Header pipe evaporator for use in an automobile

a technology for evaporators and header pipes, which is applied in the direction of indirect heat exchangers, refrigeration components, light and heating apparatus, etc., can solve the problems of increasing reducing the efficiency of evaporators, and increasing the risk of reducing the evaporator's performance, so as to reduce the number of assembly processes, reduce the risk of refrigerant leakage, and reduce the number of assembling processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

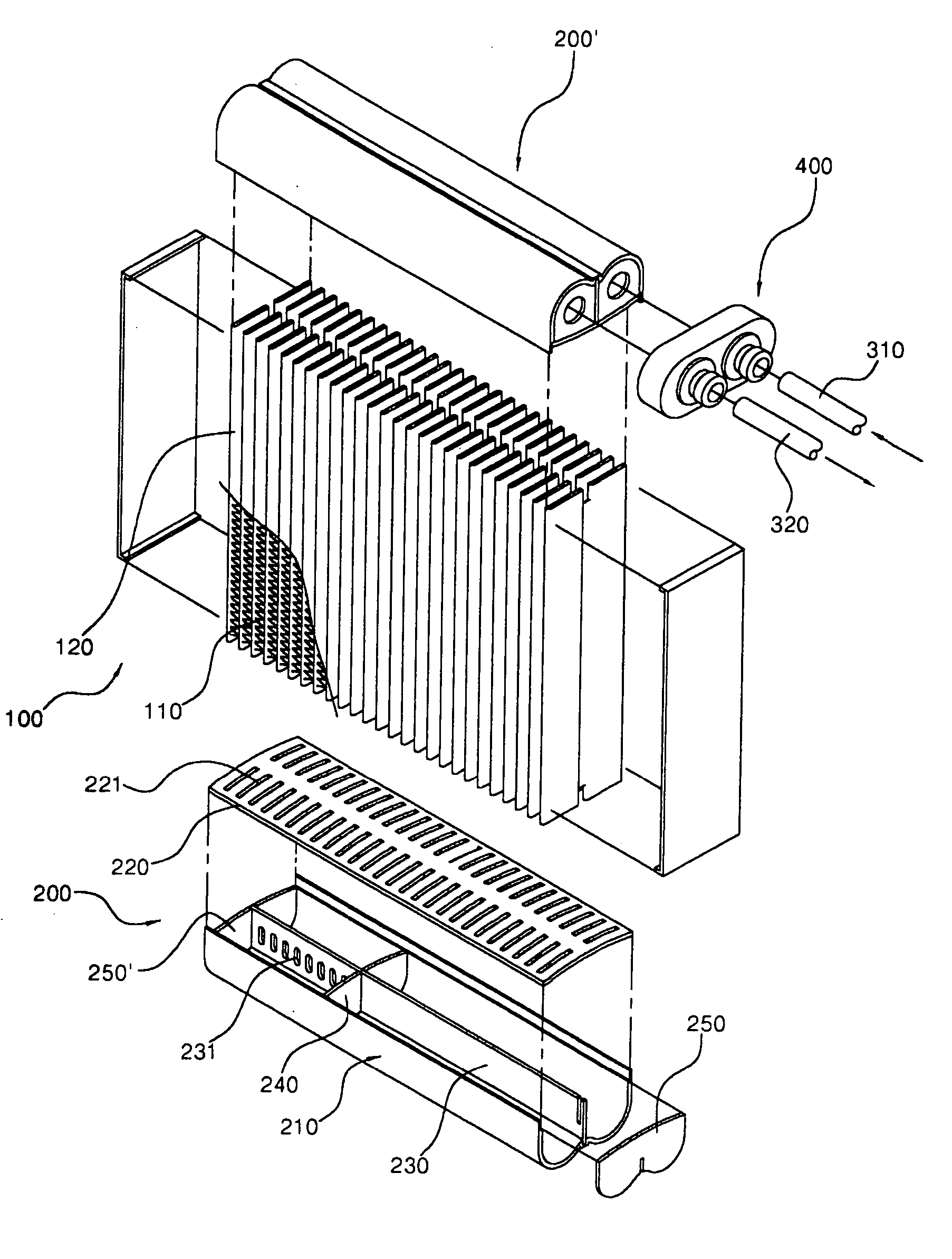

