Method for judging category of failures caused by electrical contact in sealed electromagnetic relay

A technology to seal electromagnetic, failure categories, used in the field of electromagnetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: A method for determining the type of electrical contact failure of a sealed electromagnetic relay according to the present invention, the method steps are as follows:

[0046] Step 1: First, conduct a reliability life test on several sealed electromagnetic relay test samples, and record the relationship between the contact resistance, pull-in time, overtravel time, bounce time and other characteristic parameters of each test sample and the number of actions during the entire test process; , pull-in time, release time, overtravel time, arcing time, bounce time and other six characteristic parameters form a data matrix X n×6 , where n is the number of actions;

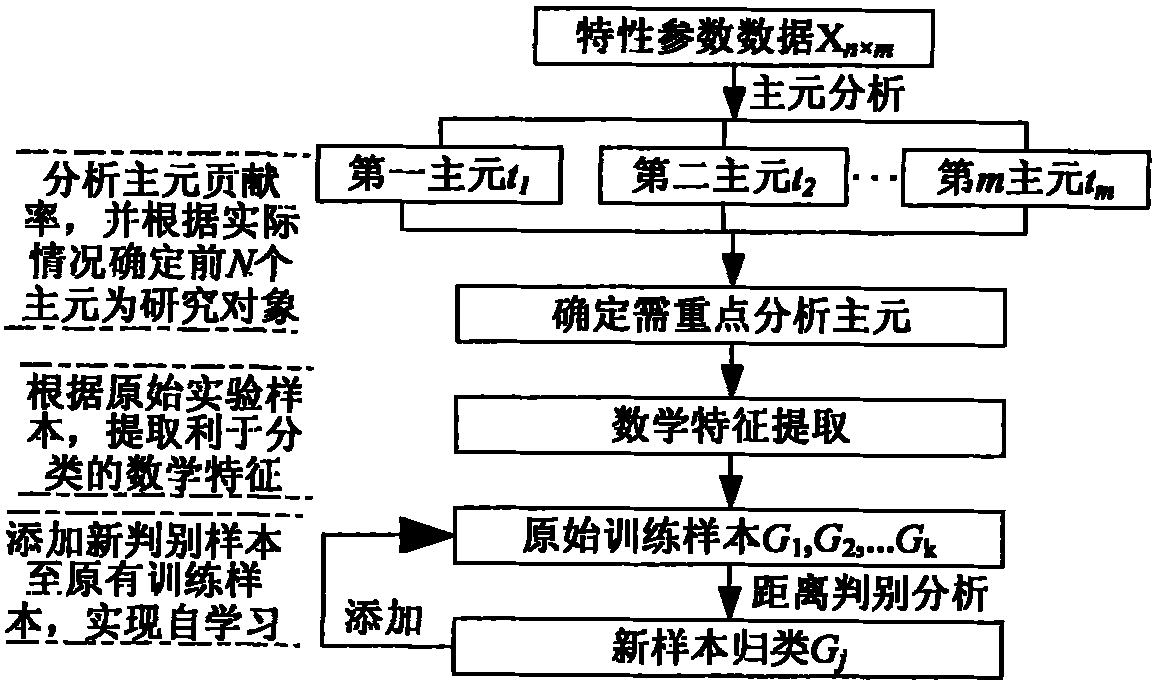

[0047] Step 2: In view of the different change characteristics of the characteristic parameters under different failure mechanisms (large dispersion, strong randomness, and strong correlation), the principal component analysis method is used to perform dimensionality reduction preprocessing on the mu...

