A scraper device for a gravure printing machine

A technology of gravure printing machine and scraper device, which is applied to gravure rotary printing machine, printing machine, rotary printing machine and other directions, can solve the problems of small circumference range of applicable plate roll, unsuitable for high-speed operation, inconvenient adjustment, etc. Use limitation, eliminate vibration phenomenon, reduce equipment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

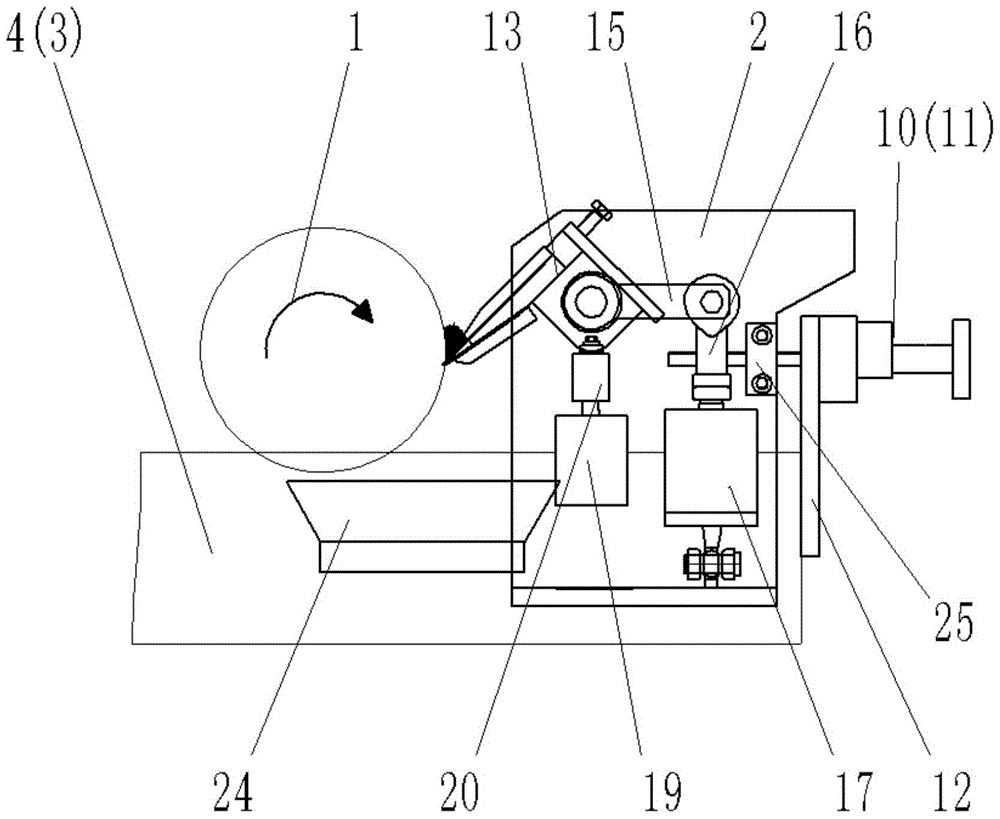

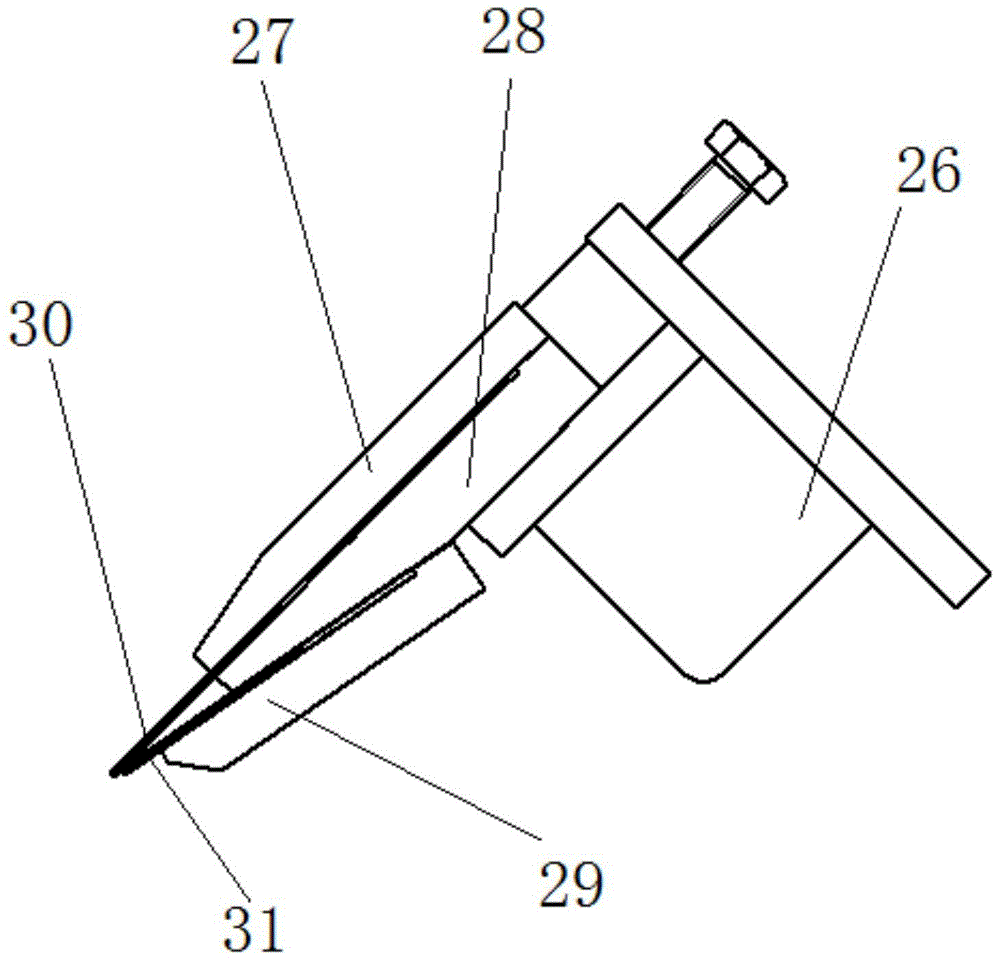

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

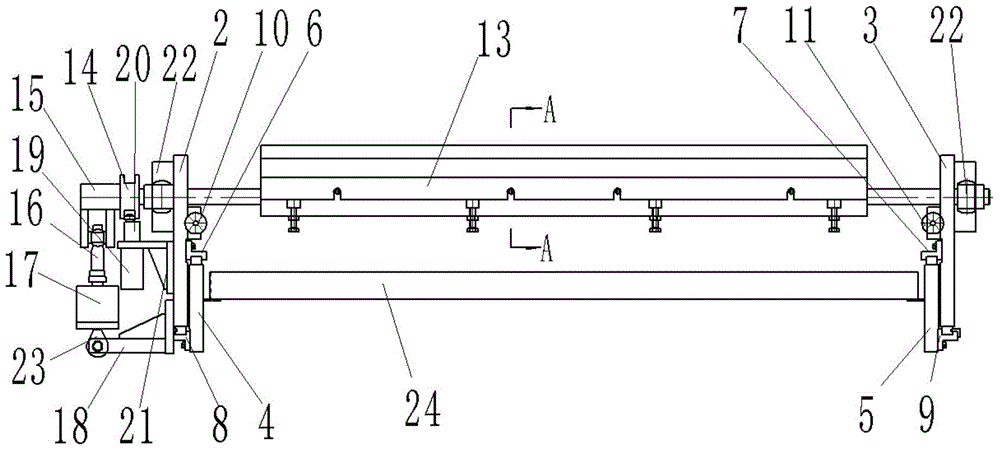

[0017] refer to figure 1 , figure 2 , the structure of the present invention is that an operation side fixed plate 4 and a transmission side fixed plate 5 are respectively fixedly installed on both sides of the gravure printing machine, and an ink tank 24 is connected between the operation side fixed plate 4 and the transmission side fixed plate 5 , the ink tank 24 is placed under the junction of the plate roller 1 and the scraper mechanism 13, which is convenient to use;

[0018] The upper and lower ends of the operation side fixed plate 4 are respectively fixedly equipped with an operation side upper rail 6 and an operation side lower rail 8, and an operation side sliding seat 2 is jointly arranged in the operation side upper rail 6 and the operation side lower rail 8, and the operation side sliding seat 2 can Along the upper and lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com