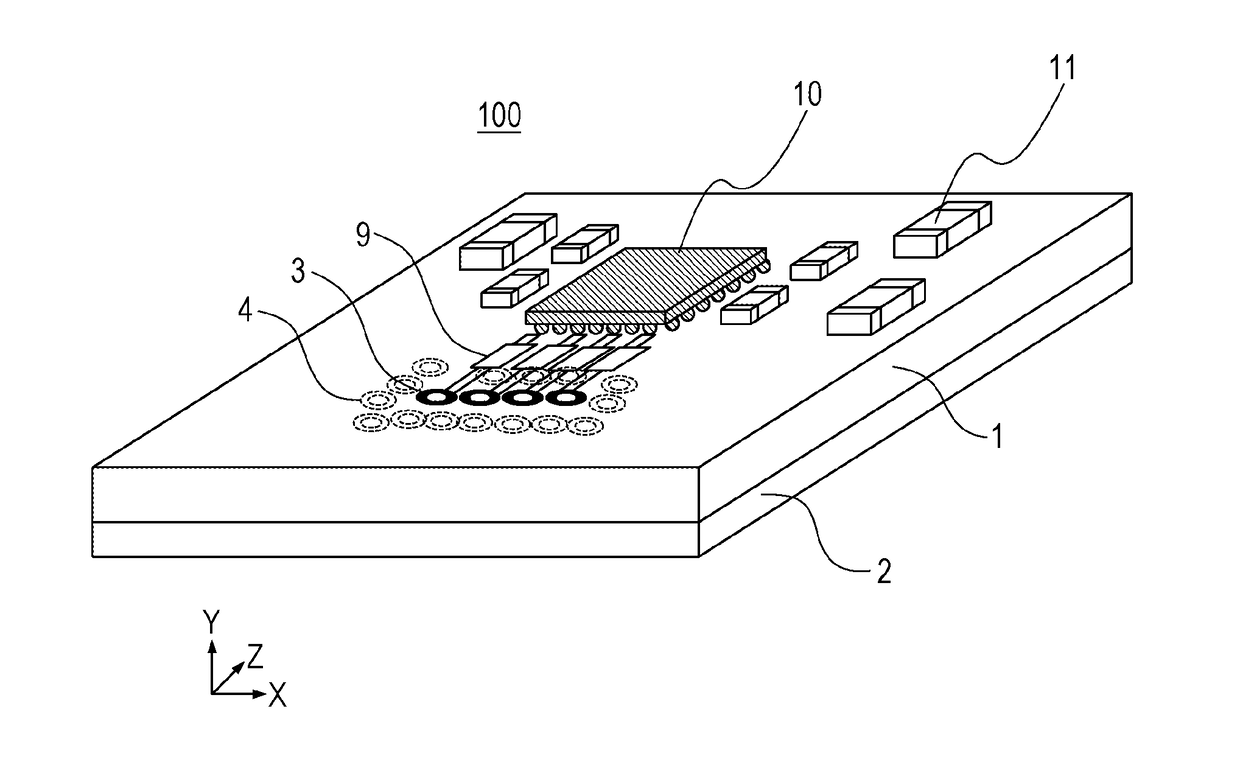

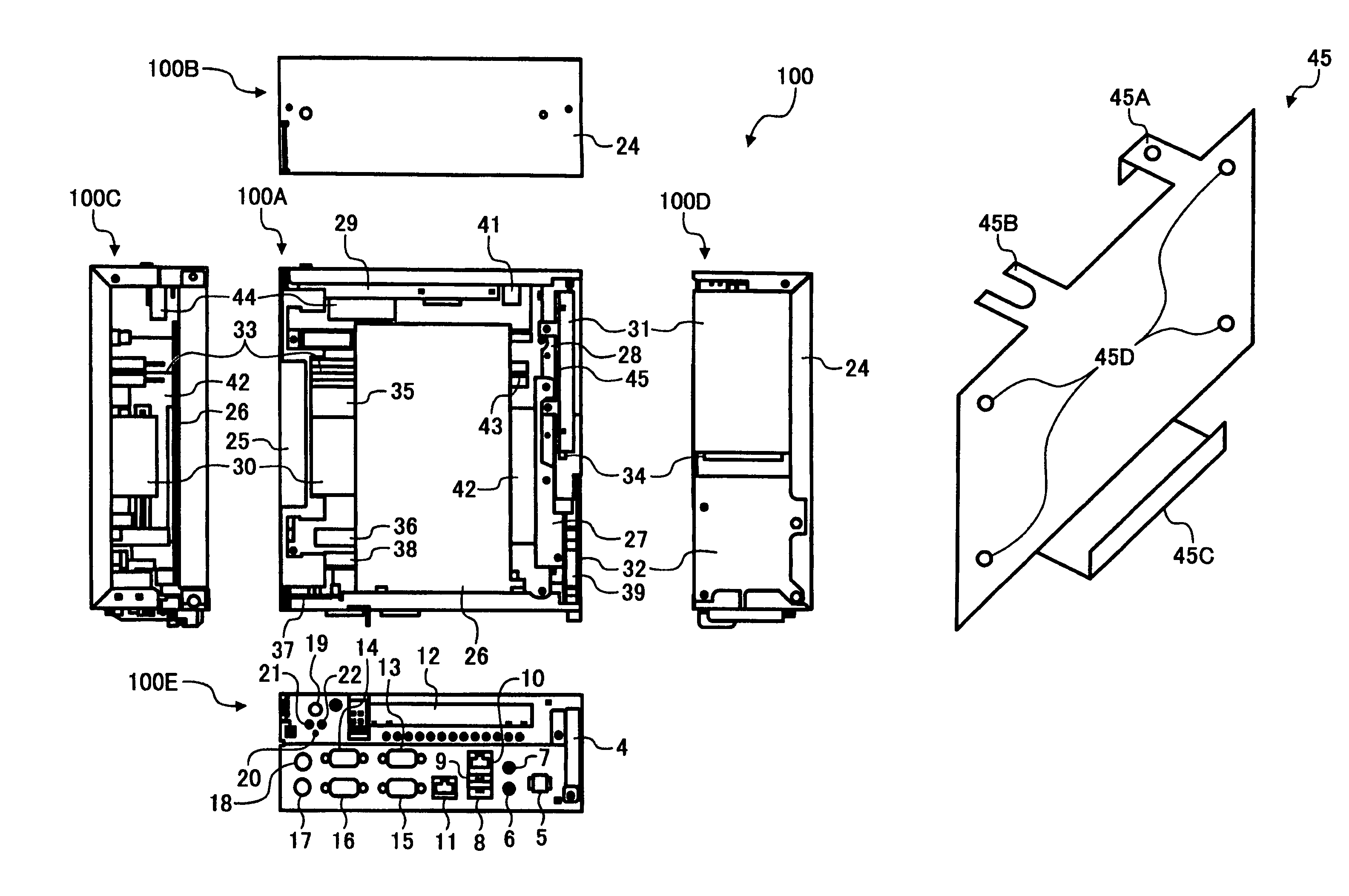

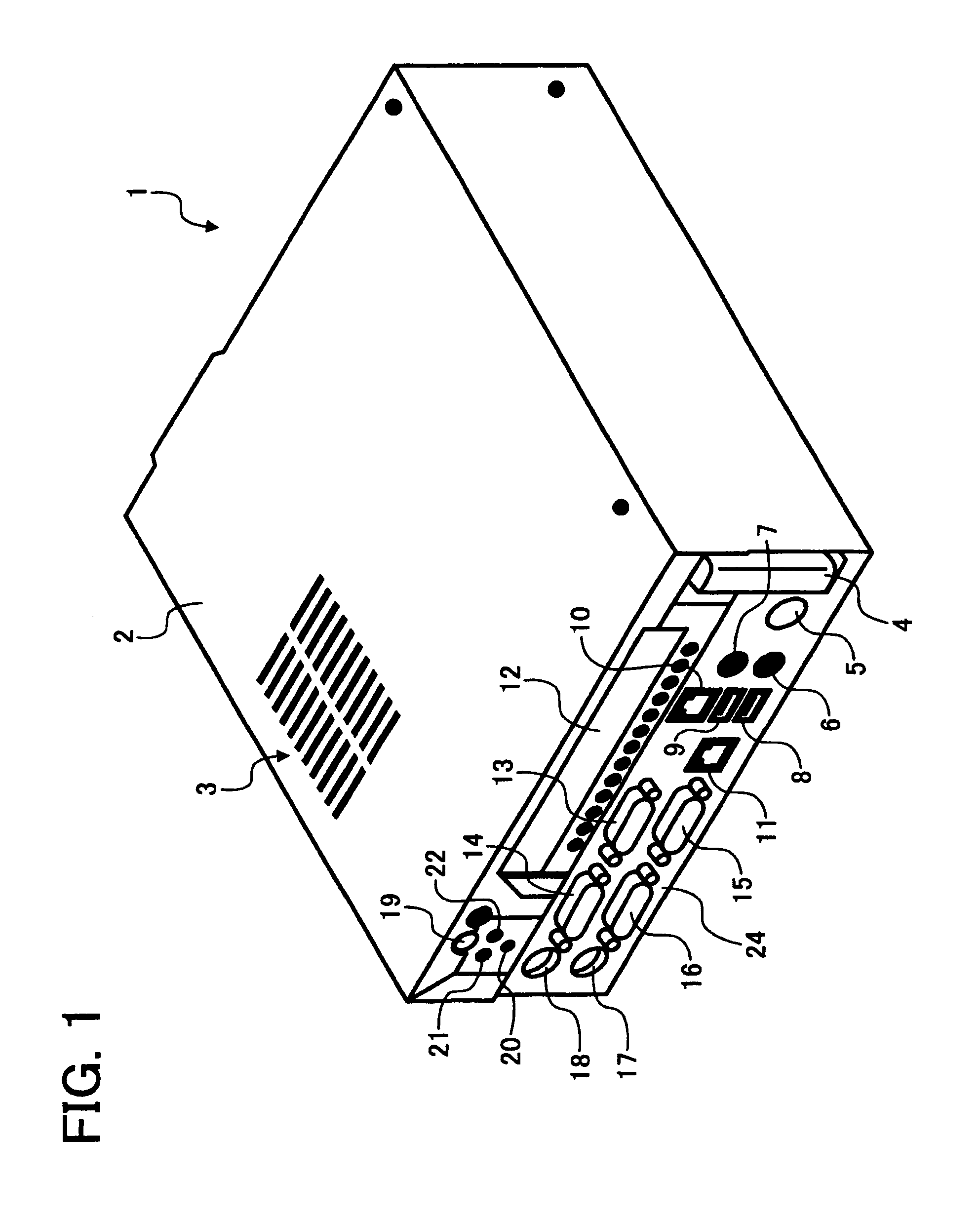

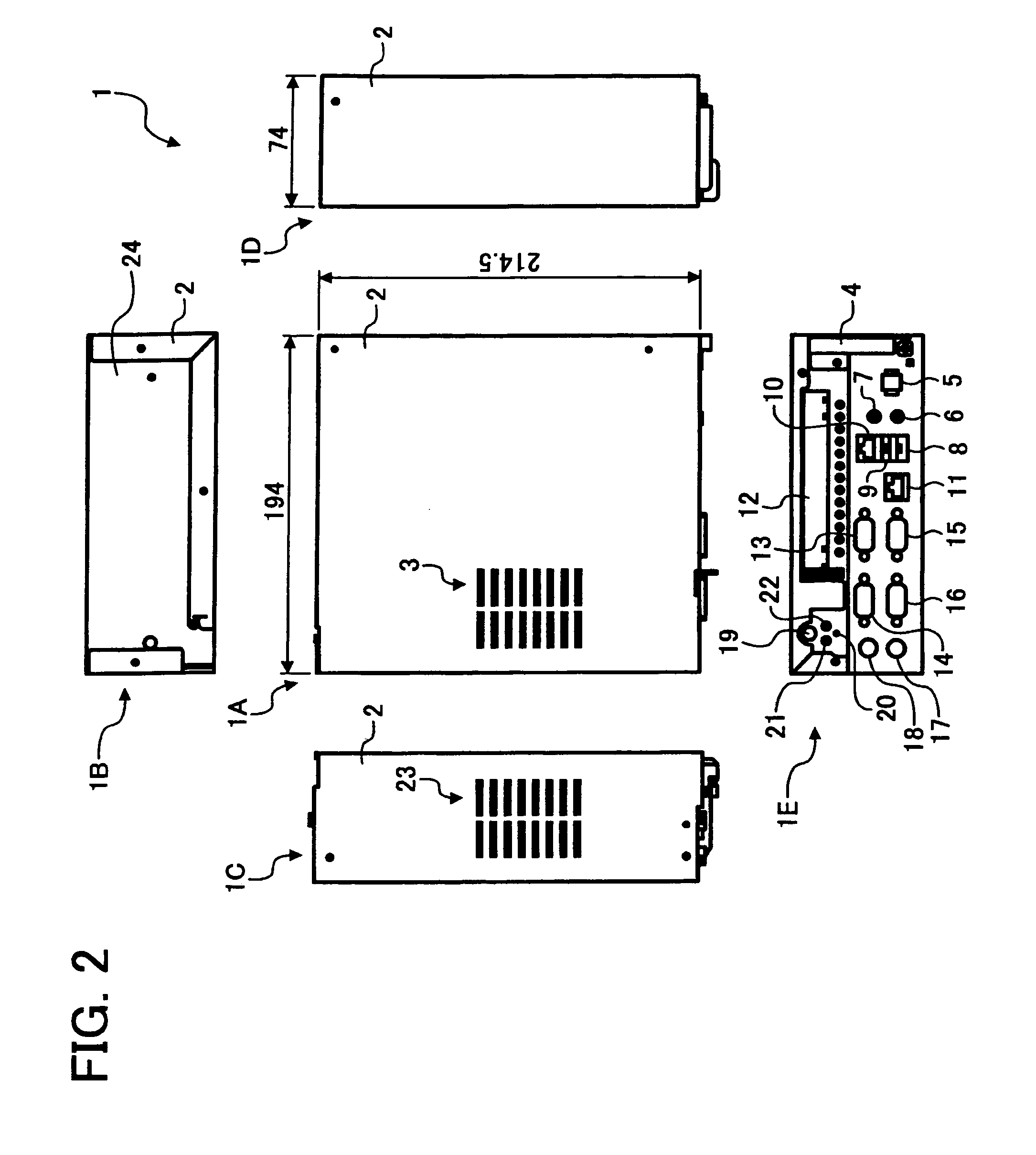

Storage device and method of efficiently arranging components in an information processing apparatus

ActiveUS20060256515A1Efficient arrangementEfficiently arrangedDigital data processing detailsElectrical connection printed elementsInformation processingExpansion card

An information processing apparatus designed for miniaturization, having a chassis, and including a motherboard; an expansion slot exchange device electronically connected to the motherboard and configured to hold an expansion card; and a memory device electronically connected to the motherboard and located within the chassis primarily in a first plane orthogonal to a primary plane of the motherboard. An expansion card can be added, occupying a plane parallel to the primary plane of the motherboard.

Owner:RICOH KK

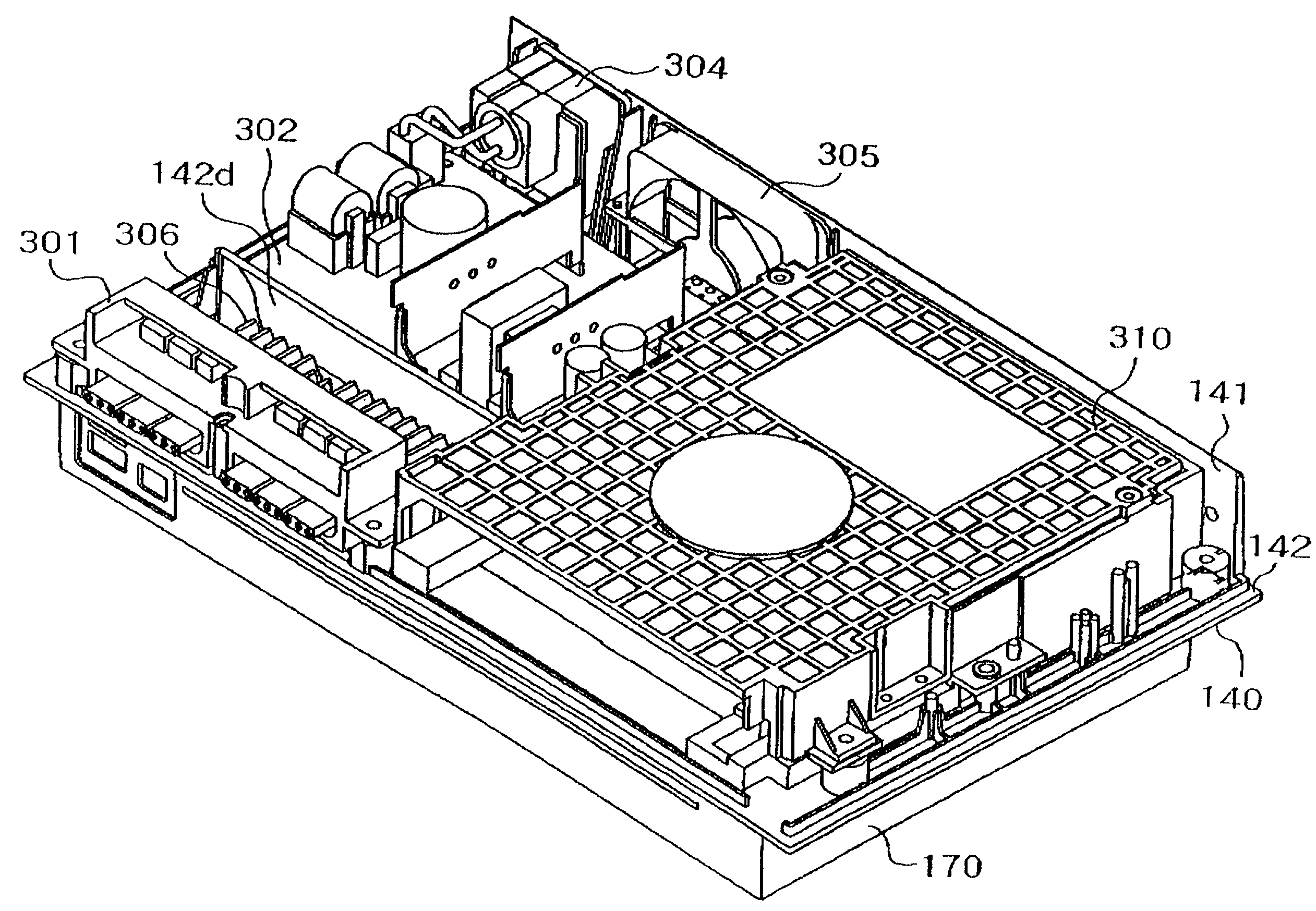

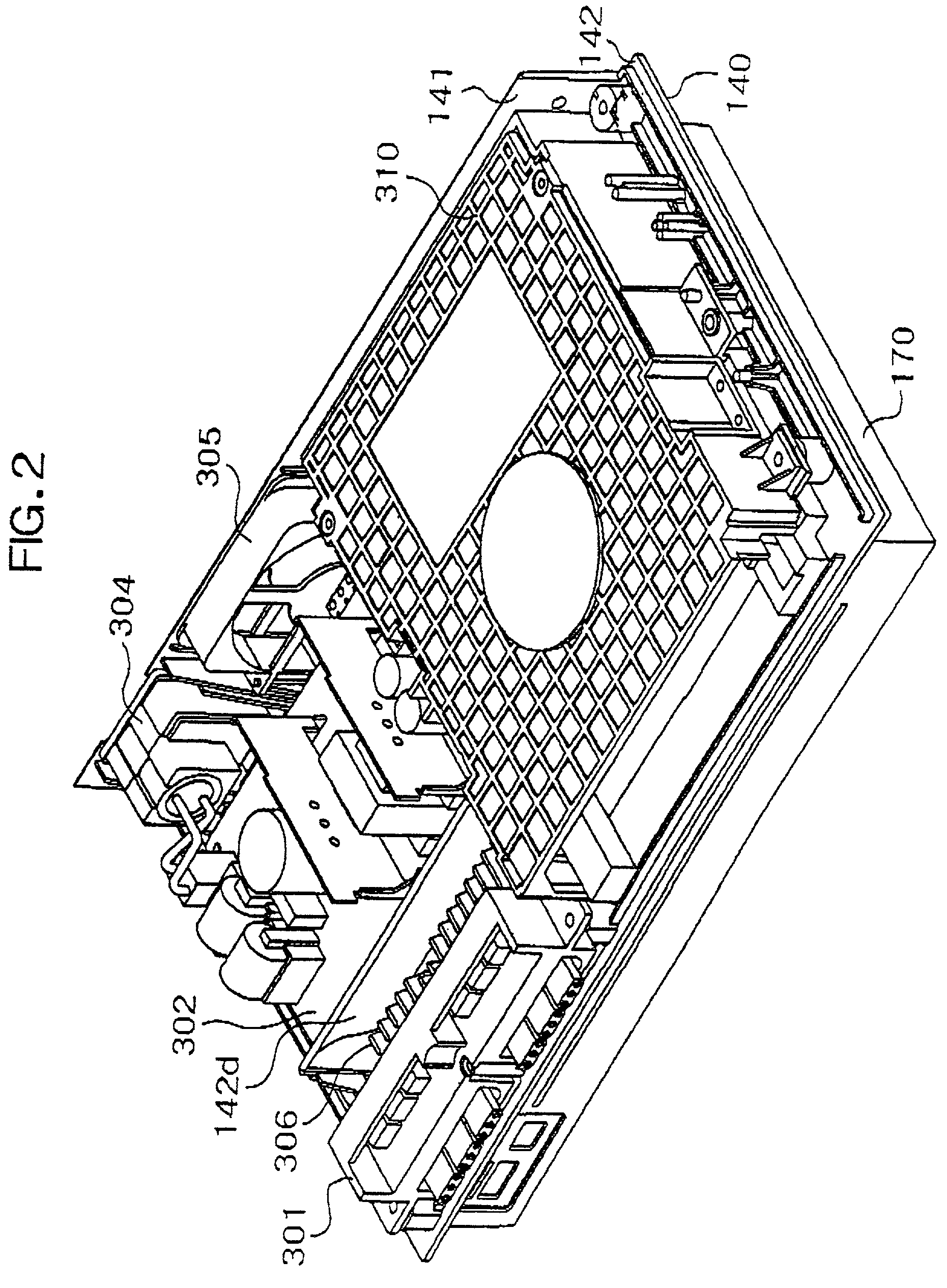

Circuit substrate unit and electronic equipment

ActiveUS7254035B2Efficient arrangementEffectively cooling partMagnetic/electric field screeningDigital data processing detailsEngineeringHeat sink

Provided is a structure in which a shield 308 and a heat sink 307 integrated with a radiation fin 306 are sandwiched by a main substrate 381a and a power source substrate 381b. A hood 142d covers the radiation fin 306 so as to collect air for cooling. Major parts of the main substrate 381a are in contact with the heat sink 307 via heat conduction members having different heat conductivity so that an even thermal distribution is provided. Thus, parts of electronic equipment can be efficiently disposed in a limited space. Moreover, the parts of the electronic equipment can be effectively cooled.

