Catheter tube for medical treatment and method of manufacturing the same

A medical and catheter technology, applied in the field of medical catheters, can solve the problems such as gradual control of insufficient rigidity and flexibility, metal braid flying out, setting the state of the catheter, etc., and achieves the effect of excellent position adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

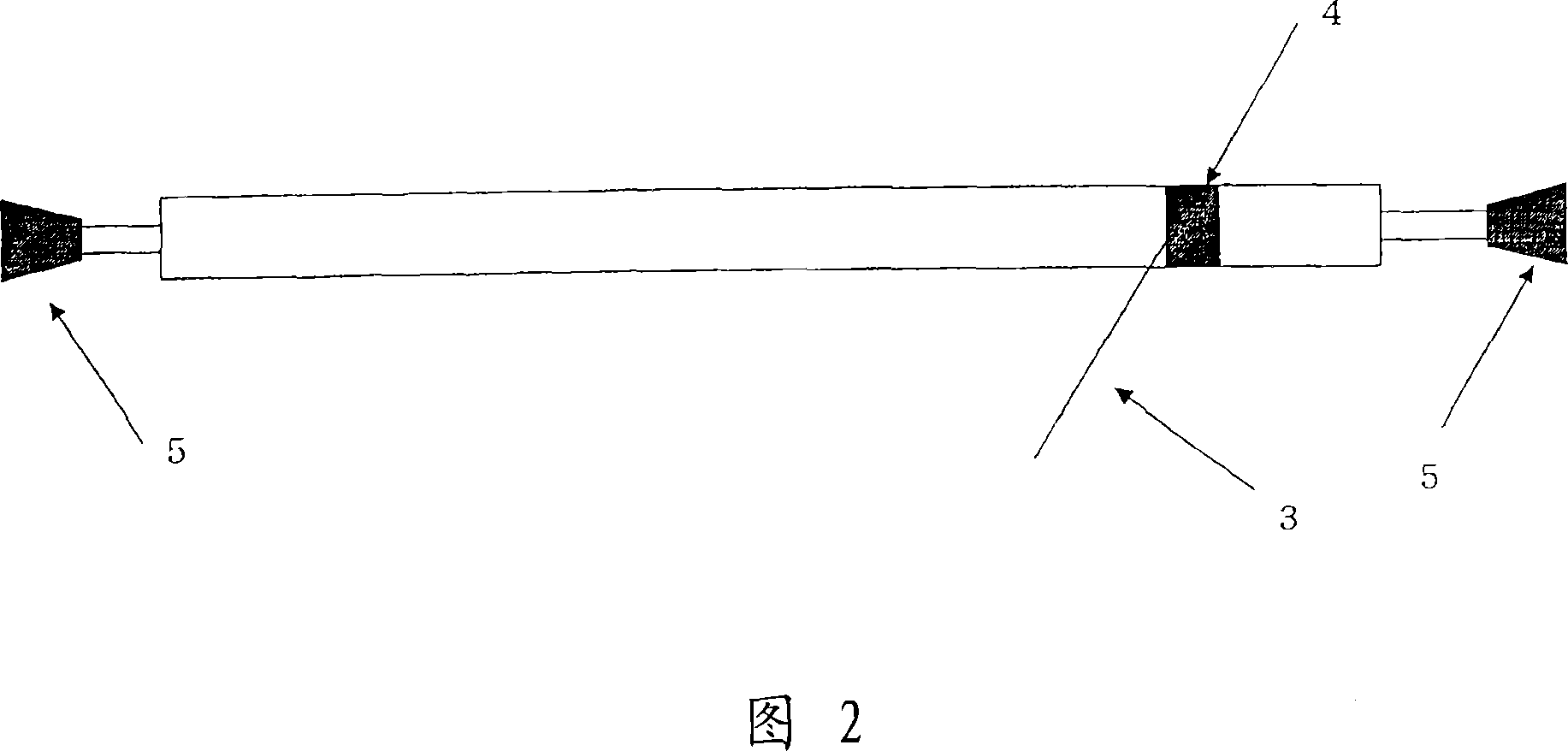

