Rolling bearing degradation state stage determination method

A technology for rolling bearings and determination methods, which is applied in the testing of measuring devices, instruments, and mechanical components, etc., can solve the problem that the permutation entropy cannot be set, and achieve fast calculation speed and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

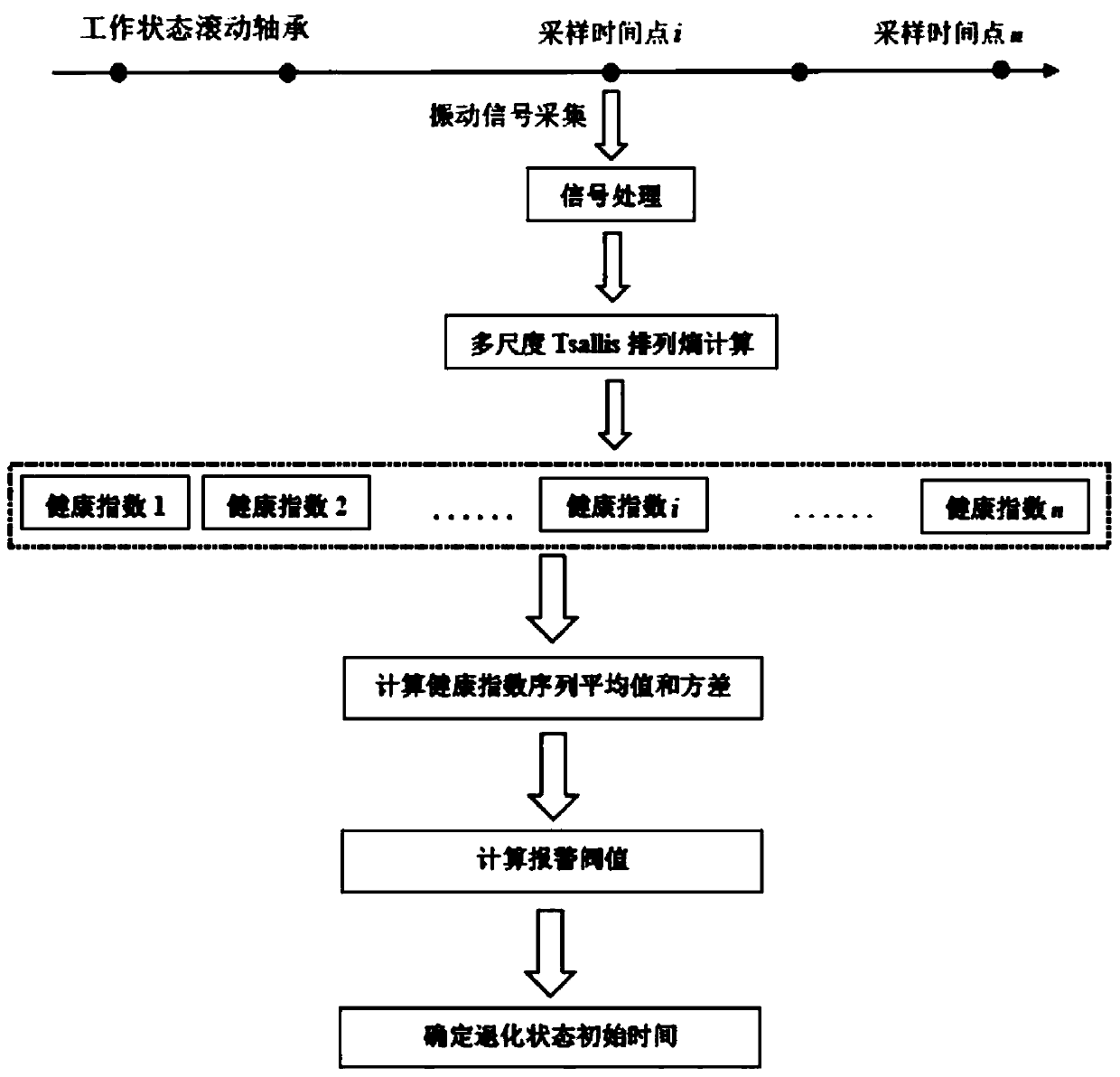

[0032] Please refer to figure 1 , A method for determining the stage of the degraded state of a rolling bearing, including the following steps:

[0033] Step 1: Collect the vibration signal that characterizes the stable working state of the rolling bearing and de-noise processing to obtain a useful signal sequence that can specifically characterize the stable working state of the rolling bearing;

[0034] Step 2: Calculate the multi-scale Tsallis permutation entropy value for the useful signal sequence obtained in Step 1, to obtain the health state index time series;

[0035] Step 3: Calculate the average value and variance value according to the health status index time series obtained in step 2;

[0036] Step 4: Calculate the alarm threshold value according to the average value and variance value obtained in Step 3, and identify the starting time point of the rolling bearing degradation stage according to the change trend of the time series composed of the entropy value of the multi-...

Embodiment 2

[0051] In order to further describe the method for determining the degraded state of a rolling bearing according to the present invention, in step 2, the calculation method of the entropy value of the multi-scale Tsallis arrangement is:

[0052] Select the entropy index q and the time scale s, for the vibration time series obtained from the kth time point test {x k (i),i=1,2,...,r}, according to the formula Construct sub-time series Where N=[r / s] means taking an integer for r / s, s means time scale, and the length of the sub-time series is N=[r / s];

[0053] Determine the embedding dimension m and the time delay τ, for the time series y s (j), j=1, 2,..., N performs phase space reconstruction as follows:

[0054]

[0055] Then any Y s The m real numbers in (i) can be arranged in increasing order as follows:

[0056] y s (j+(k 1 -1)τ)≤y s (j+(k 2 -1)τ)≤…≤y s (j+(k m -1)τ)

[0057] If Y s (j) Medium y s (j) have the same value, for example y s (j+(k m-1 -1)τ)=x ij (j+(k m -1)τ), and thei...