Owner:SONY COMPUTER ENTERTAINMENT INC +1

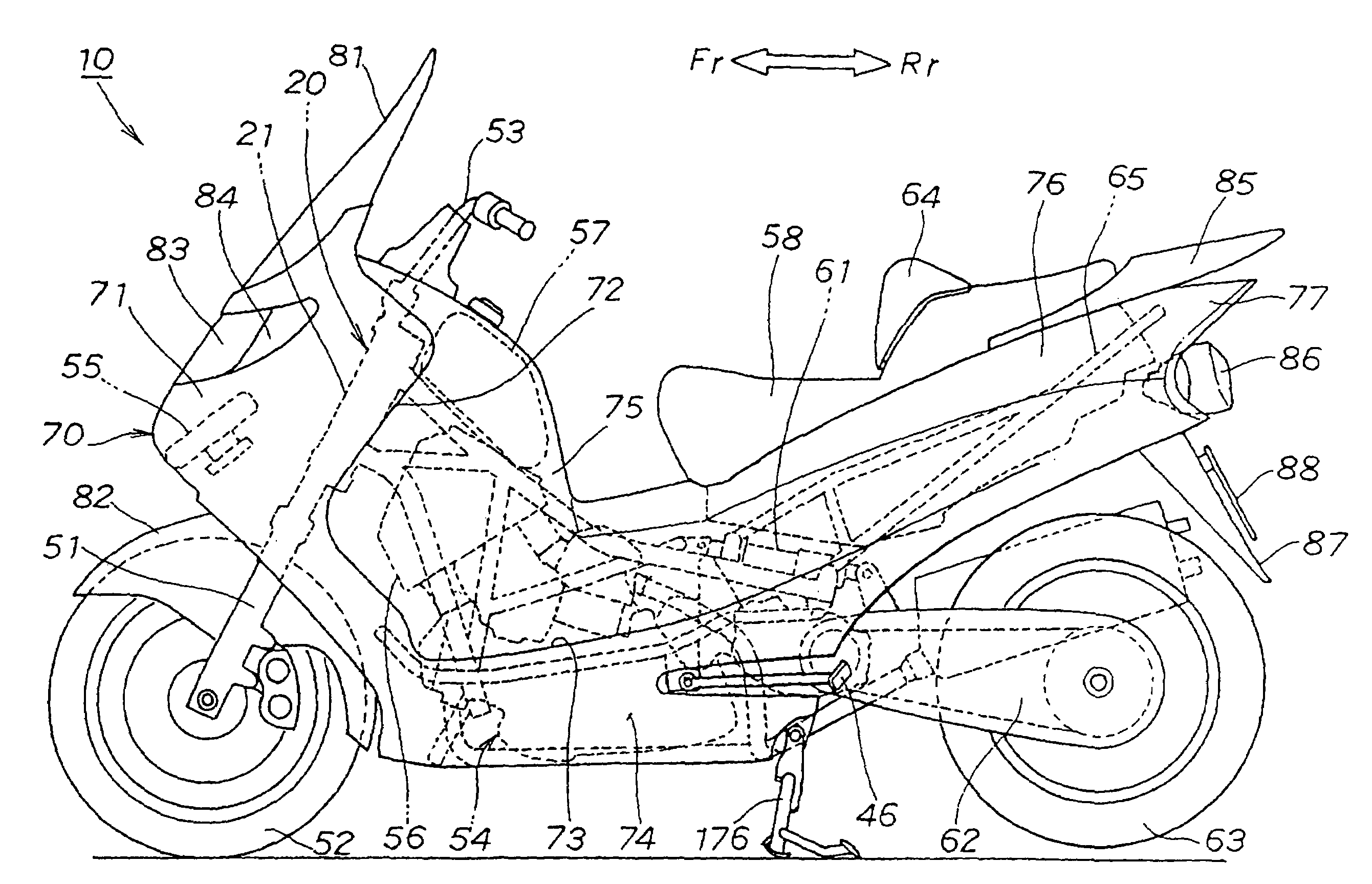

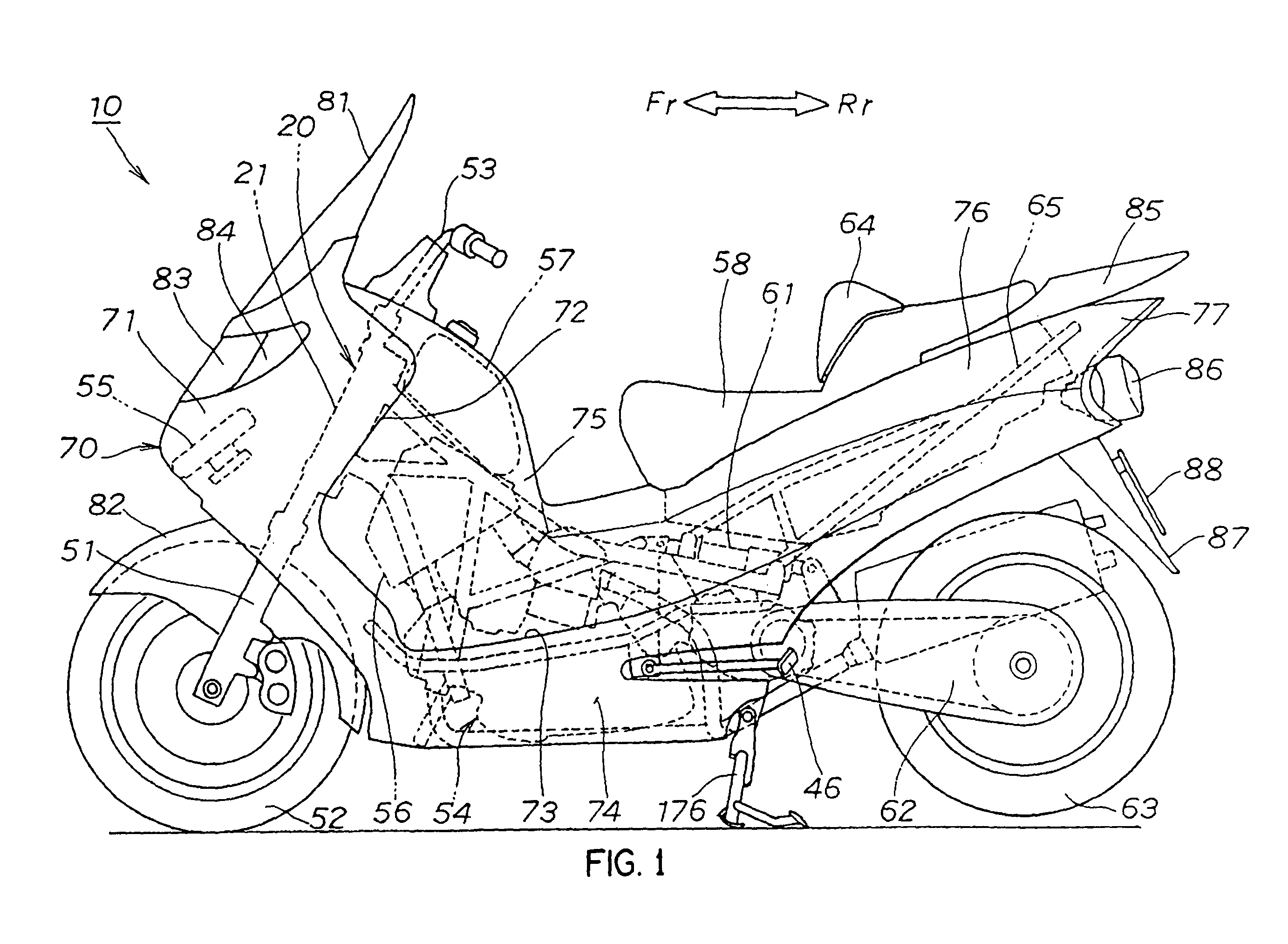

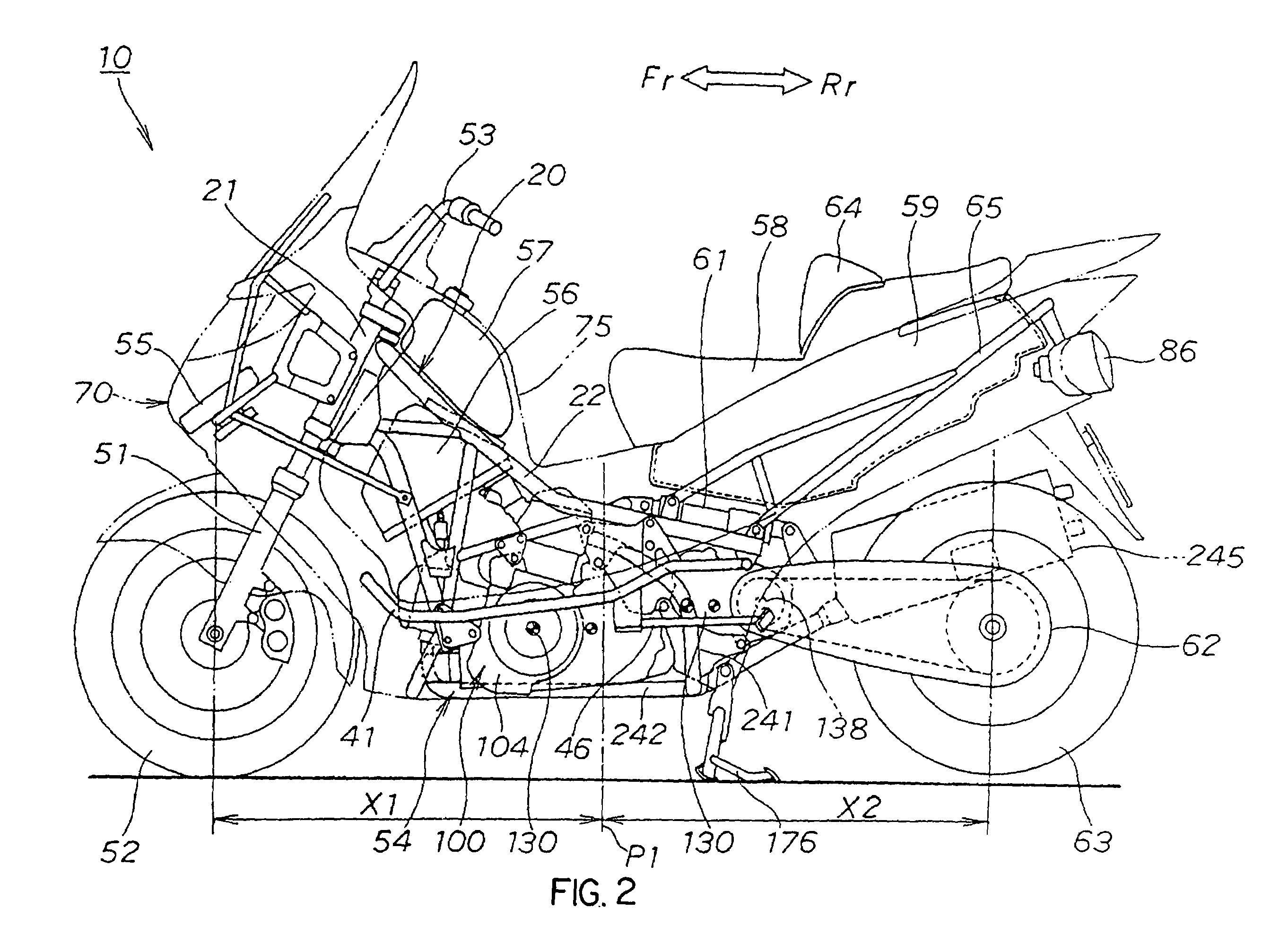

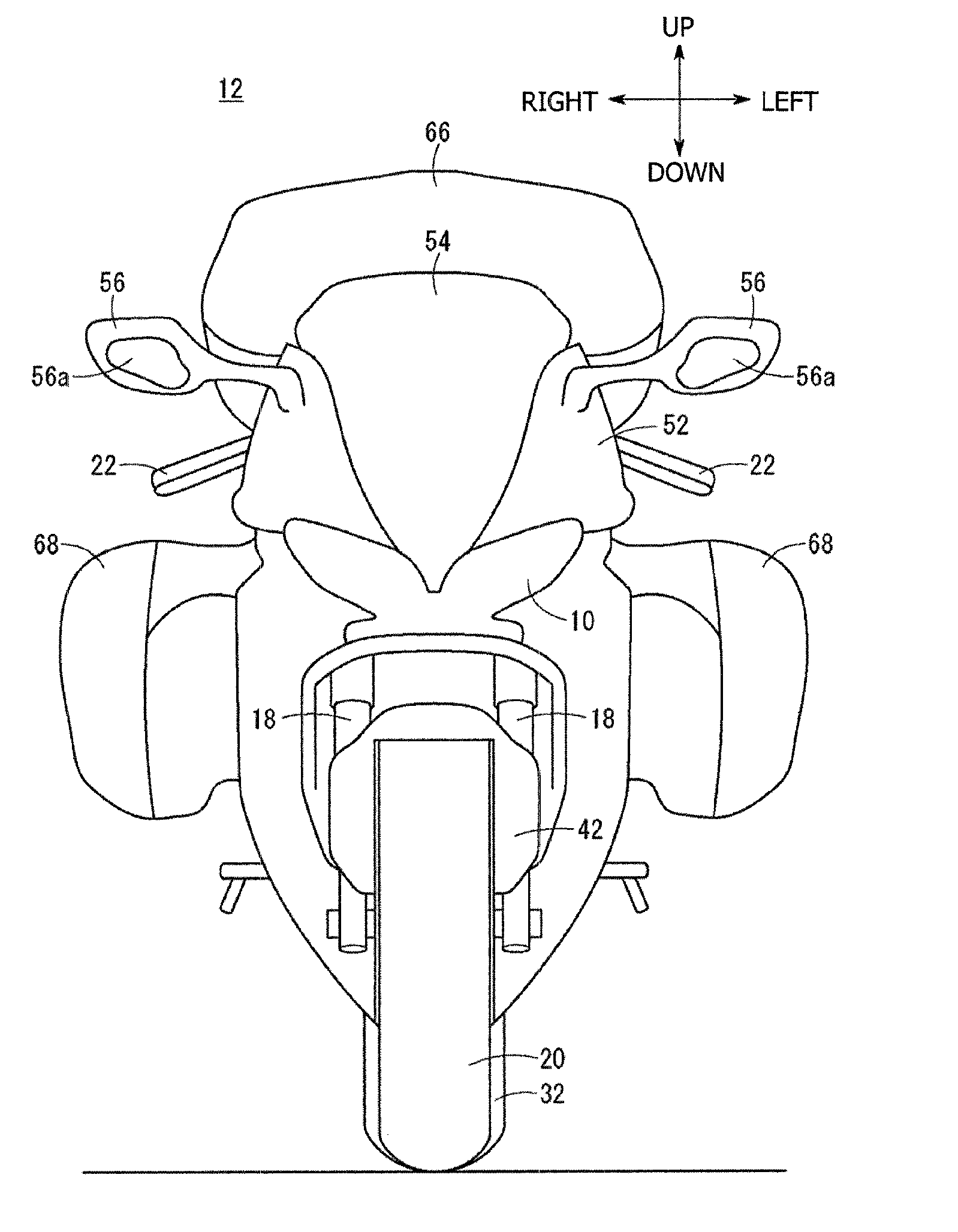

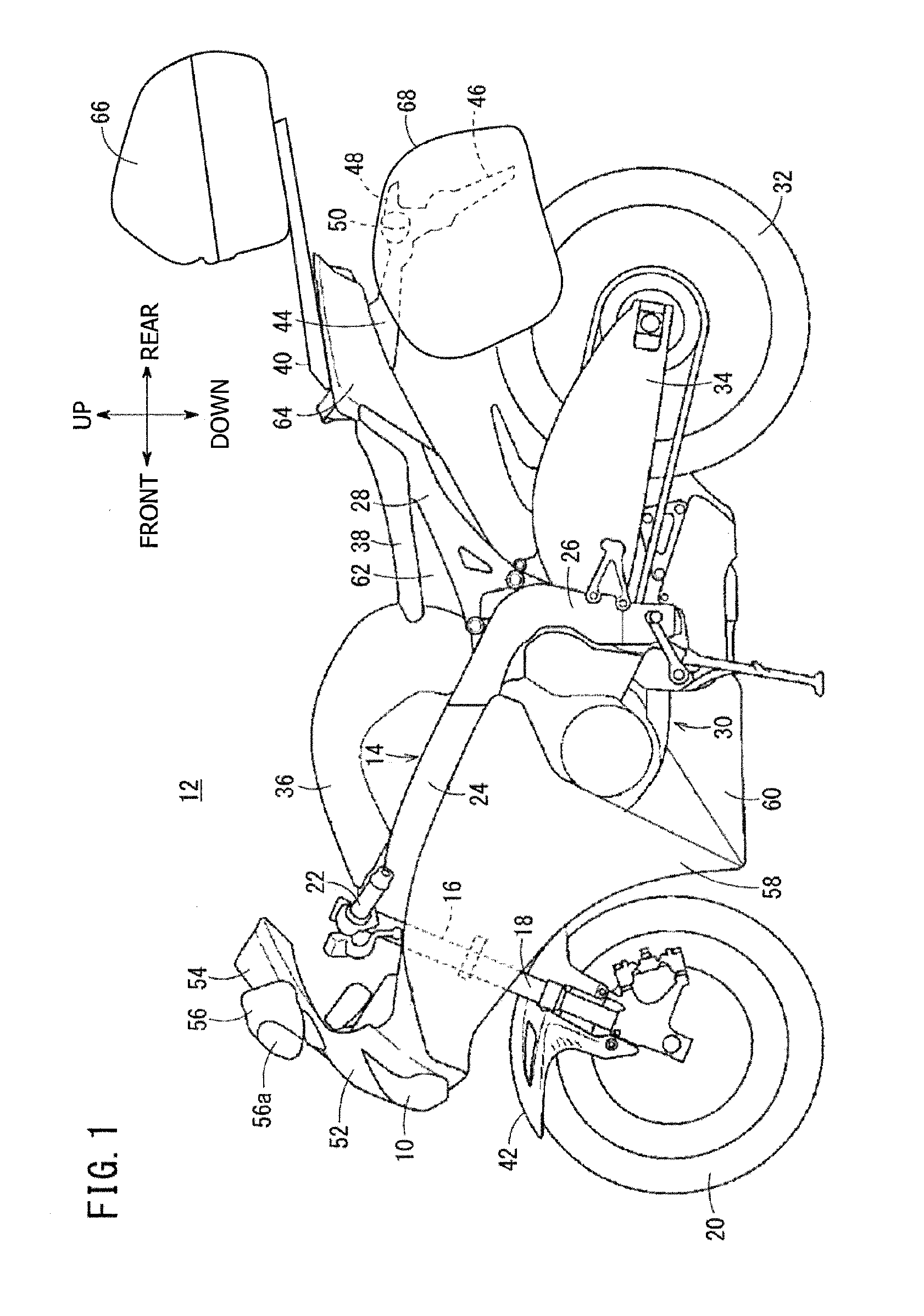

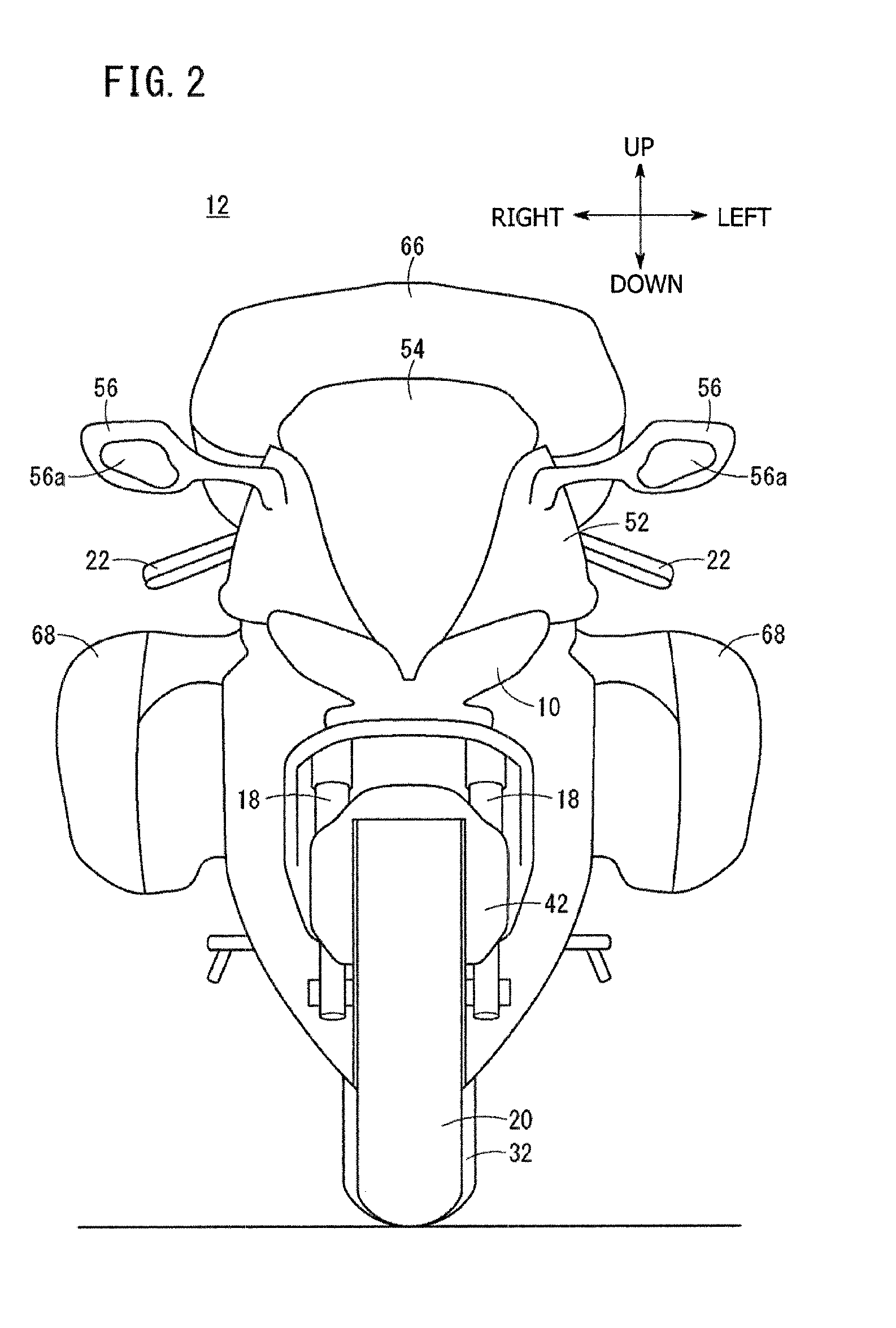

Exhaust pipe structure of vehicle with low floor

InactiveUS7044253B2Efficient arrangementEfficient use ofExhaust apparatusMotorised scootersExhaust pipePower unit

A low floor vehicle is a scooter-type motorcycle in which a power unit with a longitudinal V-type engine is mounted below a low floor. The power unit is substantially U-shaped when the power unit is viewed from the top by configuring the transmission unit of the power unit so that the transmission unit is connected to the engine on one side of the V-type engine, is extended backward on one side of the vehicle and drives a chain drive mechanism so as to drive a rear wheel from the other side of the vehicle in the vicinity of a pivot of a swing arm for the rear wheel. A first exhaust pipe connected to a rear cylinder in a bank of the V-type engine is extended backward from the cylinder, the rear end is extended downward via space which is an opening substantially U-shaped when the opening is viewed from the top, the lower end is extended backward and the rear end is connected to a second exhaust pipe connected to a front cylinder in the bank of the V-type engine.