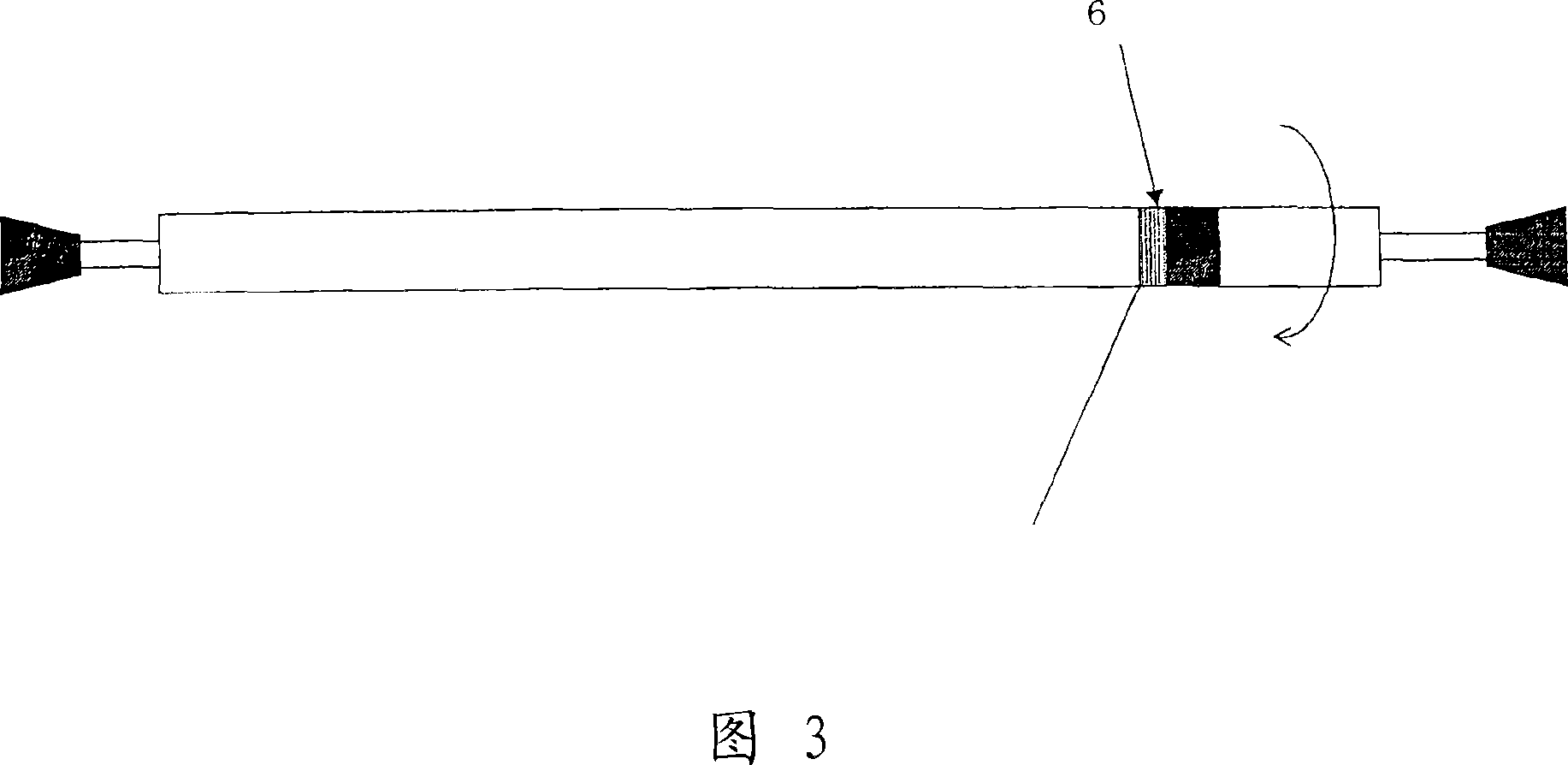

[0088] Next, the most preferable embodiment and manufacturing method of the medical catheter of the present invention will be described with reference to the drawings. These figures are diagrams schematically showing the structural features of the present invention, and the length and diameter of each part may be arbitrary as long as it is suitable as a medical catheter.

