Separated combined type plastic crawling ladder for large-scale inspection well

An inspection well and combined technology, applied to ladders, buildings, building structures, etc., can solve the problems of high replacement cost, troublesome installation and disassembly, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

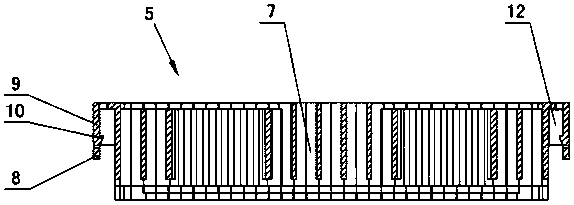

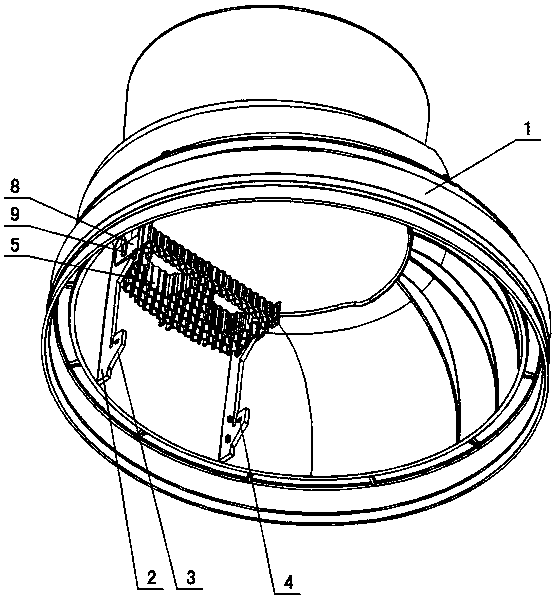

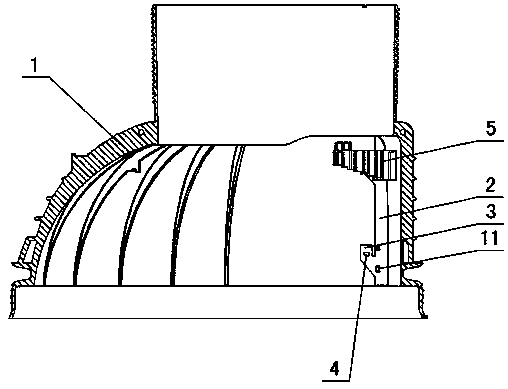

[0013] The invention relates to a split combined plastic climbing ladder for a large inspection well, such as figure 1 — Figure 6 As shown, the inspection well body 1 is included, and the inner wall of the inspection well body is connected to the climbing ladder. The upper part of the board is formed with a card hole 4, and the left and right two connecting plates are connected to the climbing ladder. The through hole 7 of the ladder plate main body 5 is formed with clamping plates 8, and there is a card slot 12 between the clamping plate and the ladder plate main body. The card slot matches the convex plate 3, and an elastic card is formed in the clamping plate. 9. A barb 10 is formed on the inner wall of the elastic card, and the barb cooperates with the card hole 4 on the convex plate. Two left and right connecting plates 2 are formed on the inner wall of the inspection well body 1 made of plastic materials, and convex plates 3 are formed on the connecting plate (accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com