Owner:HONDA MOTOR CO LTD

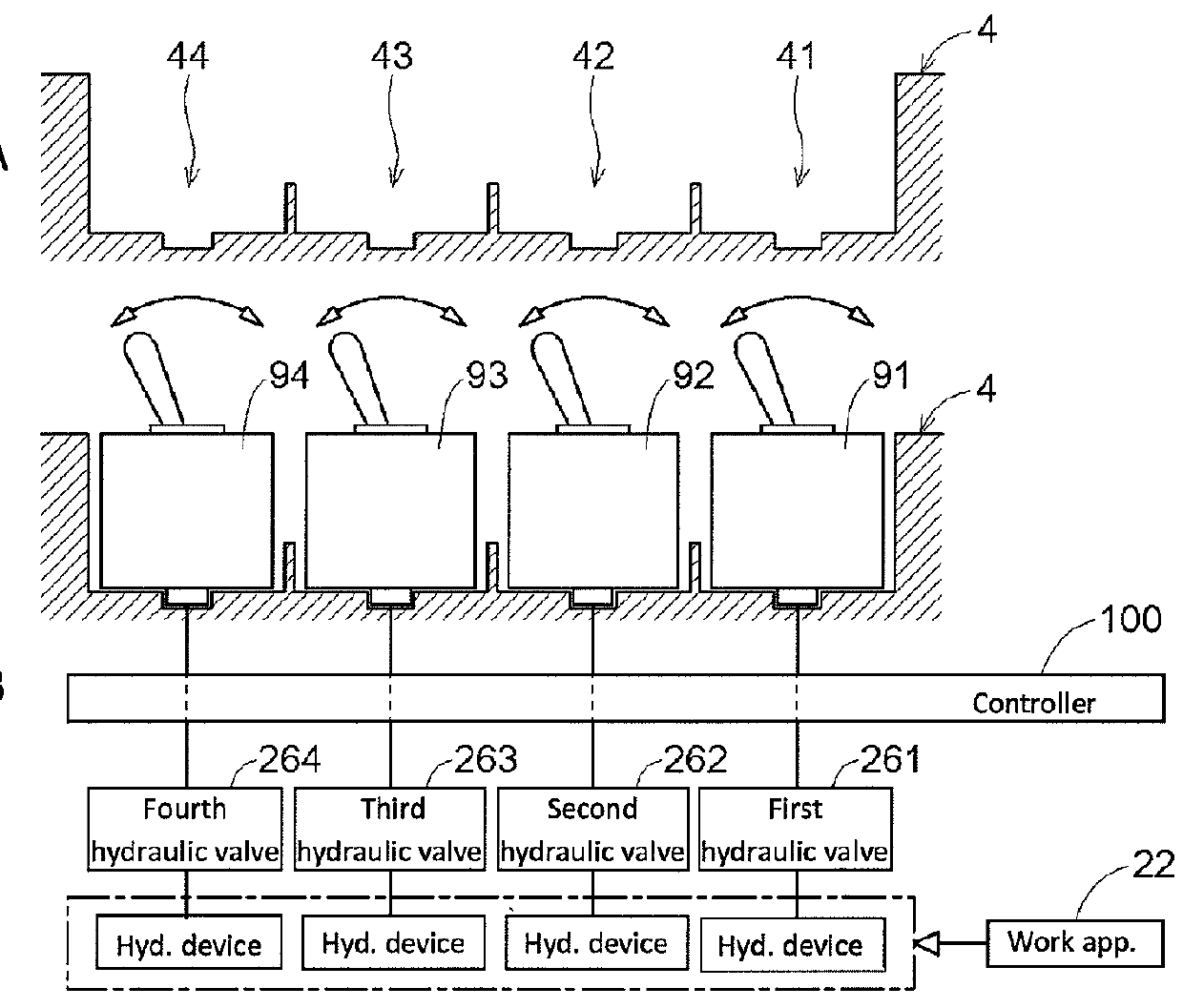

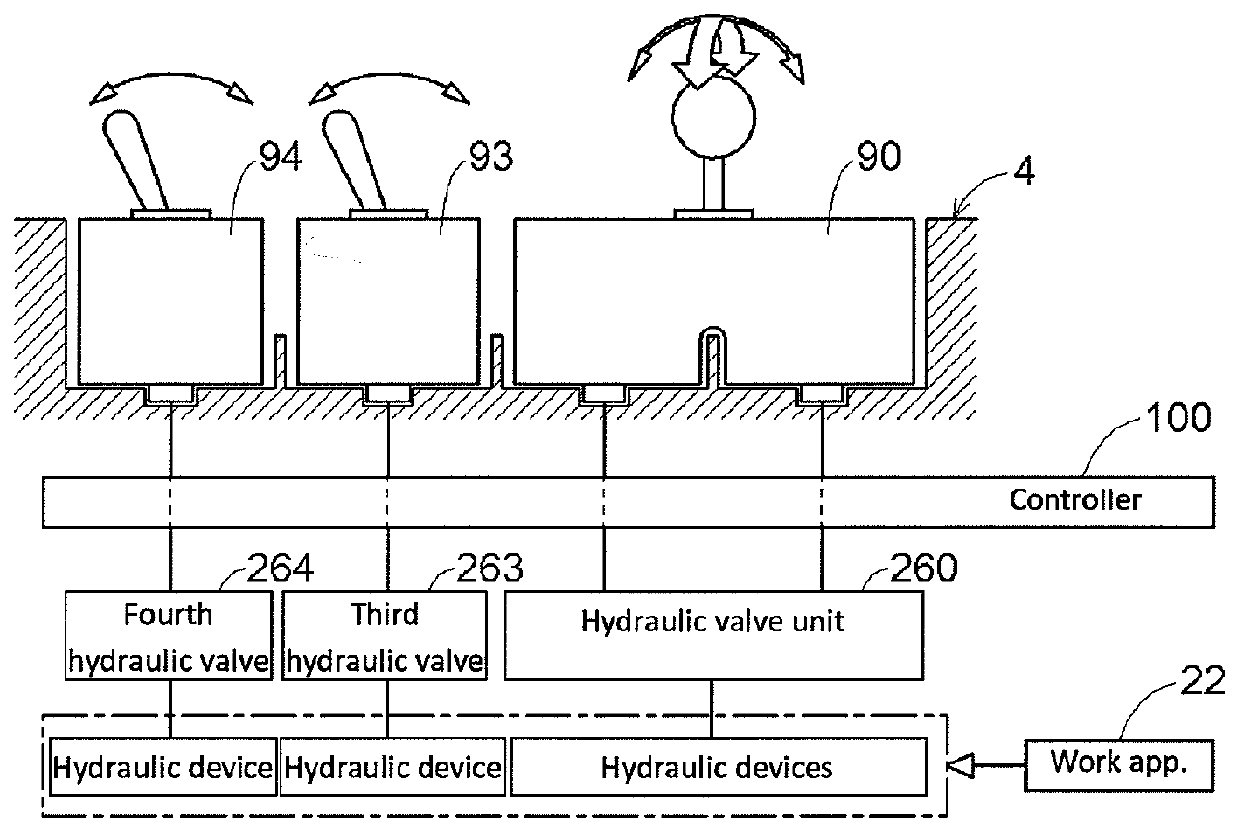

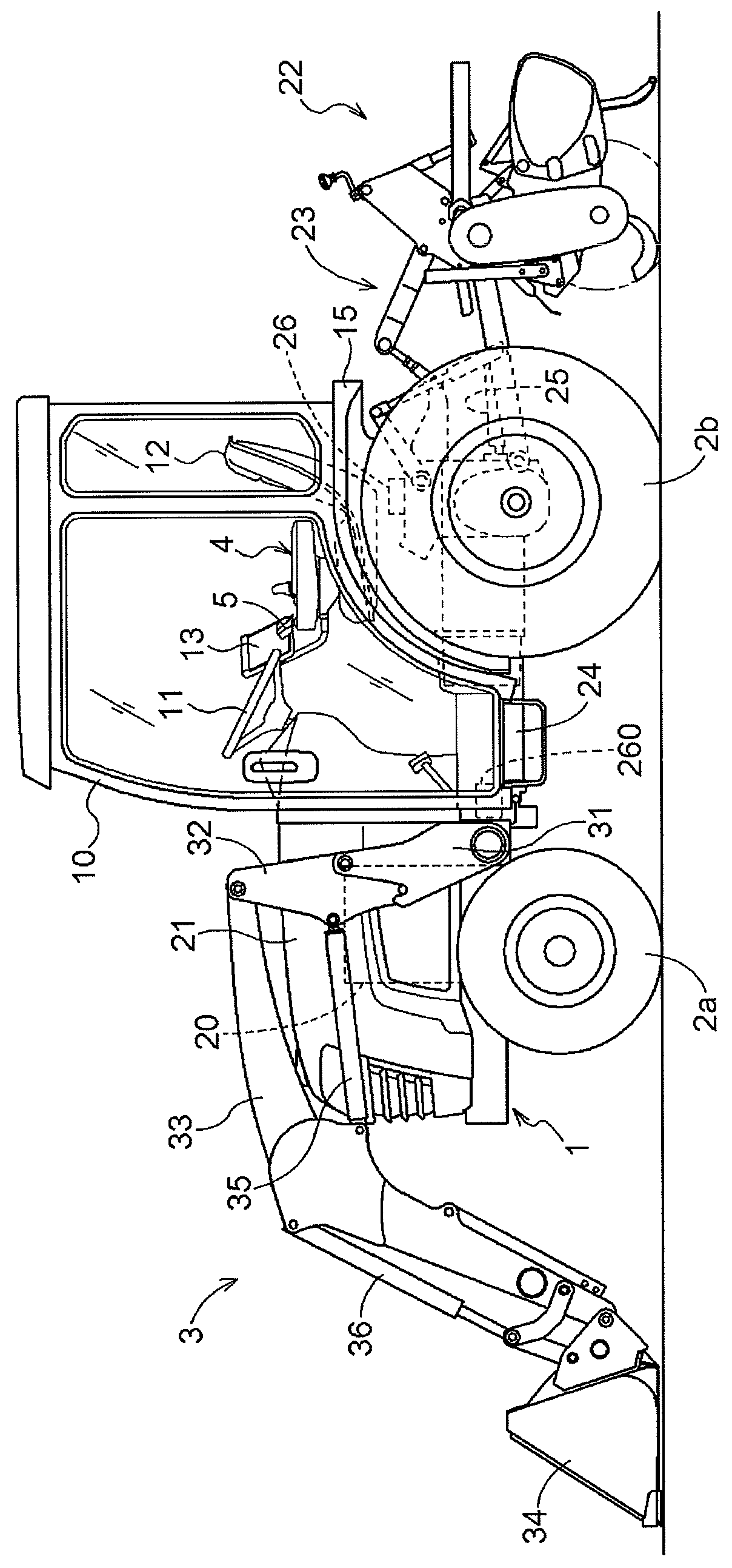

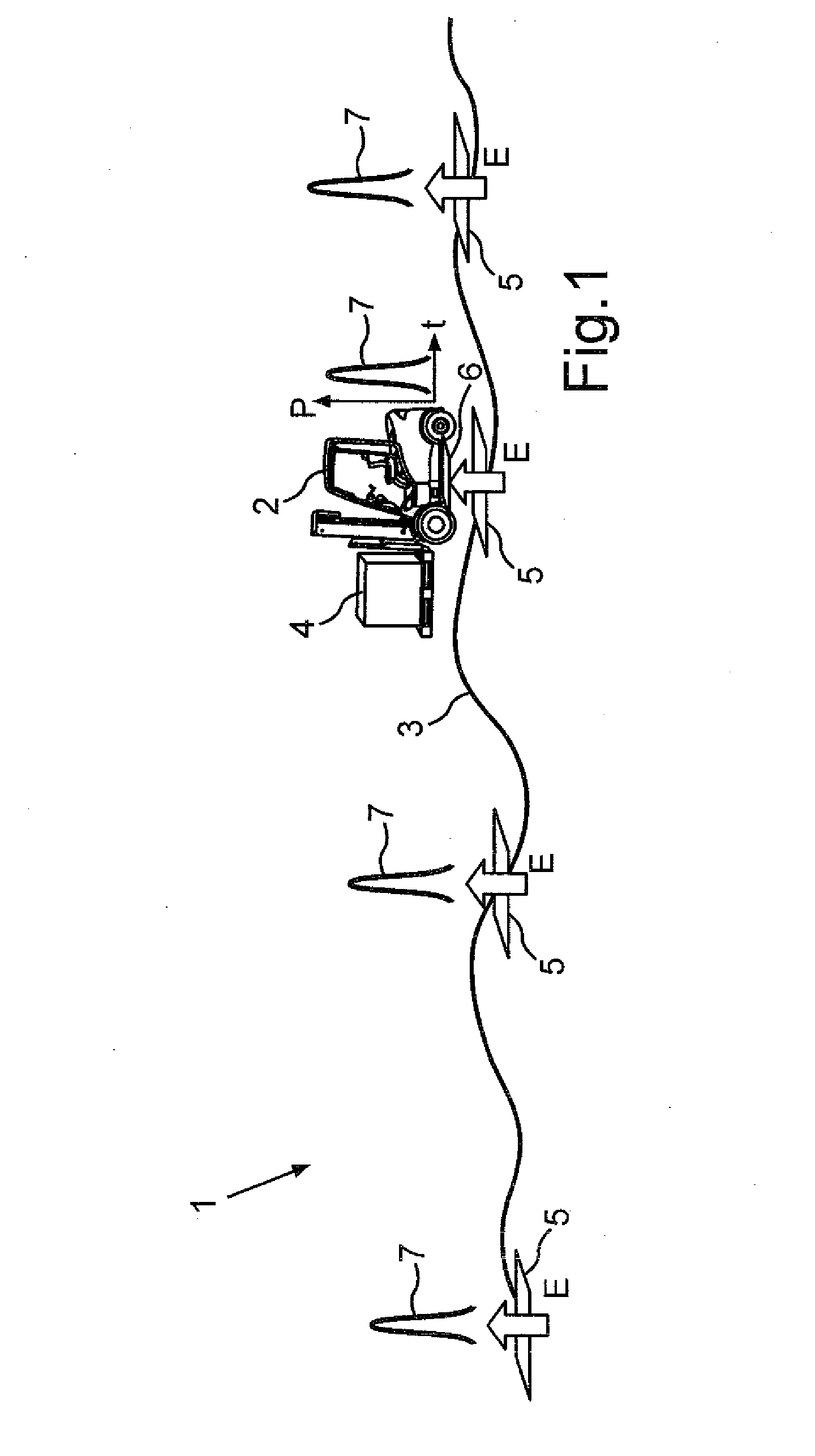

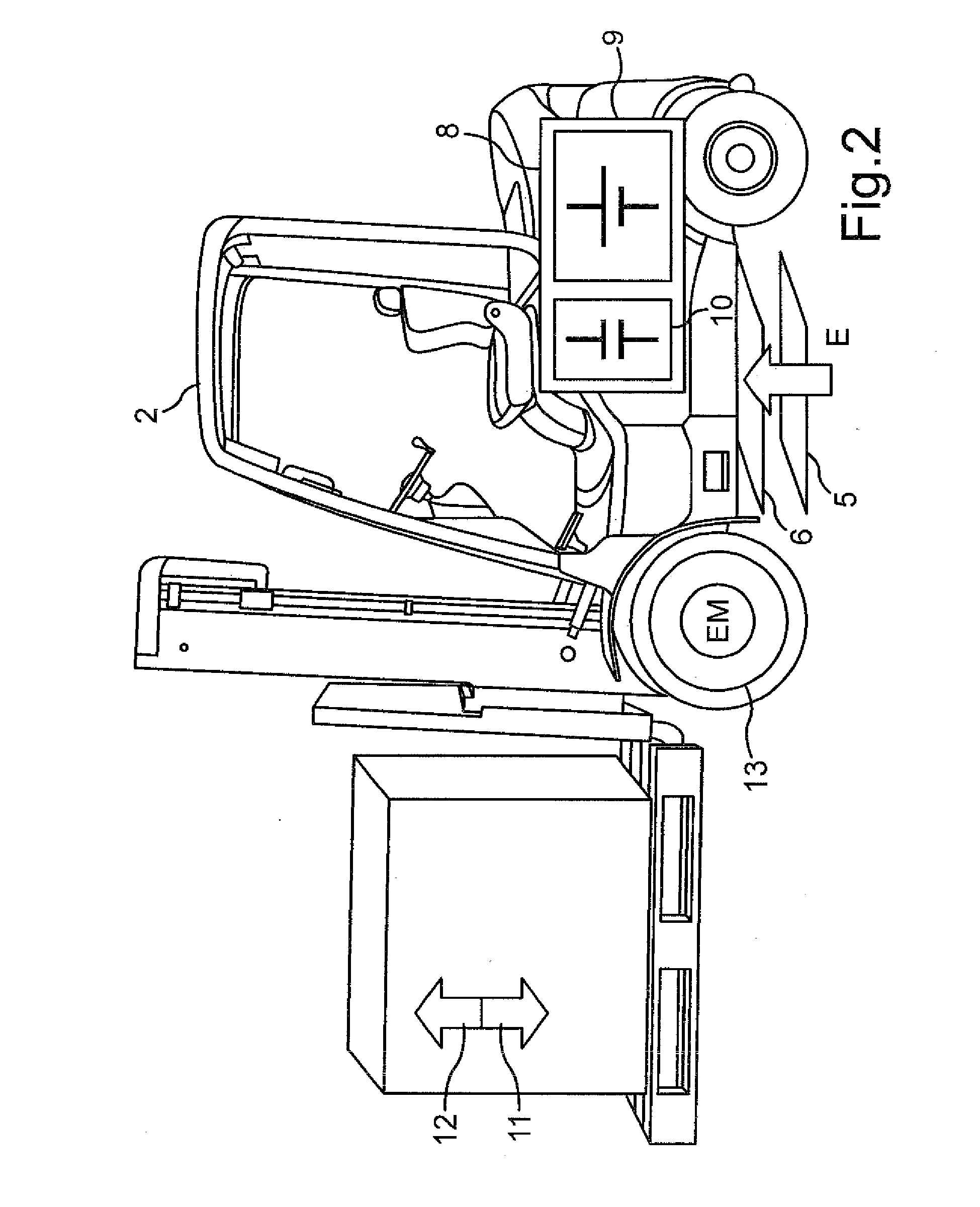

Operation control system

ActiveUS20160053779A1Efficient arrangementControl is complexManual control with multiple controlled membersDashboard fitting arrangementsEngineeringHydraulic brake

An operation control system for a work apparatus equipped to a work vehicle includes a controller controlling the work apparatus. A first hydraulic valve and a second hydraulic valve control hydraulic pressure supply to the work apparatus. An operation unit provides an operation input signal to the controller. A first mounting base and a second mounting base are provided adjacently to each other in the operation unit. A first single-operation tool is formed mountable on the first mounting base and a second single-operation tool is formed mountable on the second mounting base. Further, a multi-operation tool is mountable so as to straddle both the first mounting base and the second mounting base.

Owner:KUBOTA LTD

Checker-Equipped Door Hinge Device for Vehicle

InactiveUS20090133222A1Efficiently arrangedConvenient ArrangementWing accessoriesHingesEngineeringThick wall

A checker-equipped door hinge device for vehicle includes: a first bracket fixed to one of a body and a door; a second bracket fixed to another one of the body and the door; a hinge pin connecting the first and second brackets to each other, and allowing the brackets to be relatively rotatable; an inner cylinder connected integrally to the first bracket and disposed coaxially with the hinge pin; an outer cylinder connected integrally to the second bracket and disposed so as to surround the inner cylinder in a manner of being rotatable relative to the inner cylinder; and a checking-force generating mechanism provided between the inner cylinder and the outer cylinder, the checking-force generating mechanism generating a checking force against the door at a predetermined opening position of the door, wherein an inner peripheral surface and an outer peripheral surface of the outer cylinder are eccentric to each other, so that a thick wall portion having a large distance between the inner peripheral surface and the outer peripheral surface is formed in the outer cylinder, and the checking-force generating mechanism is provided in the thick wall portion. Thereby the door hinge device can be compact, in which the checking-force generating mechanism can be disposed in the outer cylinder without increasing the diameter of the outer cylinder.

Owner:RIKEN KAKI KOGYO CO LTD

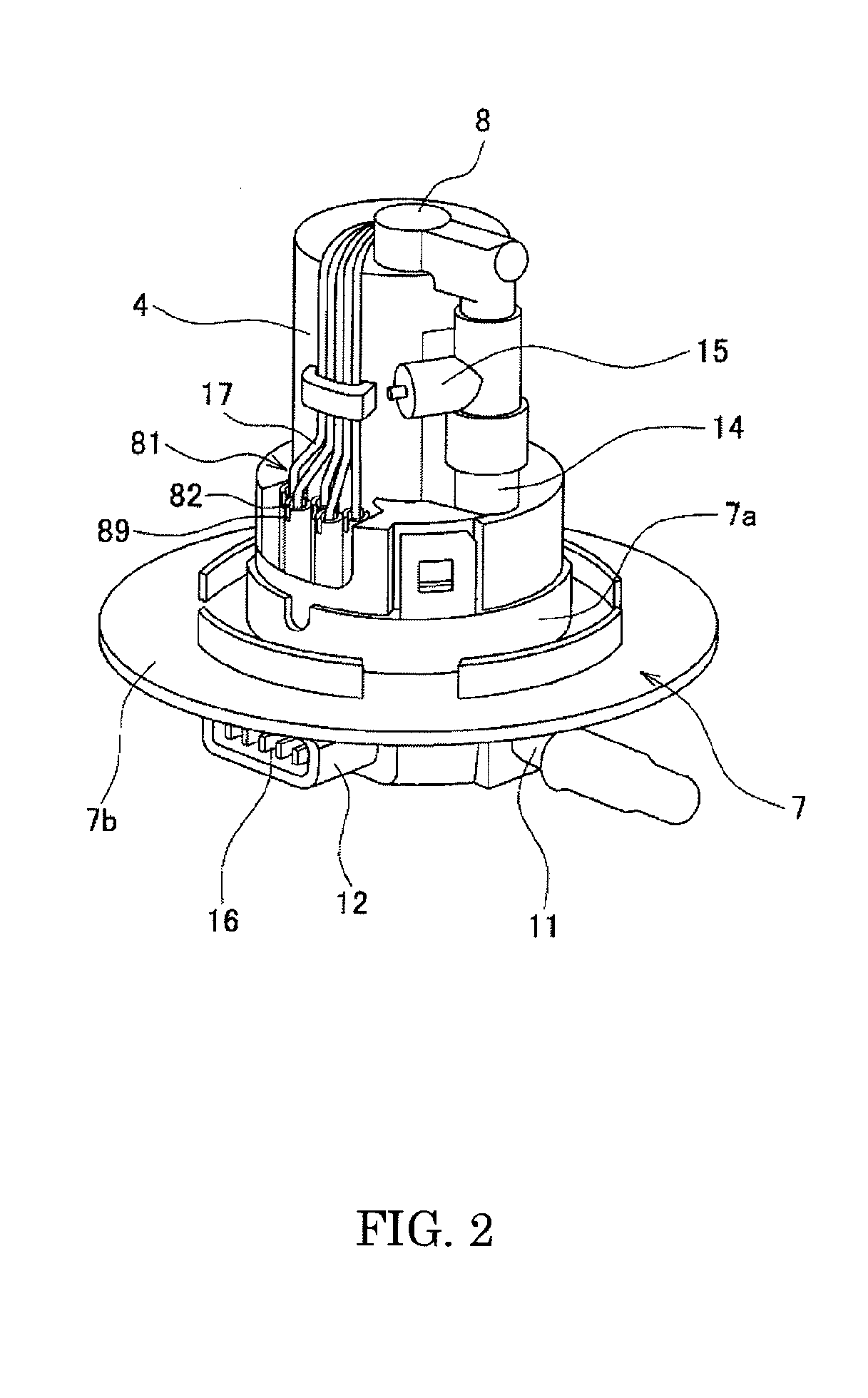

Fuel supply device

InactiveUS20100215523A1Efficiently arrangedEnsuring sealabilityElectrically conductive connectionsCircumferential flow pumpsElectricityPolygonal line

Male terminals 83 are respectively provided in terminal attachment portions 82 formed on a flange unit 7. Female terminals 84 and grommets 85 are provided for a harness 17. A seal lip portion 86 to be fitted into each of the terminal attachment portions 82 is formed on each of the grommets 85. In the cylindrical terminal attachment portions 82, the male terminals 83 are individually accommodated while being electrically insulated from each other. The terminal attachment portions 82 are arranged alternately in two rows so that a line segment obtained by connecting the respective centers of openings of the terminal attachment portions is a polygonal line. The openings 87 are arranged to form the Olympic symbol. At a fore-end of each of the terminal attachment portions 82, slits 89 are provided. Owing to the slits 89, the opening 87 is likely to be enlarged when the rubber grommet 85 is inserted therethrough. As a result, the placement of the rubber grommet 85 is facilitated.