[0089] First, a duct in which the linear body constituting the reinforcing material layer is wound without being folded as the first aspect of the present invention will be described.

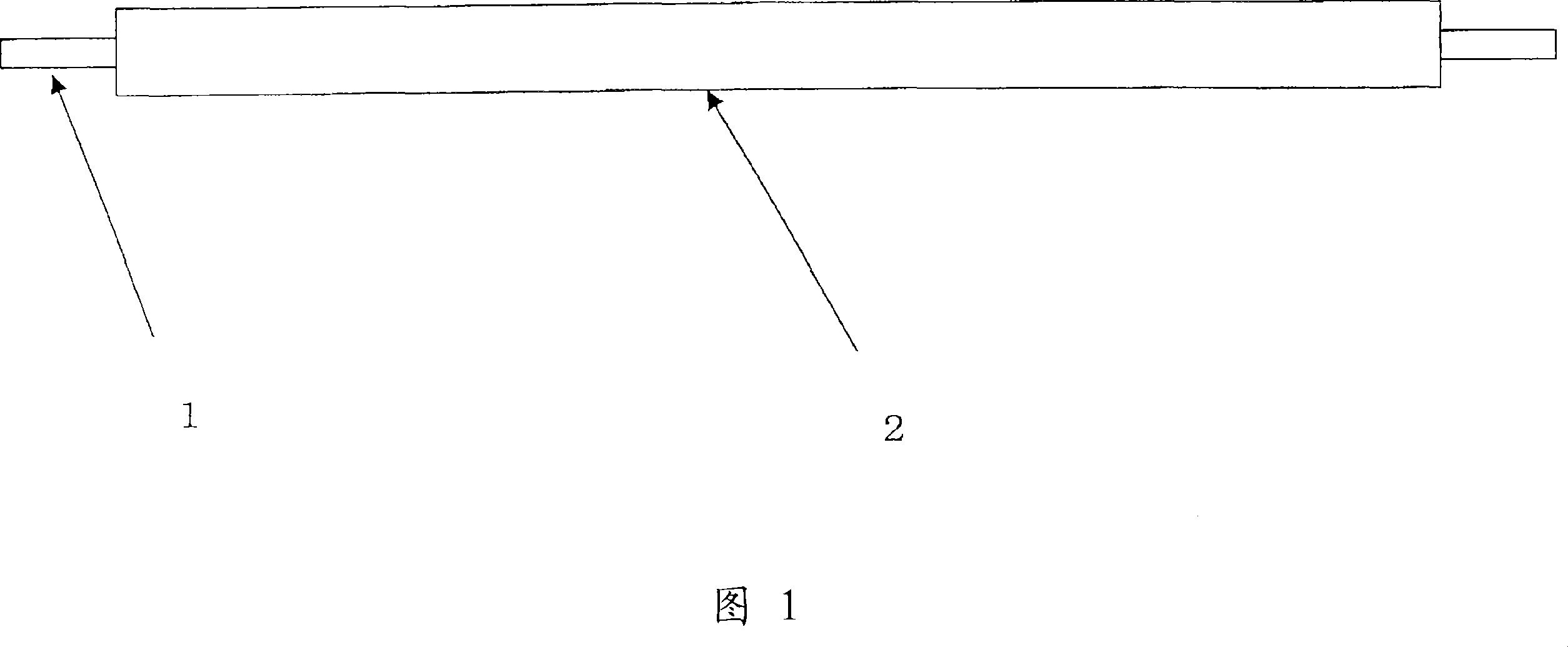

[0090] First, the inner layer tube 2 covering the metal core wire 1 as shown in FIG. 1 is prepared. In addition, in FIG. 1 , the left side is the root portion of the catheter (hereinafter referred to as the root portion), and the right side is the distal portion of the catheter (hereinafter referred to as the distal portion).

[0091] The constituent material of the inner layer tube is not particularly limited as long as it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com