Automated transmission control apparatus

A technology of automatic transmission and control equipment, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., and can solve the problem of time-consuming gear stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

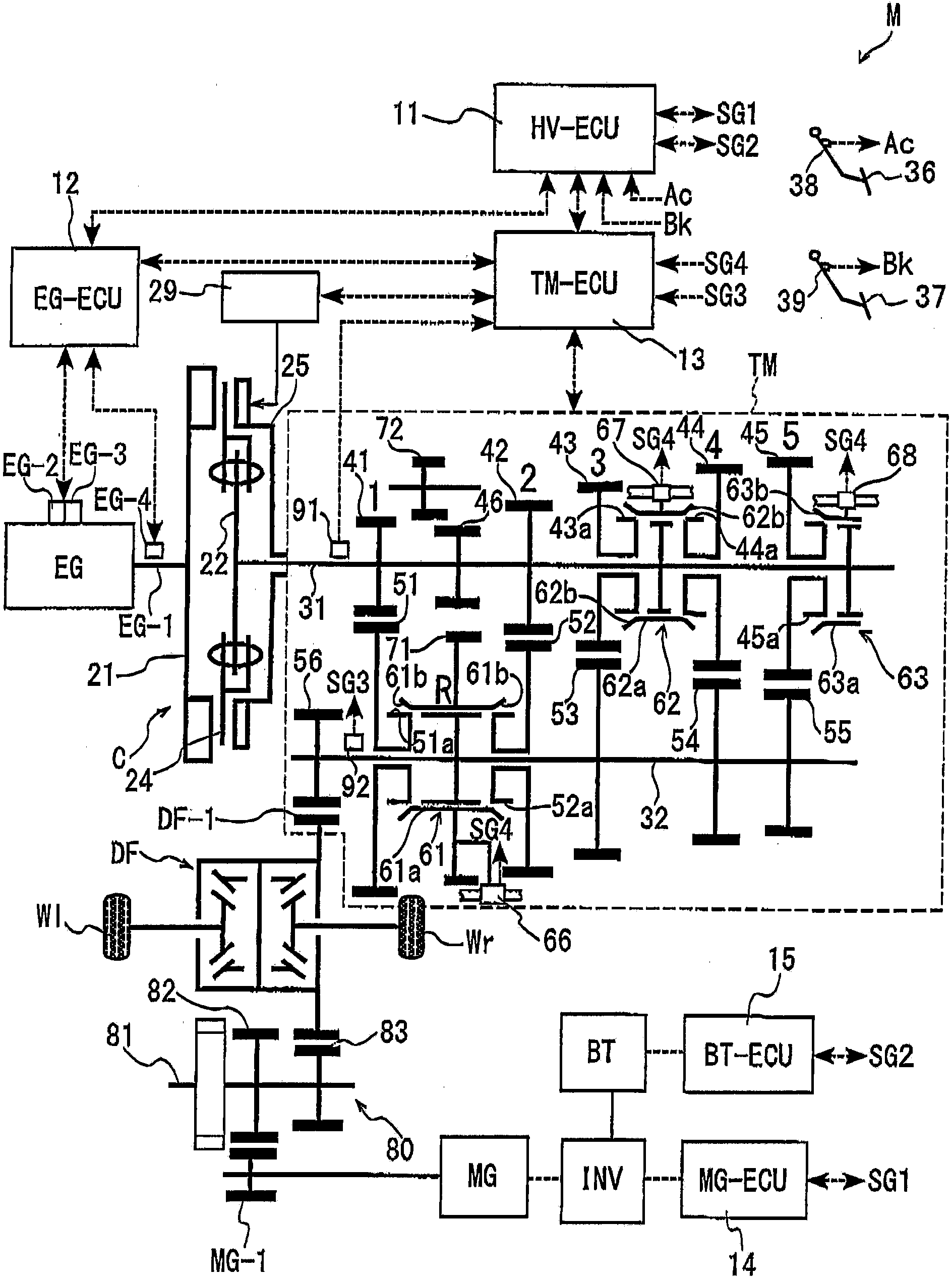

[0024] The first embodiment will be explained with reference to the drawings. In the first embodiment, an automatic transmission including the automatic transmission control apparatus according to the first embodiment is applied to a hybrid vehicle (hereinafter will be referred to as a vehicle M). figure 1 is a schematic diagram showing the configuration of the vehicle M. FIG. Such as figure 1 As shown, the vehicle M includes an engine EG, a motor generator MG, a clutch C, a transmission TM (hereinafter referred to as TM), an inverter INV, a battery BT, a hybrid electronic control unit (ECU) 11 (in HV -ECU), engine ECU12 (denoted by EG-ECU), TM ECU13, motor ECU14 (denoted by MG-ECU), battery ECU15 (denoted by BT-ECU), and speed reducer 80. In vehicle M, drive wheels WI, Wr are driven by rotational torque output from engine EG and motor MG.

[0025]The vehicle M includes an accelerator pedal 36 (ie, accelerator) and a brake pedal 37 (ie, brakes). Operating the accelerator p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com