Owner:MITSUBA CORP +1

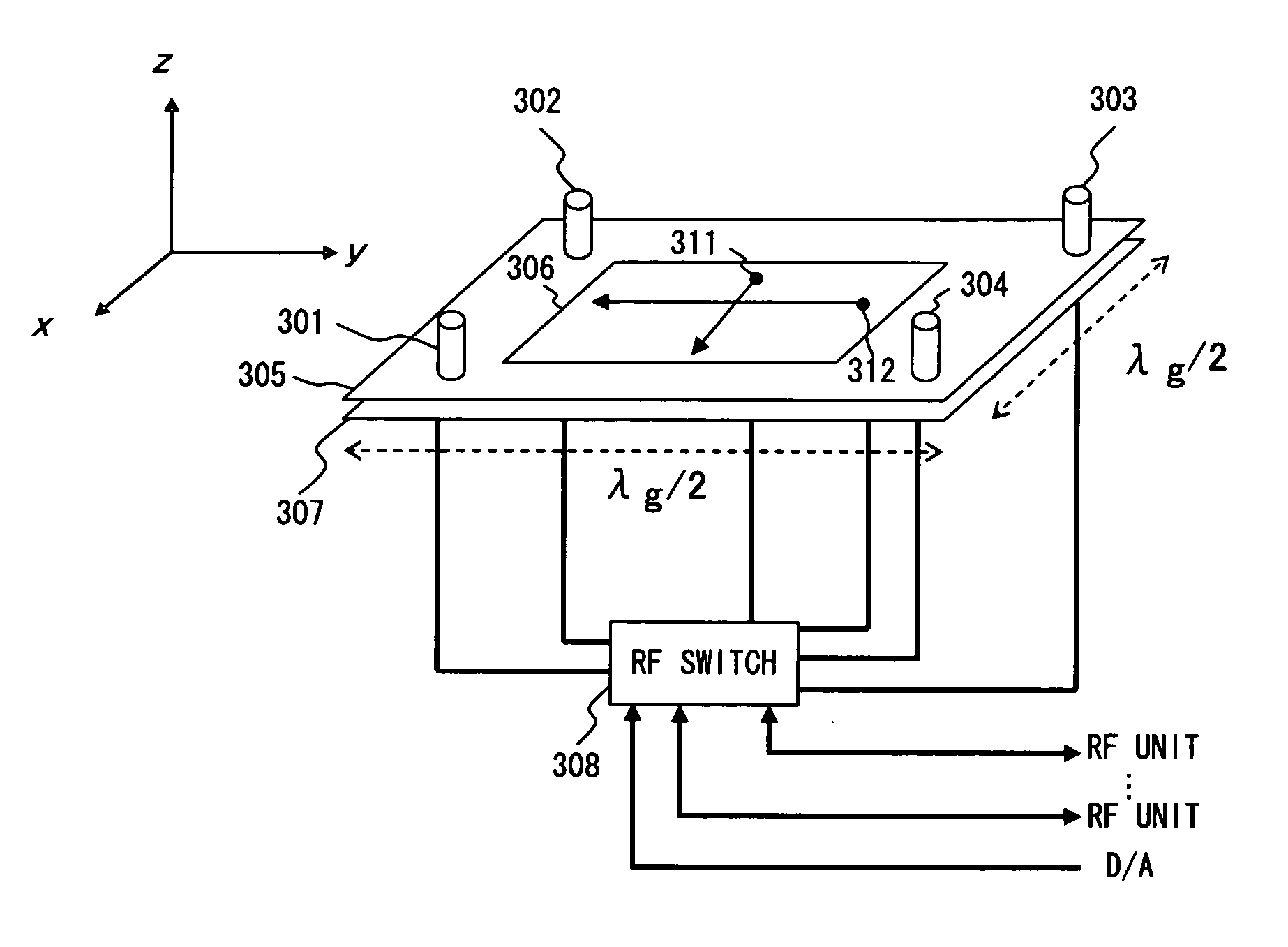

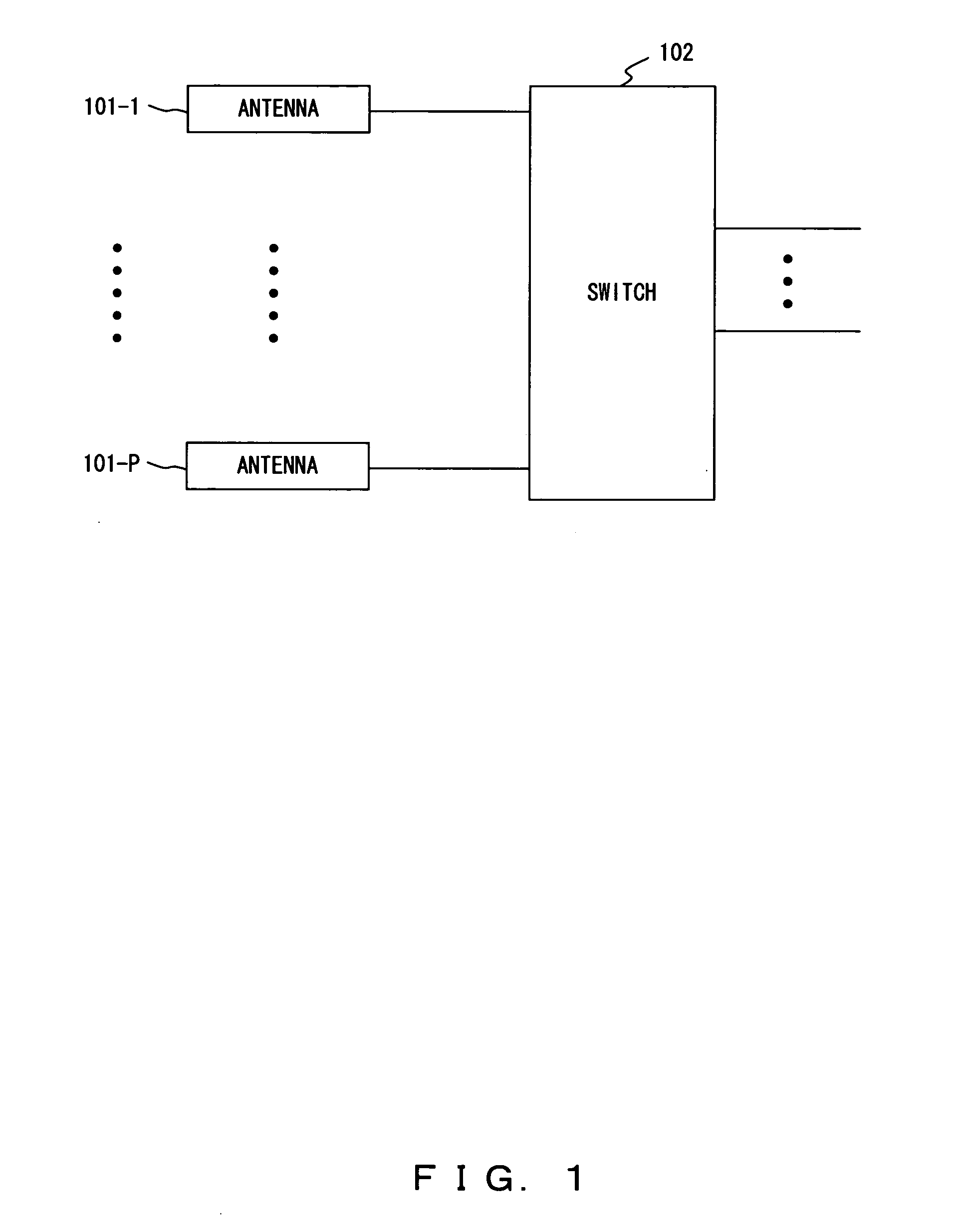

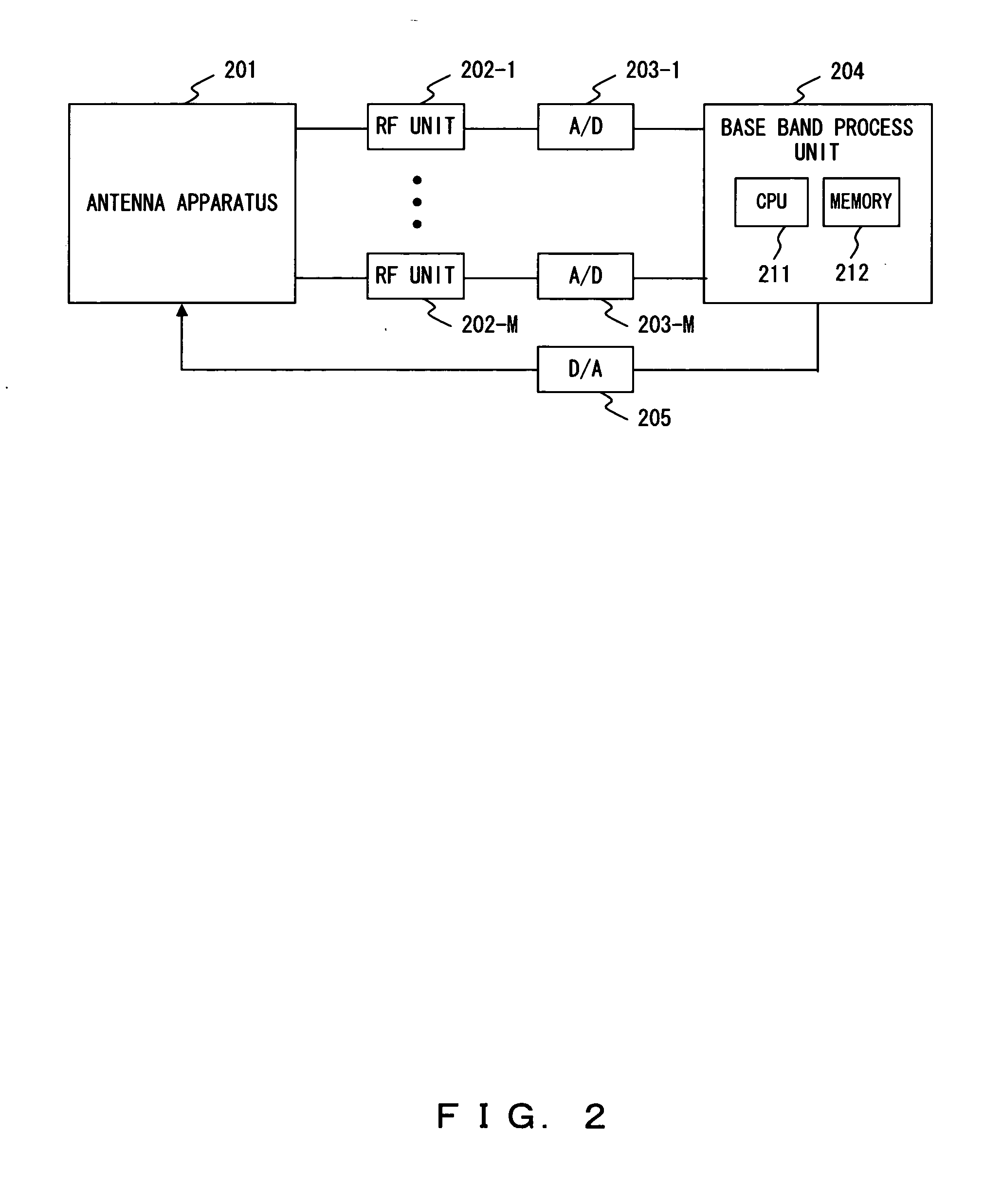

Antenna apparatus for multiple input multiple output communication

InactiveUS20070205959A1Good communication qualityEfficiently arrangedSpatial transmit diversitySimultaneous aerial operationsDirectivityMultiple input

At least two antennas are selected from a plurality of antennas which consist of at least two antennas having polarization characteristics or directivities different from one another, and which are arranged such that spatial fading correlations between the antennas are low, and a multiple input multiple output communication is conducted by using the selected antennas.

