A 50t lightweight automobile leaf spring seat

A technology for automotive panels and light weight, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve the problems of high material cost, increased weight of leaf spring seat, complex structure, etc., achieve weight reduction, increase support strength, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

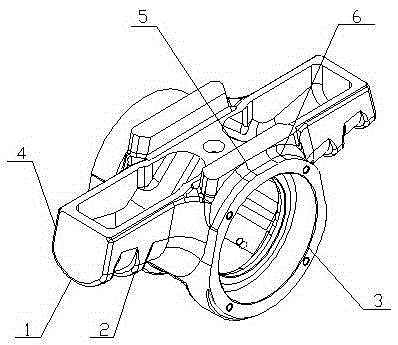

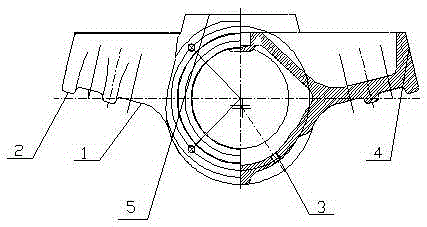

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 The schematic diagram shown shows that the 50T new lightweight automobile leaf spring seat of the present invention includes a center circle 3 and a reinforcing rib plate.

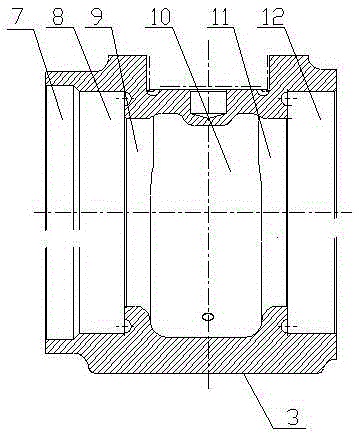

[0018] There is a cavity in the center circle 3, and the cavity is in a stepped shape, which are the first step 7, the second step 8, the third step 9, the fourth step 10, the fifth step 11, and the sixth step. Step 12, and the diameters of the first step 7, the second step 8, the fourth step 10, and the third step 9 gradually decrease. The second step 8 and the sixth step 12 have the same diameter, and the third The stepped portion 9 has the same caliber as the fifth stepped portion 11, and there is a stiffener plate on the back of the center circle 3, and the stiffener plate and the axis of the center circle 3 are perpendicular to each other, and there are arc installations on both sides of the center circle 3. The seat 6 has a reinforcing rib A5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com