Embodiment 3

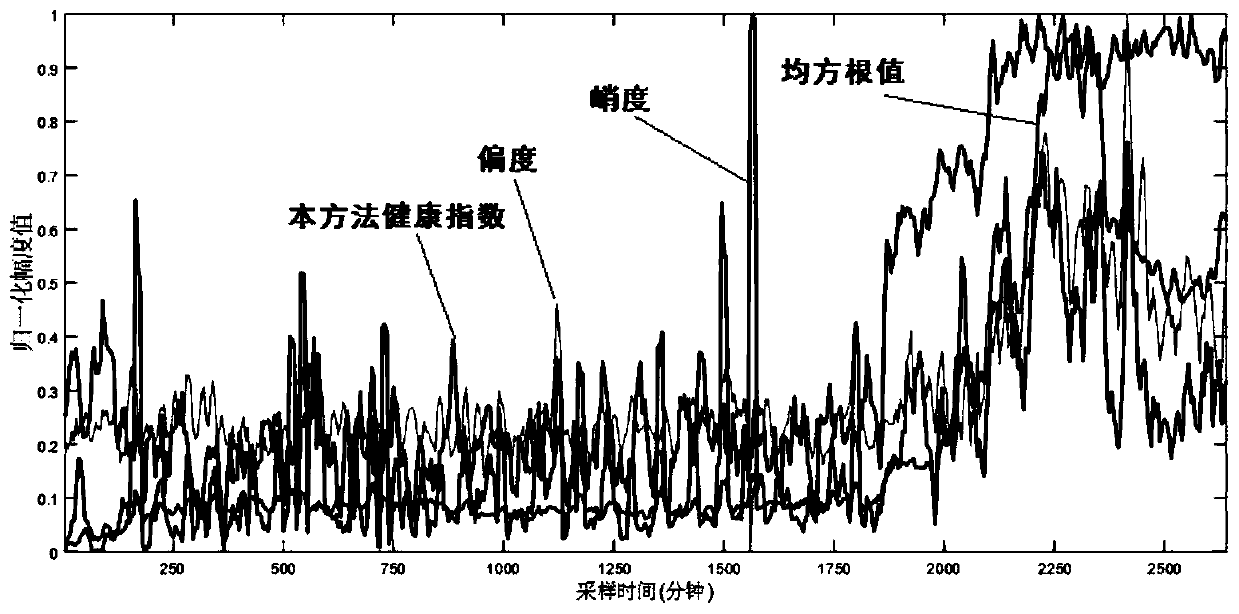

[0062] On the basis of Example 1 and Example 2, the following will test a method for determining the stage of rolling bearing degradation. Please refer to Figure 1 to Figure 4 And the following five steps.

[0063] 1. Acquisition and processing of time series signal of vibration acceleration of mechanical system.

[0064] In order to realize the trend prediction of the degradation state of the mechanical system and the feasibility of this method, based on the full life cycle experiment of rolling bearings, a set of vibration acceleration time series signals are collected every 5 minutes, and the length of each set of time series signals is 4096, a total of 530 sets of time series signals are collected, and the above-mentioned signals are collected to form a mat file, and the adaptive 2-layer wavelet method is used in Matlab for denoising.

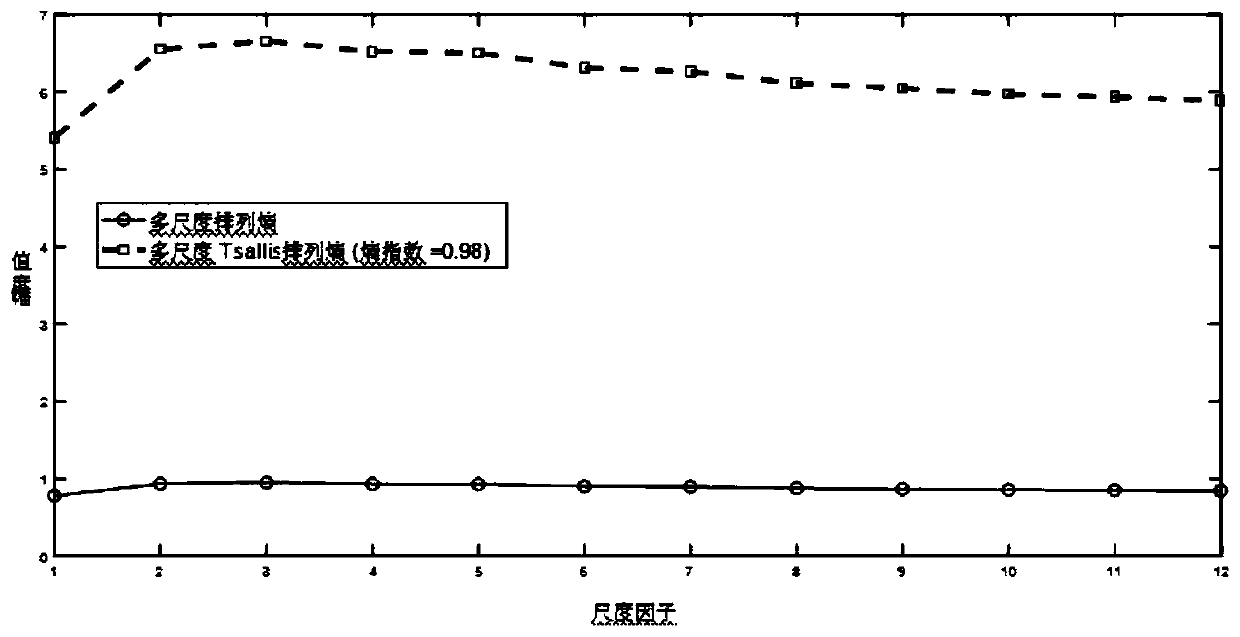

[0065] 2. Multi-scale Tsallis permutation entropy.

[0066] For the vibration acceleration time series signal x measured at the kth moment k (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com