Owner:FUJITSU LTD

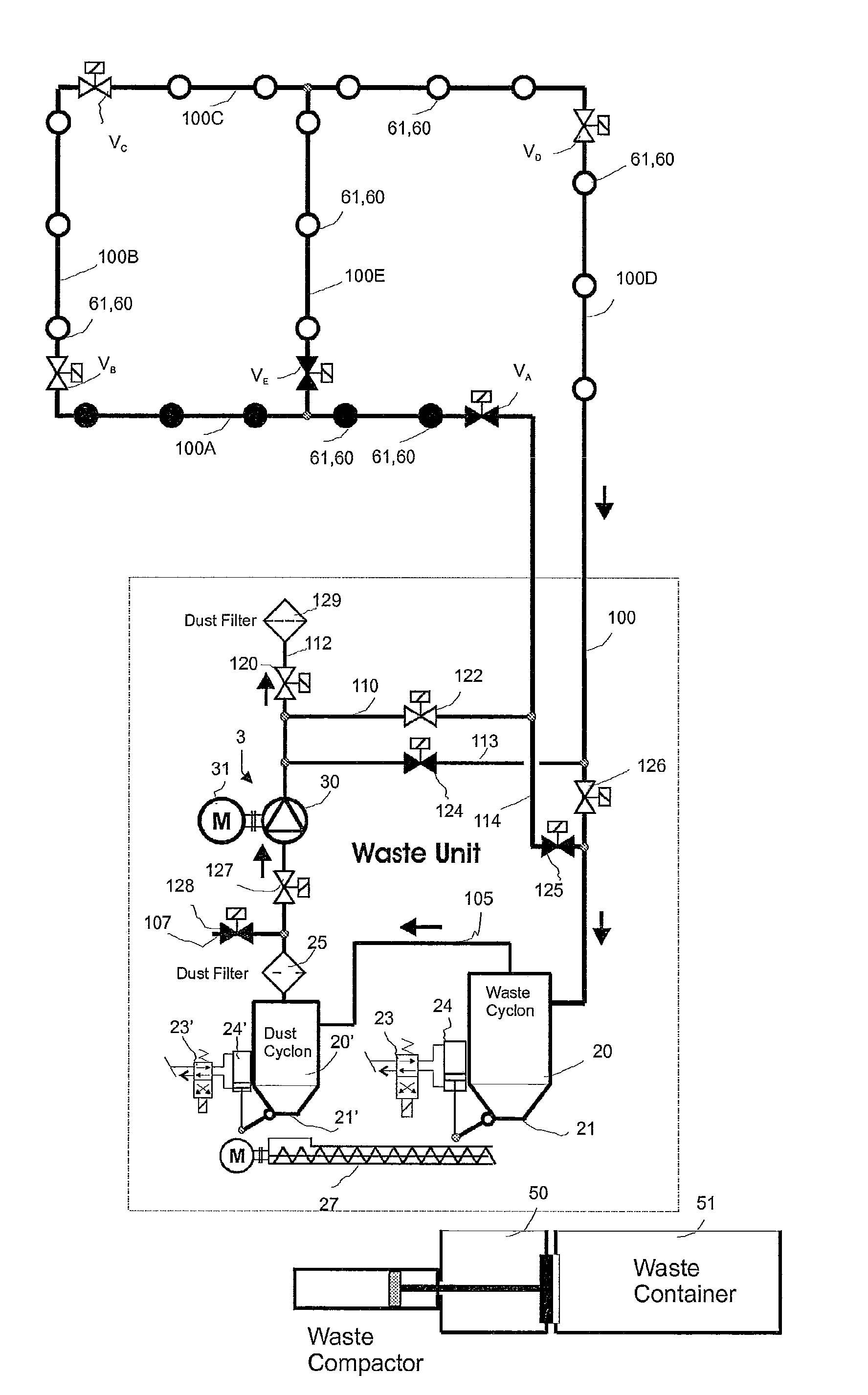

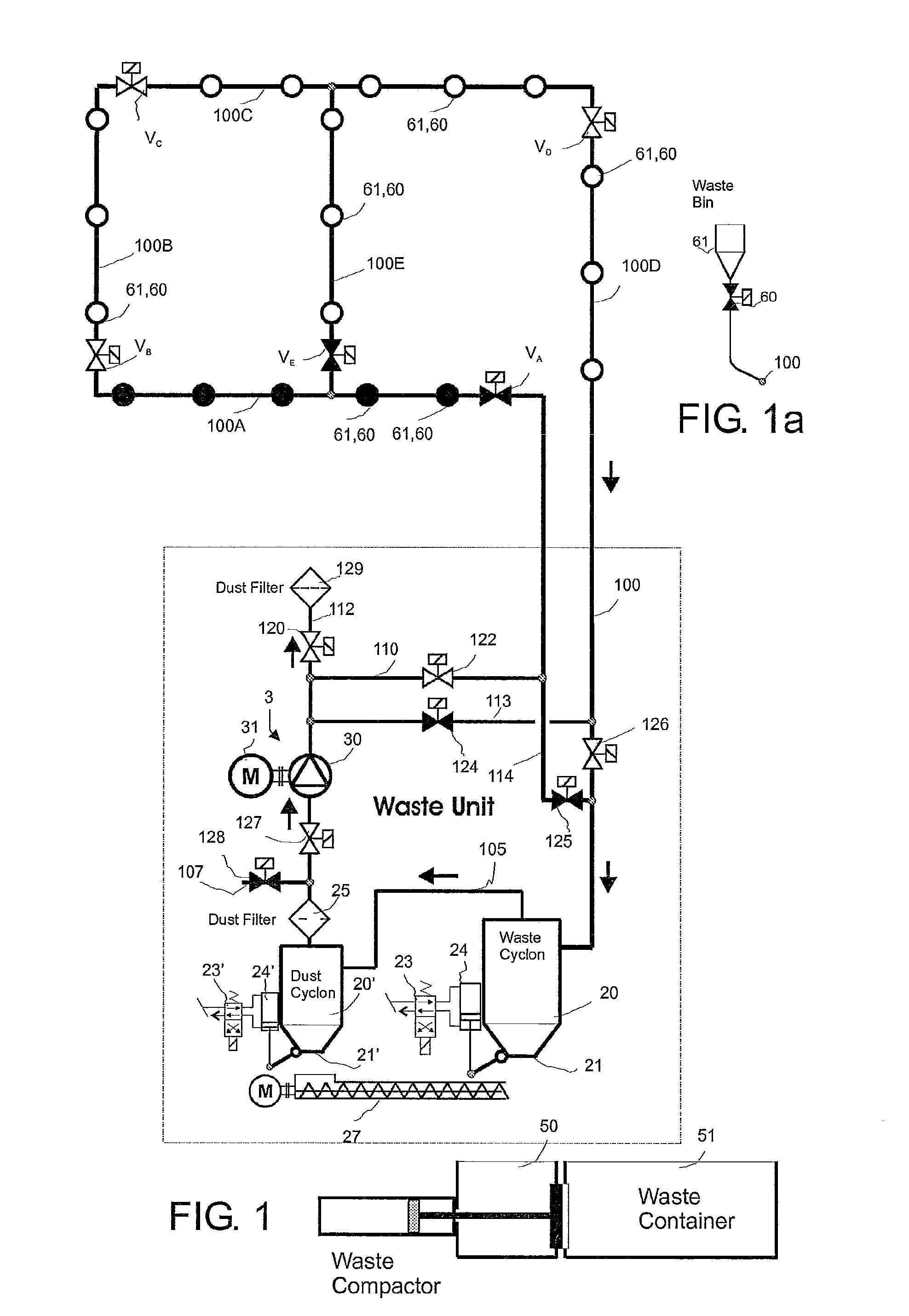

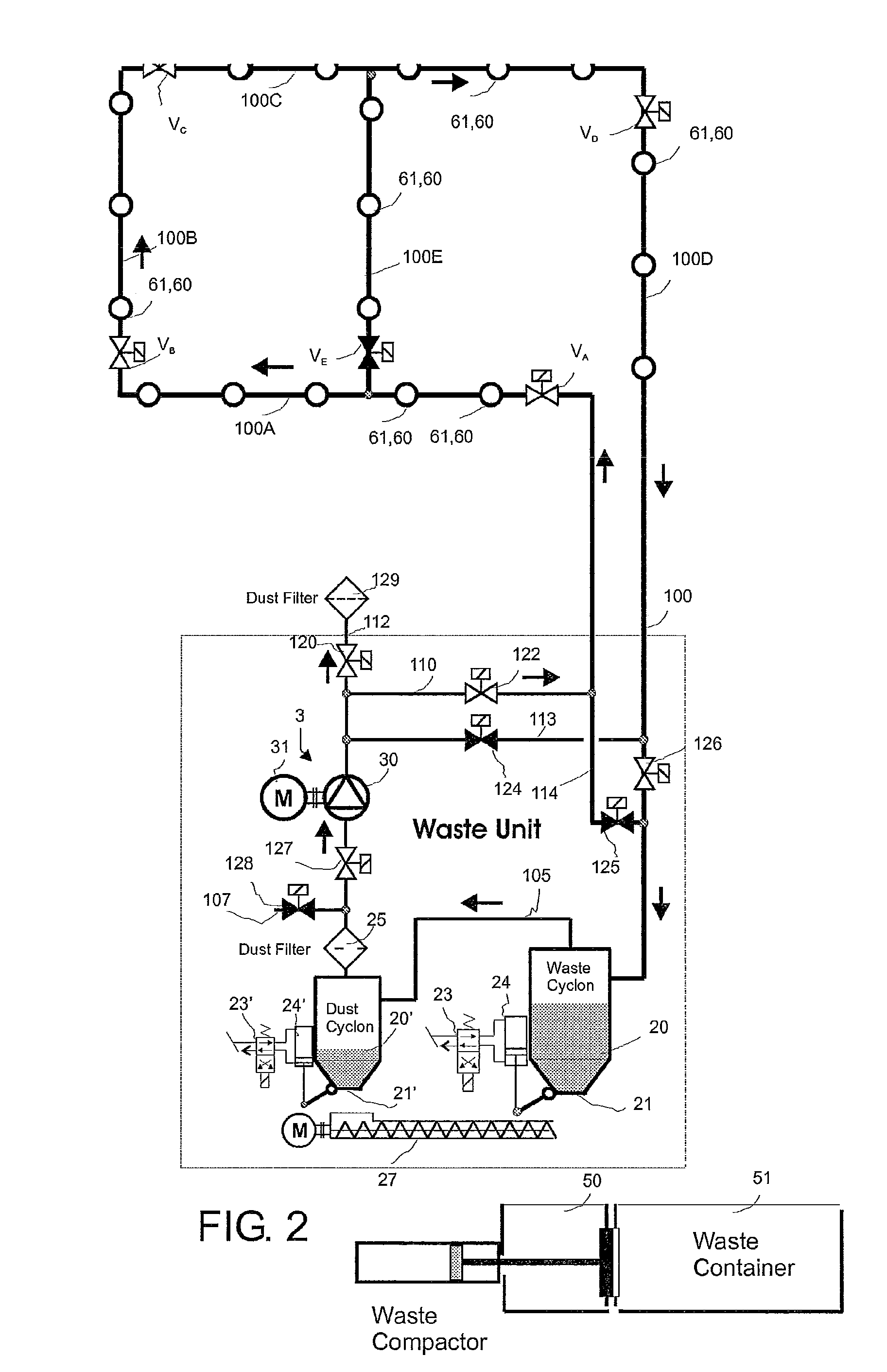

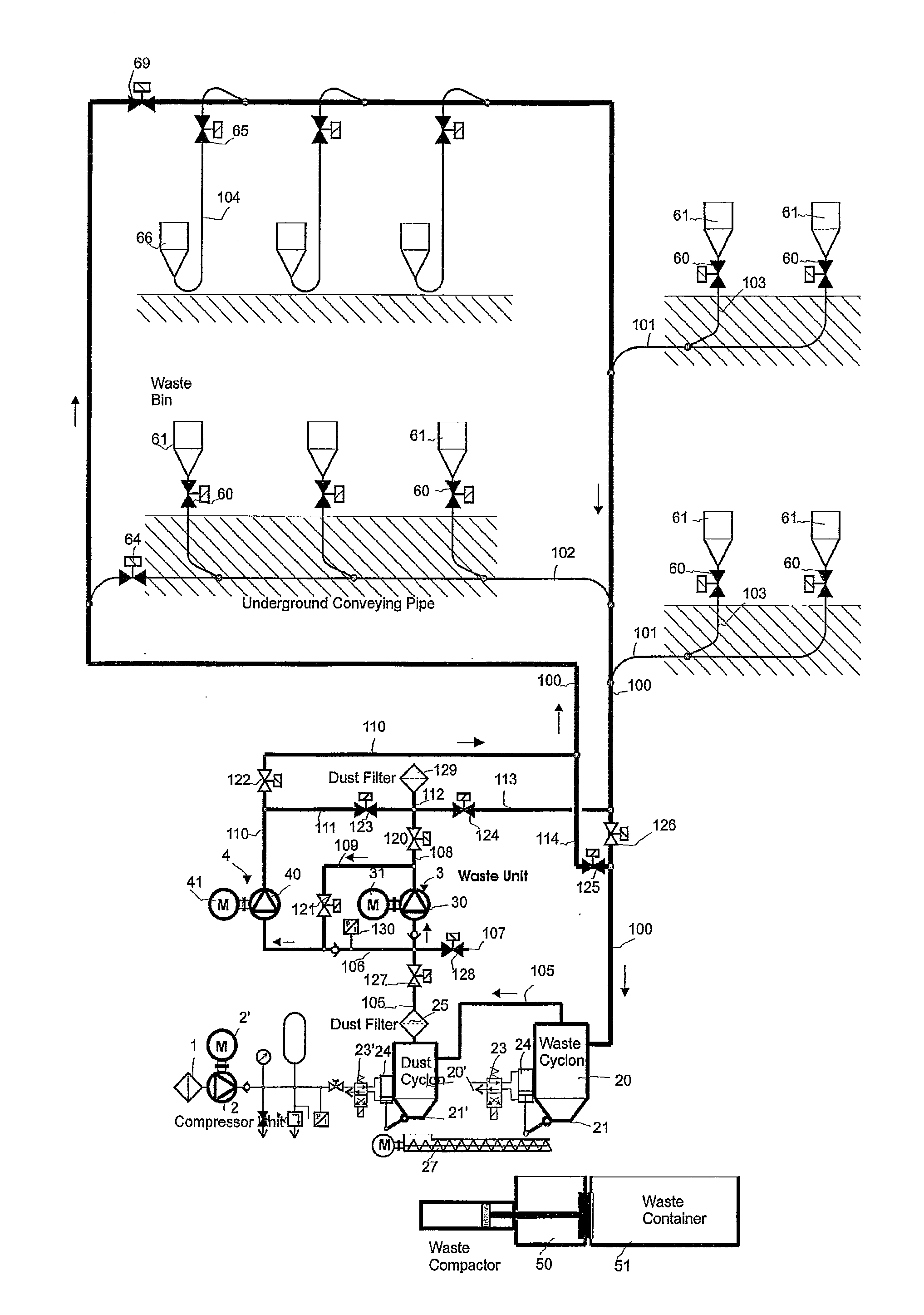

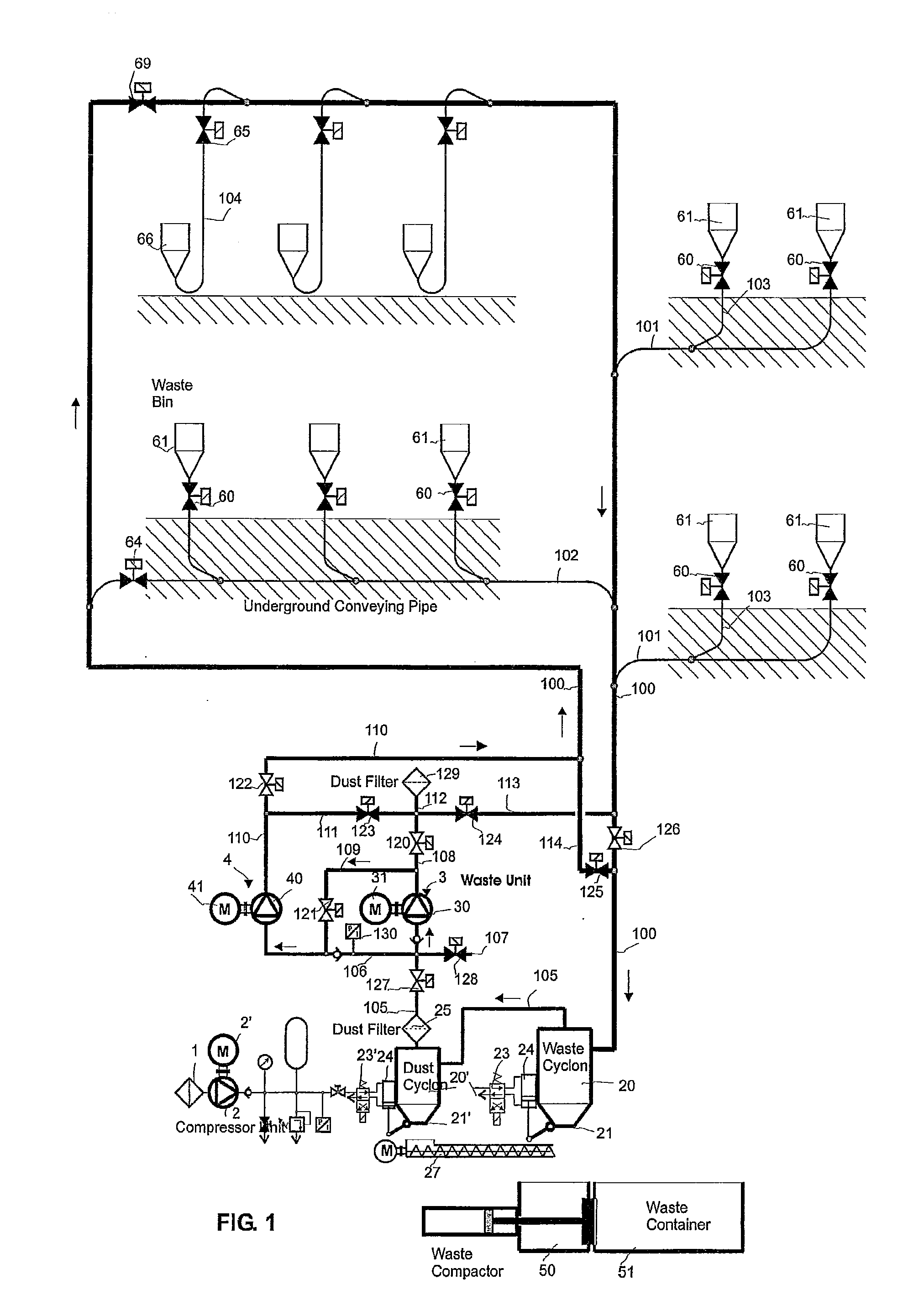

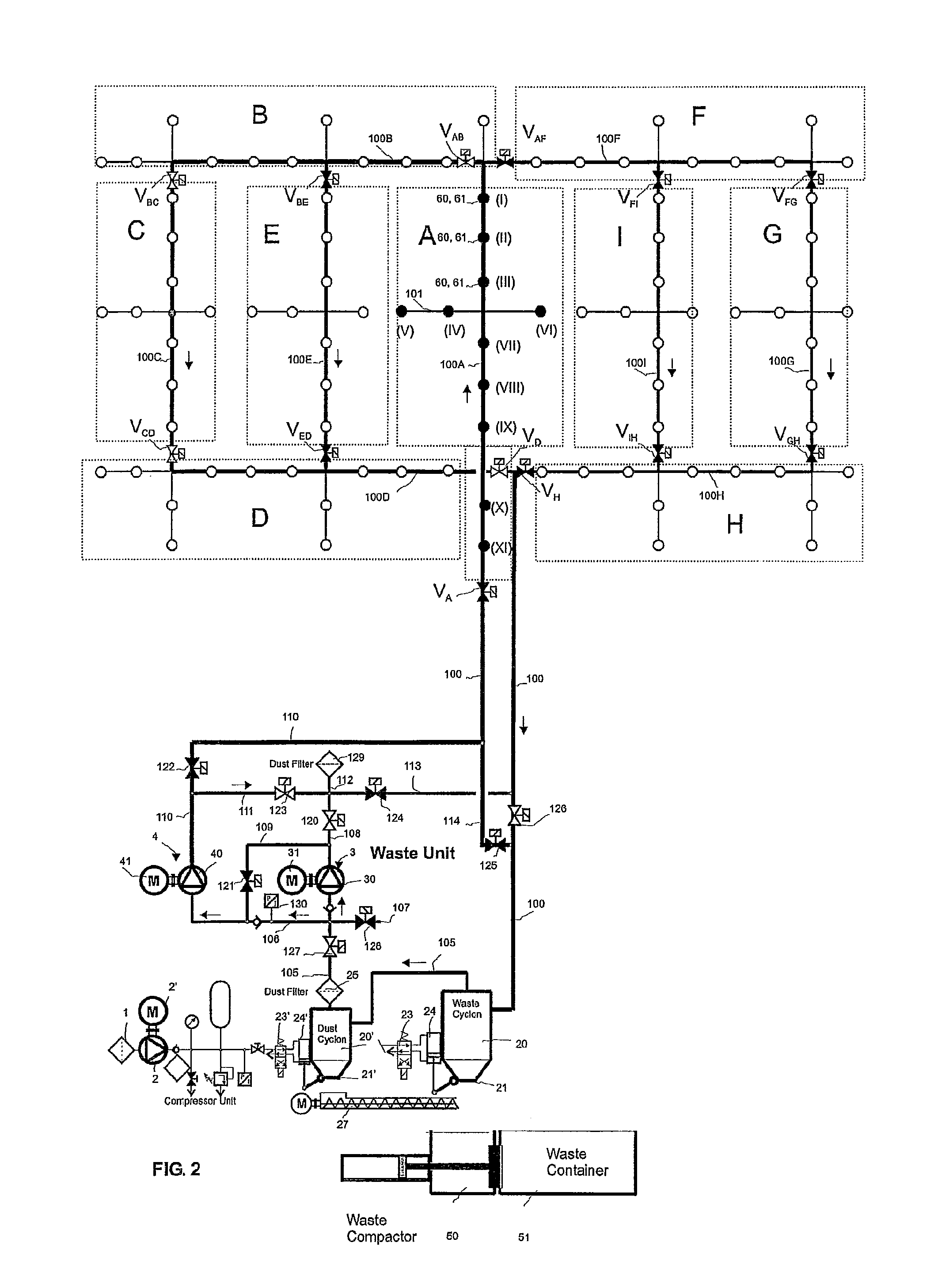

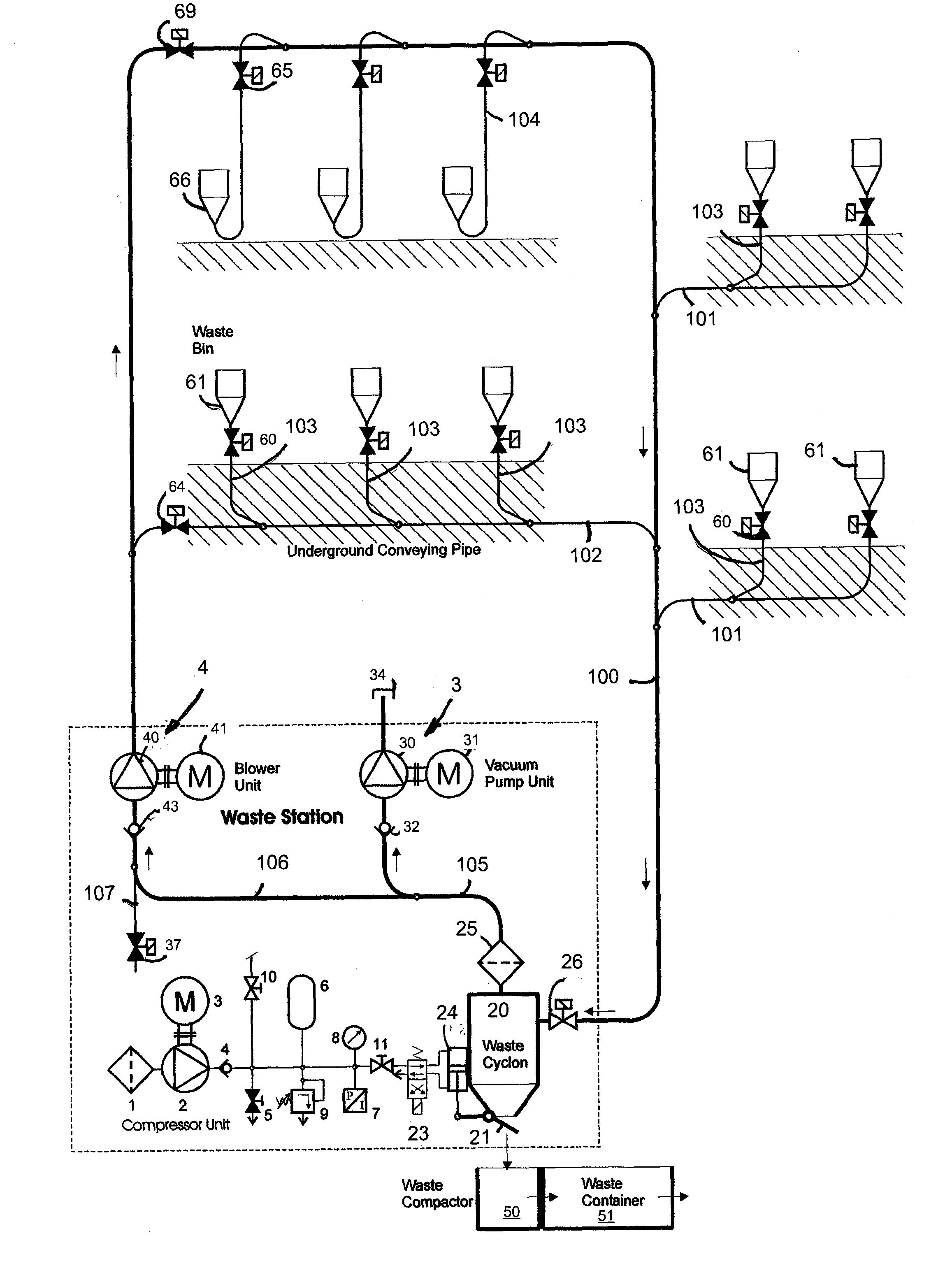

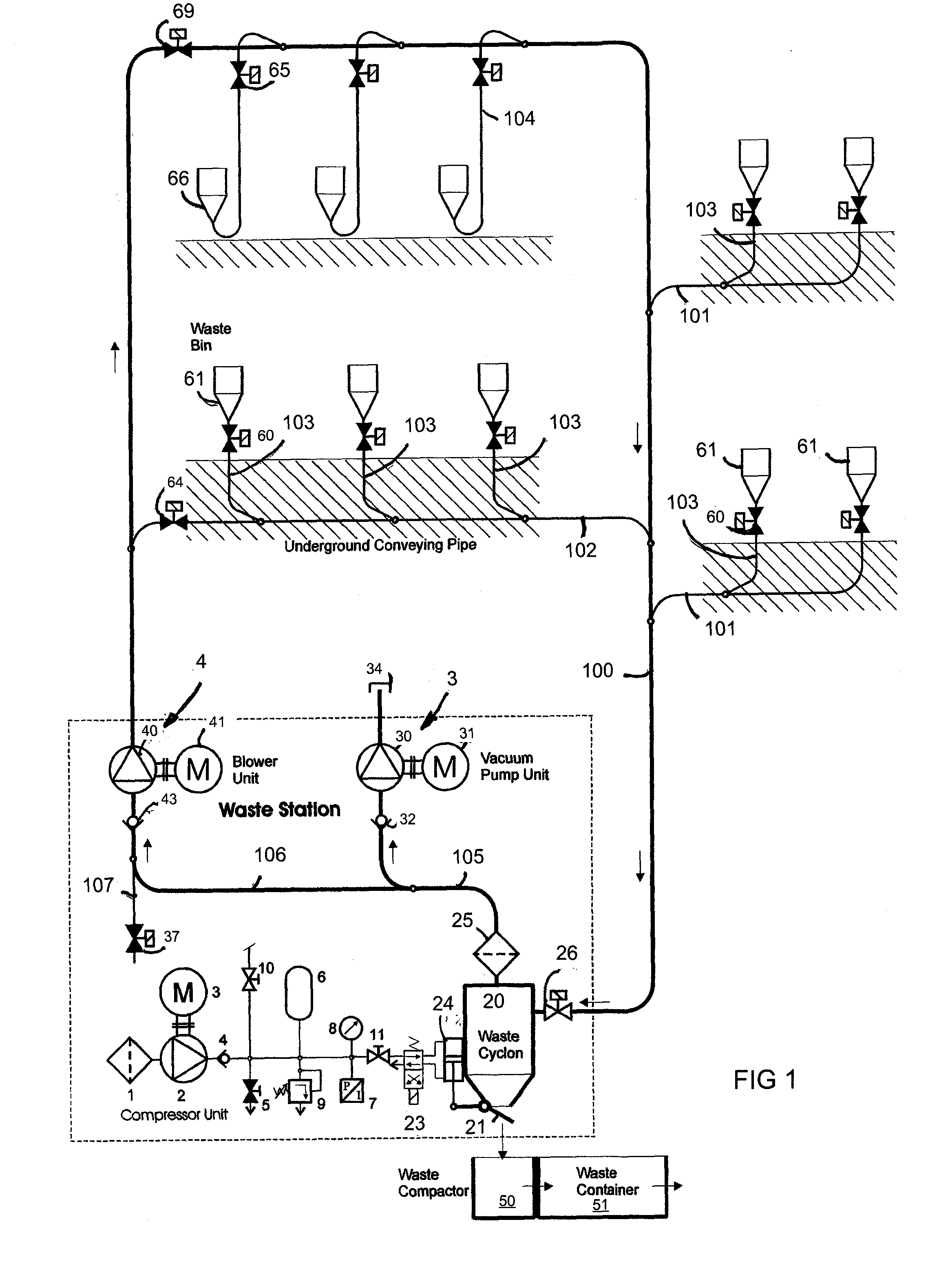

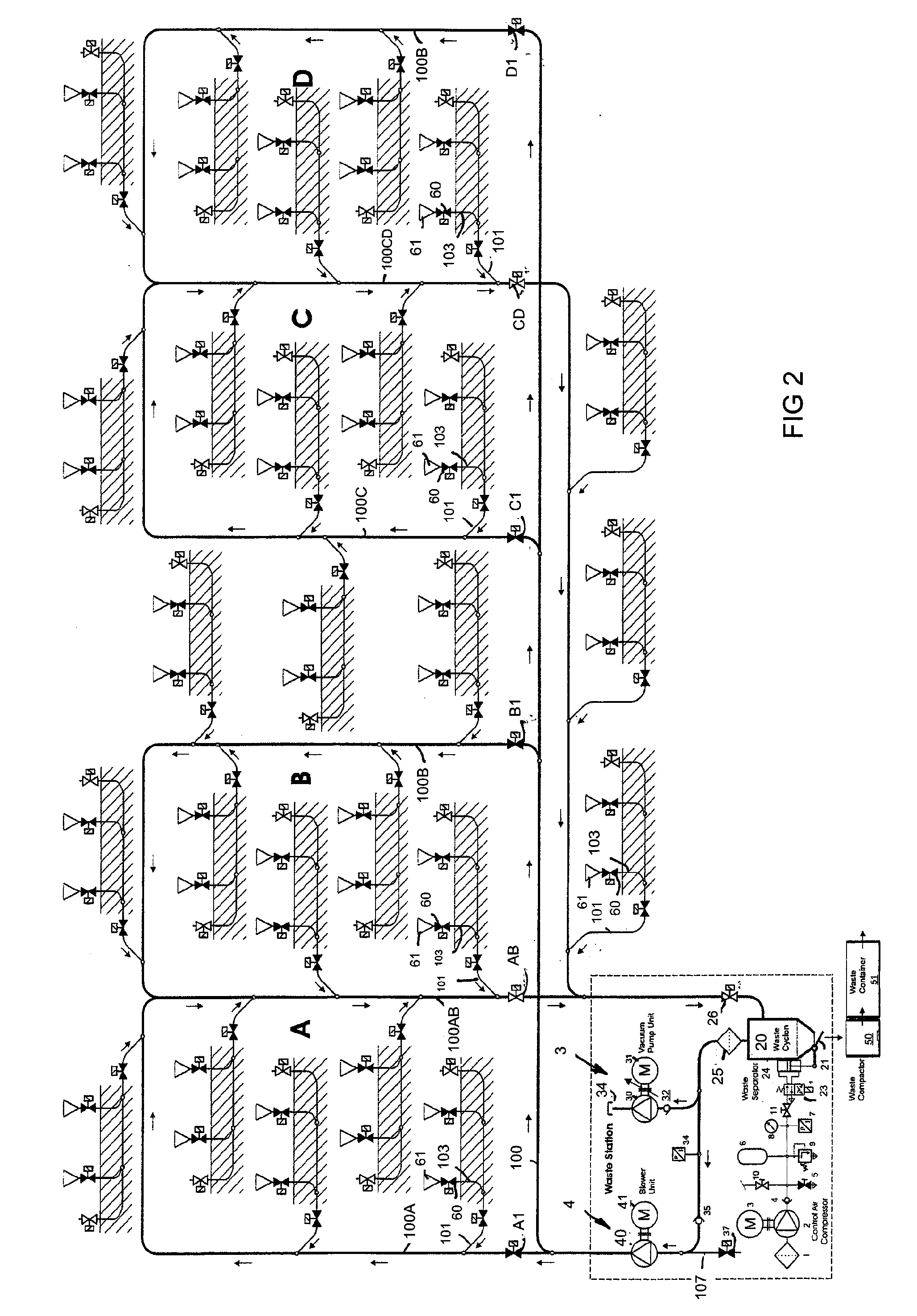

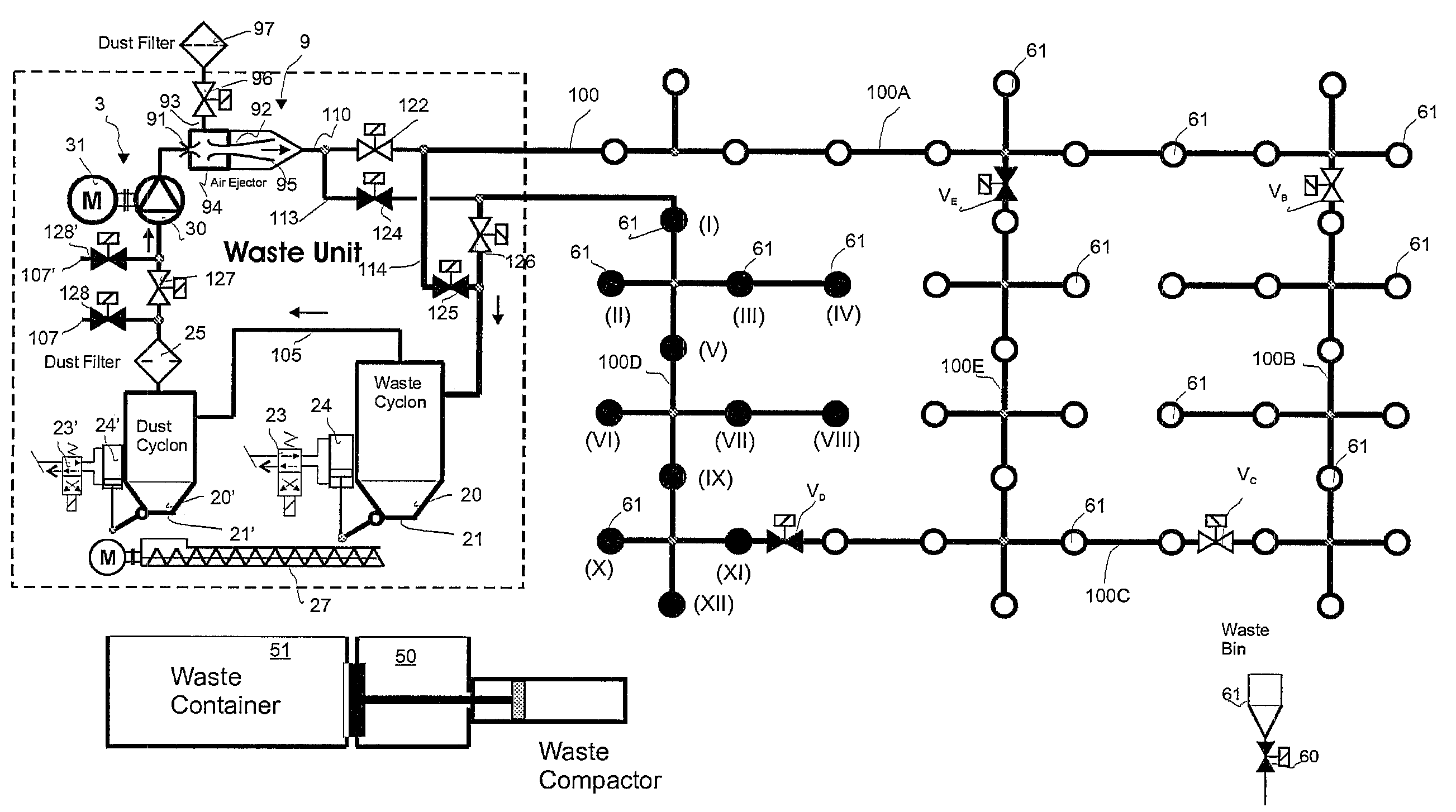

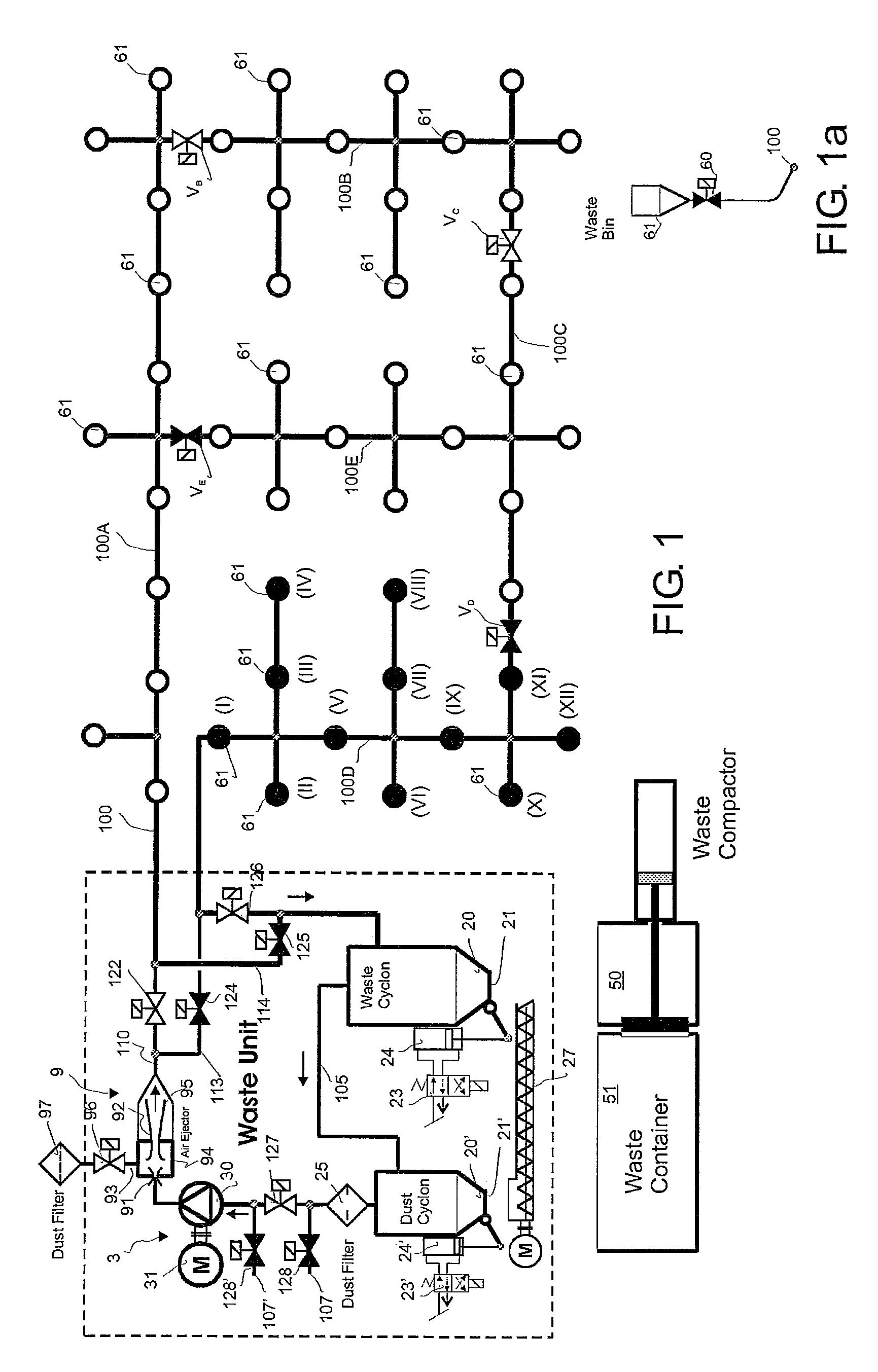

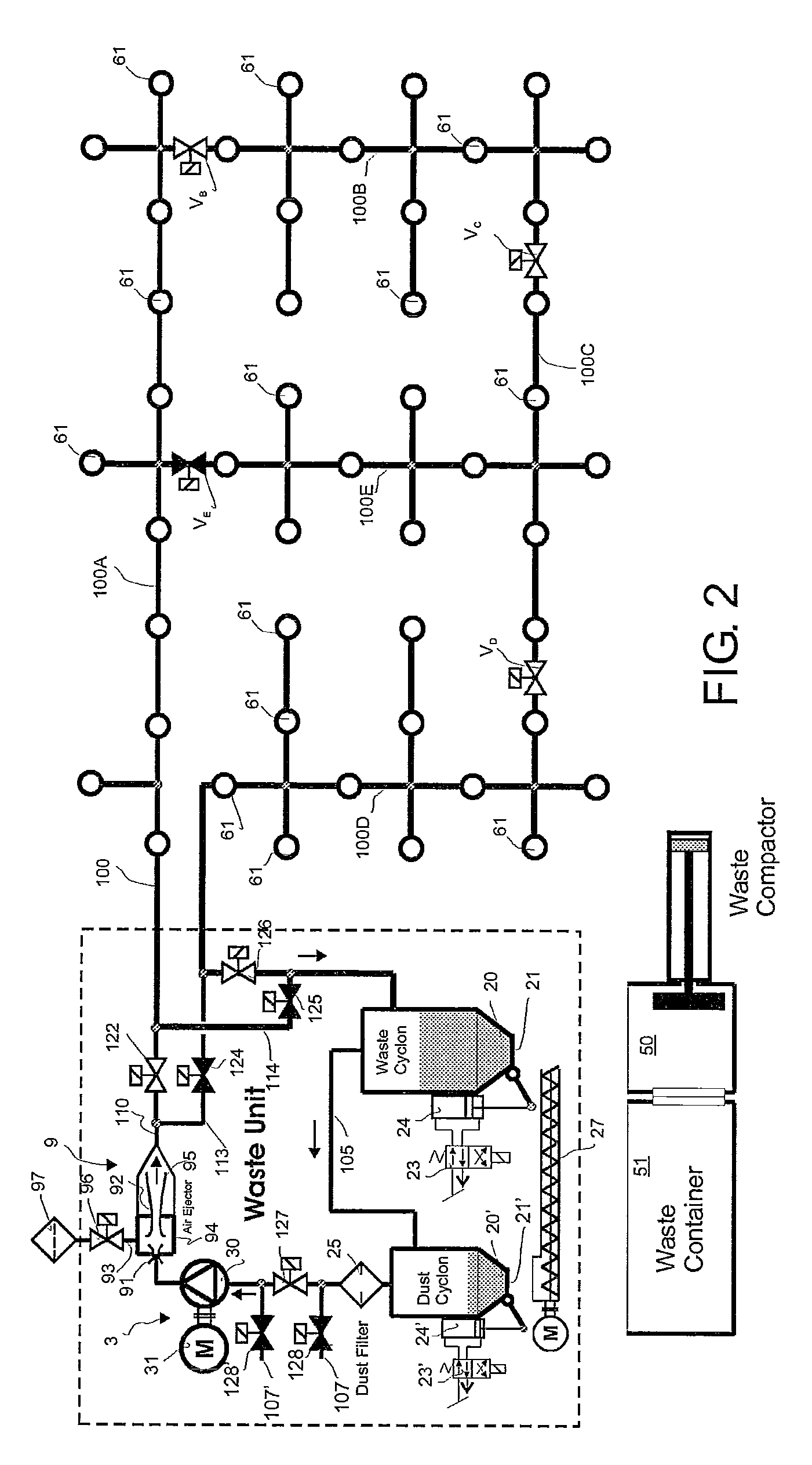

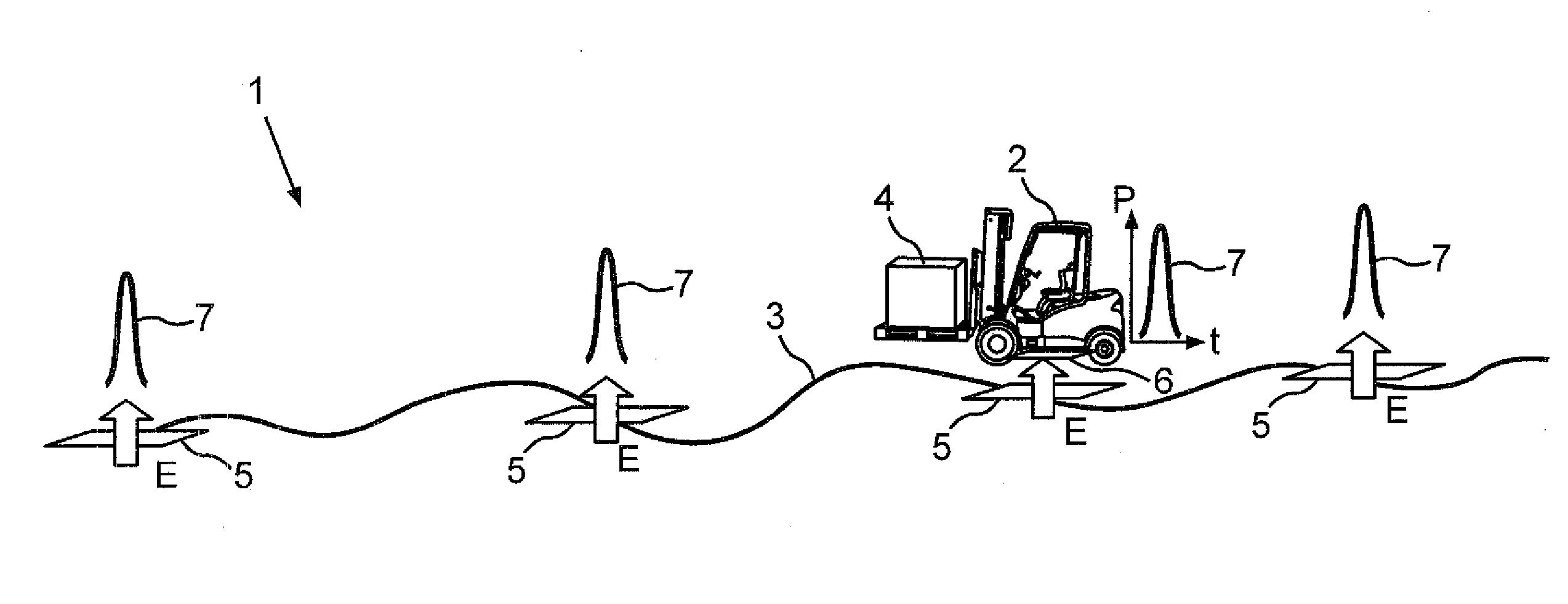

Method and apparatus in pneumatic material conveying system

InactiveUS20100310327A1Efficiently circulatedLower the volumeBulk conveyorsRefuse gatheringPressure differenceDelivery system

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material with a pump device (3) the suction side of which is connected to at least one separator device (20) and further to the conveying pipe (100) on its return side so that at least part of conveying air on the pressure side of the pump is led in the circuit on the supply side of the conveying pipe (100).

Owner:MARICAP OY

Method for ternary contents address memory table management

InactiveUS7774538B2Efficiently arrangedNo wasteSecuring communicationMemory systemsLongest prefix matchLookup table

Provided are a method for Ternary Contents Address Memory (TCAM) table management and a computer-readable recording medium for recording a program that implements the method. The method includes the steps of: a) dividing a memory area of TCAM into fixed-size blocks depending on priority to configure a lookup table; b) assigning a priority to each routing entry being inputted to the lookup table based on prefix length; c) storing the routing entry having been assigned with the priority in a lookup table block of a corresponding priority; and d) when a modification occurs in the lookup table, modifying the lookup table to maintain an arranged state for a longest prefix match.

