Shear type feed mixing device

A mixing device and shearing technology, which is applied in the field of shearing feed mixing devices, can solve the problems that the screw mechanism is easily corroded and stuck, the uniformity of mixing is not enough, and the time required for mixing is long, etc., so as to ensure rapid mixing, Improve the service life, the effect of effective and long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

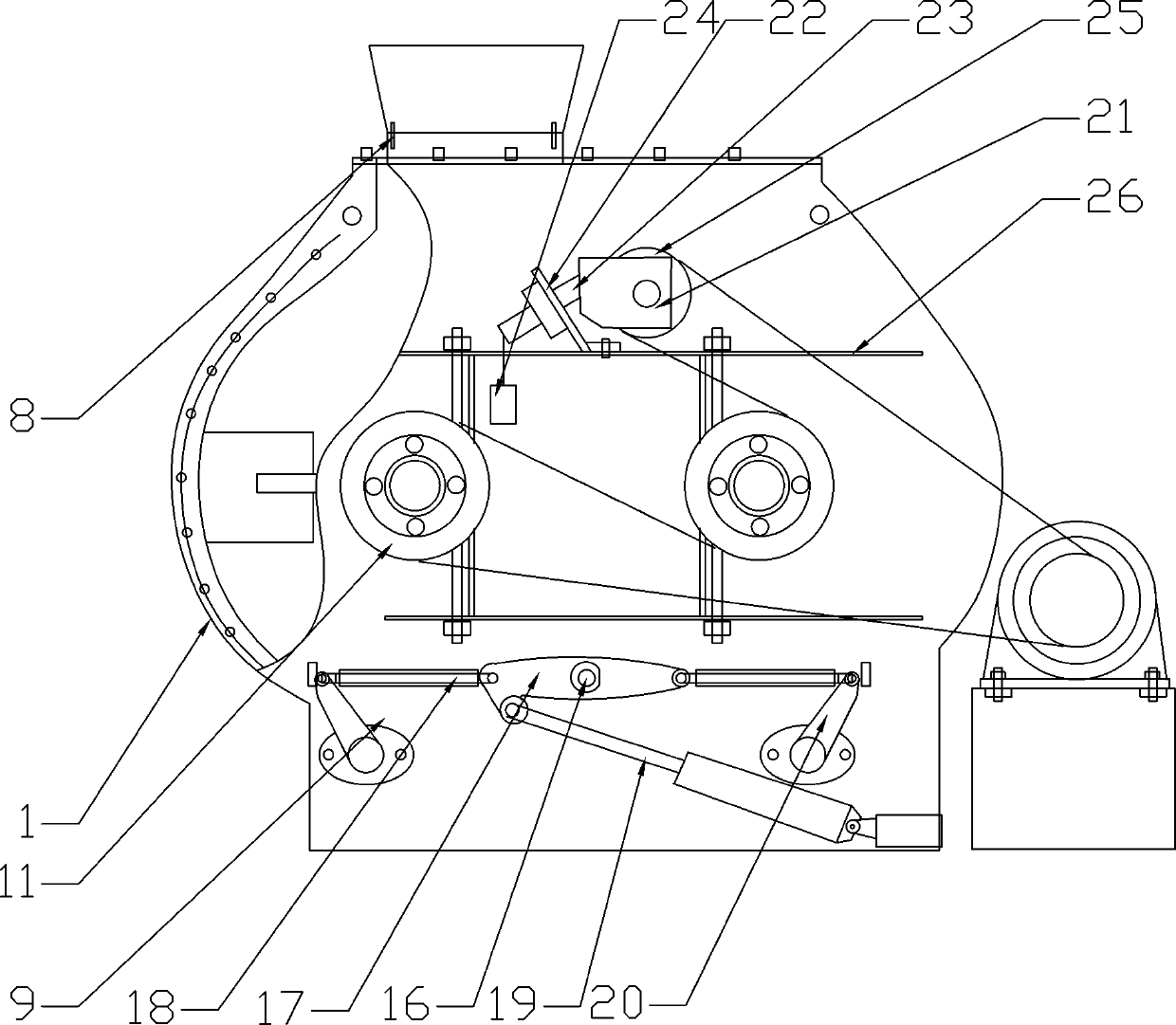

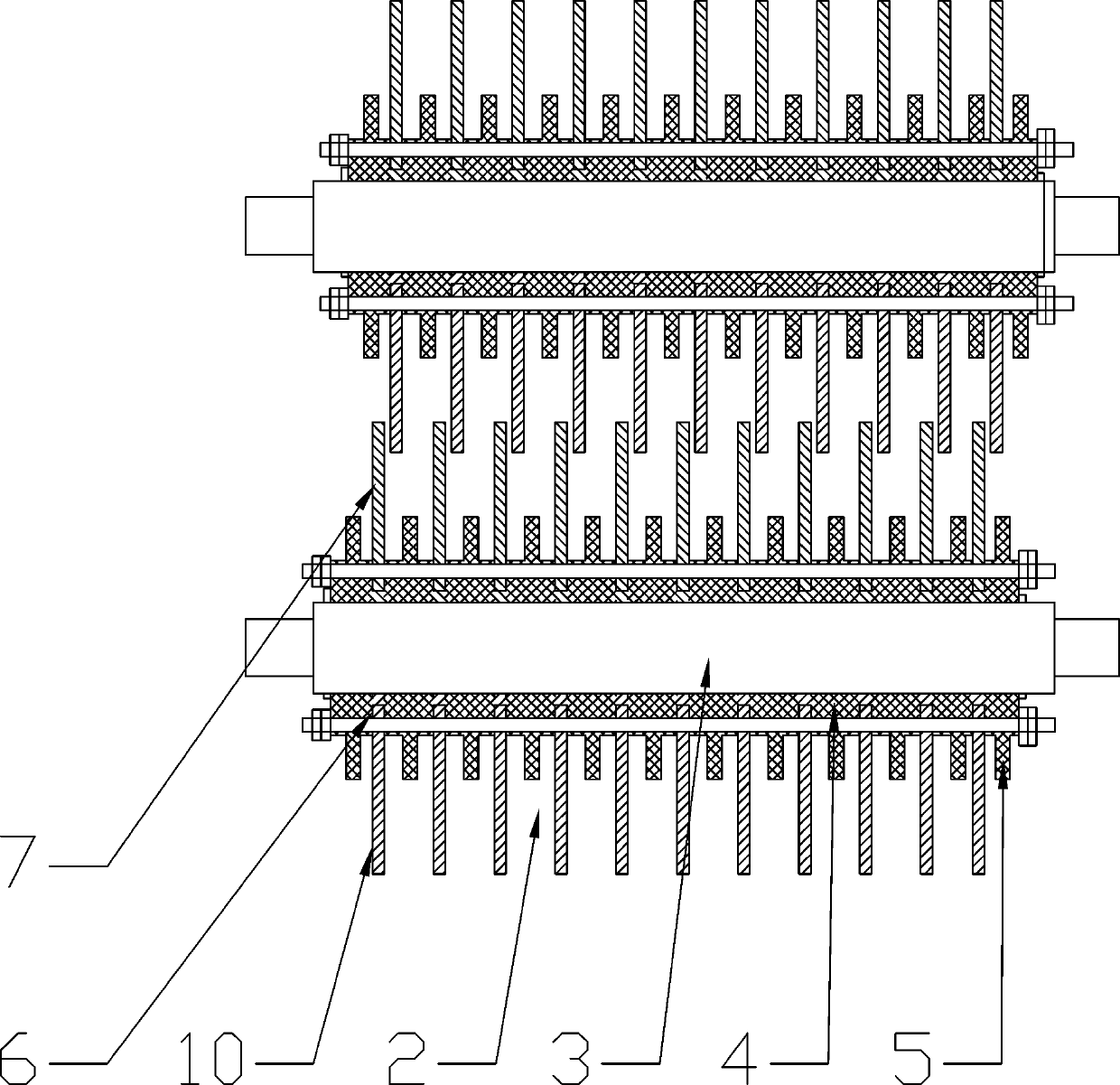

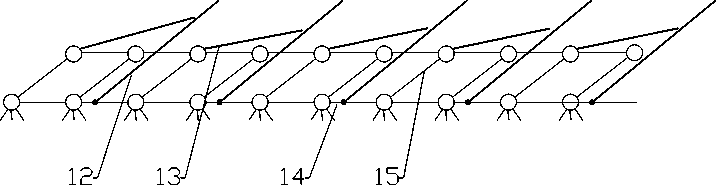

[0021] Such as Figure 1-4 As shown, a shearing type feed mixing device includes a body 1, a feed mechanism 8 and a discharge mechanism 9 are respectively arranged on the top and bottom of the body 1, and a stirring mechanism 10 is arranged in the body 1, and the stirring mechanism 10 passes through a driving mechanism 11 Drive; the stirring mechanism 10 includes two rotors 2 with opposite directions of rotation, each rotor 2 includes a rotating shaft 3, and a mounting seat 4 is installed on the rotating shaft 3, and driving rods 5 and grooves are alternately arranged on the mounting seat 4 along the length direction 6. A shearing disc 7 is installed in the groove 6, and the shearing discs 7 on the two rotors 2 are intersected, and the edge parts overlap on the horizontal projection plane. By alternately setting the shearing discs on the two rotors 2, shearing mixing can be realized during the mixing process of feed materials, and it can cooperate with the driving rod to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com