Concrete prefabricated element with assembly auxiliary structure

A prefabricated component and assembly-assisted technology, applied in structural elements, building components, stepped structures, etc., can solve the problems of easy water seepage on the balcony, limited structural support strength, and lack of protection capabilities, so as to meet the needs of protection and planting, and structural support. The effect of high strength and good anti-seepage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

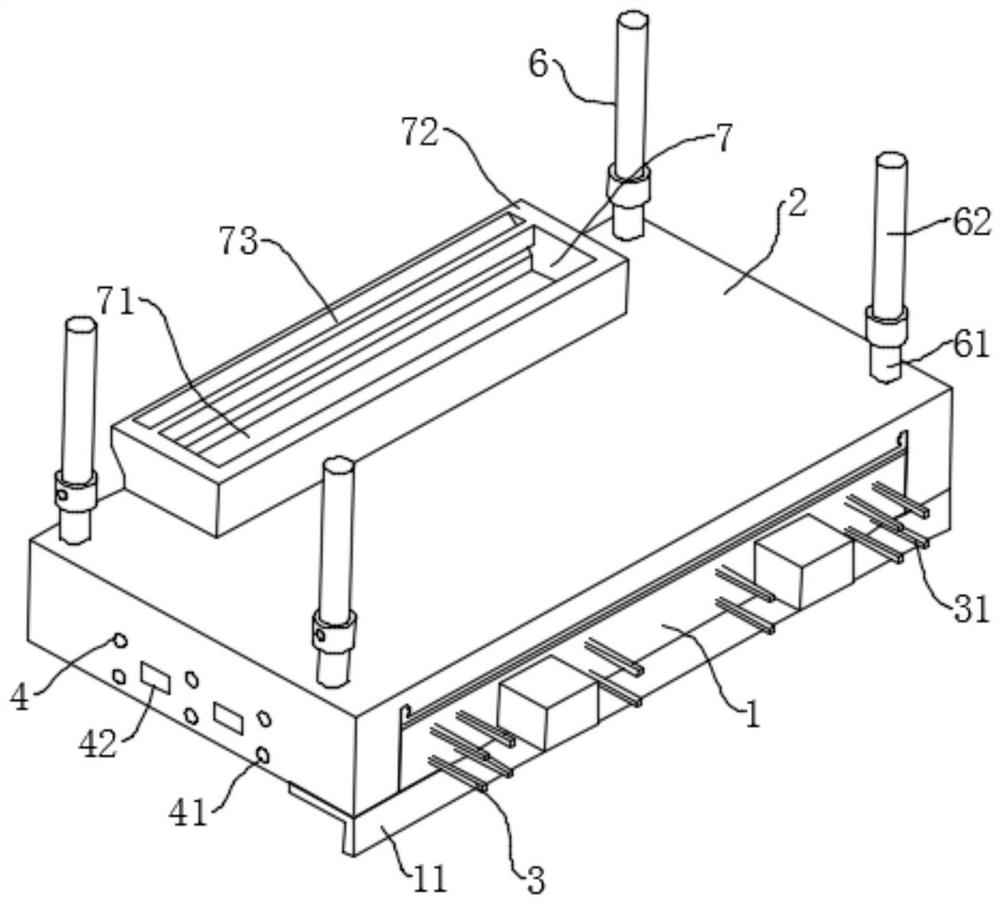

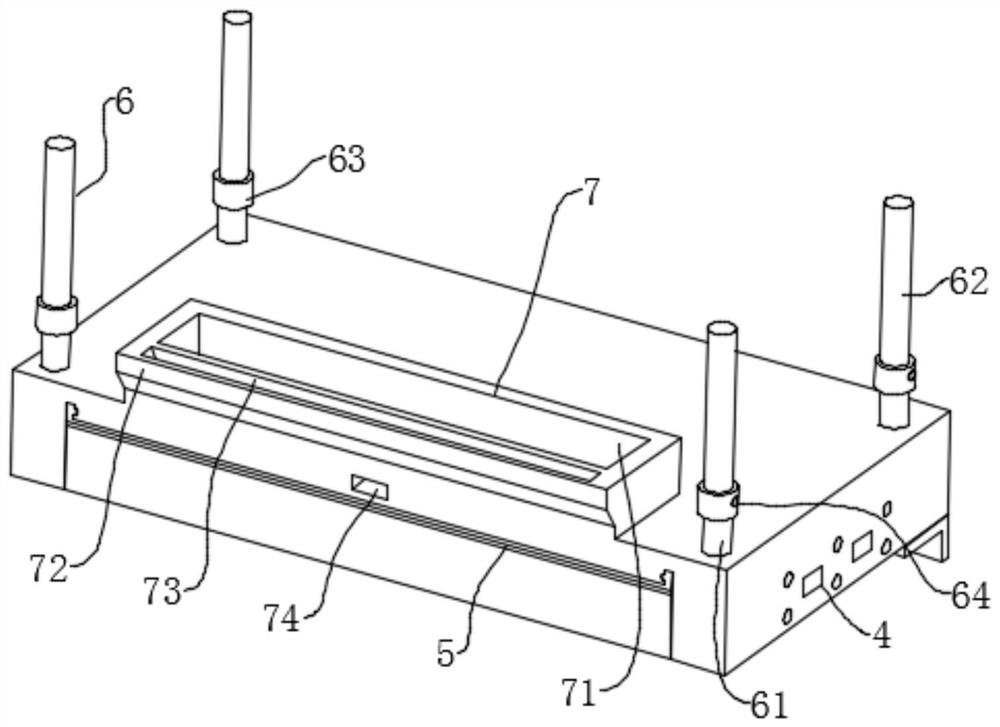

[0042] refer to figure 1 , figure 2 and image 3 , a concrete prefabricated component with assembly auxiliary structure, mainly includes the following parts:

[0043] Prefabricated balcony foundation 1 as the main support;

[0044] Pouring and forming the load-bearing foundation 2 above the prefabricated balcony foundation 1;

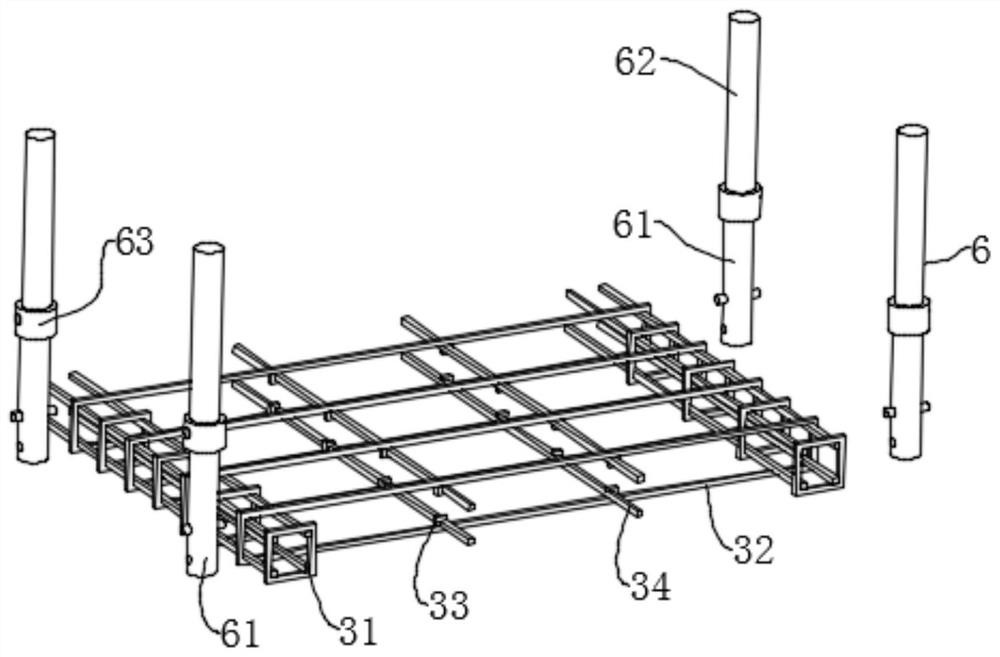

[0045] The steel reinforcement member 3 arranged in the prefabricated balcony foundation 1;

[0046] A connection component 4 for strengthening the connection structure between the prefabricated balcony foundation 1 and the load-bearing foundation 2;

[0047] A waterproof component 5 arranged between the prefabricated balcony foundation 1 and the bearing foundation 2;

[0048] Casting and forming the protective component 6 on the load-bearing foundation 2;

[0049] And the flower planting structure 7 integrally poured and formed on the bearing foundation 2 .

[0050] refer to figure 1 , figure 2 and image 3 , the concrete prefabricated compon...

Embodiment 2

[0059] refer to figure 1 , figure 2 and image 3 , a concrete prefabricated component with assembly auxiliary structure, mainly includes the following parts:

[0060] Prefabricated balcony foundation 1 as the main support;

[0061] Pouring and forming the load-bearing foundation 2 above the prefabricated balcony foundation 1;

[0062] The steel reinforcement member 3 arranged in the prefabricated balcony foundation 1;

[0063] A connection component 4 for strengthening the connection structure between the prefabricated balcony foundation 1 and the load-bearing foundation 2;

[0064] A waterproof component 5 arranged between the prefabricated balcony foundation 1 and the bearing foundation 2;

[0065] Casting and forming the protective component 6 on the load-bearing foundation 2;

[0066] And the flower planting structure 7 integrally poured and formed on the bearing foundation 2 .

[0067] refer to figure 1 , figure 2 and image 3 , the concrete prefabricated comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com