Embodiment 2

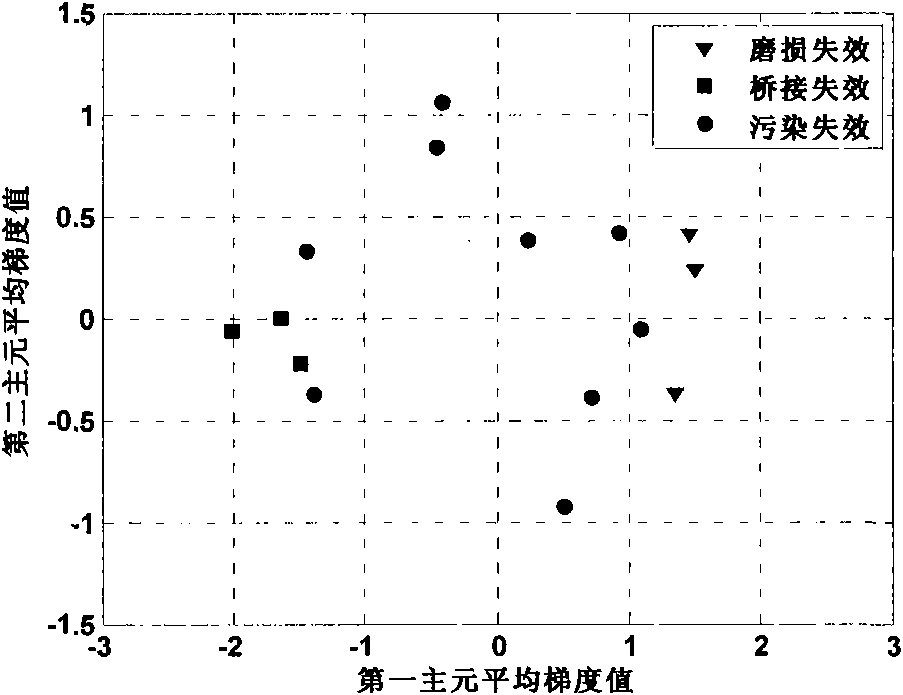

[0072] Example 2: Combining Figure 1-Figure 3 According to the invention, a method for judging the electrical contact failure category of a sealed electromagnetic relay can provide a new way for judging the electrical contact failure mechanism of the sealed electromagnetic relay. The process of using principal component analysis method and distance discriminant analysis to discriminate the contact failure mechanism of electromagnetic appliances is as follows: figure 1 shown. After principal component analysis, the original multidimensional characteristic parameters can more clearly reflect the change characteristics of contact characteristics under different failure mechanisms. Among them, the contribution rate of the first pivot is the largest, maintaining most of the correlation between the characteristic parameters. Since the change of each characteristic parameter is closely related to the change of the contact gap, the main difference between wear failure, bridging fai...

Embodiment 3

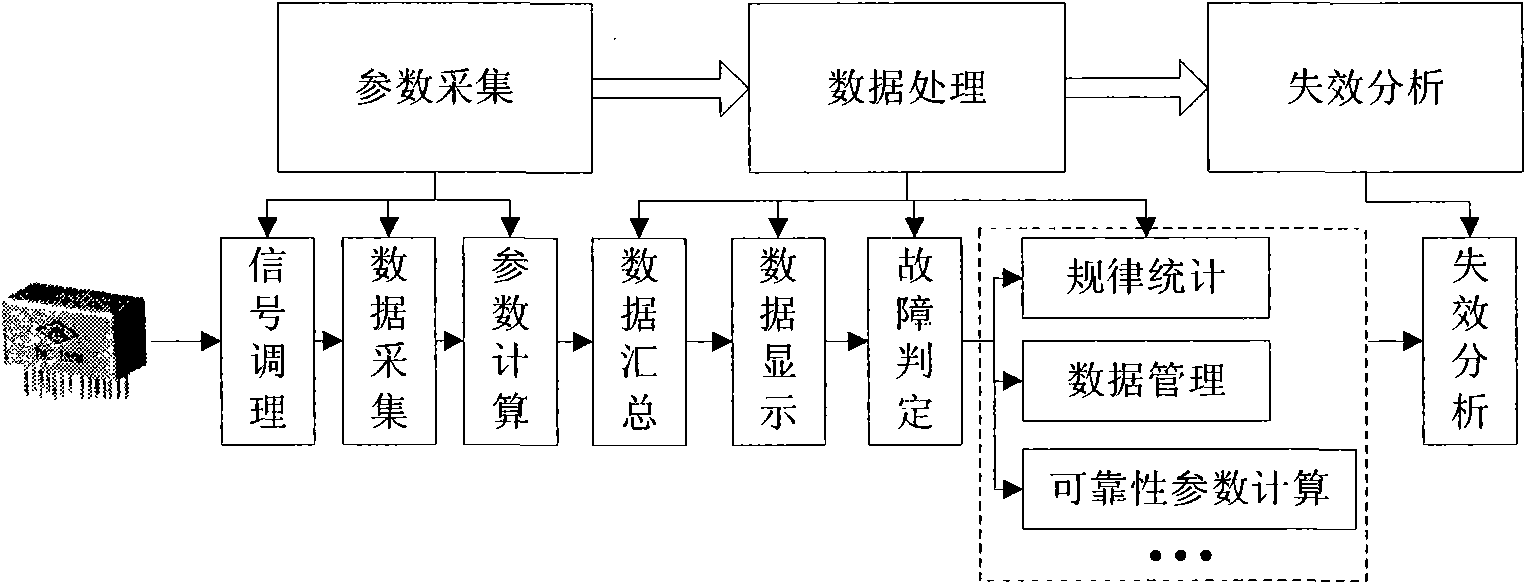

[0094] Example 3: Binding Figure 2-Figure 11 , Hermetic electromagnetic relay multi-parameter monitoring reliability life system hardware design

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com