Wheel hub motor driving device

A driving device, in-wheel motor technology, applied in power devices, control devices, motion deposition, etc., can solve problems that are not conducive to improving the motor power density, the quality of the in-wheel motor driving device, the reduction of the unsprung mass of the in-wheel motor driving device, and the large motor torque. and other problems, to achieve the effect of being conducive to heat dissipation, simple structure and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

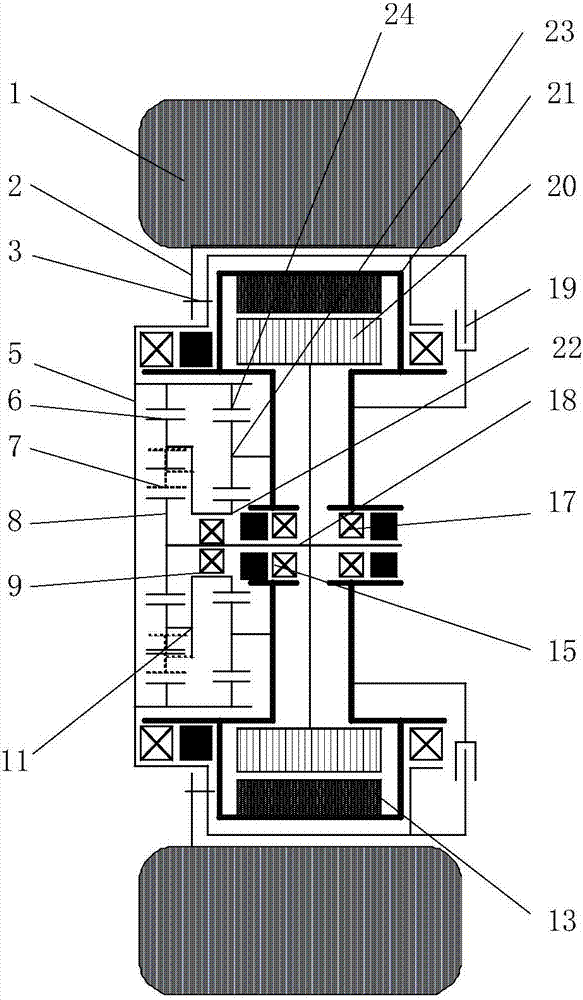

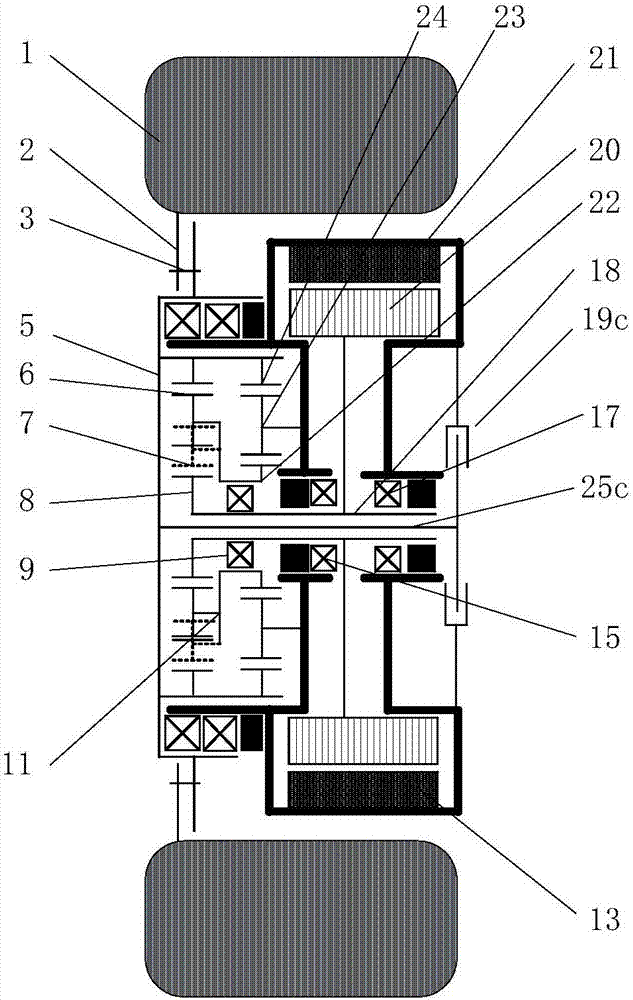

[0022] Embodiment 1: A wheel hub motor drive device, which includes: a housing 21, a motor, a two-stage planetary reducer, a rim 2, and a tire 1;

