Multiple concentric cylindrical co-coiled heat exchanger

a heat exchanger and concentric helical coil technology, applied in the direction of indirect heat exchangers, heat exchange apparatus, lighting and heating apparatus, etc., can solve the problems of multiple co-coiled concentric helical coils that have multiple concentric helical coils, serious flow imbalance, and difficulty in re-circuiting, etc., to achieve low tube count, high flow resistance, and low tube count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

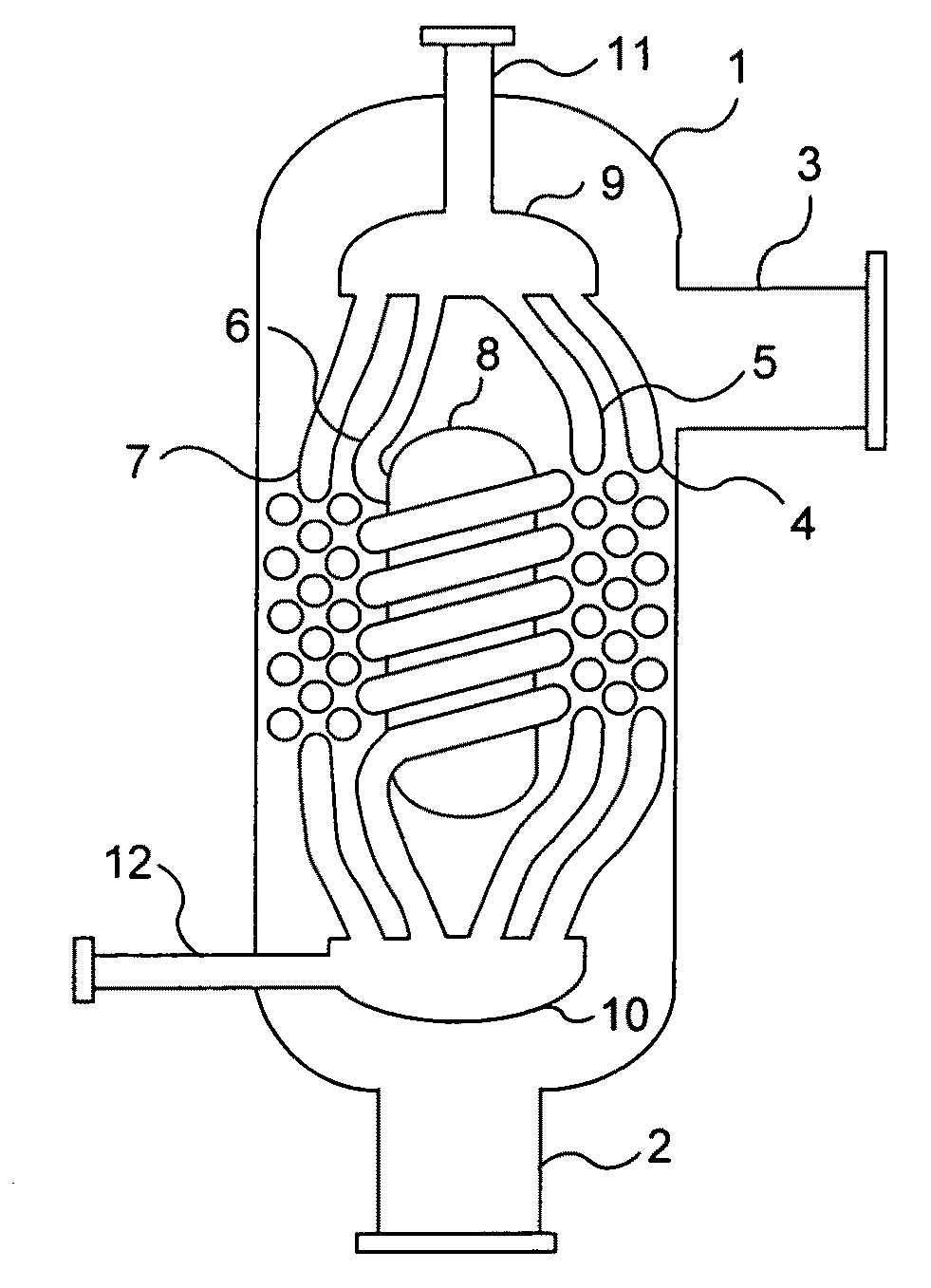

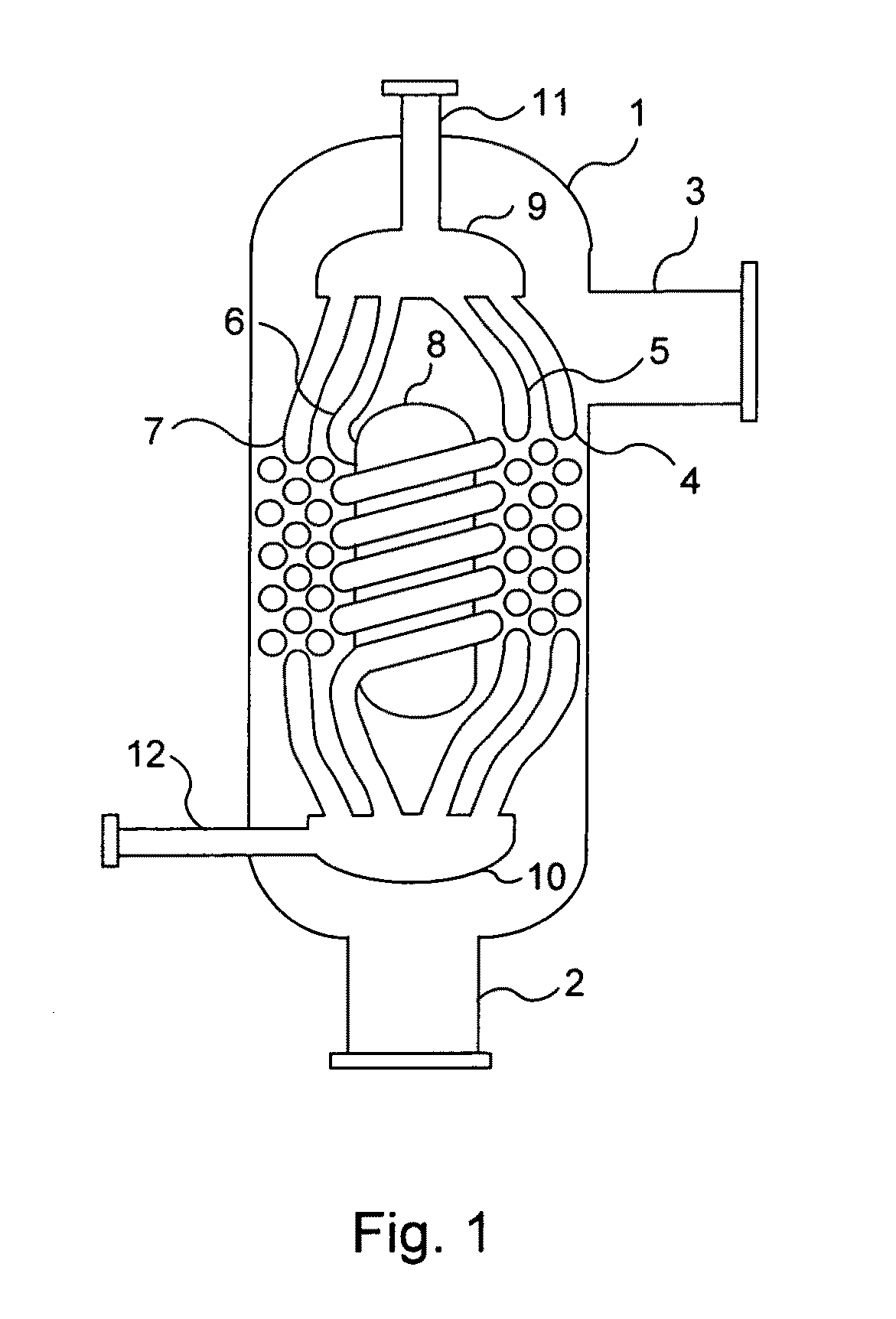

[0020]FIG. 1 illustrates the basic overall heat exchanger configuration disclosed: cylindrical shell 1 with shell-side inlet 2 and outlet 3; multiple co-coiled concentric helical coils of tubing 4, 5, 6, and 7; core blocker 8; tube headers 9 and 10 for the tubes at each end of the bundle of tube coils; and the tube header connectors 11 and 12. The critical features that enable the compactness are the close proximity or spacing of adjacent tubes, plus their staggered alignment. That close spacing and alignment is established and maintained by spacers, which are shown in subsequent figures. The illustrated shell-side upflow arrangement is the preferred configuration when it is used as a refrigerant heat exchanger.

[0021]Whereas FIG. 1 illustrates gathering all the tubes at each end of the bundle to a single tubesheet and header, the artisan will recognize that it is possible to divide the tubes into two or more groups, and provide a separate pair of tubesheets and headers for each grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com