High-speed high- precision servo linear motor sliding table

A linear motor, high-precision technology, applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve problems such as movement lag, wear, vibration, etc., achieve low noise and wear, safe and reliable work, and improve sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

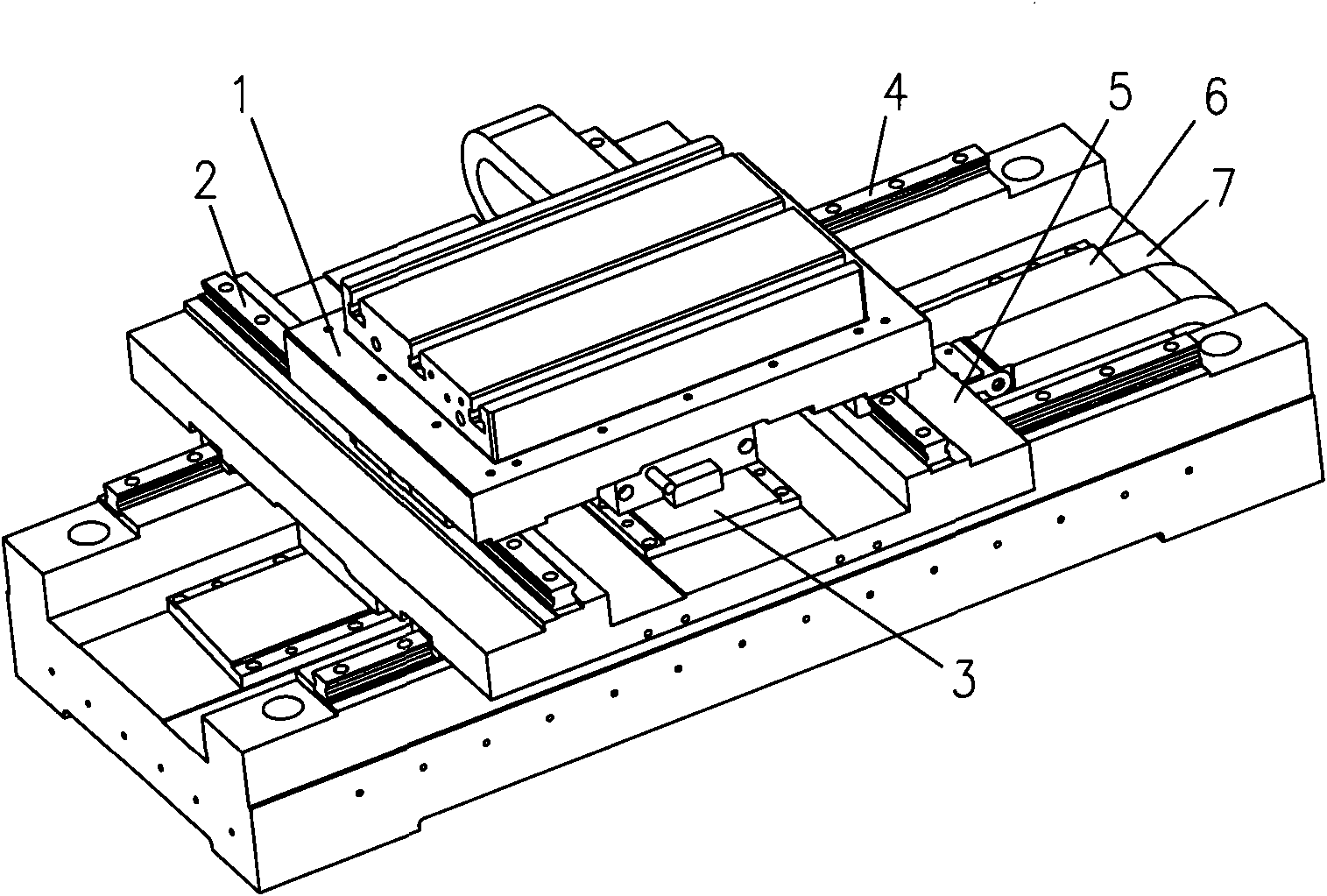

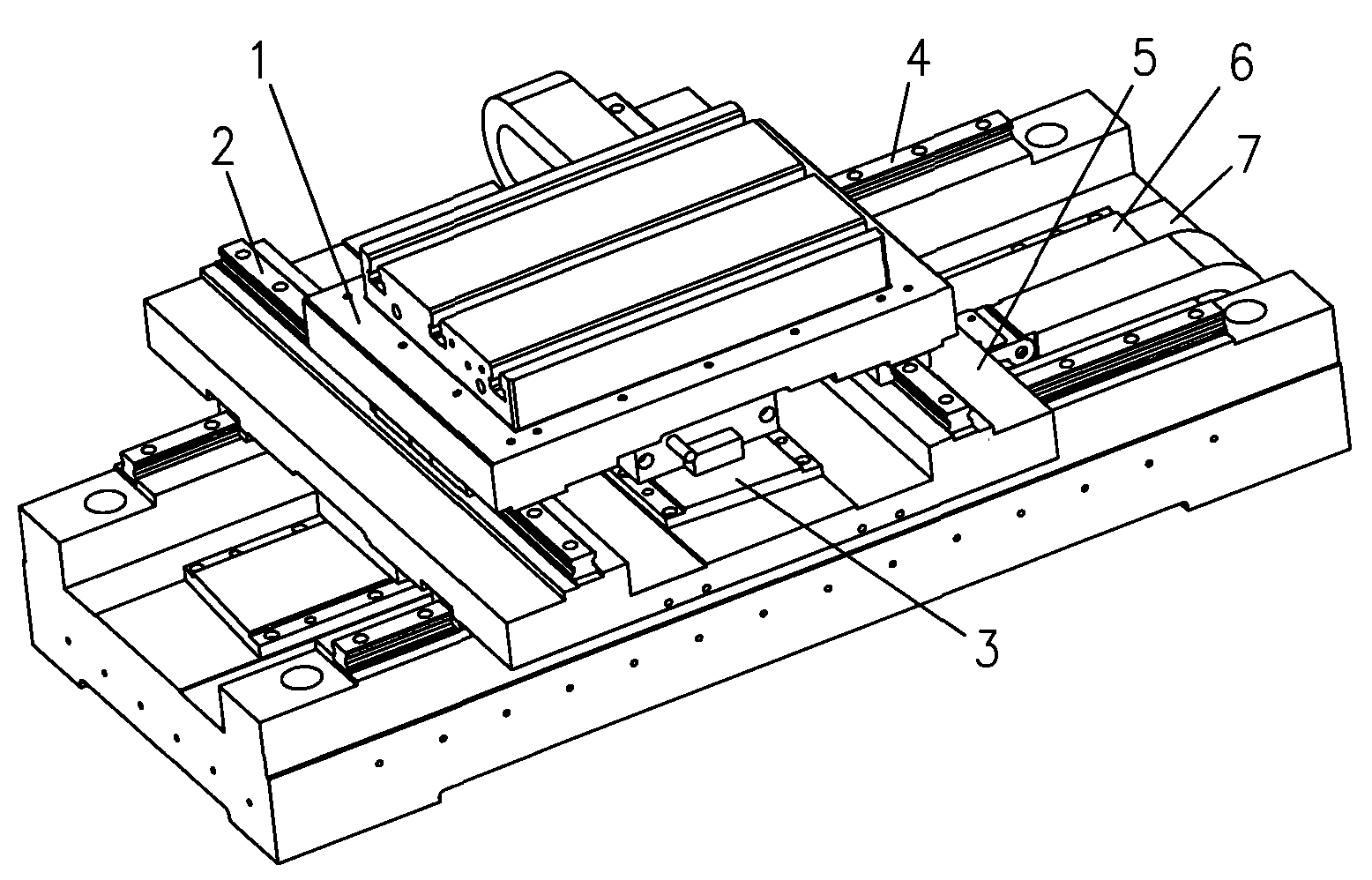

[0018] like figure 1 As shown, the high-speed and high-precision servo linear motor slide table of the present invention includes a slide table base 7, a slide table 5 is slidably connected to the slide table base 7, an upper slide table 1 is slidably connected to the slide table base 7, and the slide table base 7, The upper sliding platform 1 and the lower sliding platform 5 are casted with high-performance cast iron, which has strong vibration absorption and structural rigidity, ensuring the stability of moving parts. There are Z-axis linear guide rails 4 on both sides of the top of the slide base 7, and the sliding table 5 is connected to the Z-axis linear guide rails 4. A Z-axis servo linear motor 6 is arranged between the sliding table 5 and the Z-axis linear guide rails 4, and the Z-axis servo The linear motor 6 is arranged between the two Z-axis linear guide rails 4, the stator of the Z-axis servo linear motor 6 is fixed on the slide base 7, and the mover of the Z-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com