Uniform-temperature panel and manufacturing method thereof

A manufacturing method and technology of a vapor chamber, which are applied in cooling/ventilation/heating renovation, lighting and heating equipment, tubular elements, etc., can solve the cracking of the sealed cavity, the deformation of the sealed chamber of the vapor chamber, and affect the evaporation efficiency of the working medium. and other problems, to achieve the effect of saving production costs and improving the strength of structural support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

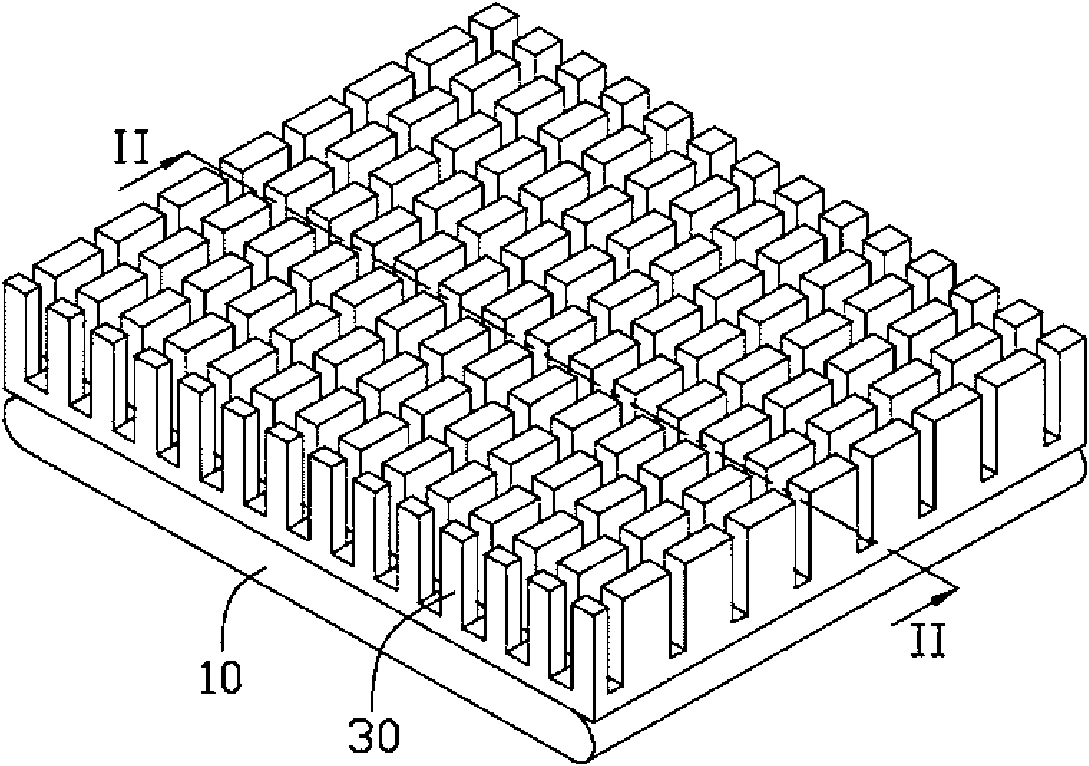

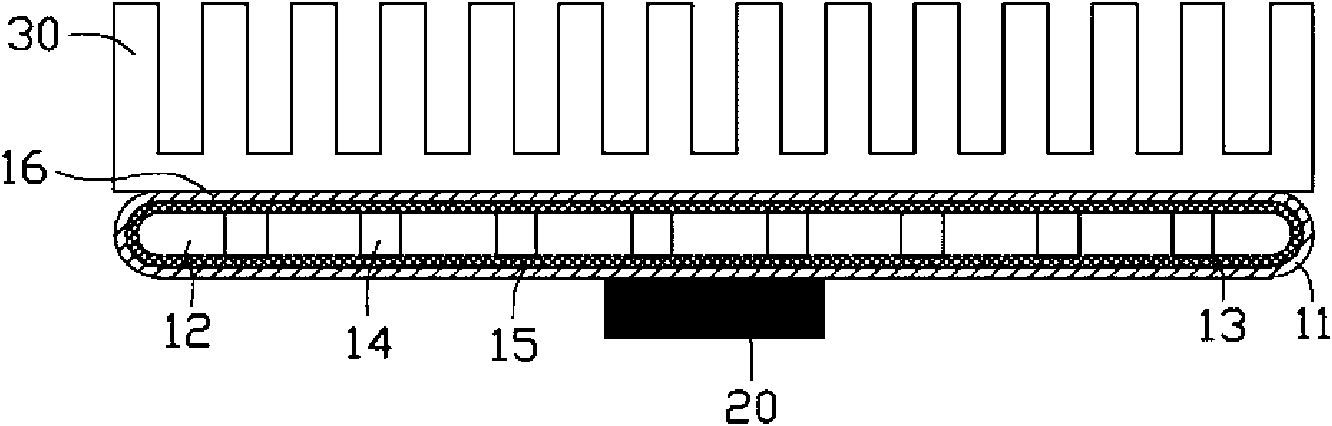

[0015] see figure 1 and figure 2 , the vapor chamber 10 according to an embodiment of the present invention is used to dissipate heat from a heat-generating electronic component 20 . A radiator 30 is usually added on the top of the vapor chamber 10 to dissipate the heat absorbed by the vapor chamber 10 to the surrounding environment.