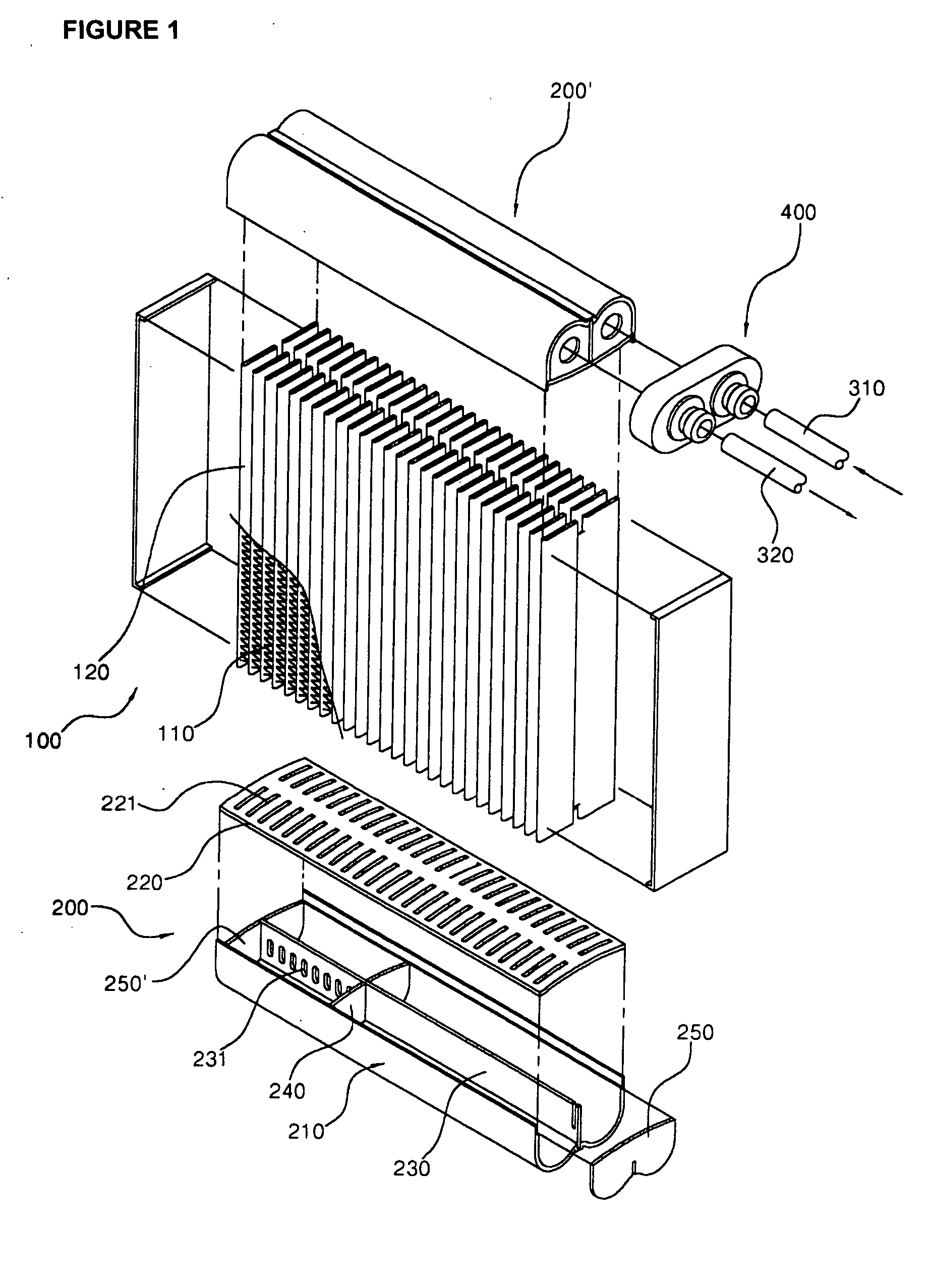

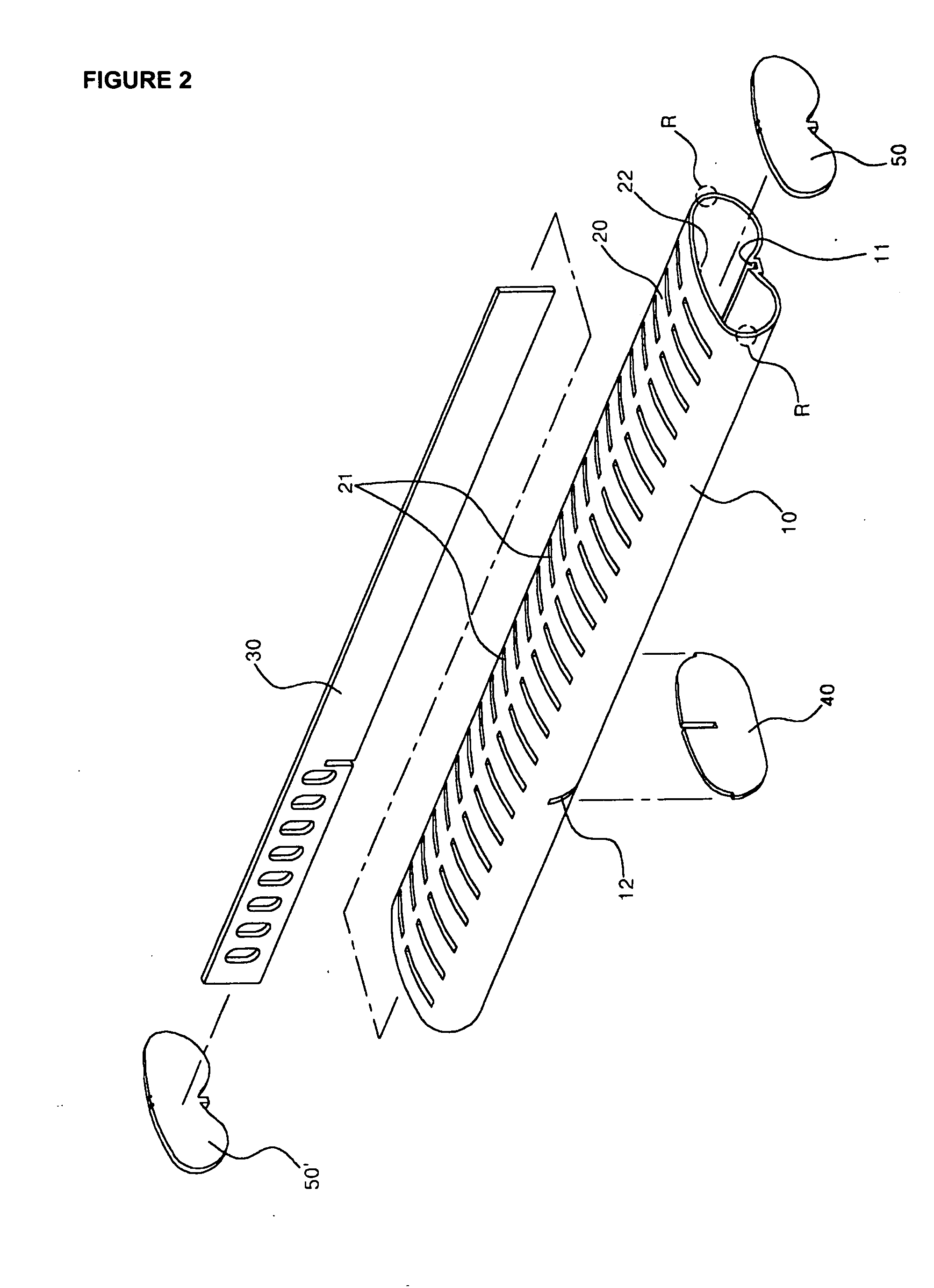

[0018] The attached FIG. 2, FIG. 4, and FIG. 5 present, respectively, this invention's header pipe appearance in a perspective view of separate parts, assembling perspective view, and a perspective view of a nearly completed assembly; while FIGS. 3 and 6 present perspective views of the right-side end portions of FIGS. 2 and 5, respectively.

[0019] As shown on the illustrations, this invention's header pipe is realized, wherein the tank part (10) having the refrigerant flow path space where the refrigerant flows, and the header part (20) form a tube body, the header part (20) covering the tank part (10)'s flow path space and having numerous through-holes (21) for connecting the end portions of the refrigerant tubes (not shown); the tank part (10) and the header part (20) are formed into an integral structure by extrusion or other method. In particular, by forming a rounding portion (R) at the connecting portion of the tank part (10) and the header part (20), joined into an integral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com