[0023] The inner side of the housing 21 is arranged with a steering system, a suspension system, a motor cable and a cooling system;

[0024] The motor includes: stator 13, rotor 20, and output shaft 18; the stator 13 is fixedly connected to the inner side of the housing 21, and the rotor 20 transmits the power of the motor to the two-stage planetary reducer through the output shaft 18 arranged on the motor bearings 15 and 17 ;

[0025] The motor and the two-stage planetary reducer are coaxially arranged, and the two-stage planetary reducer includes: an internal and external meshing planetary row composed of the first planet carrier 11, the first ring gear 6, the first planetary gear 7, and the first sun gear 8, and A planetary row composed of the second planet carrier 23, the second ring gear 24, and the second sun gear 22; the s...

Embodiment 2

[0027] Embodiment 2: see attached figure 1 , on the basis of Embodiment 1, add a brake 19 arranged coaxially with the motor and the two-stage planetary reducer; the brake 19 is installed on the inner side of the output end 5 of the two-stage planetary reducer close to the direction of the vehicle body, and the brake caliper and the shell Body 21 is fixed together.

Embodiment 3

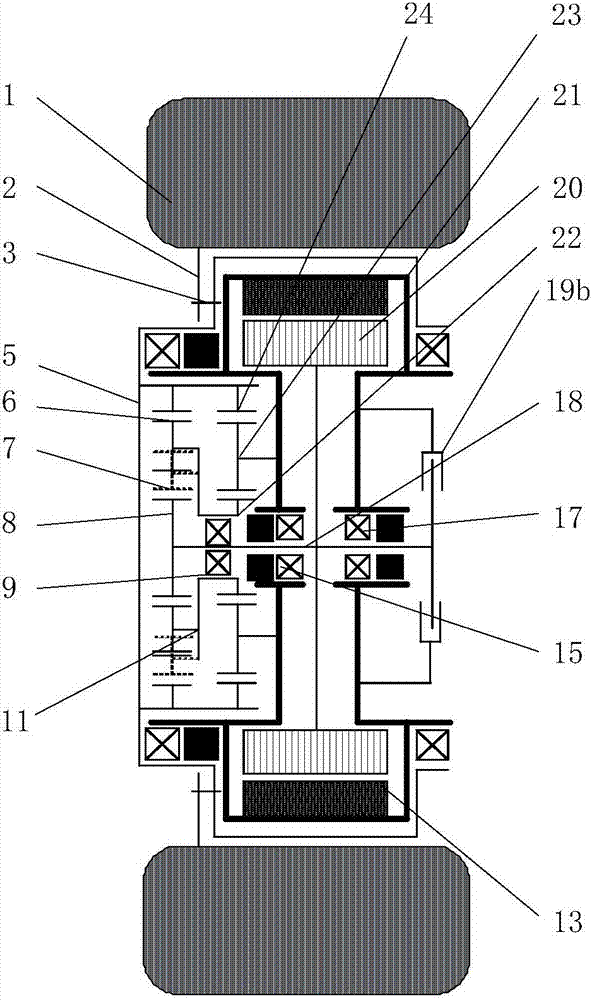

[0028] Embodiment 3: see attached figure 2 , on the basis of Embodiment 1, increase the brake 19b arranged coaxially with the motor and the two-stage planetary reducer; the brake 19b is fixedly connected to the output shaft 18 of the motor, and the brake caliper is connected to the housing 21; The planetary reducer is amplified, so the braking torque is small, and the diameter of the brake 19b is relatively small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com