[0016] The above-mentioned uniform temperature plate 10 is a rectangular plate body as a whole, which includes a hollow shell 11, a sealed accommodating chamber 12 formed in the shell 11, and is arranged on the shell 11 to surround the accommodating chamber. A capillary structure layer 13 on the inner surface of the cavity 12 and a plurality of supporting elements 14 accommodated in the cavity 12 . When in use, the accommodating chamber 12 is pumped to a low pressure and filled with a phase-changing working medium such as water, ethanol, paraffin, and the like.

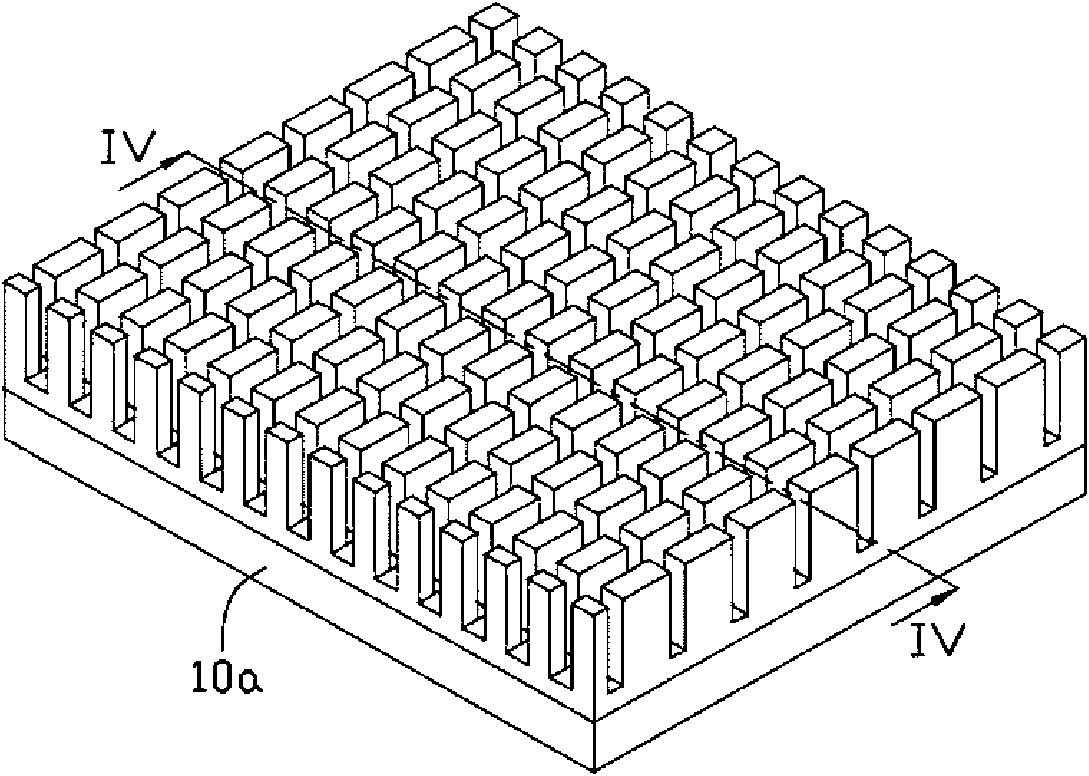

[0017] Please also see image 3 and Figure 4 The housing 11 can be made of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com