Owner:ELECTRONICS & TELECOMM RES INST

Method in pneumatic material conveying system and a pneumatic material conveying system

InactiveUS20100303559A1Efficient arrangementLower the volumeBulk conveyorsRefuse gatheringEngineeringPressure difference

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3, 4) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material with at least one first pump device, such as a vacuum unit (3), and with at least one second pump device, such as a blower unit (4).

Owner:MARICAP OY

Headlight device for motorcycle

InactiveUS20140293629A1Efficiently disposeEfficiently arrangedVehicle headlampsOptical signalHeadlampDistribution characteristic

Owner:HONDA MOTOR CO LTD

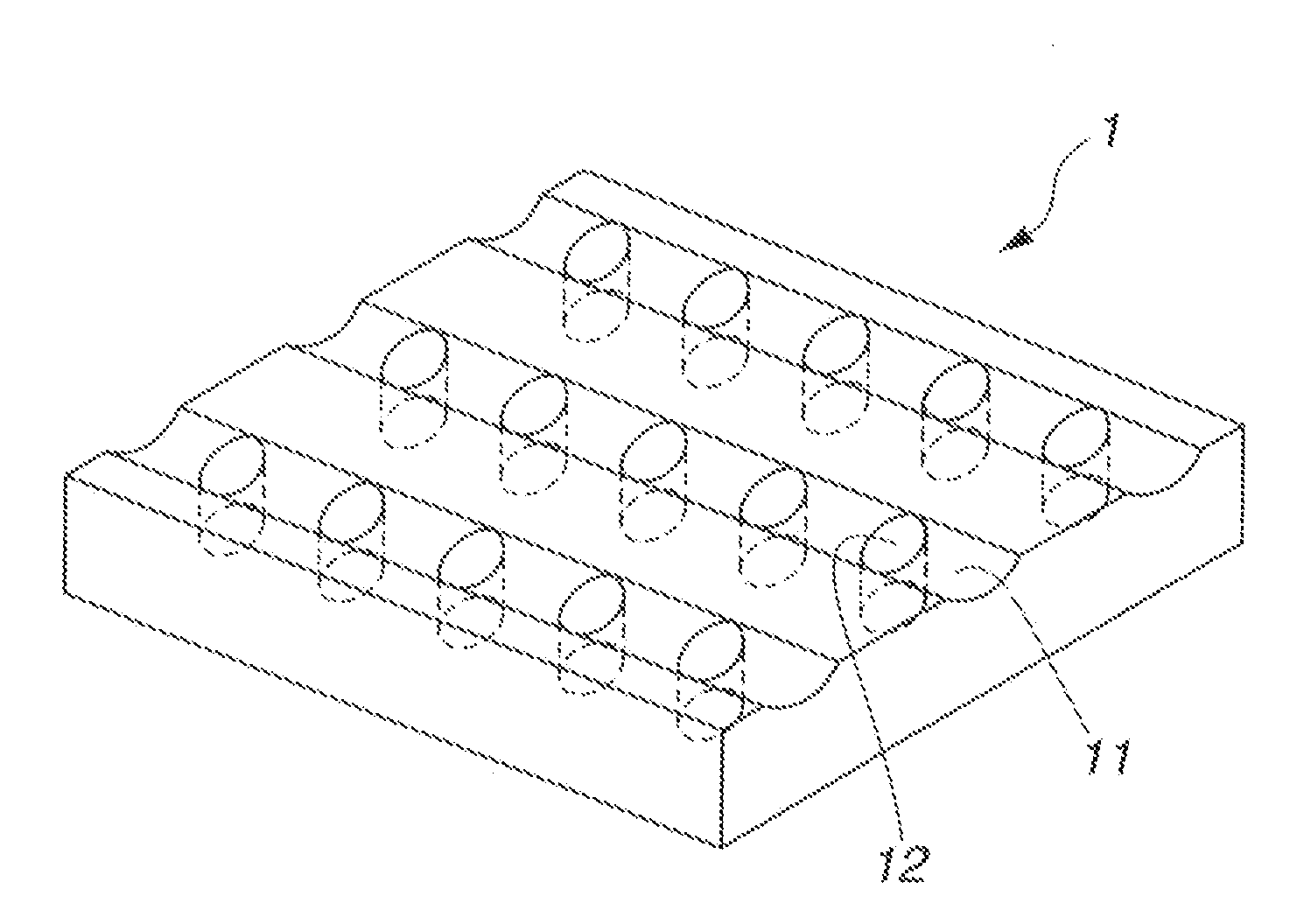

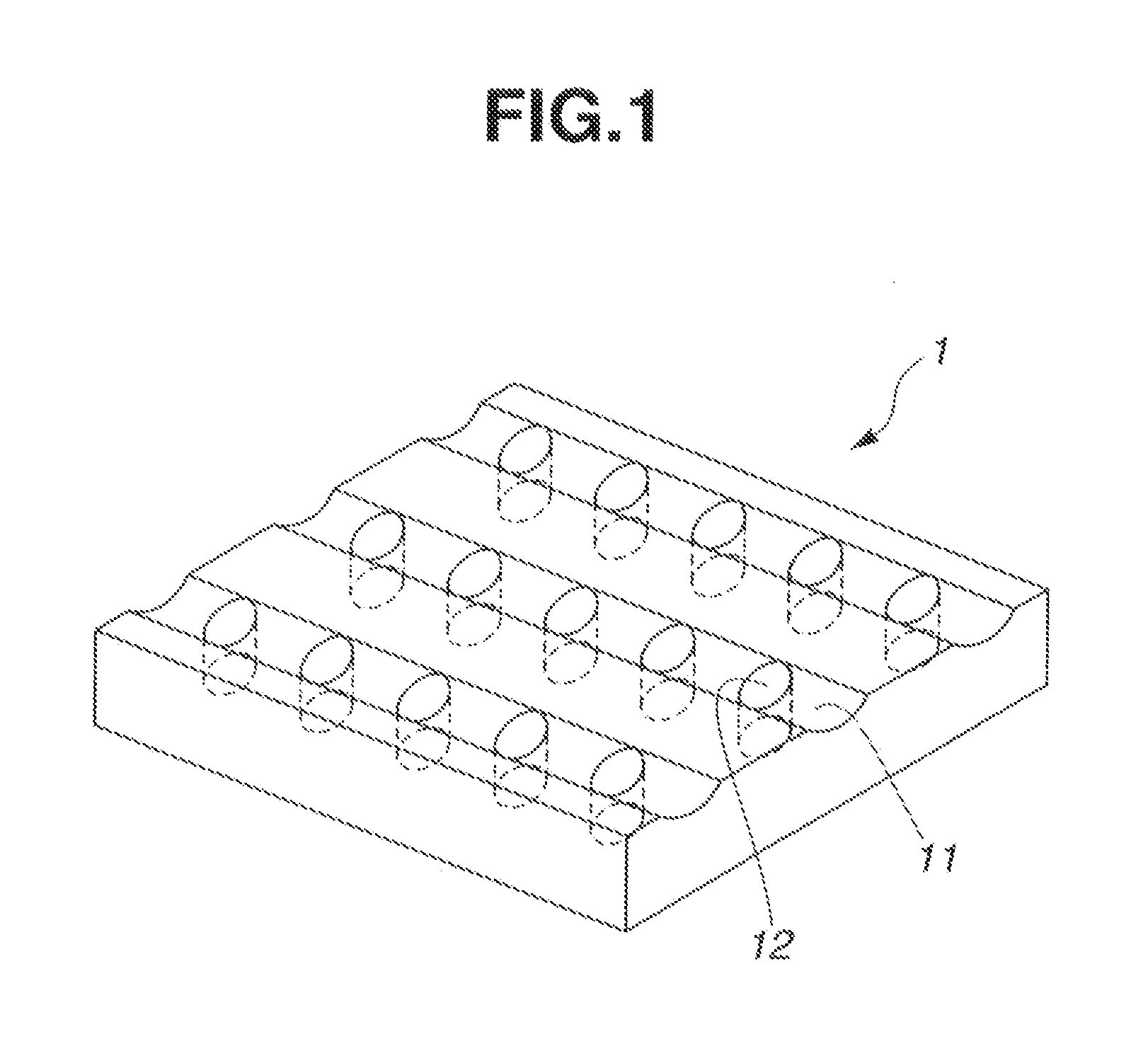

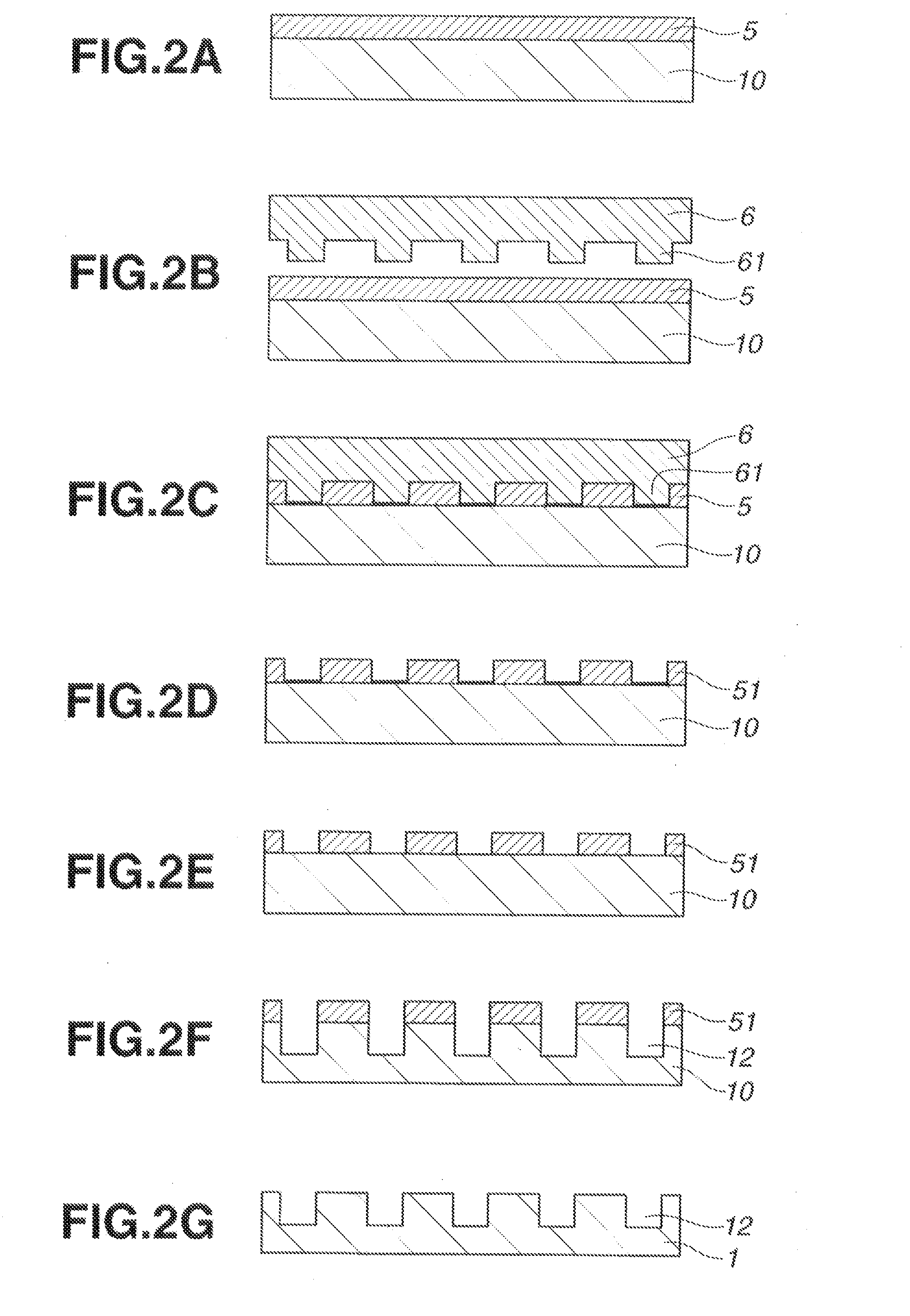

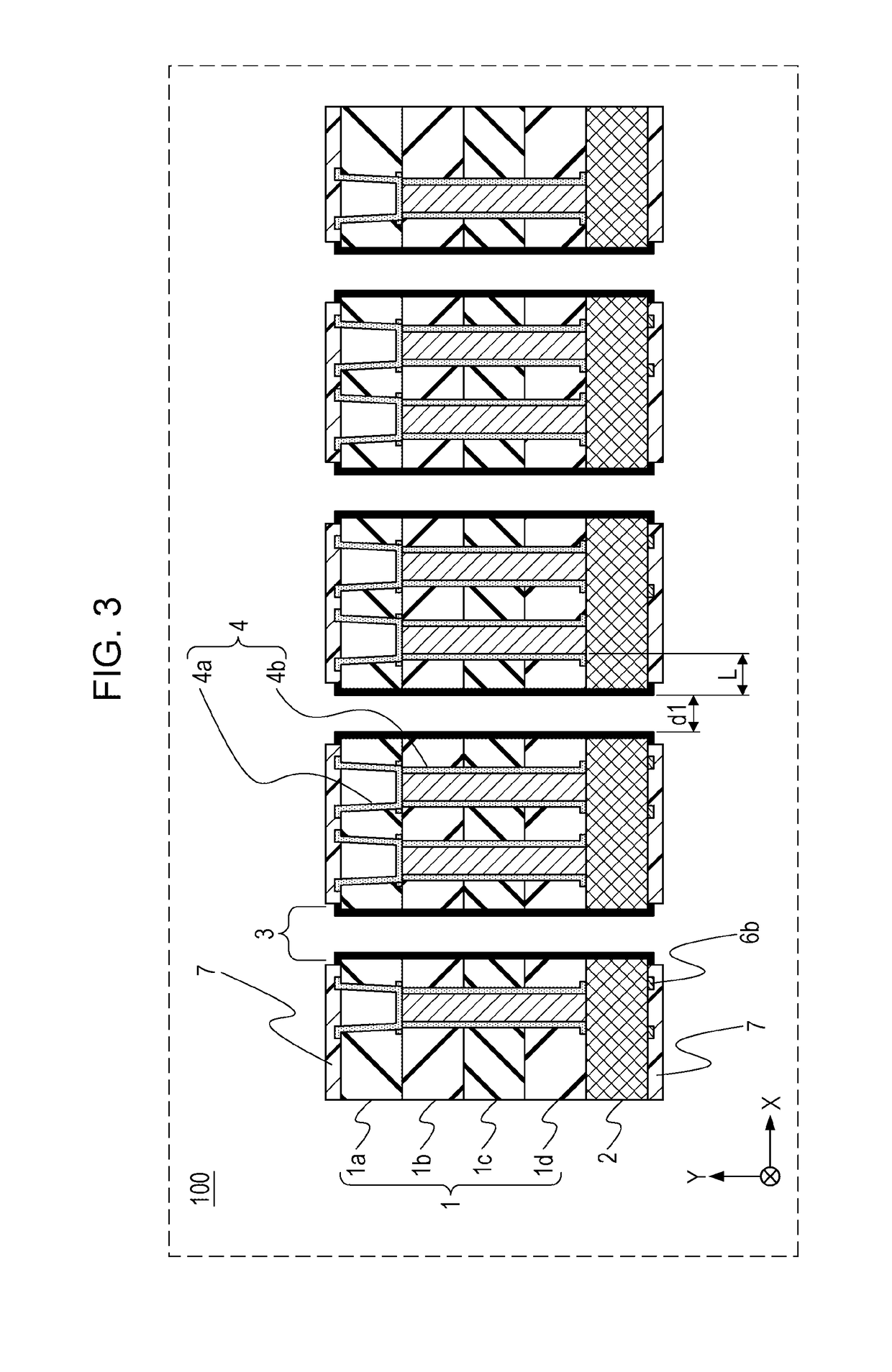

High density magnetic recording medium and manufacturing method thereof

InactiveUS20110195277A1Stably and efficiently arrangingHigh densityMagnetic materials for record carriersPretreated surfacesDispersed mediaHigh density

A high density magnetic recording medium including aggregates of magnetic nanoparticles arranged stably and efficiently in demarcated sections in the surface of a substrate is manufactured by the steps of forming a plurality of parallel tracks in the surface of the substrate, forming a plurality of minute recesses serially at approximately equal intervals in each of the tracks, casting a liquid dispersion of magnetic nanoparticles into the minute recesses, and evaporating dispersing medium from the liquid dispersion, thereby forming an aggregate of magnetic nanoparticles in each of the minute recesses.

