Preparation method for large-sized bended insensitive multimode optical fiber preform

A bend-insensitive, optical fiber prefabricated rod technology, applied in the field of optical communications, can solve problems affecting the geometric uniformity and refractive index uniformity of optical fibers, and affecting the bandwidth performance of optical fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Provide several detailed embodiments below, the present invention is described further.

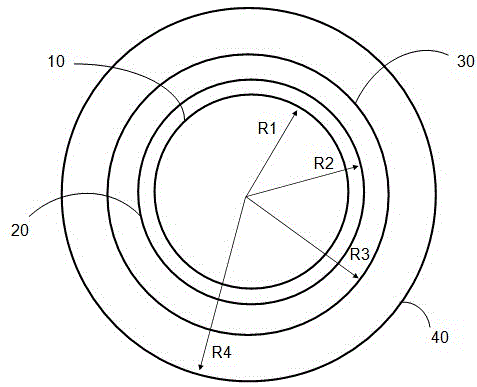

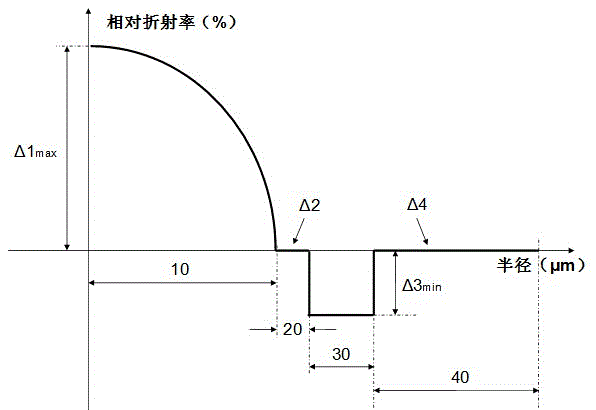

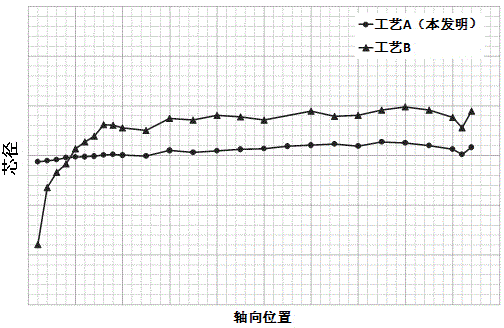

[0053] Method 1: Doping deposition is performed on the inner wall of the pure quartz glass liner by PCVD process, and the reaction gas silicon tetrachloride (SiCl 4 ) and oxygen (O 2 ), and then into the fluorine-containing gas (C 2 f 6 ) and germanium tetrachloride (GeCl4) to adjust the refractive index, the mass flow controller (MFC) is used to precisely control the gas flow throughout the process; the reaction gas in the liner is turned into a plasma by microwave, and finally deposited in the form of glass On the inner wall of the liner, all the deposited layers constitute the core layer 10 of the preform, and the rest of the liner constitutes all or part of the inner cladding 20; after the deposition is completed, the deposition tube is melted into a solid mandrel by an electric heating furnace; and then PCVD Or the MCVD process carries out fluorine-doped deposition on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com