Owner:WASEDA UNIV +1

Display Device

ActiveUS20090039355A1Efficiently arrangedStatic indicating devicesDigestive systemPower flowScan line

A current pixel circuit of a display device includes a switching transistor which may be turned on in response to the current selection signal to transfer a data signal, a driving transistor for outputting a current corresponding to the data signal, and first and second transistors being turned on in response to the previous selection signal. In the display device, the gate electrodes of the switching transistor of a previous pixel and the first and second transistors of the current pixel are coupled to one scan line for transferring the previous selection signal. Accordingly, the transistors are arranged in the order of the switching transistor of the previous pixel and the first and second transistors of the current pixel on the scan line at an area between two adjacent data lines.

Owner:SAMSUNG DISPLAY CO LTD

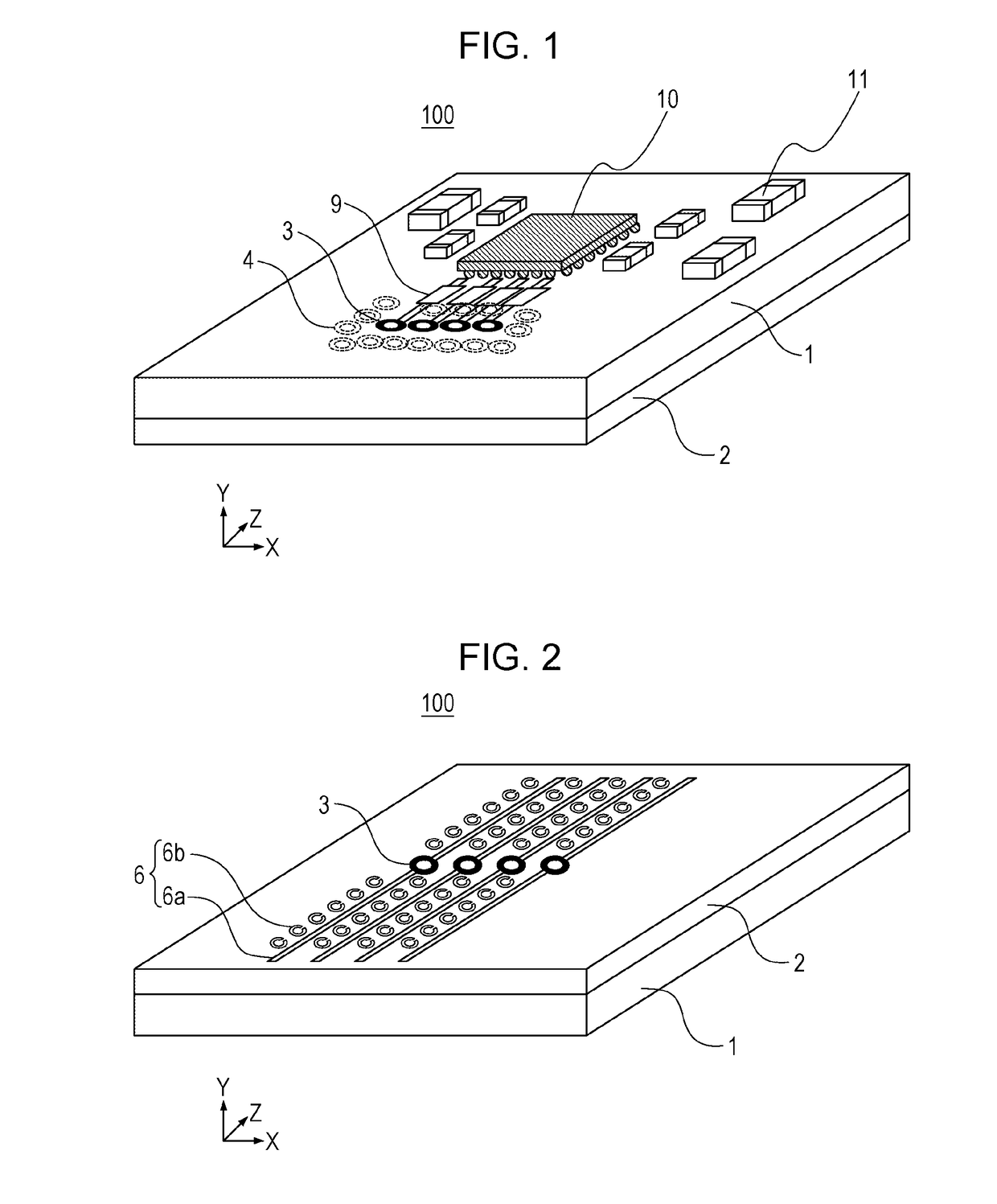

Antenna module

ActiveUS20170346195A1Efficiently arrangedTransmission lossWave based measurement systemsElectrically long antennasElectrical conductorBeam direction

An antenna module includes a multilayer board, a phased array antenna that includes antenna elements arranged on an outer face of a second conductor layer included in the multilayer board and adjusts one or more beam directions of the antenna elements, a radio frequency (RF) chip that is arranged on an outer face of first conductor layers included in the multilayer board and outputs the radio frequency signal, a matching circuit that is arranged on the outer face of the first conductor layers and adjusts matching between impedance of the antenna elements and impedance of the RF chip, a through hole that couples the first conductor layers and the second conductor layer, and one or more vias that are on an outer side in a diameter direction of the through hole and couples the first conductor layers.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method in pneumatic material conveying system and a pneumatic material conveying system

InactiveUS20100278598A1Efficiently arrangedEfficiently circulatedRefuse gatheringBulk conveyorsEngineeringPressure difference

A method for feeding and conveying material in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3, 4) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. Underpressure is provided in the conveying pipe (100) at least at the point of the feed point (61) intended to be emptied, the feed points are emptied to the conveying pipe (100) using an emptying sequence in which first is emptied a feed point located closer to the separator device (20) in the material conveying direction and next a feed point (61) located substantially farther from the separator device (20) in the material conveying direction.

Owner:MARICAP OY

Method and apparatus in pneumatic material conveying system

InactiveUS20100278596A1Guarantee effective circulationLower the volumeRefuse gatheringBulk conveyorsAir cyclePressure difference

A method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one feed point (61) of material, particularly of waste material, a material conveying pipe (100) which is connectable to the feed point (61), a separator device (20) in which the material being conveyed is separated from conveying air, and means (3) for providing a pressure difference in the conveying pipe (100) at least during the conveyance of the material. At least a part of the conveying piping (100) is connectable as a section of a circuit in which conveying air is circulated at least during the conveyance of the material and, in the method, conveying air circulation is connected, at least momentarily, to a reverse direction in relation to the normal conveying direction, at least in a section of the circuit, which section of the circuit is formed by at least a part of the conveying pipe (100), advantageously for removing a possible blockage.

Owner:MARICAP OY

Electric vehicle with fast-charge function

InactiveUS20160297307A1Efficiently arrangedEfficient arrangementRail devicesBatteries circuit arrangementsCouplingFast charging

A vehicle includes an electric drive motor for driving the vehicle, an electrochemical accumulator for storing and providing electric energy for the drive motor, the accumulator being configured to only take up a charging power which is smaller than a predetermined maximal power value, an electric auxiliary storage for storing and providing electric energy for the drive motor, the auxiliary storage being configured to take up a charging power during charging which is greater than the maximal power value; a charging device for receiving energy from a vehicle-external charging station as a power pulse which has an amplitude greater that the maximal power value and to store the received energy in the auxiliary storage; and a coupling circuit coupling the auxiliary storage with the accumulator and configured to transmit the energy from the auxiliary storage into the accumulator with a charging power which is smaller than the maximal power value.

Owner:AUDI AG

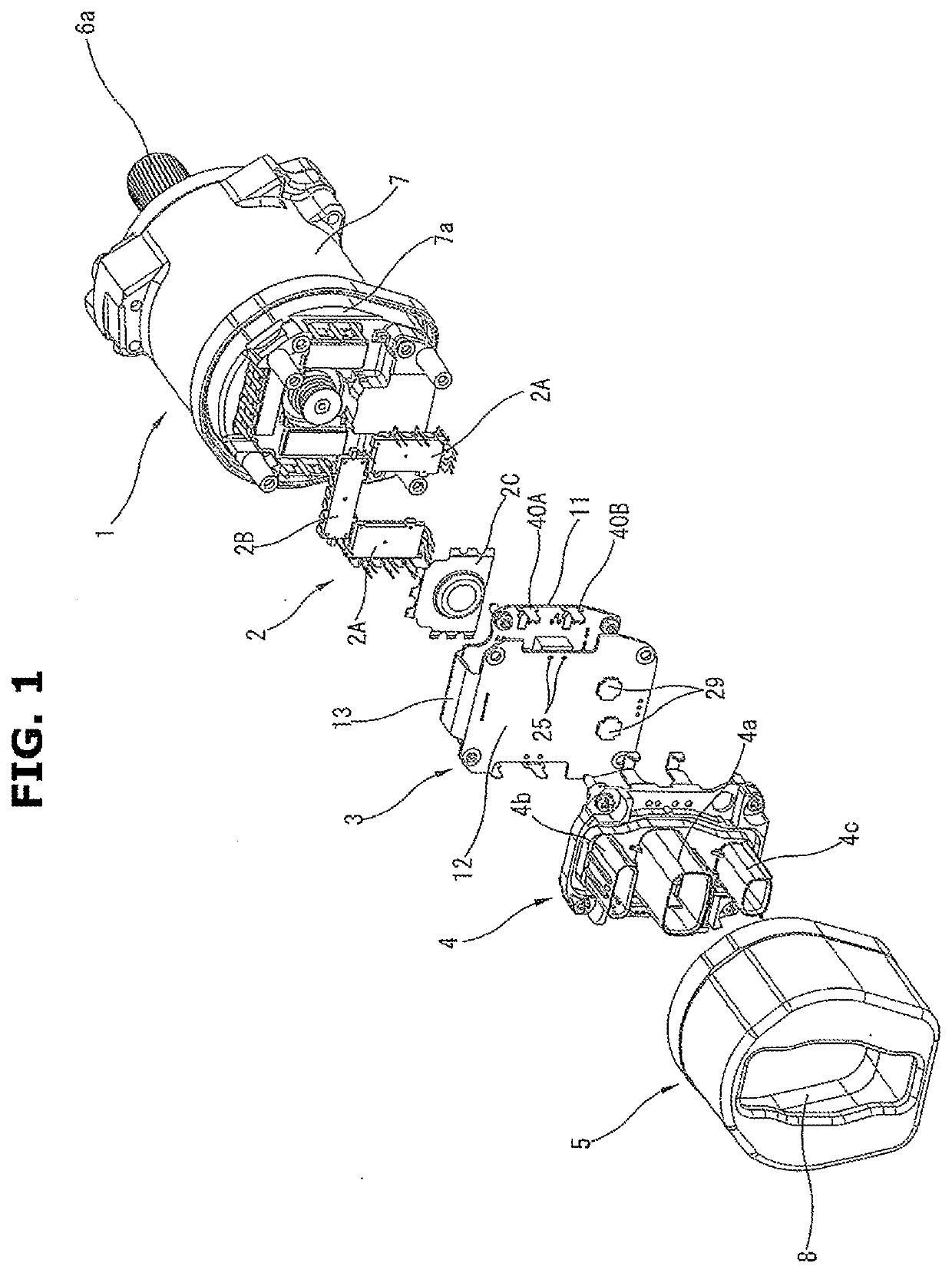

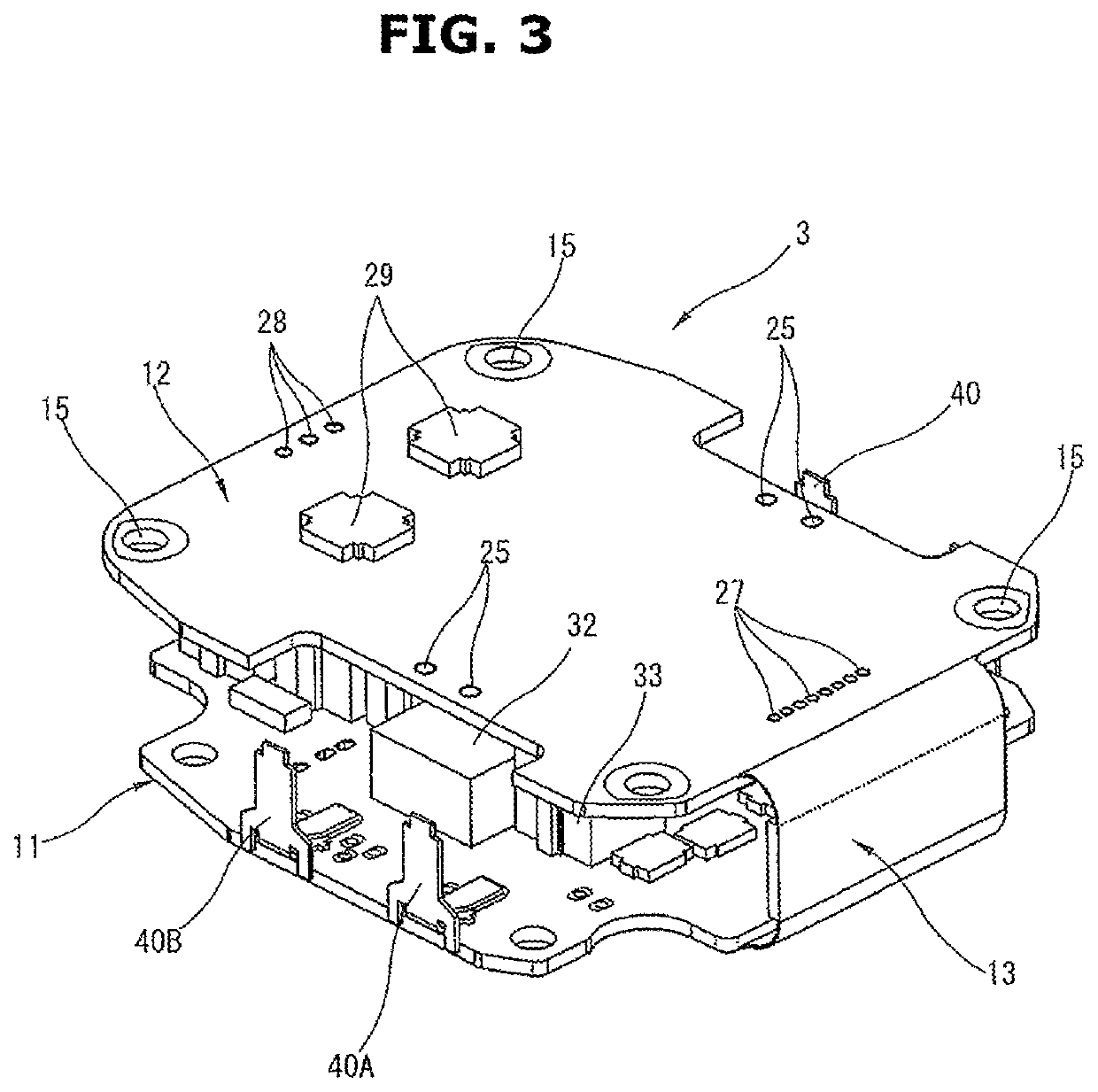

Electronic control device

ActiveUS20200321839A1Reduce the numberThin thicknessCircuit bendability/stretchabilityAssociation with control/drive circuitsCapacitanceDriver circuit

A wiring board (3) has first and second rigid sections (11, 12) each having six metal leaf layers, and a flexible section (13) having two metal leaf layers that connect the both rigid sections (11, 12). A capacitor unit (34) and a filter unit 31, which supplies power to an inverter, are mounted on the first rigid section (11), and a CPU (21) and a pre-driver circuit element (22) are mounted on the second rigid section (12). Mutually-independent two control systems are arranged so as to be symmetrical about a board center line (M). Detection signal lines (51) of rotation sensors (37, 38) located at the middle of the first rigid section (11) extend along the board center line (M) on the flexible section (13). Each of the two control systems is configured along a wiring direction of the detection signal lines (51).

Owner:HITACHI ASTEMO LTD

Storage device and method of efficiently arranging components in an information processing apparatus

ActiveUS7466557B2Efficiently arrangedDigital data processing detailsElectrical connection printed elementsElectricityInformation processing

An information processing apparatus designed for miniaturization, having a chassis, and including a motherboard; an expansion slot exchange device electronically connected to the motherboard and configured to hold an expansion card; and a memory device electronically connected to the motherboard and located within the chassis primarily in a first plane orthogonal to a primary plane of the motherboard. An expansion card can be added, occupying a plane parallel to the primary plane of the motherboard.

Owner:RICOH KK

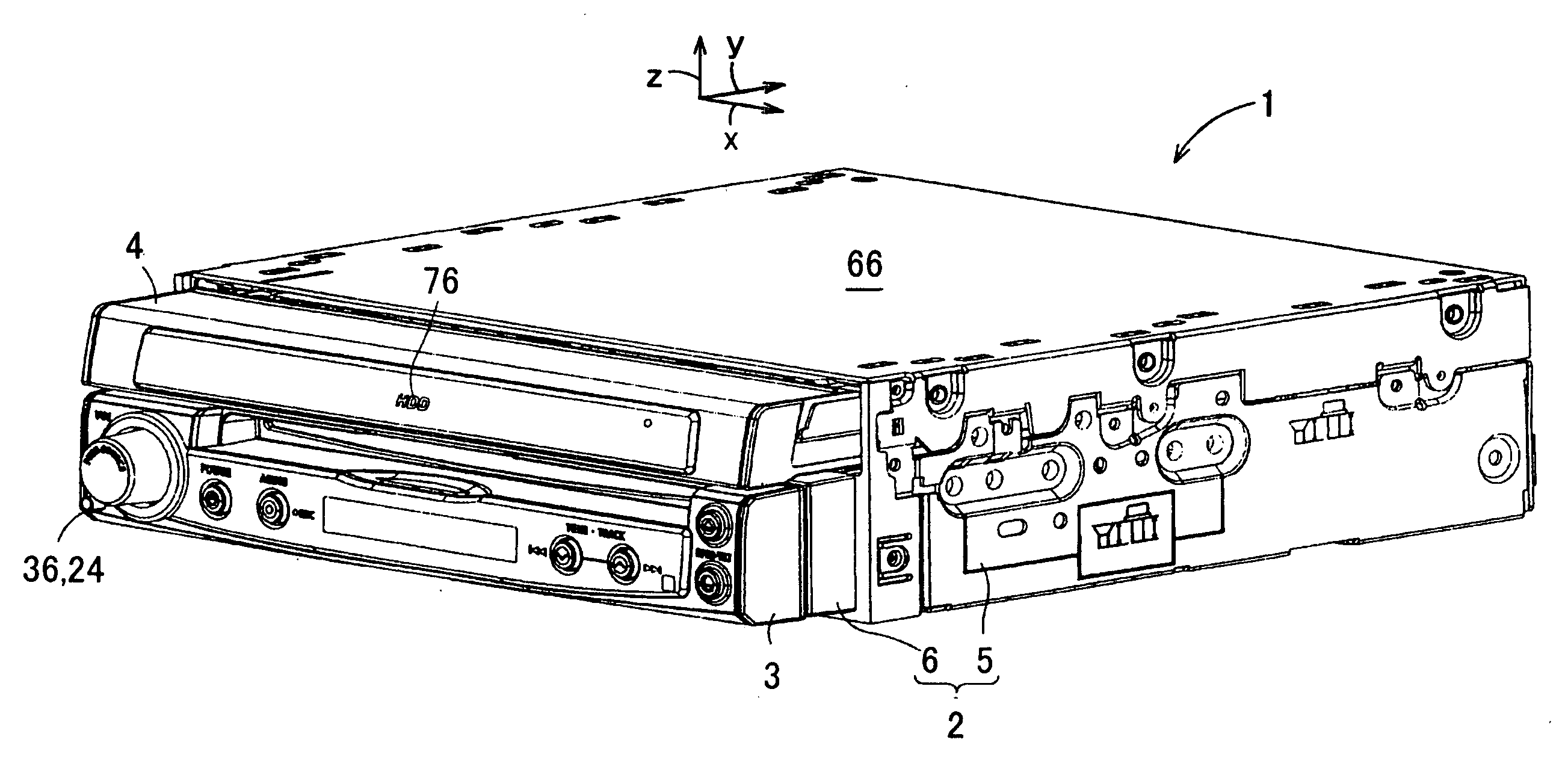

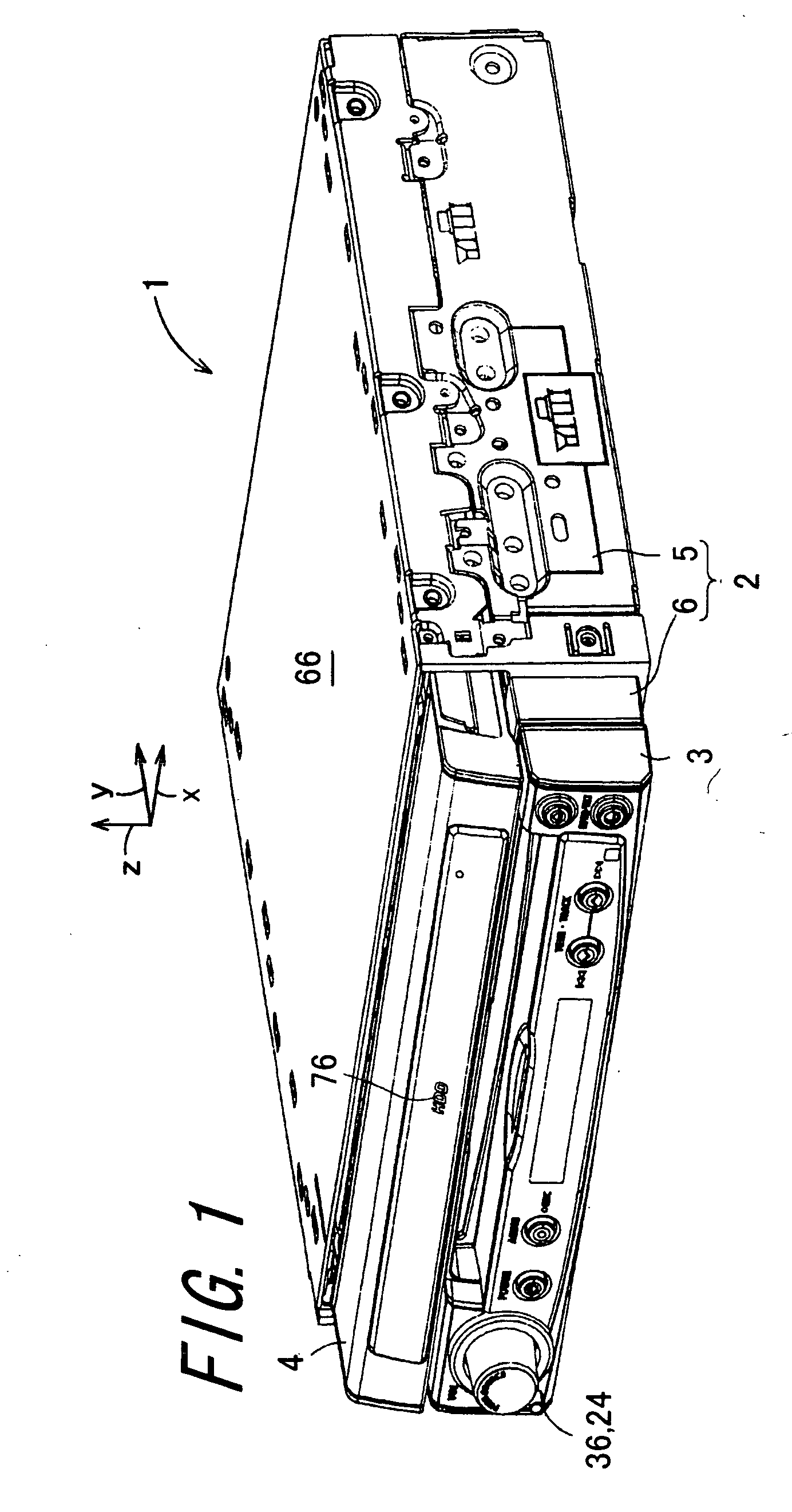

Vehicle-mounted electronic apparatus

InactiveUS20070085419A1Reduce distanceQuality improvementPassenger spaceElectric devicesHard disc driveQuality of service

There is provided an electronic apparatus in which components and boards are arranged in a highly dense state to realize downsizing. The electronic apparatus has a first board in which an avoiding portion shaped into a cutout or a hole for avoiding a hard disk drive is formed, and a second board arranged over the hard disk drive. The hard disk drive is connected to the second board, whereby downsizing is realized and high quality of service is obtained.

Owner:FUJITSU GENERAL LTD

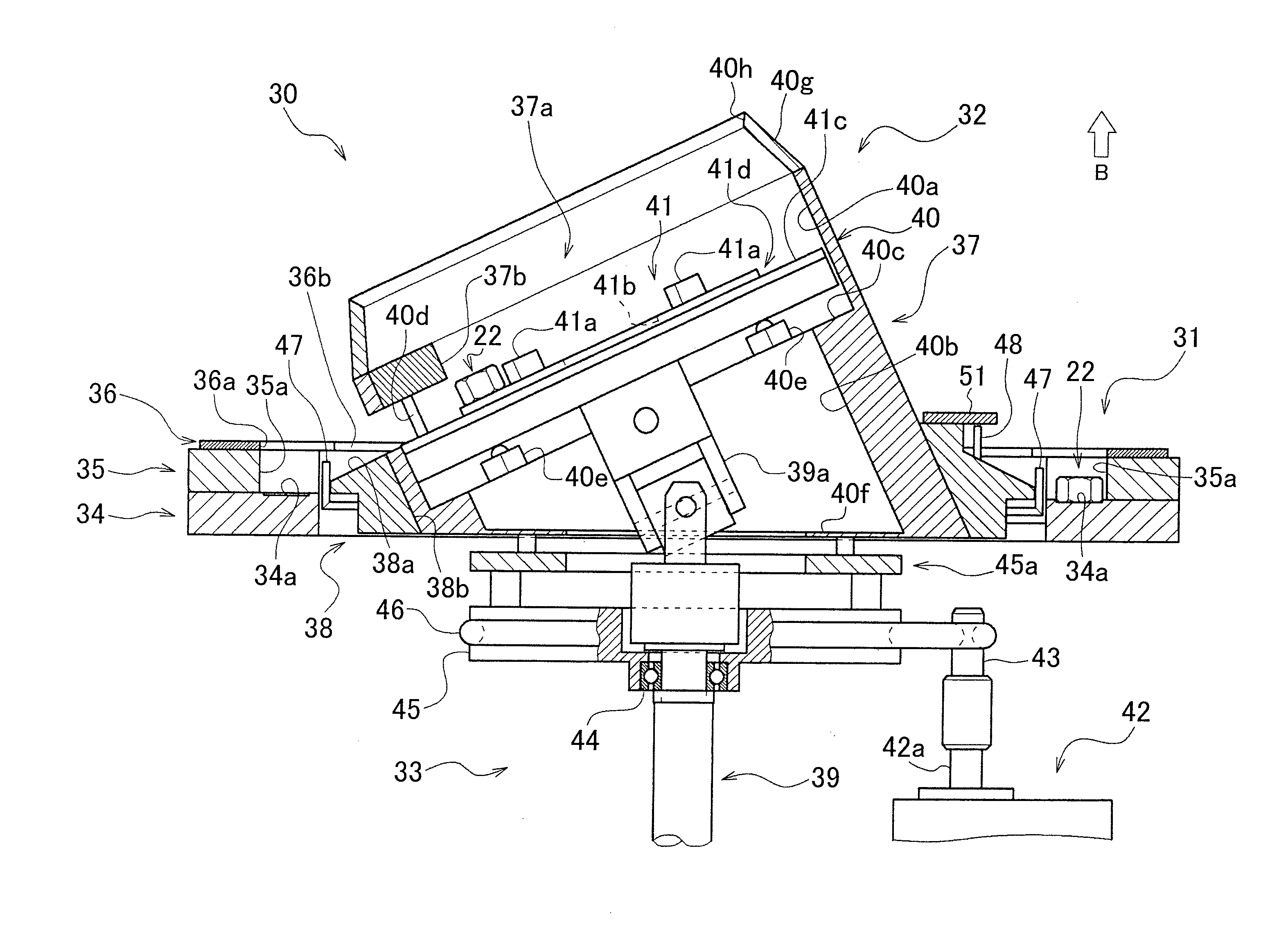

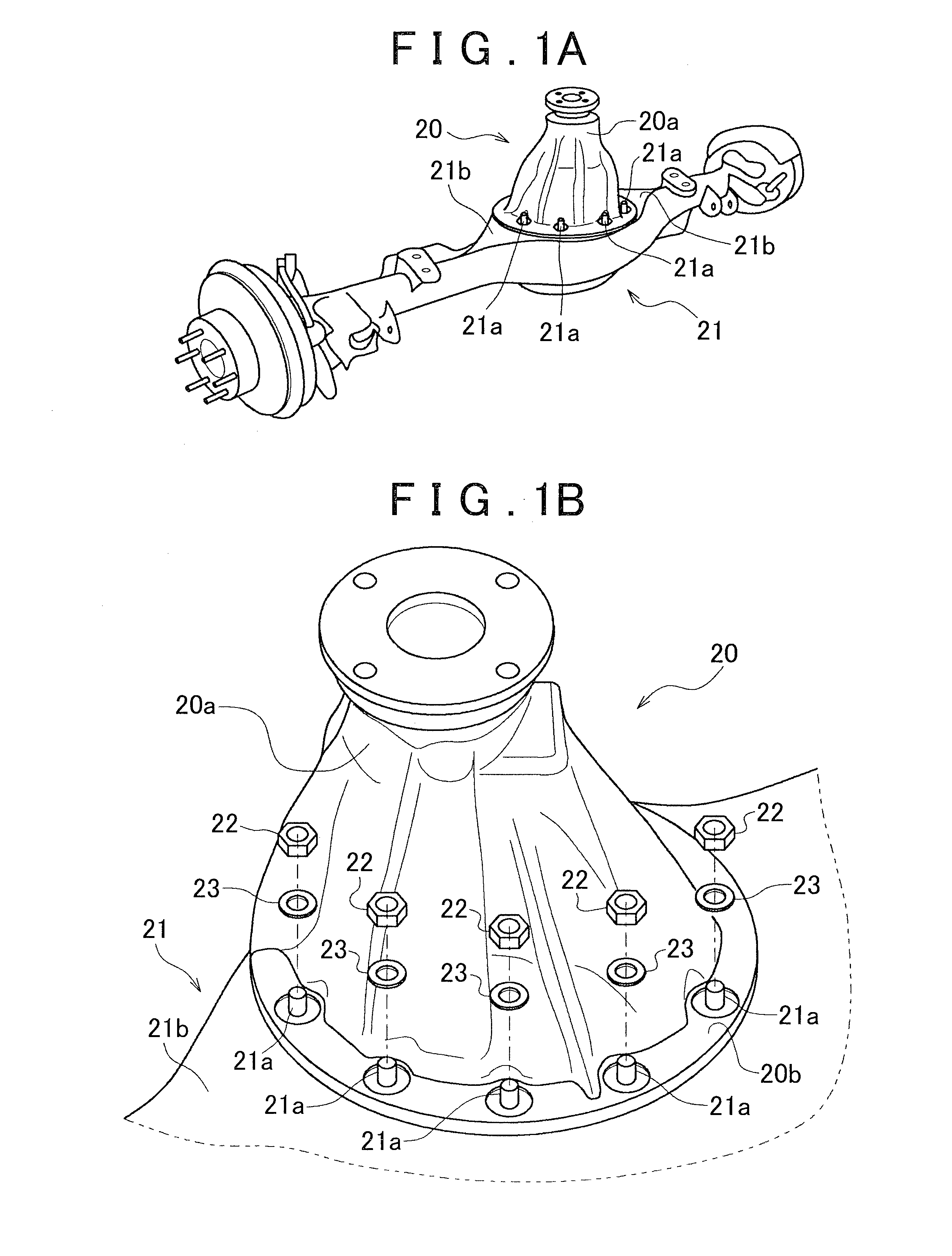

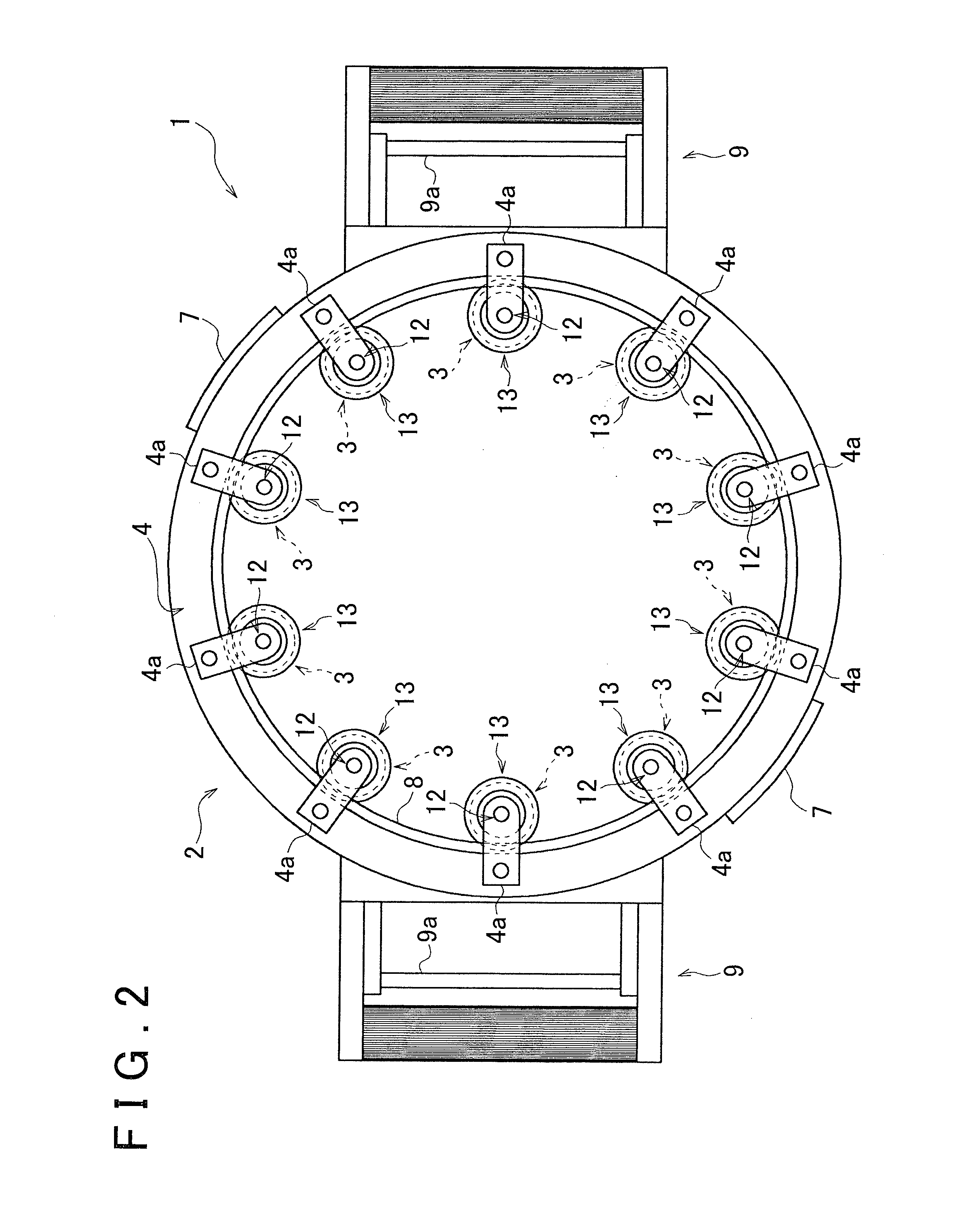

Nut arranging apparatus

Owner:TOYOTA JIDOSHA KK

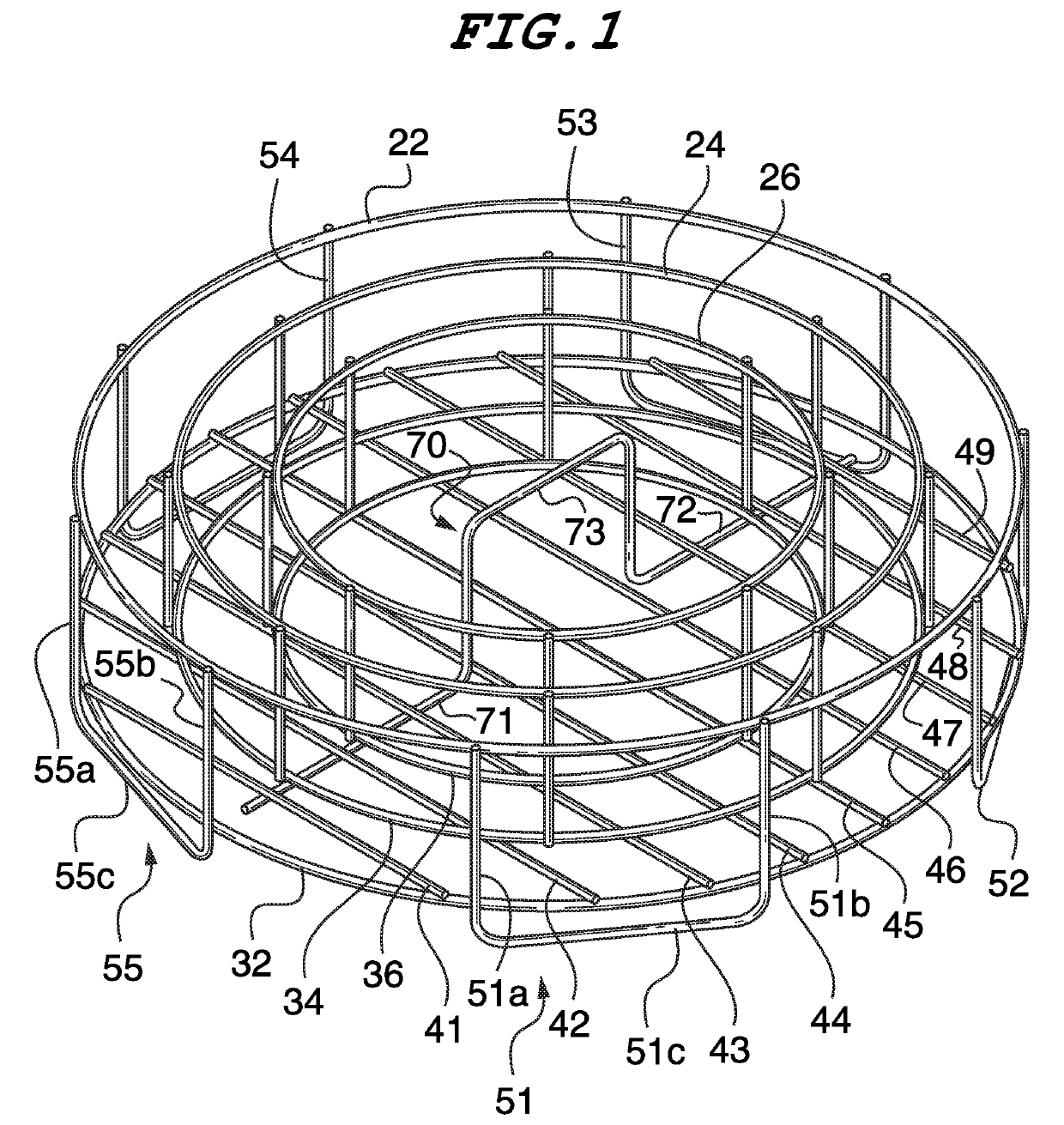

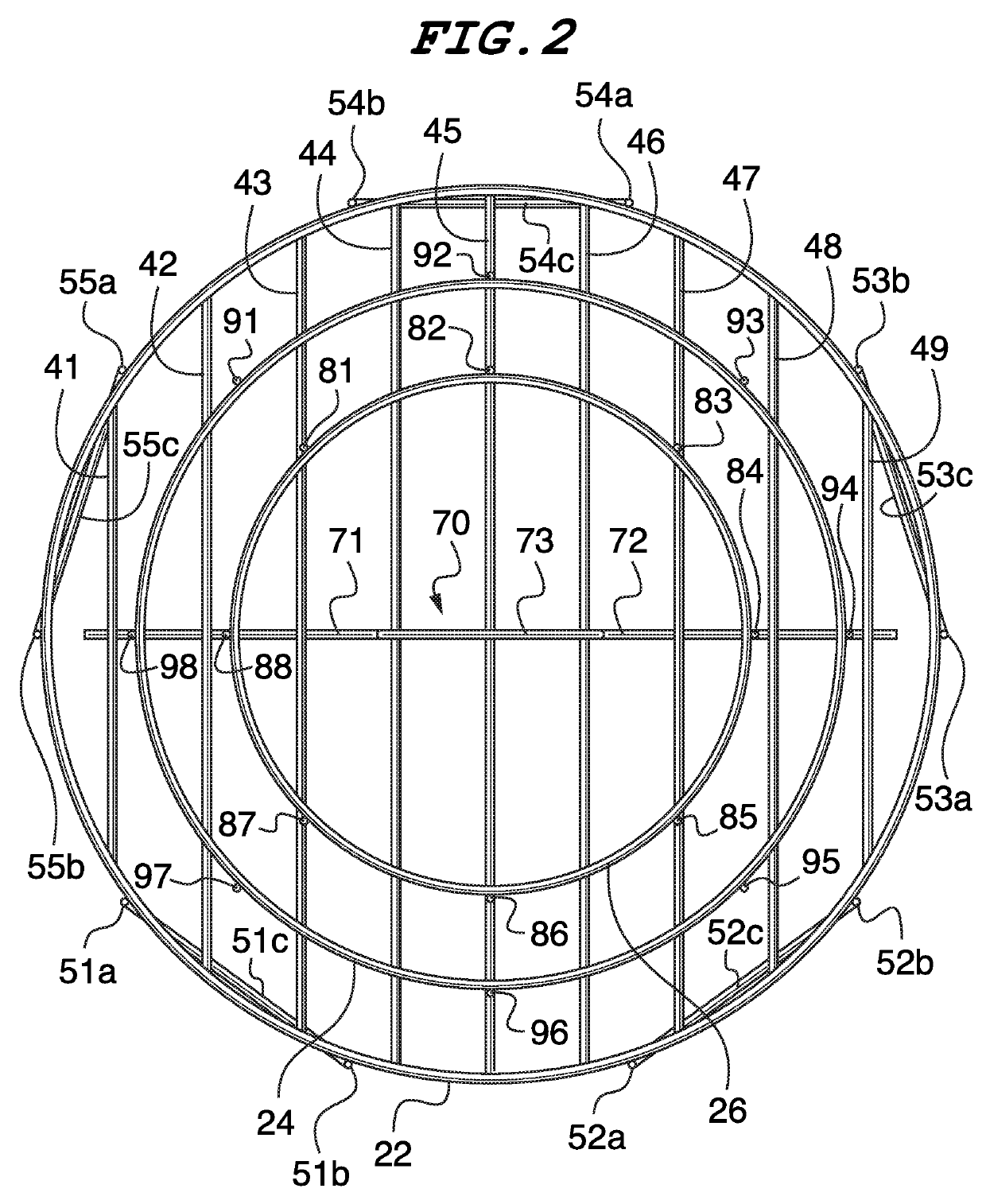

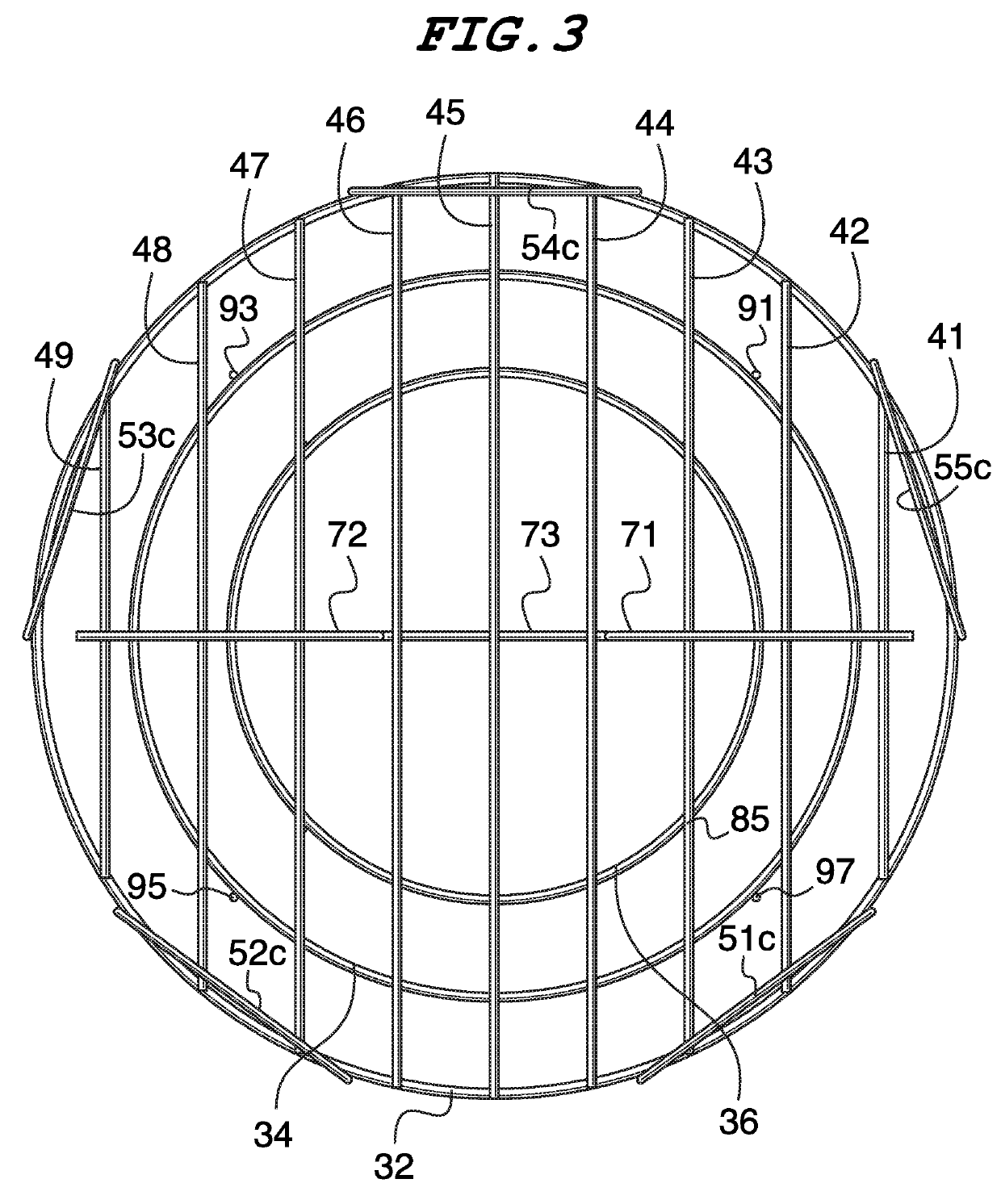

Support structure for cooking food

ActiveUS20190246839A1Efficient arrangementMaximize food productionRoasters/grillsEngineeringFood item

Owner:THE BBQ GURU INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com